LLF10-LLF40 Install

advertisement

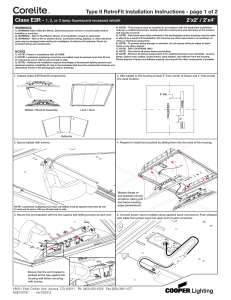

P.O. Box 60080 • 16555 East Gale Ave. City of Industry, California 91716-0080 626/968-5666 • FAX 626/330-3861 Finishing Sections LLF10, LLF20, LLF30, & LLF40. For use in Rough-In Sections 85145 & 85146 Installation Instructions ! WARNING: Fixtures must be grounded in accordance with local codes or the National Electrical Code. Failure to do so may result in serious personal injury. CAUTION: The fixture label must indicate the same electrical data as the ballast label. NOTE: Use only the lamp type and wattage shown on the fixture label in the reflector. KEEP THIS SHEET FOR FUTURE REFERENCE. Tool Required: ❑ Flat Blade Screwdriver ❑ B" Allen Wrench ! Make sure electricity is OFF before starting installation. Ballast Installation: 1. Remove fiberboard cover from front of housing. The cover and screws may be be discarded. 2. Remove cover plate from junction box and pull supply leads and ground wire into housing. 3. Loosen the two ballast/socket mounting screws on the back wall of the housing and install the ballast/socket assembly. For all model except LLF40: Place assembly on mounting screws with ballast at bottom near junction box (see fig. 1). Tighten mounting screws. For LLF40 models: Place assembly on mounting screws with ballast at top of housing (see fig. 2). Tighten mounting screws. Remove the two support brackets and screws from plastic bag supplied with ballast assembly and install brackets in recessed bosses at top flange of housing. These brackets hold the top of the ballast plate against the back wall of the housing for proper heat transfer. 4. Connect ballast/socket input leads to supply leads, i.e., green-to-ground, white-to-common, and black-to-voltage . 5. Push supply lead connections into junction box and replace cover being careful that no wires are pinched within the fixture and that none of the wires are installed behind the ballast plate or socket bracket. All field supply wires must not enter the main housing as the operating temperatures may be to great for their insulation. Support Brackets Figure 1 Figure 2 LLF10 LLF20 LLF30 Revised 2/16/07 ECN 5040 Cover Plate Status 11 LLF40 Cover Plate Part No. 95399 Finishing Sections LLF10, 20, 30, & 40 Installation Instructions Reflector and Lamp Installation 1. Install the reflector in the housing with the four screws furnished. NOTE: For LLF20 and LLF30 asymmetric distributions, check the label on the reflector to be sure that the light pattern will be thrown down the stairway or ramp. For LLF40 models the reflector is inverted. 2. Install the correct type and wattage lamp in accordance with the fixture label in the reflector and the ballast label on the ballast assembly. LLF10 LLF20 WARNING! This H.I.D. / Fluorescent fixture utilizes a lamp that may contain mercury. For information on disposal of lamp, go to website at: www.lamprecycle.org Door Assembly Installation 1. Check that the flange area of the housing is clean and free of any concrete or paint build-up. Make sure there is no dirt in the four screw holes in the LLF40 LLF30 corner of the flange. 2. Before installing the door frame assembly, always coat the four 10-32 captive screws with silicone grease. 3. Install the door frame assembly and tighten the four screws progressively and evenly to insure even gasket seating around the door frame. Do not exceed 20 inch/pounds torque on these screws. MAINTENANCE To replace lamp, proceed as follows: ! Make certain electrical supply is OFF. 1. Remove door frame assembly and discard lamp. 2. Install lamp of type and wattage specified on fixture label in reflector. 3. Clean flange area of housing, door frame gasket, and lens. 4. Coat door frame screws with silicone grease and install door frame assembly. Tighten the four screws progressively and evenly to insure even gasket seating around the door frame. Do not exceed 20 inch/pounds torque on these screws. To replace ballast assembly proceed as follows: 1. 2. 3. 4. 5. 6. 7. 8. 9. ! Make certain electricial supply is OFF. Remove door frame, lamp, and reflector. Save all screws. Remove cover plate from junction box at bottom surface of housing. Disconnect ballast input leads from supply leads. Disconnect green ground lead from circuit ground lead. Loosen the two ballast mounting screws and remove ballast assembly. Reinstall ballast assembly per ballast installation on reverse side. Note: If ballast type and/or watts are not the same as replaced equipment, mark fixture label in reflector to correspond with new ballast information. Clean reflector surfaces with soapy water. Do not rub with a dry rag or paper towel as this will scratch the surface. Do not use alkaline or acid cleaners on reflector surfaces. Install lamp of type and wattage specified on fixture label in reflector. Clean flange area of housing, door frame gasket, and lens. Coat door frame screws with silicone grease and install door frame assembly. Tighten the four screw progressively and evenly to insure even gasket seating around the door frame. Do not exceed 20 inch/pounds torque on these screws. Catalog Number LLF10 LLF20 LLF30 LLF40 Page 2 Replacement Parts List Lens Reflector Lens Frame Glass Lexan MV, MH, HPS 116 INC. Gasket 84045R 84053R 60325-2 60325-1 82170 84045R 84053R 60327-3 60327-1 82170 84045R 84053R 60327-4 60327-2 82170 84045R N/A 60325-2 60325-1 82170 NOTE: When ordering a door frame assembly give model, lens type, and finish, i.e.; LLF10/Lexan/BL-P Kim Lighting•16555 E. Gale Ave.•P.O. Box 60080 •City of Industry, CA 91716-0080 •626/968-5666•FAX 626/369-2695 Finishing Sections LLF10, 20, 30 & 40 Installation Instructions KIM LIGHTING LIMITED WARRANTY When installed in accordance with Kim Installation Instructions and accepted trade practices, the following shall apply: General Product Limited Warranty Coverage All material and component parts used in the manufacture of Kim Products, are warranted to be free from defects of material and/or workmanship for a period of 1 year from date of sale, with the following exceptions: Auxiliary Equipment All auxiliary equipment (such as lamps, ballasts, and transformers) provided by and/or included in Kim Products shall carry the component manufacturer's warranty. Copper and Bronze Landscape Components Copper and Bronze Landscape fixture components shall be warranted against defects of material and/or workmanship, and failure due to corrosion, for a period of 25 years from date of sale. Composite In-Grade Components Composite In-Grade fixture components installed below grade, shall be warranted against defects of material and/or workmanship, and failure due to corrosion, for a period of 7 years from date of sale. Aluminum Landscape Components Aluminum Landscape fixture components not in direct contact with soil, shall be warranted against defects of material and/or workmanship for a period of 3 years from date of sale. Aluminum fixture components in direct contact with soil shall be warranted from defects of material and failure from corrosion for a period of 1 year from date of sale. Limit of Liability and General Conditions Only products which are installed, used and maintained in accordance with applicable Kim instructions, specifications and accepted trade practices, are covered by the Kim Warranty. During the warranty period, with proof of purchase, Kim will repair or replace with the same or similar product, at Kim's option, without charge. Labor costs are the owner's responsibility and are excluded from this warranty. This warranty is void if the product is modified, tampered with, misapplied, poorly installed, improperly maintained, or subjected to abnormal conditions. Repair or replacement as provided under this warranty is the exclusive remedy of the purchaser. This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of fitness for a particular application. Kim Lighting shall not be liable to the purchaser for indirect or consequential damages. How may we serve you better? Please let us know. Visit our website at: www.kimlighting.com Your input matters to us. Page 3 Kim Lighting • 16555 E. Gale Ave. • P.O. Box 60080 • City of Industry, CA 91716-0080 • 626/968-5666 • FAX 626/330-3861