Manual Index

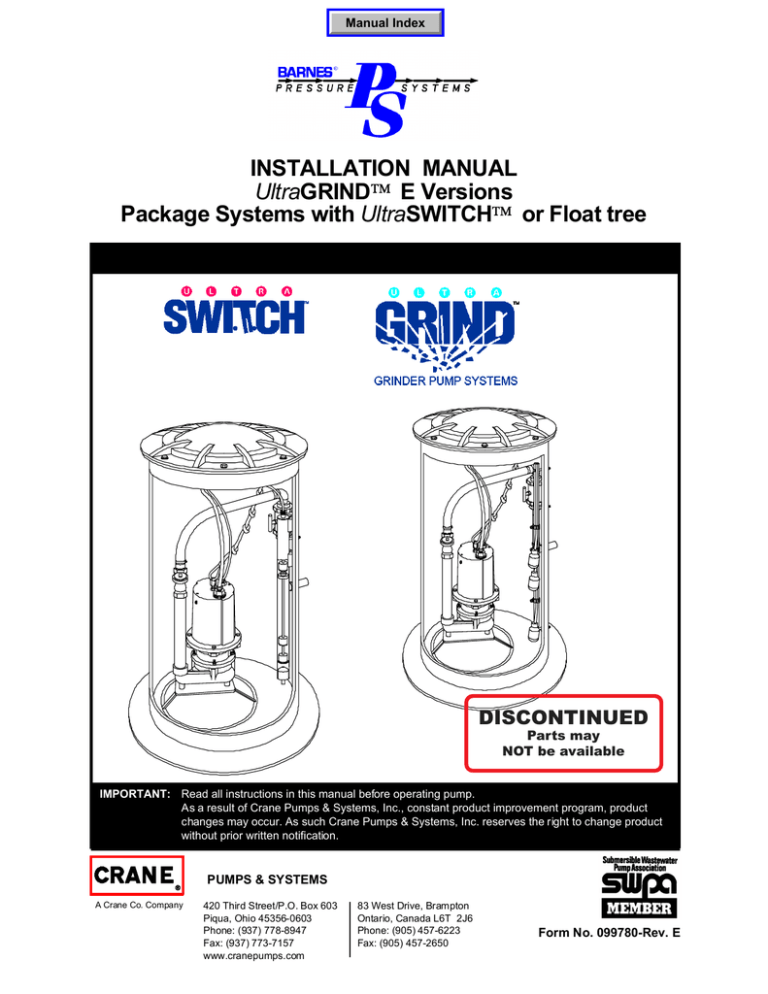

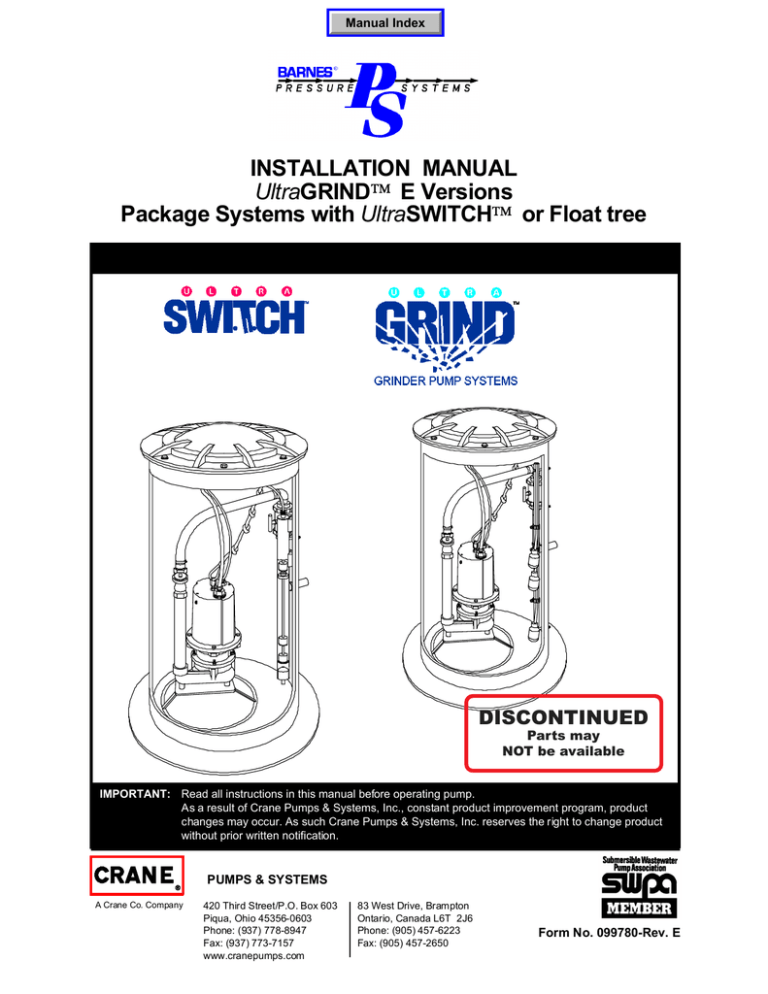

INSTALLATION MANUAL

UltraGRIND E Versions

Package Systems with UltraSWITCH or Float tree

DISCONTINUED

Parts may

NOT be available

IMPORTANT: Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program, product

changes may occur. As such Crane Pumps & Systems, Inc. reserves the right to change product

without prior written notification.

PUMPS & SYSTEMS

A Crane Co. Company

420 Third Street/P.O. Box 603

Piqua, Ohio 45356-0603

Phone: (937) 778-8947

Fax: (937) 773-7157

www.cranepumps.com

83 West Drive, Brampton

Ontario, Canada L6T 2J6

Phone: (905) 457-6223

Fax: (905) 457-2650

Form No. 099780-Rev. E

TABLE OF CONTENTS

USER GUIDE........................................................................................................................3

SAFETY FIRST.....................................................................................................................4

A. GENERAL INFORMATION

(Receiving, Storage, Service Centers, Unpacking, Location) ...............................................5

B. INSTALLATION

(Bedding, Gravel Specifications) (Fig. 1)...............................................................................5

(Placing into Hole, Locating and Installing Inlet) (Fig. 2, 3, 4 & 5) ........................................5 - 6

(Discharge, Control Panel) (Fig. 6) .......................................................................................6 - 7

(Pump Preparation (Fig. 7 & 8) .............................................................................................7

(Pump Installation) (Fig. 9 & 10) ...........................................................................................7 - 8

(Incoming Cable Location) (Fig. 11, 12, 13) ..........................................................................8 - 9

(Backfill) (Fig. 14) ..................................................................................................................9

(Junction Box Connections & Direct Burial Cable) (Fig. 15)..................................................9 - 10

C. REPLACEMENT PARTS ......................................................................................................10

JUNCTION BOX WIRING FOR UltraSWITCH:

SGV Simplex with 14/2 Temp. (Fig. 16) ................................................................................11

SGV Simplex with 18/5 Moist. & Temp (Fig. 17) ...................................................................11

SGPC Simplex (Fig. 18) & Duplex (Fig. 19) ..........................................................................12

SGV Duplex with 14/2 Temp. (Fig. 20) .................................................................................13

SGV Duplex with 18/5 Moist. & Temp. (Fig. 21) ...................................................................13

UltraSWITCH WIRING:

SGV Simplex (Fig. 22) .......................................................................................................... 14

SGPC Simplex (Fig. 23) ........................................................................................................14

SGV Duplex (Fig. 24) ............................................................................................................14

SGPC Duplex (Fig. 25) .........................................................................................................14

EXPLODED VIEW - SIMPLEX (Fig. 26) ...............................................................................15

PARTS LIST - SIMPLEX .......................................................................................................16 - 17

EXPLODED VIEW - DUPLEX (Fig. 27).................................................................................18

PARTS LIST - DUPLEX ........................................................................................................19 - 20

DIRECT BURIAL CABLE REQUIREMENTS ........................................................................21

BASIN VOLUME CHART......................................................................................................22

BASIN BALLAST REQUIREMENTS.....................................................................................23

RETURNED GOODS POLICY ....................................................................................................24

WARRANTY

Other brand and product names are trademarks or registered trademarks of their respective holders.

UltraGRIND is a trademark of Barnes Pumps, Inc.

UltraSWITCH is a trademark of Barnes Pumps, Inc.

® Barnes is a registered trademark of Barnes Pumps, Inc.

© Barnes Pumps, Inc. 1996 2000, 2003

Alteration Rights Reserved.

2

Printed in U.S.A.

The grinder pump

generates sufficient

pressure to pump

this slurry from your home to the wastewater

plant.

USER GUIDE

Congratulations on

your purchase of a

Barnes UltraGRIND grinder pump system.

With proper care and by following a few

simple guidelines your grinder pump will give

you many years of dependable service.

Power Failure

Y our gri nder pump ca nnot di spose o f

wastewater or provide an alarm signal without

electrical power. If electrical power service is

interrupted, keep water usage to a minimum.

Use and Care

Th e UltraGRIND grinder pump station is

d esi gn ed t o ha ndl e rou tin e, do mes tic

sewage. Solid waste materials should be

thrown in the trash. While your station is

capable of accepting and pumping a wide

range of materials, regulatory agencies

advise that the following items should not be

introduced into any sewer either directly or

through a kitchen waste disposal:

• Glass

• Metal

• Diapers

• Socks, rags or cloth

• Plastic objects (e.g., toys, utensils, etc.)

• Sanitary napkins or tampons

Warranty

Your grinder pump is furnished with a

warranty against defects in material or

workmanship. A properly completed Start

Up/Warranty Registration form must be on file

at the Barnes factory in order to activate your

warranty. In addition your pump must be

installed in accordance with the installation

instructions.

If you have a claim under the provisions of the

warranty, contact your local Barnes Pumps,

Inc. Distributor.

When contacting your representative for

service, please include your station serial

number, pump model number, and pump

serial number.

In addition you must NEVER introduce into

any sewer:

• Explosives

• Flammable Material

• Lubricating Oil and/or Grease

• Strong Chemicals

• Gasoline

For future reference, record the following

information:

Station Serial No:

Pump Model No:

General Information

Your home wastewater disposal service is

part of a low pressure sewer system. The key

el eme nt in this sys tem i s the Bar nes

UltraGRIND grinder pump station. The basin

collects all wastewater from the house. The

solids in the sewage are then ground to a

small size suitable for pumping in the slurry.

Pump Serial No:

Local Distributor:

Distributor Telephone:

3

SAFETY FIRST!

PLEASE READ THIS BEFORE INSTALLING

OR OPERATING PUMP.

GENERAL

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Most accidents can be avoided by using COMMON SENSE.

Read this operation and maintenance instruction manual.

Do not wear loose clothing that may become entangled in the impeller or other moving parts.

Always wear appropriate safety gear, such as safety glasses, when working on the pump or piping.

Bronze/brass and bronze/brass fitted pumps may contain lead levels higher than considered safe for potable water systems. Various government agencies have determined that leaded copper alloys should not be used in potable water applications. For nonleaded copper alloy materials of construction, please contact factory.

Minimize the amount of cooking grease entering the system.

Do Not leave pump cover off the basin, except while servicing, to prevent entrance of foreign materials such as rocks, metal, soil,

animals or humans.

Prevent large articles of clothing, large amounts of chemicals, other materials or substances such as are uncommon in domestic

sewage from entering the system.

During power black-outs, discontinue water consumption at the home(s) to prevent sewage from backing up into the house.

Prevent infiltration or direct flow of rain or run-off water into the pump basin to minimize pump cycling. This will prevent overloading

the treatment facility, and will facilitate swift transportation of sewage.

Always keep the shut-off valve completely open when system is in operation (unless advised otherwise by the proper authorities).

Keep the control panel locked or confined to prevent unauthorized access to it.

If the pump is idle for long periods of time, it is advisable to start the pump occasionally by adding water to the basin.

Before removing the pump from the basin, be sure to close the shut-off valve. (This prevents back flow from the pressure sewer.)

Make sure level controls are provided at time of installation.

This basin system is intended for use with water, sewage and effluent applications. This basin must be vented in accordance with

local codes. This basin system is not to be installed in locations in which the basin interior would be classified as a hazardous location in accordance with NEC ANSI/NPFA 70.

PUMPS

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Recommended no more than 10 starts per hour.

Pumps build up heat and pressure during operation-allow time for pumps to cool before handling or servicing.

Only qualified personnel should install, operate and repair pump.

Keep clear of suction and discharge openings. DO NOT insert fingers in pump with power connected.

Do not pump hazardous materials (flammable, caustic, etc.) unless the pump is specifically designed and designated to handle them.

Do not block or restrict discharge hose, as discharge hose may whip under pressure.

Make sure lifting handles are securely fastened each time before lifting.

Do not lift pump by the power cord.

Do not exceed manufacturers recommendation for maximum performance, as this could cause the motor to overheat.

Secure the pump in its operating position so it can not tip over, fall or slide.

Keep hands and feet away from impeller when power is connected.

Submersible Pumps are not approved for use in swimming pools, recreational water installations, decorative fountains or any installation where human contact with the pumped fluid is common.

29. Do not operate pump without safety devices in place.

30. Always replace safety devices that have been removed during service or repair.

ELECTRICAL

31. To reduce risk of electrical shock, pump must be properly grounded in accordance with the National Electric Code (NEC) and all applicable state and local codes and ordinances.

32. To reduce risk of electrical shock, always disconnect the pump from the power source before handling or servicing. Lock out power

and tag.

33. Any wiring of pumps should be performed by a qualified electrician.

34. Never operate a pump with a power cord that has frayed or brittle insulation.

35. Cable should be protected at all times to avoid punctures, cut, bruises and abrasions - inspect frequently.

36. Never handle connected power cords with wet hands.

37. Do not remove cord and strain relief. Do not connect conduit to pump.

38. To reduce risk of electrical shock, all wiring and junction connections should be made per the NEC and applicable state and local

codes. Requirements may vary depending on usage and location. See wiring diagrams in manual.

39. Do Not operate the pump in the “HAND” control position and leave the pump unattended.

40. CAUTION - This unit may have more than one connection to the source of supply. To reduce the risk of electric shock, disconnect all

such connections before servicing.

41. All connections inside this tank and/or junction box must be made with listed watertight connectors.

IMPORTANT! BARNES® PUMPS, INC. IS NOT RESPONSIBLE FOR LOSSES, INJURY, OR DEATH RESULTING FROM A

FAILURE TO OBSERVE THESE SAFETY PRECAUTIONS, MISUSE OR ABUSE OF PUMPS OR EQUIPMENT.

4

GRAVEL SPECIFICATION:

SECTION A: GENERAL INFORMATION

A-1) RECEIVING:

Upon receiving the Basin Package System, it should be

inspected for damage or shortages. If damage has

occurred, file a claim immediately with the company that

delivered the basin package.

1. A naturally rounded aggregate is required, clean and

free flowing with particle size not less than 1/8" or more

than 3/4" in diameter. Use this description when

specifying or ordering because material is known by

different names in different areas. This material is

commonly called "pea gravel".

A-2) STORAGE:

Basin:

If Basin Packages are going to be stored make sure all

outside openings are sealed, i.e., discharge coupling,

electrical coupling (if equipped) etc., also secure access door

or basin cover.

2. Stone or gravel crushing with angular particle size not

less than 1/8" or more than 1/2" diameter washed and

free flowing is acceptable as an alternate material. This

material must meet ASTM C-33 paragraph 9.1

requirements for quality and soundness.

B-2) PLACING STATION INTO HOLE:

Lifting the basin system, into place should be done with a cloth

or nylon type strap around basin or by a lifting harness

connected to eyebolts that are set into the concrete pad that

is connected to basin by anchor bolts. Never use chain or

cable type lifting device around outer basin. This can and may

create a fracture in the fiberglass. See Figures 2 and 3.

A-3) SERVICE CENTERS:

For the location of the nearest Barnes® Pumps Service

Center, check your catalog, your Barnes Pumps, Inc.

representative or Barnes Pumps, Inc. Service Department in

Piqua, Ohio, telephone (937) 778-8947.

A-4) UNPACKING:

Before installing Basin Package remove the tape from all

outside openings, discharge coupling, etc. Remove basin

cover on simplex or open access door on duplex units being

careful not to damage gasket, to unpackage anything that was

secured for shipment.

Figure 2

A-5) LOCATION:

This basin system is intended for use with water and sewage

applications. The standard basin is vented, any alterations

from the standard must be in accordance with local codes.

This basin system is not to be installed in locations in which

the basin interior would be classified as a HAZARDOUS

location in accordance with NEC ANSI/NFPA 70.

SECTION B: INSTALLATION

B-1) BEDDING:

Prepare the hole to the proper depth. Add and level bedding

of select aggregate (pea gravel - see Gravel Specifications )

of 4 to 6 inches or concrete pad or a concrete donut shall be

laid before basin is lowered into the ground. The aggregate

must conform to the bottom of the basin and reach a

compaction of 85% Standard Proctor Density. (See Figure 1).

Figure 1

Lower the basin, centering it into the hole and orienting it to

allow for proper inlet installation. A minimum clearance of 4

to 6 inches should be maintained between the tank wall and

the surrounding earth. ALL OSHA PROCEDURES SHOULD

BE FOLLOWED REGARDING INSTALLATION OF BASIN.

The basin must be leveled after placement to within 1/2

bubble. To prevent the basin from floating upward when the

ground water is high, a weight of 63 pounds per cubic foot of

basin volume must anchor the basin in place (see "BALLAST

REQUIREMENTS" on page 23).

5

Figure 3

NOTE: Schedule 40 and SDR35 pipe require different sizes

of flexible pipe fittings. Check to be sure the inlet pipe matches

the flexible pipe fitting supplied.

To install the inlet pipe into the flexible pipe fitting, chamfer

the end and lube the pipe with soapy water for ease of

installation, see Figure 4. An OPTIONAL adapter or caulking

hub may be used in place of the flexible pipe fitting.

This can be done by fastening the ballast support flange to a

concrete pad or donut, or by adding the equivalent amount of

gravel and/or concrete to the surrounding basin area

(surrounding the 2" flange).

B-3) LOCATING & INSTALLING INLET:

B-3.1) FLEXIBLE PIPE FITTING INLET:

The flexible pipe fitting for the inlet must be installed.

1. Find the location where the center of the coupling will be

positioned on basin. See Fig. 5 for recommended location.

2. Using a HOLE SAW, cut the hole in the basin (DO NOT

use a Saber Saw). Refer to the chart below for hole size.

3. Install flexible pipe fitting in the opening. See Figure 4.

Figure 5

TABLE for FIGURE 5

24" - 30" DIA

Simplex Basins

Angle "A" Should Be

Between 30° - 60°

36" And Larger Simplex

and All Duplex Basins

Angle "B" Should Be 45°

Maximum

B-3.2) Discharge:

Connect the sanitary main to the NPT discharge connection

located on the outside of the basin (see Figure 6). It is required

that a shut-off valve and a redundant check valve be located

at the property line near the sanitary main (by others). A

flexible pipe coupling should be installed at the basin to

prevent line breakage during ground settling. The check valve

should be of a flap style able to operate in a horizontal

position. It is recommended that in cold regions the piping

above the frost grade be insulated. Consult factory for

severely cold climates.

Figure 4

Flexible Pipe

Fitting Size

Hole Size

Color Code

1-1/4

1-1/2

2

3"

Black-40

Black/Red-40

Black/Blue-40

3

4"

White-40

4

6

5"

7"

Grey-40, Maroon-35

Black-40, Yellow-35

6

The Ball Check Valve (G) will come assembled to the 14.00"

long PVC pipe (F). Then install the pipe and valve assembly in

the pump discharge, again using pipe sealant on the threads.

Attach the pipe assembly to the Upper Pump Bracket (C) with

3/8-16 x 2.62" U-Bolt, hex nuts and washers (H)

(see Figure 8).

NOTE: Pipe "F" should

have a 1/8" dia. hole 5"

from end nearest to volute

and oriented towards the

pump body.

Figure 6

B-3.3) Control Panel:

Next locate and mount electrical control panel, and run wire to

the basin package (see Control Panel Manual).

CAUTION !

Figure 8

ALL MODEL PUMPS AND CONTROL PANELS MUST

BE PROPERLY CONNECTED AND PROPERLY

GROUNDED PER THE NATIONAL ELECTRICAL CODE,

STATE, AND LOCAL CODES. IMPROPER GROUNDING

VOIDS WARRANTY.

Attach lifting rope (K) or chain to the pump (see Figure 8). Install

Hose assembly (L) into Check Valve (G). Remove top part of

the True Union Valve (M) (located in basin) and attach it to the

Hose assembly (L).

B-4.1) PUMP INSTALLATION:

Remove basin cover or open access door, lower pump

assembly, utilizing the lifting rope or chain, down into the basin,

slowly (DO NOT DROP!). Observe OSHA recommendations

when installing and removing pump.

NOTE: A proper motor controller must be provided that is

compatible with the pump(s) being installed. (Motor Controller

is part of control panel when factory supplied.)

B-4) PUMP PREPARATION:

First attach the Pump Support (A) to the bottom of the pump

with a quantity of three 5/16-18 x 1.00" long hex head cap

screws, flat washers and lock washers (B) for SGV Pumps and

four (4) for SGPC Pumps. Assemble the Upper Pump Bracket

(C) to the discharge side of pump (see Figure 7).

CAUTION !

RISK OF ELECTRICAL SHOCK. DO NOT LOWER PUMP

BY THE POWER CORD.

Figure 7

Figure 9

7

B-6.1) Direct Burial Cable with Cable Grips:

Backfill and compact to a convenient level to work around

top of basin. Locate and drill holes (see page 21 for hole

sizes) for the Direct Burial Cable grips in the basin wall.

Holes should be located at least 18 inches below grade or

per NEC and local codes. Remove junction box cover to

connect pump, sensor and control cords to incoming direct

burial cables. Refer to Figures 16 through 25. Feed the

direct burial cable through the cable grips and into the

junction box and tighten the grips on the box and the

basin. It Is Important To Leave Enough Cable Slack

Between The Junction Box And Basin Wall So That The

Basin Cover Can Be Completely Removed From Basin

opening (See Figure 11).

NOTE: A hoist or crane may be used in lowering and

removing the pump. Center the pump under the hook so

that the pump can be lifted straight up. Lifting a pump that

is not centered will create side pulls which may strain the

crane and/or cause the pump to swing and damage the

basin. Follow all general precautions in the crane’s manual

when installing and operating the crane (see Figure 9).

B-6.2) Direct Burial Cable with Conduit Coupling:

Backfill and compact to a convenient level to work around

top of basin. To install an OPTIONAL conduit coupling (see

Figure 12).

JUNCTION BOX

BASIN WALL

Figure 10

Orient the pump as shown with the pump discharge on the

opposite side of the basin from the True Union Ball Valve.

Once pump assembly is in place, attach the hose assembly

onto the True Union Valve (see Figure 10). Place rope and

cords onto the hooks (for Duplex ONLY), and make wiring

connections per sections B-6 & B-8.

CABLE GRIPS

B-6) INCOMING CABLE LOCATION:

Figure 12

For installations using a cover & J-Box go to Section B-6.1.

For installations using the combination cover go to Section

B-6.3.

JUNCTION BOX

CONDUIT

COUPLING

1. Find the location where the center of the coupling will

be positioned on basin.

2. Using a HOLE SAW, cut the hole in the basin to the

outside diameter of the coupling being installed.

3. Place coupling on basin wall and drill mounting holes

in basin.

4. Apply gasket, sealing or caulk to back of coupling, and

mount coupling on basin.

5. Insert bolts, washers and nuts through basin wall and

coupling, and tighten.

BASIN WALL

After coupling has been installed, remove junction box

cover to connect pump, sensor and control cords to

incoming direct burial cables. Refer to Figures 16 through

25. Run the direct burial cable through the coupling and into

the junction box and tighten the grips on the box. It Is

Important To Leave Enough Cable Slack Between The

Junction Box And Basin Wall So That Basin Cover Can

Be Completely Removed From Basin Opening. See

Section B-8 for sealing of junction box.

CABLE GRIPS

CABLE GRIPS

Figure 11

DIRECT BURIAL

CABLE

DIRECT BURIAL

CABLE

8

B-6.3) Direct Burial Cable with Cable Grips

(Combination Cover):

Backfill and compact to a level comfortable to work around

basin. Remove cord grip located in parts common box,

shipped inside the basin. Make sure cable will fit and seal in

the cord grip prior to mounting in the basin. Drill a hole to

size specified in chart for your size cord grip supplied. The

hole should be located a minimum of 18 inches below grade

or per NEC and local codes. Install the grip with the cord grip

body inside the basin and the lock nut on the outside and

tighten locknut to 1/2 turn past hand tight. Feed the direct

burial cable through the grip and into the grommet assembly

labeled "DB" in the insert. Reference the label on top of the

control panel to locate the correct grip in the control panel to

put the wire into. Leave enough cable inside the panel to

reach all connection points. Tighten the grips leaving

enough slack between the basin wall and the insert to

remove the insert completely off the basin.

3. Feed the cord through the appropriate cord grip on the

control panel making sure that the rubber grommet is

installed in the grip.

• The cable jacket should be visible from inside the control

panel to insure that the grommet is not sealing on

individual wire strands.

• Care should be taken to make sure there are no slits or

damage on the cable jacket where the cord grip is

sealing.

4. Tighten the control panel grips to 1/4 turn past hand tight

using a pair of channel locks. After tightening the grip,

make sure the retaining nut for the grip on the inside of

the panel is tight.

5. Tighten the gland nuts per the instructions on the

control panel label (3 turns past finger tight).

6. Reference the Control Panel manual for panel wiring

details.

After the coupling has been installed, run the direct burial

cable through the coupling and into the grommet labeled

"DB" in the insert. Reference the lable on top of the

control panel to locate the correct grip in the control panel

to put the wire into. Leave enough cable inside the

panel to reach all connection points. Tighten the grips

leaving enough slack between the basin wall and the

insert to remove the insert completel off the basin.

CONTROL

PANEL

CABLE GRIPS

B-7) Backfill:

Finish backfill and compaction (see Figure 14). Place at least

4 inches and preferably 6 inches of aggregate in layers

around the entire periphery of the basin in the ground, being

careful not to damage or loosen any connections.

CONVERTABLE

COVER INSERT

Figure 13

CABLE GRIPS

CAUTION !

B-6.4) Direct Burial Cable with Conduit Coupling

(Combination Cover):

Backfill and compact to a convenient level to work around

top of basin. To install an OPTIONAL conduit coupling

(see Figure 12 & 13).

IN FREEZING CONDITIONS BACKFILL MUST BE

DRY AND FREE OF ICE.

1. Feed the cables up through the appropriate holes on

the new insert.

• The holes are labeled "DB" (Direct Burial Cable),

"PP" (Pump Power), "PC" (Pump Control - SGV Units

Only)

and "LC" (Level Control).

• Make sure at this point, that all of the cables will be long

enough to reach their connection points in the panel

while

still having enough room to remove the insert from

the basin.

2. Looking at the color-coded diagram on the lable

attached to the panel, slide the appropriate color-coded

friction ring, color-coded gromment, second color-coded

friction ring and gland nut over the cable. Loosely thread

the gland nut into the gland molded into the insert so that

the cable will still move in the assembly.

9

Figure 14

The basin warranty is automatically voided if other than

approved bed and backfill materials are employed without

advance written approval.

Fo r OPTIONAL conduit from the basin to the motor

controller, it is recommended that a packing material such as

a sprayable urethane foam be used in the conduit line, placed

around the wires, at the conduit coupling to help prevent

gases from entering the motor controller (see Figure 15).

Packing is recommended for ALL entries into the motor

control panel. It is very important to keep the conduit line dry

and free from moisture during this process.

B-8) JUNCTION BOX CONNECTIONS:

SECTION: C REPLACEMENT PARTS

DO NOT use backfill materials other than those specified

above. In areas where specified materials are not available

contact Barnes Pumps, Inc. for information on approved

alternate materials.

C-1 ORDERING REPLACEMENT PARTS:

When ordering replacement parts, ALWAYS furnish the

following information:

IMPORTANT !

CHECK TO BE CERTAIN THAT ALL POWER IS OFF.

1. Model number. (C-3)

2. Serial number and date code. (C-4)

3. Part number. (C-2)

4. Part description.

5. Item part number.

6. Quantity required.

7. Shipping instructions.

8. Billing Instructions.

IMPORTANT !

ALL CONNECTIONS INSIDE THIS TANK AND/OR

JUNCTION BOX MUST BE MADE WITH "UL" LISTED

WATER TIGHT CONNECTORS.

CAUTION !

THIS UNIT MAY HAVE MORE THAN ONE

CONNECTION TO THE SOURCE OF SUPPLY. TO

REDUCE THE RISK OF ELECTRIC SHOCK,

DISCONNECT ALL SUCH CONNECTIONS BEFORE

SERVICING.

1

2

3

Wire Size: Consult a qualified electrician for proper wire size.

See Pump Manual for electrical information.

C-2 PART NUMBER:

The part number consists of a six (6) digit number, which

appears in the catalog. A one or two letter suffix may follow

this number to designate the design configuration. This

number is used for ordering and obtaining information.

Direct Burial Cable:

Due to the availability of multi conductor direct burial cables,

several options have been left to the installer (see "DIRECT

BURIAL CABLE REQUIREMENTS " on page 21).

C-3 MODEL NUMBER:

This designation consists of numbers and letters which

represent the diameter, depth and design. This number is

used for ordering and obtaining information.

C-4 SERIAL NUMBER:

The serial number block will consist of a six digit number,

which is specific to each unit and may be preceded by an

alpha character, which indicates the plant location. This

number will also be suffixed with a four digit number, which

indicates the date the unit was built (Date Code).

EXAMPLE: A012345 0490.

Reference the six digit portion (Serial Number) of this number

when referring to the product.

Figure 15

10

Simplex UltraSWITCH - 2HP SGV Grinder

with Pump Cable and 14/2 Sensor Cable.

Figure 16

Simplex UltraSWITCH - 2HP SGV Grinder

with Pump Cable and 18/5 Sensor Cable.

Figure 17

11

Simplex UltraSWITCH - 1HP SGPC Grinder

with Pump Cable.

Figure 18

Duplex UltraSWITCH - 1HP SGPC Grinder

with Pump Cable.

Figure 19

12

Duplex UltraSWITCH - 2HP SGV Grinder

with Pump Cable and 14/2 Sensor Cable.

Figure 20

Duplex UltraSWITCH - 2HP SGV Grinder

with Pump Cable and 18/5 Sensor Cable.

Figure 21

13

Simplex UltraSWITCH

Connections

SGV PUMPS

SGPC PUMPS

Figure 22

Figure 23

Duplex UltraSWITCH

Connections

SGV PUMPS

SGPC PUMPS

Figure 24

Figure 25

14

SIMPLEX

Figure 26

15

SIMPLEX REPAIR KIT

UltraSWITCH For SGV Pump.........P/N: 098874

UltraSWITCH For SGPC Pump......P/N: 102817

SIMPLEX PARTS LIST

IMPORTANT! Specify Package Model Number & Part Number when ordering parts or service inquiries.

ITEM

1

QTY

1

2

3

4

1

1

1

5

6

1

2

1

1

1

1

1

6

2

2

1

7

8

9

10

11

13

14

15

15A

15B

15C

15D

15E

15F

16

17

18

19

20

21

2

2

3

7

1

1

5

1

1

1

1

1

1

1

1

1

1

2

2

2

10

1

8

1

1

4

PART No.

076149

075898

076941

076111

063847

063848

063850

(Specify Size)

(Specify Size)

104046

104045

104049

104047

099216

099220

099753

085115

100213

093925

099218A

099218N

099218C

099218D

099218E

099217

099239

103748

103748A

103748C

103748C

103748D

099217

103734

20-14-1

026322

034452

-------062941

074758

074759

094487

094482

101799

100868

100867

075831

093927

026210A

1-40-1

20-14-1

15-23-1

20-13-1

076619

082727

085448

-------093952

DESCRIPTION

Flexible Pipe Fitting, Inlet

Caulking Hub

Lifting Rope

Basin

Junction Box

Discharge Assembly

Elbow

Pipe Nipple

True Union Ball Valve

Pipe Nipple

Close Nipple

Hose Assembly

Hose Adapter

Hose Clamp

Hose Assembly

4"

4"

6"

6"

4"

6"

8"

Sch., 40 PVC, Grey

SDR 35, PVC (STD), Maroon

Sch., 40 PVC, Black

SDR 35 PVC, Yellow

Cast Iron

Cast Iron

Cast Iron

SGV, UltraSWITCH

SGPC, UltraSWITCH

SGV, Floats

SGPC, Floats

1.25"

Sch 80, FNPT x FNPT, PVC

1.25" NPT x 4.00" Lg, PVC

1.25" NPT, PVC

1.25" NPT x 6.00", PVC

1.25" NPT, PVC

SGV, 24" Dia x 48" Deep Basin

SGV, 24" Dia x 60" Deep Basin

SGV, 24" Dia x 72" Deep Basin

SGV, 24" Dia x 84" Deep Basin

SGV, 24" Dia x 96" Deep Basin

1.25 , Insert x MNPT

Size-20, Stainless

SGPC, 24" Dia x 48" Deep Basin

SGPC, 24" Dia x 60" Deep Basin

SGPC, 24" Dia x 72" Deep Basin

SGPC, 24" Dia x 84" Deep Basin

SGPC, 24" Dia x 96" Deep Basin

1.25 , Insert x MNPT

1.75", Punch-Lock

3/8", Stainless

5/16", Stainless

Hose Adapter

Hose Clamp

Lock Washer

Lock Washer

Gasket, Pressure Sensitive

Adhesive

DOW #RTV732

Flat Washer

5/16, Stainless

Upper Pump Bracket

U-Bolt

3/8-16 x 2.625

Cover for 2" Bug Vent,

24" Dia Basin, Fiberglass

Cover for 2" Bug Vent,

24" Dia Basin, Steel

Cover, Polyethylene Convertable, 24" Dia. ONLY

Cover, Polyethylene Convertable w/Insert, 24" Dia. ONLY

Cover Insert

Bug Free Vent

2" NPT (Not used with Convertable Cover)

Close Nipple

2" NPT (Not used with Convertable Cover)

Flange Coupling

2" NPT (Not used with Convertable Cover)

Hex Hd Screw

3/8-16 x 1.50" Lg, Stainless

Lock Washer

3/8, Stainless

Hex Nut

3/8-16, Stainless

Lock Washer

1/4", Stainless

Flexible Pipe Fitting, Discharge 1.25 Sch 40, PVC

Flat Washer

3/8, Stainless

Ball Check Valve

1.25", PVC

Name Plate

Weatherseal Washer

5/16, Stainless

16

SIMPLEX PARTS LIST

IMPORTANT! Specify Package Model Number & Part Number when ordering parts or service inquiries.

ITEM

QTY

PART No.

DESCRIPTION

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1

1-2

1

1

4

1

9

3

1

6

2

4

1

1

39

1

099208

094730

099210

099242

086538

089062

15-5-1

1-156-1

1-32-1

1-36-1

15-23-1

15-19-1

100111

106186

106189

104515

079625

079627

079629

079631

104513

104092

104094

104096

104098

073617

073617

095032

1-4-1

095031

20-12-1

15-4-1

100209

105671

105673

105674

105676

105678

1-526-1

105406

095253

Pump Support

Kwik Block, Large

U-Bolt

Pipe Nipple

Flat Washer

Kwik Block, Small

Hex Nut

Hex Hd Screw, SGV Pumps

Hex Hd Screw

Hex Hd Screw

Hex Nut

Hex Nut

Hose

UltraSWITCH Assy, SGV

UltraSWITCH Assy, SGPC

Float Pole Assy.

39A

40

41

42

43

44

45

47

3

4

4+

4

1

1

1

1

1

49

50

53

1

1

1

Stainless

2.50 x 5.00

1.25 x 14.00" Lg Sch40

1/4", Stainless

1/4-20, Stainless

5/16-18 x 1.00" Lg, Stainless

3/8-16 x .75" Lg, Stainless

3/8-16 x 1.25" Lg, Stainless

3/8-16, Stainless

5/16-18, Stainless

.375 x .625 OD, Rubber

SGV, 48" Deep Basin

SGV, 60" Deep Basin

SGV, 72" Deep Basin

SGV, 84" Deep Basin

SGV, 96" Deep Basin

Float Pole Assy.

SGPC, 48" Deep Basin

SGPC, 60" Deep Basin

SGPC, 72" Deep Basin

SGPC, 84" Deep Basin

SGPC, 96" Deep Basin

Float Switch, SGV, Included with Float Pole Assy.

Float Switch, SGPC, Included with Float Pole Assy.

WeatherSeal Washer

1/4", Stainless

Hex Hd Screw

1/4-20 x 1.25" Lg, or #10, Stainless

Weatherseal Washer

#10, Stainless

Lock Washer

#10, Stainless

Hex Nut

#10-32, Stainless

Hex Hd Screw

#10-32, Stainless

Extension Tube

48" Deep Basin, used with UltraSwitch

60" Deep Basin, used with UltraSwitch

72" Deep Basin, used with UltraSwitch

84" Deep Basin, used with UltraSwitch

96" Deep Basin, used with UltraSwitch

Cap Screw

1/4-20 x 2.00" Lg., Stainless

Hose Clamp

Bent Bolt

1/4-20 x 2.50" Lg., Stainless

17

DUPLEX

Figure 27

18

DUPLEX REPAIR KIT

UltraSWITCH For SGV Pump.........P/N: 098874

UltraSWITCH For SGPC Pump......P/N: 102817

DUPLEX PARTS LIST

IMPORTANT! Specify Package Model Number & Part Number when ordering parts or service inquiries.

ITEM

1

2

3

4

5

QTY

1

6

2

1

1

1

4

1

1

1

2

1

2

4

2

1

4

1

1

1

2

1

2

4

2

2

7

8

9

10

11

13

14

15

4

4

14

16

1

1

18

2

2

1

15A

15B

15C

15D

15E

15F

16

17

18

19

20

1

1

1

2

2

2

10

1

6

2

1

5

PART No.

076149

075898

076941

076111

063847

063848

063850

(Specify Size)

(Specify Size)

095106

100210

099220

073280

100528

100212

085115

079139

100213

093925

100556

100527

099220

073280

100211

100212

085115

079139

100213

093925

100556

099218N

099218C

099218D

099218E

099218F

099217

099239

20-14-1

026322

034452

----062941

074758

074759

098077

094165

075831

093927

026210A

1-40-1

20-14-1

15-23-1

20-13-1

099730

082727

085448

-----

DESCRIPTION

Flexible Pipe Fitting, Inlet

Caulking Hub

Lifting Rope

Basin

Junction Box

Discharge Assy

Elbow

Elbow

Pipe Nipple

Tee

True Union Ball Valve

Pipe Nipple

Pipe Nipple

Close Nipple

Reducer Bushing

Discharge Assy

Elbow

Elbow

Pipe Nipple

Tee

True Union Ball Valve

Pipe Nipple

Pipe Nipple

Close Nipple

Reducer Bushing

Hose Assembly

Hose Adapter

Hose Clamp

Lock Washer

Lock Washer

Gasket, Pressure Sensitive

Adhesive

Flat Washer

Upper Pump Bracket

U-Bolt

Cover for 2" Bug Vent

4"

4"

6"

6"

4"

6"

8"

Sch., 40 PVC, Grey

SDR 35, PVC (STD), Maroon

Sch., 40 PVC, Black

SDR 35 PVC, Yellow

Cast Iron

Cast Iron

Cast Iron

SGV UltraSwitch

36" Basin Dia x 1.25" NPT

1.25", Sch 80, FNPT x FNPT, PVC

1.50", PVC

1.50" NPT x 5.00" Lg, PVC

1.50" NPT, Sch80, PVC

1.25" NPT, PVC

1.50" NPT x 4.00", PVC

1.25" NPT x 6.00", PVC

1.25" NPT, PVC

1.50" x 1.25", PVC

48" Basin Dia x 1.25" NPT

1.25", Sch 80, FNPT x FNPT, PVC

1.50", PVC

1.50" NPT x 8.00" Lg, PVC

1.50" NPT, Sch80, PVC

1.25" NPT, PVC

1.50" NPT x 4.00", PVC

1.25" NPT x 6.00", PVC

1.25" NPT, PVC

1.50" x 1.25", PVC

SGV, 48" Deep Basin

SGV, 60" Deep Basin

SGV, 72" Deep Basin

SGV, 84" Deep Basin

SGV, 96" Deep Basin

1.25 , Insert x MNPT

Size-20, Stainless

3/8", Stainless

5/16", Stainless

DOW #RTV732

5/16, Stainless

3/8-16 x 2.625

36" Dia Basin, Fiberglass

48" Dia Basin, Steel w/Door

Bug Free Vent

2" NPT

Close Nipple

2" NPT

Flange Coupling

2" NPT

Hex Hd Screw

3/8-16 x 1.50" Lg, Stainless

Lock Washer

3/8, Stainless

Hex Nut

3/8-16, Stainless

Lock Washer

1/4" Stainless

Flexible Pipe Fitting, Discharge 1.50 Sch 40, PVC

Flat Washer

3/8, Stainless

Ball Check Valve

1.25", PVC

Name Plate

19

DUPLEX PARTS LIST

IMPORTANT! Specify Package Model Number & Part Number when ordering parts or service inquiries.

ITEM

QTY

21

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

47

8

2

2+

2

2

4

2

9

6

1

6

2

20

2

1

49

50

53

1

1

1

4

4

1

2

2

1

PART No.

DESCRIPTION

093952

099208

094730

099210

099242

086538

089062

15-5-1

1-156-1

1-32-1

1-36-1

15-23-1

15-19-1

100111

106188

095032

1-4-1

095031

20-12-1

15-4-1

100209

105671

105673

105674

105676

105678

1-526-1

105406

095253

Weatherseal Washer

Pump Support

Kwik Block, Large

U-Bolt

Pipe Nipple

Flat Washer

Kwik Block, Small

Hex Nut

Hex Hd Screw, SGV Pumps

Hex Hd Screw

Hex Hd Screw

Hex Nut

Hex Nut

Hose

UltraSWITCH Assy, SGV

WeatherSeal Washer

Hex Hd Screw

Weatherseal Washer

Lock Washer

Hex Nut

Hex Hd Screw

Extension Tube

Cap Screw

Hose Clamp

Bent Bolt

20

5/16, Stainless

Stainless

2.50 x 5.00

1.25 x 14.00" Lg Sch40

1/4", Stainless

1/4-20, Stainless

5/16-18 x 1.00" Lg, Stainless

3/8-16 x .75" Lg, Stainless

3/8-16 x 1.25" Lg, Stainless

3/8-16, Stainless

5/16-18, Stainless

.375 x .625 OD, Rubber

1/4", Stainless

1/4-20 x 1.25" Lg, Stainless

#10, Stainless

#10, Stainless

#10-32, Stainless

#10-32, Stainless

48" Deep Basin, used with UltraSwitch

60" Deep Basin, used with UltraSwitch

72" Deep Basin, used with UltraSwitch

84" Deep Basin, used with UltraSwitch

96" Deep Basin, used with UltraSwitch

1/4-20 x 2.00" Lg., Stainless

1/4-20 x 2.50" Lg., Stainless

DIRECT BURIAL CABLE REQUIRMENTS

For *Wall Mount Control Panels.

SIMPLEX

+

CONTROL

PANEL

SERIES

UGP

CONTROL

CABLE

SIZE

UCP

CONTROL

CABLE

SIZE

NUMBER

CONTROL

CABLES

UGP

POWER

CABLE

SIZE

UCP

POWER

CABLE SIZE

NUMBER

POWER

CABLES

PUMP

CONTROL

(SGV)

101, 102,

102B, 105,

106, 109, 110,

113, 114

18/8

18/6

1

10/4

12/3 (230V)

10/3 (115V)

1

Temp Sensor

103, 104, 107,

108, 111, 112,

115, 116

18/10

18/6

1

10/4

12/3 (230V)

10/3 (115V

1

Temp

Sensor,

Moisture

Sensor

DUPLEX

201, 202, 205,

206, 209, 210,

213, 214

18/12

18/8

1

10/4

12/3 (230V)

10/3 (115V

2

Temp Sensor

203, 204, 207,

208, 210, 212,

215, 216

18/6

18/8

3 (SGV)

1 (SGPC)

10/4

12/3 (230V)

10/3 (115V

2

Temp Sensor

Moisture

Sensor

CABLE DESCRIPTION; Ref. NEC article #340

• Type TC (ROUND) tray cable, THHN or THWN (TFFN)

• UL recognized, direct burial cable.

• Volts, rated 600V continuous use at 90C dry and 75C wet.

• Cable to meet requirements of UL83 for THHN or THWN.

Jacket to be printed or indented, “size and number of conductors THHN or THWN (TFFN) type TC 600V (UL)”.

* For Convertable Cover, 1-10/5 DBC required for UGP 1-12/5 for UCP 230 Volt Panels, 1-10/4 DBC required for UCP 115 Volt.

THROUGH BASIN WALL USE

CABLE

PART NUMBER

GRIP RANGE

CORD GRIP #

LOCK NUT

DRILL SIZE

10/3

102195

0.236-0.472

100607

100609

7/8"

10/4

098118

0.236-0.472

100607

100609

7/8"

10/5

102197

0.354-0.629

094270

097310

1"

12/3

104060

0.236-0.472

100607

100609

7/8"

12/5

104061

0.236-0.472

100607

100609

7/8"

18/4

100204

0.236-0.472

100607

100609

7/8"

18/6

096555

0.236-0.472

100607

100609

7/8"

18/8

101726

0.236-0.472

100607

100609

7/8"

18/10

101727

0.236-0.472

100607

100609

7/8"

18/12

098117

0.354-0.629

094270

097310

1"

Required from home to control panel:

10/4 (3 power 1 ground) and 30 Amp breaker at the service drop.

21

BASIN VOLUME CHART IN U.S. GALLONS

SIZE

Dia X Ht

24 x 48

24 x 60

24 x 72

24 x 78

24 x 84

24 x 90

24 x 96

24 x 108

24 x 120

24 x 144

30 x 48

30 x 60

30 x 72

30 x 78

30 x 84

30 x 90

30 x 96

30 x 108

30 x 120

30 x 144

36 x 48

36 x 60

36 x 72

36 x 78

36 x 84

36 x 90

36 x 96

36 x 108

36 x 120

36 x 132

36 x 144

36 x 150

42 x 48

42 x 60

42 x 72

42 x 78

42 x 84

42 x 90

42 x 96

42 x 108

42 x 120

42 x 144

48 x 48

48 x 60

48 x 72

48 x 78

48 x 84

48 x 90

48 x 96

48 x 108

48 x 120

48 x 144

60 x 48

60 x 60

60 x 72

60 x 78

60 x 84

60 x 90

60 x 96

60 x 108

60 x 120

60 x 144

VOLUME

GALLONS

94.0

117.5

141.0

152.9

164.6

176.4

188.2

211.7

235.2

282.2

146.9

183.6

220.3

238.7

257.0

275.0

293.8

330.5

367.2

440.6

211.7

264.6

317.5

344.0

370.4

396.9

423.4

476.3

529.2

581.7

634.6

661.0

287.9

359.8

431.8

467.8

503.8

539.8

575.8

647.7

719.7

863.7

376.0

469.8

563.7

610.7

657.7

704.7

751.7

845.6

939.6

1227.5

587.5

734.4

881.3

954.7

1028.4

1101.6

1175.0

1321.9

1468.8

1762.6

VOLUME

"OFF"

19.6

"

"

"

"

"

"

"

"

"

30.6

"

"

"

"

"

"

"

"

"

44.1

"

"

"

"

"

"

"

"

"

"

"

60.0

"

"

"

"

"

"

"

"

"

78.3

"

"

"

"

"

"

"

"

"

122.4

"

"

"

"

"

"

"

"

"

VOLUME

"ON"

43.1

"

"

"

"

"

"

"

"

"

66.3

"

"

"

"

"

"

"

"

"

97.0

"

"

"

"

"

"

"

"

"

"

"

131.9

"

"

"

"

"

"

"

"

"

172.3

"

"

"

"

"

"

"

"

"

269.3

"

"

"

"

"

"

"

"

"

VOLUME

"ALARM"

51.0

"

"

"

"

"

"

"

"

"

79.6

"

"

"

"

"

"

"

"

"

114.7

"

"

"

"

"

"

"

"

"

"

"

155.9

"

"

"

"

"

"

"

"

"

203.7

"

"

"

"

"

"

"

"

"

318.2

"

"

"

"

"

"

"

"

"

VOLUME BETWEEN

ON - OFF

23.5

"

"

"

"

"

"

"

"

"

36.7

"

"

"

"

"

"

"

"

"

52.9

"

"

"

"

"

"

"

"

"

"

"

72.0

"

"

"

"

"

"

"

"

"

94.0

"

"

"

"

"

"

"

"

"

146.9

"

"

"

"

"

"

"

"

"

72 x 162

2855.3

176.3

387.8

458.4

211.6

NOTES:

1) Pump will displace approximately 3.3 gallons.

2) Ref. 1 gallon = 0.0034 x height (inches) x diameter (inches).

22

BASIN BALLAST REQUIREMENTS

63 LB. PER CUBIC FOOT OF VOLUME REQUIRED

SIZE

Dia X Ht

24 x 48

24 x 60

24 x 72

24 x 78

24 x 84

24 x 90

24 x 96

24 x 108

24 x 120

24 x 144

30 x 48

30 x 60

30 x 72

30 x 78

30 x 84

30 x 90

30 x 96

30 x 108

30 x 120

30 x 144

36 x 48

36 x 60

36 x 72

36 x 78

36 x 84

36 x 90

36 x 96

36 x 108

36 x 120

36 x 132

36 x 144

36 x 150

42 x 48

42 x 60

42 x 72

42 x 78

42 x 84

42 x 90

42 x 96

42 x 108

42 x 120

42 x 144

48 x 48

48 x 60

48 x 72

48 x 78

48 x 84

48 x 90

48 x 96

48 x 108

48 x 120

48 x 144

60 x 48

60 x 60

60 x 72

60 x 78

60 x 84

60 x 90

60 x 96

60 x 108

60 x 120

60 x 144

72 x 162

BASIN VOLUME

CU. FT.

12.57

15.71

18.85

20.44

22.00

23.58

25.16

28.30

31.45

37.73

19.64

24.55

29.45

31.91

34.40

36.77

39.28

44.19

49.09

58.90

28.30

35.38

42.45

45.99

49.52

53.07

56.61

63.68

70.75

77.77

85.00

88.37

38.49

48.11

57.73

62.54

67.35

72.17

76.98

86.59

96.22

115.48

50.27

62.81

75.37

81.65

87.93

94.21

100.50

113.06

125.62

164.12

78.54

98.19

117.83

127.64

137.47

147.28

157.10

176.73

196.37

235.66

381.75

REQUIRED BALLAST

LBS.

791.8

989.7

1187.7

1287.9

1386.4

1485.8

1585.2

1783.2

1981.1

2377.0

1237.4

1546.5

1855.6

2010.6

2164.7

2316.4

2474.7

2783.8

3093.0

3711.2

1783.2

2228.8

2674.3

2897.5

3119.9

3343.1

3566.3

4011.9

4457.5

4899.7

5348.7

5567.7

2425.0

3030.6

3637.1

3940.3

4243.6

4546.8

4850.0

5455.6

6062.1

7275.0

3167.1

3957.2

4748.1

5144.0

5539.9

5935.8

6331.6

7122.6

7914.3

10339.3

4948.6

6185.9

7423.3

8041.5

8660.6

9279.0

9897.1

11134.5

12371.9

14846.6

24050.5

NOTES:

1) Gallons x .1337 = cu. ft.

2) One cu. ft. ballast = 140 lbs.

23

REQUIRED BALLAST

CU. FT.

5.5

7.0

8.5

9.1

9.9

10.6

11.3

12.7

14.1

17.0

8.8

11.0

13.3

14.4

15.5

16.5

17.7

20.0

22.0

25.7

12.7

15.9

19.1

20.7

22.3

23.8

25.5

28.7

31.8

35.0

38.2

39.8

17.3

21.6

26.0

28.1

30.3

32.5

34.6

38.9

43.3

51.9

22.6

28.3

33.9

36.7

39.5

42.4

45.2

50.8

56.5

73.8

35.3

44.2

53.0

57.4

62.0

66.3

70.6

79.5

88.4

106.0

171.8

IMPORTANT !

WARRANTY REGISTRATION

Your product is covered by the enclosed Warranty. This warranty is

ONLY effective provided the warranty registration is completed and

returned to the Barnes Pumps, Inc. service department. See appropriate

registration form located in the "Start-Up/Troubleshooting" Manual.

IMPORTANT! If you have a claim under the provision of the warranty,

contact your local Barnes Pumps, Inc. Distributor.

RETURNED GOODS

RETURN OF MERCHANDISE REQUIRES A "RETURNED GOODS AUTHORIZATION".

CONTACT YOUR LOCAL CRANE PUMPS & SYSTEMS, INC. DISTRIBUTOR.

Products Returned Must Be Cleaned, Sanitized,

Or Decontaminated As Necessary Prior To Shipment,

To Insure That Employees Will Not Be Exposed To Health

Hazards In Handling Said Material. All Applicable Laws

And Regulations Shall Apply.

24

Limited 1 Year Warranty

We warrant that products of our manufacture will be free of defects in material and workmanship under normal use and

service for twelve (12) months after notice of owner’s acceptance, but no greater than twenty-four (24) months after receipt

of shipment, when installed and maintained in accordance with our instructions.

This warranty gives you specific legal rights, and there may also be other rights which vary from state to state. In the event

the product is covered by the Federal Consumer Product Warranties Law (1) the duration of any implied warranties

associated with the product by virtue of said law is limited to the same duration as stated herein, (2) this warranty is a

LIMITED WARRANTY, and (3) no claims of any nature whatsoever shall be made against us, until the ultimate consumer,

his successor, or assigns, notifies us in writing of the defect, and delivers the product and/or defective part(s) freight

prepaid to our factory or nearest authorized service station. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY

AND ALL WARRANTIES WITH RESPECT TO ANY PRODUCT SHALL BE TO REPLACE OR REPAIR AT OUR

ELECTION, F.O.B. POINT OF MANUFACTURE OR AUTHORIZED REPAIR STATION, SUCH PRODUCTS AND/OR

PARTS AS PROVEN DEFECTIVE. THERE SHALL BE NO FURTHER LIABILITY, WHETHER BASED ON

WARRANTY, NEGLIGENCE OR OTHERWISE. Unless expressly stated otherwise, guarantees in the nature of

performance specifications furnished in addition to the foregoing material and workmanship warranties on a product

manufactured by us, if any, are subject to laboratory tests corrected for field performance. Any additional guarantees, in

the nature of performance specifications must be in writing and such writing must be signed by our authorized

representative. Due to inaccuracies in field testing if a conflict arises between the results of field testing conducted by or

for user, and laboratory tests corrected for field performance, the latter shall control. RECOMMENDATIONS FOR

SPECIAL APPLICATIONS OR THOSE RESULTING FROM SYSTEMS ANALYSES AND EVALUATIONS WE

CONDUCT WILL BE BASED ON OUR BEST AVAILABLE EXPERIENCE AND PUBLISHED INDUSTRY

INFORMATION. SUCH RECOMMENDATIONS DO NOT CONSTITUTE A WARRANTY OF SATISFACTORY

PERFORMANCE AND NO SUCH WARRANTY IS GIVEN.

This warranty shall not apply when damage is caused by (a) improper installation, (b) improper voltage (c) lightning (d)

excessive sand or other abrasive material (e) scale or corrosion build-up due to excessive chemical content. Any

modification of the original equipment will also void the warranty. We will not be responsible for loss, damage or labor

cost due to interruption of service caused by defective parts. Neither will we accept charges incurred by others without

our prior written approval.

This warranty is void if our inspection reveals the product was used in a manner inconsistent with normal industry practice

and\or our specific recommendations. The purchaser is responsible for communication of all necessary information

regarding the application and use of the product. UNDER NO CIRCUMSTANCES WILL WE BE RESPONSIBLE FOR

ANY OTHER DIRECT OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST

INCOME, LABOR CHARGES, DELAYS IN PRODUCTION, IDLE PRODUCTION, WHICH DAMAGES ARE CAUSED

BY ANY DEFECTS IN MATERIAL AND\OR WORKMANSHIP AND\OR DAMAGE OR DELAYS IN SHIPMENT. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTY, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No rights extended under this warranty shall be assigned to any other person, whether by operation of law or otherwise,

without our prior written approval.

PUMPS & SYSTEMS

A Crane Co. Company

420 Third Street/P.O. Box 603

Piqua, Ohio 45356-0603

Phone: (937) 778-8947

Fax: (937) 773-7157

www.cranepumps.com

83 West Drive, Brampton

Ontario, Canada L6T 2J6

Phone: (905) 457-6223

Fax: (905) 457-2650

Barnes Pressure Sewer Systems

Piqua, Ohio