DNA-decorated carbon-nanotube-based chemical sensors on

advertisement

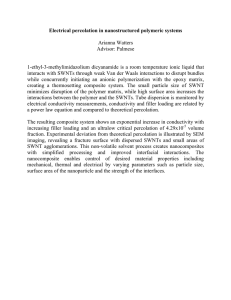

IOP PUBLISHING NANOTECHNOLOGY Nanotechnology 21 (2010) 095504 (8pp) doi:10.1088/0957-4484/21/9/095504 DNA-decorated carbon-nanotube-based chemical sensors on complementary metal oxide semiconductor circuitry Chia-Ling Chen1, Chih-Feng Yang1 , Vinay Agarwal2 , Taehoon Kim3 , Sameer Sonkusale2, Ahmed Busnaina3 , Michelle Chen4 and Mehmet R Dokmeci1,5 1 Department of Electrical and Computer Engineering, NSF Nanoscale Science and Engineering Center for High-rate Nanomanufacturing, Northeastern University, 360 Huntington Avenue, Boston, MA 02115, USA 2 Department of Electrical and Computer Engineering, Tufts University, Medford, MA 02155, USA 3 Department of Mechanical and Industrial Engineering, NSF Nanoscale Science and Engineering Center for High-rate Nanomanufacturing, Northeastern University, 360 Huntington Avenue, Boston, MA 02115, USA 4 Physics Department, Simmons College, 300 The Fenway, Boston, MA 02115, USA E-mail: chen.ch@neu.edu, yang.chi@neu.edu, vinay.agarwal84@gmail.com, thkim@coe.neu.edu, sameer@ece.tufts.edu, busnaina@coe.neu.edu, michelle.chen@simmons.edu and mehmetd@ece.neu.edu Received 18 September 2009, in final form 14 January 2010 Published 8 February 2010 Online at stacks.iop.org/Nano/21/095504 Abstract We present integration of single-stranded DNA (ss-DNA)-decorated single-walled carbon nanotubes (SWNTs) onto complementary metal oxide semiconductor (CMOS) circuitry as nanoscale chemical sensors. SWNTs were assembled onto CMOS circuitry via a low voltage dielectrophoretic (DEP) process. Besides, bare SWNTs are reported to be sensitive to various chemicals, and functionalization of SWNTs with biomolecular complexes further enhances the sensing specificity and sensitivity. After decorating ss-DNA on SWNTs, we have found that the sensing response of the gas sensor was enhanced (up to ∼300% and ∼250% for methanol vapor and isopropanol alcohol vapor, respectively) compared with bare SWNTs. The SWNTs coupled with ss-DNA and their integration on CMOS circuitry demonstrates a step towards realizing ultra-sensitive electronic nose applications. (Some figures in this article are in colour only in the electronic version) pollutants is becoming increasingly important in the need to understand the local and global trends and the complicated side effects of air pollution. Accordingly, there are pressing demands for miniature, low power and ultra-sensitive gas sensing systems. Single-walled carbon nanotubes (SWNTs) possess hollow geometry at the nanoscale with large surface area to volume ratios (>1500 m2 g−1 ) that give rise to very high gas absorptive capacity and electrical mobility. Hence SWNTs are excellent materials for ultra-sensitive gas/chemical sensors in environmental monitoring and low power lab-ona-chip systems. Bare SWNTs are found to be sensitive to 1. Introduction Detection of gas molecules is critical in monitoring environmental pollution arising from combustion to automotive emissions, control of chemical processes and biomedical applications [1]. For instance, nitrogen dioxide (NO2 ), which is one of the most prominent air pollutants and a deadly poison arising from the combustion of fossil fuels (vehicles, electricity generation and industrial processes), contributes to both smog and acid precipitation. Real-time monitoring of environmental 5 Author to whom any correspondence should be addressed. 0957-4484/10/095504+08$30.00 1 © 2010 IOP Publishing Ltd Printed in the UK Nanotechnology 21 (2010) 095504 C-L Chen et al also amenable to CMOS technology. Previous nanotube-based integration approaches utilized high voltage (>20 Vpp ) DEP assembly parameters which were incompatible with CMOS circuitry and required additional photolithography steps [36]. The heterogeneous integration of SWNTs onto CMOS circuitry was presented previously by our group [37]. In this work, we report the first integration of ss-DNAdecorated SWNTs onto CMOS circuitry for chemical sensing applications. The ss-DNA was decorated on the SWNTs to enhance the sensitivity of the gas sensor (up to ∼300% and ∼250% enhancement was measured for methanol vapor and isopropanol alcohol vapor, respectively). Furthermore, the top (M3) metal layer of the foundry CMOS process is about 1.7 μm higher than the rest of the substrate, and hence by assembling SWNT sensors on microelectrodes using the M3 layer enabled us to fabricate suspended nanotube sensors which eliminated the influence of the substrate on the sensing performance, critical for certain applications [25, 26]. numerous gases [1–5]. Moreover, functionalization of SWNTs with polymers [6–9] and biomolecular complexes [10–12] was shown to enhance the specificity and sensitivity of the SWNTbased sensors. Among nucleic acid biomolecules, single-stranded DNA (ss-DNA) is an intriguing candidate as a molecular recognition layer, since it can bind to SWNTs through non-covalent π –π stacking interactions [13, 14], and can be engineered to achieve affinity to a variety of molecular targets [15, 16]. Recently, it was reported that SWNTs decorated with a nanoscale layer of ss-DNA display remarkable chemical sensing capabilities, making them promising for ‘electronic nose’ applications [11]. Label-free detection of DNA hybridization was also achieved optically [17] and electrically [18–20] on ss-DNA-functionalized SWNTs. It has been demonstrated that ss-DNA can be used to sort the chirality of SWNTs [21], and the DNA-SWNT may provide a means for ultrafast DNA sequencing [22]. Furthermore, most of the current carbon nanotube sensors are attached to a substrate [6, 23, 24]. Sensors based on suspended carbon nanotubes not only maximize the active surface area for molecular functionalization, but also eliminate nanotube–substrate interactions which are desirable for various nanotube-based sensing devices [25, 26]. At present, many of the SWNT-based sensors require an additional read-out circuitry or a measurement unit for recognition of sensing response which not only limits the range of applications, but also are prone to parasitics due to wire bonding pads and long interconnect lines [27]. Furthermore, in the case of high density (n > 100) sensor arrays for detecting multiple chemistries, the area lost from wire pads and the signal lines would be intolerable for many applications. Another benefit of monolithic integration is the ability to perform signal detection, amplification, buffering, storage on a single chip and possibly wireless transmission with onchip coils. Accordingly, integration of nanomaterials onto CMOS circuitry is essential to realize miniaturized, high performance sensing systems. Depending on the application, on-chip circuitry can provide high performance due to reduced parasitics and interconnect lines as well as provide signal conditioning and storage on the same chip. Well-known approaches for synthesizing carbon nanotubes include laser ablation, arc-discharge and chemical vapor deposition [28]. None of these approaches are compatible with commercial CMOS technology since the CNT growth processes require relatively high temperatures (>500 ◦ C). Lowering the growth temperatures have also been pursued, yet, to date, the highest quality nanotubes are only obtained via growth at elevated temperatures. Several other approaches have been developed to incorporate nanoscale materials onto microdevices such as drop casting [29], dip coating [30], inkjet printing [31] and field-assisted assembly [32]. One such technique, dielectrophoretic (DEP) assembly, utilizing a nonuniform electric field by the application of an AC voltage, is a versatile and low temperature technique to manipulate nanoscale materials [33–35]. During the DEP process, nanomaterials suspended in a solution can be attracted to regions where the intensity of the field is maximum, known as positive DEP. This simple, low cost and high yield assembly process is 2. Experimental details The integration of SWNTs onto functional electronic circuitry via a post-CMOS fabrication process can be found in our previous publication which include a double-zincation process to remove the Al2 O3 layer prior to DEP assembly, incorporation of SWNTs onto CMOS circuitry via DEP assembly and a third zincation process to fix the SWNT/metal electrode contact problem [37]. In this research, we first demonstrate successful decoration of ss-DNA onto SWNTs assembled on a CMOS circuitry, then demonstrate enhanced gas sensing with ss-DNA-decorated SWNTs compared with bare SWNTs both with passive electrodes on the CMOS chip and also via SWNT sensors connected to active CMOS circuitry and finally explore sensitivity enhancement versus different ss-DNA sequences. The ss-DNA sequences chosen for the experiments are shown here: Seq. 1: 5 to 3 GAG TCT GTG GAG GAG GTA GTC Seq. 2: 5 to 3 GTG TGT GTG TGT GTG TGT GTG TGT Seq. 3: 5 to 3 CTT CTG TCT TGA TGT TTG TCA AAC. Seq. 1 and seq. 3 were chosen based on previous fluorescence [38] and electrical [11] measurements showing sensitivity to various volatile compounds. Seq. 2 was chosen based on a previous report that it can readily wrap around SWNTs and resulting in effective sorting of the SWNTs [21]. The oligonucleotides were obtained from Invitrogen (Carlsbad, CA) and diluted in deionized water to make a stock solution of 100 μmol. After odor responses of the bare SWNT sensors were measured, a 2 μl drop of ss-DNA solution was applied to them for 45 min in a humid environment and then dried with a nitrogen stream (figure 1(a)) [11]. About 20 devices were selected for detailed analysis here. The I –V measurements (HP 4155A, semiconductor parameter analyzer) from the assembled SWNTs on the CMOS chip before (34.67 k) and after (54.44 k) ss-DNA decoration are shown in figure 1(b). 2 Nanotechnology 21 (2010) 095504 (a) C-L Chen et al Amplifier (b) Assembly area ss-DNA decorated SWNTs CMOS (c) (d) 200 nm 200nm Figure 1. (a) The optical photograph of the CMOS chip and a schematic drawing of the DNA-decorated SWNT sensors integrated onto CMOS circuitry, (b) I –V characterization of SWNTs on CMOS circuitry before and after ss-DNA decoration. Ss-DNA decoration was found to increase the resistance while maintaining sufficient conduction in the devices. (c) Typical side-view SEM micrographs of the suspended SWNTs assembled between the microelectrodes realized by the M3 layer of the CMOS chip. (d) A close-up view of ss-DNA-decorated SWNTs on CMOS circuitry. alcohol. The experiments were performed by measuring their resistances under a probe station (SUSS, MicroTec, PM5) using a multimeter (HP 34401A) with LabView control. The chemical response of the bare SWNTs on the CMOS chip was characterized first. The resistance of the sensors was measured for 20 min under ambient conditions, which showed the stability of the devices. Then the sensors were exposed to chemical vapors for 15 min, during which their resistance increased and reached a stable value. Finally, the vapor source was removed and the sensors were allowed to rest in ambient conditions for 30 min in order for their resistance to recover the original values prior to being exposed to the chemical vapors. Three cycles are shown in figure 2 to demonstrate the reproducibility and stability of the sensing response. The resistances were normalized to the value when exposed to air ( R0 ∼ 20 k in this case). Under methanol vapor (figure 2(a) (black data)), the increase in the measured resistance of SWNTs was about 13.41 ± 1.03%, suggesting that the methanol vapor near the SWNTs changed the electrostatics in such a way that decreased the hole carrier density in the SWNTs [39]. Next, three different sequences of ss-DNA were decorated onto the SWNTs to enhance their chemical sensing properties. Exposing ss-DNA-decorated SWNT sensors to methanol vapor increased their resistance by about 18.43 ± 0.81%, 58.02 ± 3.36% and 24.7 ± 1.34% for seq. 1, seq. 2 and seq. 3, respectively, as shown in figure 2(a) (red, green and Ss-DNA decoration on SWNTs was found to increase the resistance of SWNTs by about 57.02%. This could be due to weak carrier scattering by the molecular coating, as well as some displacement of a small number of SWNTs during the decoration of ss-DNA and/or the drying process. There is increasing interest in the controlled assembly of suspended nanostructures for sensing applications since they expose more of the nanosensor surface. Selecting M3 as the integration layer in our process allowed us to realize suspended structures since the M3 layer was 1.7 μm above the substrate. Typical sideview SEM micrographs of suspended SWNTs integrated on CMOS circuitry before and after ss-DNA decoration are shown in figures 1(c) and (d), respectively. 3. Results and discussion Chemical sensing tests were performed on both bare SWNTs and ss-DNA-decorated SWNTs which were assembled onto microelectrodes on the CMOS chip. These microelectrodes were stand-alone test structures and not connected to the on-chip amplifiers and hence were utilized for the initial characterization of our sensors. Here, two chemical vapors, methanol and isopropanol alcohol, were used to test the sensing response of the SWNT sensors. The saturation vapor pressure at 20 ◦ C is 97.48 Torr for methanol and 33 Torr for isopropanol 3 Nanotechnology 21 (2010) 095504 (a) C-L Chen et al DNA-decorated SWNTs were exposed to isopropanol alcohol vapor and their responses were measured. Measurements shown in figure 2(b) (red, green and yellow data for seq. 1, seq. 2 and seq. 3, respectively) indicated that, under isopropanol alcohol vapor, the resistance of the same sample increased by about 5.65 ± 0.3%, 11.25 ± 0.33% and 7.38 ± 0.49% and the measured chemical sensing response of ssDNA-functionalized SWNT sensors were enhanced by about 73.84%, 248.30% and 128.48% for seq. 1, seq. 2 and seq. 3, respectively. Both data show that the ss-DNA-decorated SWNT sensors reached a stable resistance value which was within a few minutes after exposure to the vapors of the analytes. Similarly, after removal of the vapor source, the resistance of the sensors dropped down to half (50%) of the highest resistance value within a minute before taking some extra time to return to its initial value. Comparing our sensor’s response with other researchers’ results, we found that our response and recovery time is of the order of a few minutes, which is longer than the few seconds that was reported by Staii et al [11]. Possible reasons include: first, the sensing response and the recovery time includes the time it takes for the chemical analytes to be delivered to the sensors. In our experimental set-up the chemical vapors are delivered to the SWNTs through diffusion in the chamber where Staii et al delivered the chemical analytes to the devices through a carrier gas with a 0.1 ml s−1 flow rate. The dimensions of our chamber are about 10 cm × 10 cm × 2.5 cm and the chemical analyte inside a container was placed in the center of the cell. The diffusion coefficient is about 0.2 cm2 s−1 for methanol [40] and 0.0959 cm2 s−1 for IPA [41], respectively. The √ diffusion time in one dimension can be estimated by L = 2 Dt , where L is the diffusion length, D is the diffusion coefficient and t is the diffusion time. The diffusion time is calculated to be around 31.2 s and 65.17 s for methanol and IPA, respectively. From this calculation, we noticed that the diffusion time for the chemical analytes to reach the walls of the cell is in the range of 30–60 s for one dimension. For a three-dimensional cell, the diffusion time should be longer. Second, our devices consist of small bundles of SWNTs and it is reasonable to assume that it would take a longer time for the chemical analytes to reach the saturation sensing response for all tubes. The sensing mechanisms for SWNT sensors are most commonly attributed to charge transfer or chemical gating [1], while the exact mechanism is not well understood. Charge transfer is unlikely to take place here because neither methanol nor isopropanol are strong electron donors/acceptors. One possible mechanism is that ss-DNA forms kinked structures when adsorbed on SWNTs [14], forming binding pockets for chemical analytes. These binding pockets in the adsorbed ssDNA may provide preferred orientations for analyte molecules, thus allowing detection of polar molecules (e.g. methanol and isopropanol) in an uncharged state. It is possible that the presence of the binding pockets locally enhance the chemical vapor concentration around the nanotubes, thus enhancing the sensing response. Since the binding pocket morphology depends on the DNA sequence, this could give rise to the sequence dependence of the gas sensing response. Methanol out Methanol in (b) IPA out IPA in Figure 2. Change in sensor resistance upon chemical vapor exposure. Resistances are normalized to the value when exposed to air. (a) Bare SWNTs respond to methanol vapor (black line) with about 13.41 ± 1.03% increase in resistance. The SWNTs decorated with ss-DNA show enhanced response to methanol (red, green and yellow lines for seq. 1, seq. 2 and seq. 3, respectively) with a resistance increase of about 18.43 ± 0.81%, 58.02 ± 3.36% and 24.7 ± 1.34%, respectively. (b) Bare SWNTs respond to isopropanol alcohol vapor (black line) with about 3.23 ± 0.50% increase in resistance. The same SWNTs decorated with ss-DNA show enhanced response to isopropanol alcohol (red, green and yellow lines for seq. 1, seq. 2 and seq. 3, respectively) with a resistance increase of about 5.65 ± 0.30%, 11.25 ± 0.33% and 7.38 ± 0.49%, yellow data for seq. 1, seq. 2 and seq. 3, respectively). The enhanced chemical sensing property of ss-DNA-functionalized SWNT sensors compared with that of bare SWNTs was measured to be about 37.43%, 332.66% and 84.19% for seq. 1, seq. 2 and seq. 3 under methanol vapor. We also exposed bare and ss-DNA-decorated SWNTs to isopropanol alcohol vapor. When bare SWNTs were exposed to isopropanol alcohol vapor, an increase in resistance of about 3.23 ± 0.5% was measured (figure 2(b) (black data)). The change in resistance of bare SWNTs under isopropanol alcohol vapor was less than that when they were exposed to methanol vapor. This observation is due to the differences in the chemical nature of the solvents, as well as the different saturation vapor concentrations between the two chemicals. Next, three different sequences of ss4 Nanotechnology 21 (2010) 095504 C-L Chen et al (a) 60 12 Response (R/R0) (c) 14 Response (R/R0) (b) 70 50 40 30 20 10 20 40 60 80 10 8 6 4 2 100 5 Vapor Pressure (Torr) 10 15 20 25 30 35 Vapor Pressure (Torr) Figure 3. Preliminary data regarding the sensor response versus vapor pressure of ss-DNA (seq. 2)-decorated SWNTs upon exposure to IPA and methanol (a) Time versus response measurement. (b) Vapor pressure versus response measurement for methanol. (c) Vapor pressure versus response measurement for IPA. Table 1. ss-DNA decorated SWNT under vapor testing. Odor Methanol (97.48 Torr) IPA (33 Torr) R/R0 (%) Improvement (%) Time constant (min) R/R0 (%) Improvement (%) Time constant (min) Bare SWNTs SWNTs + seq 1 SWNTs + seq 2 SWNTs + seq 3 13.41 ± 1.03 — 2.85 3.23 ± 0.50 — 3.02 18.43 ± 0.81 37.43 1.03 5.65 ± 0.30 73.84 2.56 58.02 ± 3.36 332.66 2.36 11.25 ± 0.33 248.30 10.03 24.7 ± 1.34 84.19 1.74 7.38 ± 0.49 128.48 2.42 results are summarized in table 1. From the time constant calculations, we have found that the time constant for different DNA sequences are sequence-dependent. For instance, seq. 2 (the highest response) has a higher time constant compared with seq. 1 and seq. 3. The possible reason could be that the binding between seq 2 DNA and gas molecules is stronger than that between seq 1 and seq 3. Under methanol vapor, the change in sensing response was 18.43%, 58.02% and 24.7% for seq. 1, seq. 2 and seq. 3, respectively, and the calculated time constant was 1.03, 2.36 and 1.74 for seq. 1, seq. 2 and seq. 3, respectively. These data suggest that the binding between seq. 2 and gas molecules is the strongest among the three ssDNA sequences used. A similar trend was observed when the decorated SWNT sensors were exposed to IPA vapor where the SWNTs decorated with seq. 2 had the maximum response. Since seq. 2 has the maximum response, preliminary experiments regarding the sensor response versus vapor pressure have been conducted and the measurements are shown in figure 3. The vapor pressure was modified by adding a The data from bare SWNTs and ss-DNA-decorated SWNTs measured after exposure to both methanol and isopropanol alcohol vapors were listed in table 1 for comparison. The gas sensing response is expected to be DNA-sequencedependent, which is one of the motivating factors to use DNA-decorated SWNTs as selective gas sensors. Notice that from table 1, after decoration with ss-DNA sequence 2, the sensing property of the SWNT sensors is much higher (58.02 ± 3.36% for methanol and 11.25 ± 0.33% for isopropanol alcohol) compared with the bare SWNTs (13.41 ± 1.03% for methanol and 3.23 ± 0.50 for isopropanol alcohol). The enhancements in the sensitivity were calculated to be ∼300% and ∼250% for methanol vapor and IPA vapor, respectively. It has been reported that the GT sequence can wrap around SWNTs better compared to other sequences [21]. To fully understand the relationship between sequence dependence and the enhancement in sensing response, a numerical analysis has been conducted to determine the time constants in the decay of the sensor response after removal of the gas vapor and these 5 Nanotechnology 21 (2010) 095504 (a) C-L Chen et al (b) (c) Figure 4. Measured AC amplifier gain in response to variations in gas vapors. Corresponding to different gas vapors, the gain decreased according to gain ∼−RSWNT /Ri . (a) For seq. 1 ss-DNA-decorated SWNT sensors, while exposed to methanol vapor, the gain of the inverting amplifier increased by about 20.71%, while exposed to the isopropanol alcohol vapor, the gain increased by 7.75%. (b) For seq. 2 ss-DNA-decorated sensors, while exposed to methanol vapor, the gain of the inverting amplifier increased by about 55.00%, while exposed to the isopropanol alcohol vapor, the gain increased by 13.70%. (c) For seq. 3 ss-DNA-decorated sensors, while exposed to methanol vapor, the gain of the inverting amplifier increased by about 31.19%, while exposed to the isopropanol alcohol vapor, the gain increased by 8.25%. Table 2. Gas sensing results measured from the amplifier. SWNTs + seq 1 Odor Vapor pressure (Torr) Air Methanol 97.48 IPA 33 Gain G/G 0 (%) R/R0 (%) −1.02 — −1.23 20.71 −1.10 7.75 — 18.43 5.65 SWNTs + seq 2 Gain G/G 0 (%) R/R0 (%) −1.00 — −1.55 55.00 −1.14 13.70 solvent to the chemical analyte, which was dipropylene glycol, which has low vapor pressure (0.06 mm Hg @ 25 ◦ C), and the CNTs do not respond to it [11]. For methanol vapor measurements under different vapor pressures, the resistance change was 18.58%, 27.73%, 43.97% and 58.02% for vapor pressures of 24.37 Torr, 48.74 Torr, 73.11 Torr and 97.48 Torr, respectively. Similar results are obtained for IPA vapor measurements at different vapor pressures; the resistance change was 3.43%, 6.68%, 8.09% and 11.25% for vapor pressures of 8.25 Torr, 16.5 Torr, 24.75 Torr and 33 Torr, respectively. We also compared our results with data from [11] and [42] with the same sequences of DNA decorated onto SWNTs under the same chemical analyte (methanol). Our measurements show similar values to the results obtained in [11] and [42] and even a slightly higher sensitivity which we think may be due to two reasons: one is that the DEP assembly of SWNTs forms bundles of SWNTs while Staii et al have used a single SWNT for their sensor. The other reason is that our SWNTs are suspended from the substrate which reduced the surface effects from the substrate and increased the active surface area for sensing. To demonstrate SWNT gas sensors with active circuitry, we next assembled ss-DNA-decorated SWNTs onto microelectrodes that are connected to an operational amplifier (op-amp) on the CMOS chip. The SWNTs were assembled onto the feedback path ( Rref ) of a Miller-compensated single-ended opamp [43] configured as an inverting amplifier with an external resistor ( Ri ) connected to a circuit. Measured input and output signals from the inverting op-amp with three different — 58.02 11.25 SWNTs + seq 3 Gain G/G 0 (%) R/R0 (%) −1.09 — −1.43 31.19 −1.18 8.25 — 24.7 7.38 sequences of ss-DNA-decorated SWNTs in the feedback path are displayed in figure 4 and the gain of the inverting amplifier was measured as −1.02, −1.00 and −1.09 for seq. 1, seq. 2 and seq. 3, respectively. We next exposed the SWNT sensors on the CMOS chip to various gaseous vapor conditions and characterized their gas sensing properties. We expected that, as the sensors were exposed to vapors of different gases, their resistance would increase, which would lead to an increase in amplifier gain compared to the value measured under ambient conditions. Figure 4 shows the response of the ss-DNAdecorated SWNT sensors to different gas vapors (methanol and isopropanol alcohol) measured from the output of the operational amplifier. Table 2 shows that the measured gain of the inverting amplifier when exposed to methanol vapor was measured to be −1.23, −1.55 and −1.43 for seq. 1, seq. 2 and seq. 3, which was 20.71%, 55.00% and 31.19% higher than the value measured under ambient conditions, respectively. A similar trend was observed while the chip was exposed to isopropanol alcohol vapor. Under IPA vapor, the measured gain of the inverting amplifier was found to be −1.10, −1.14 and −1.18 for seq. 1, seq. 2 and seq. 3, which was 7.75%, 13.70% and 8.25% higher compared to the measurements from the same sample under ambient conditions, respectively. The measurements taken from the amplifier agreed well with the measurements obtained from the SWNT sensors attached to plain electrodes not connected to active amplifiers. This data validated successful integration of the ss-DNA-decorated SWNT sensors onto CMOS circuitry. 6 Nanotechnology 21 (2010) 095504 C-L Chen et al 4. Conclusions [3] Chopra S, McGuire K, Gothard N, Rao A M and Pham A 2003 Appl. Phys. Lett. 83 2280 [4] Valentini L, Armentano I, Kenny J M, Cantalini C, Lozzi L and Santucci S 2003 Appl. Phys. Lett. 82 961 [5] Li J, Lu Y, Ye Q, Cinke M, Han J and Meyyappan M 2003 Nano Lett. 3 929 [6] Snow E S, Perkins F K, Houser E J, Badescu S C and Reinecke T L 2005 Science 307 1942 [7] Qi P, Vermesh O, Grecu M, Javey A, Wang Q and Dai H 2003 Nano Lett. 3 347 [8] Novak J P, Snow E S, Houser E J, Park D, Stepnowski J L and McGill R A 2003 Appl. Phys. Lett. 83 4026 [9] Bradley K, Gabriel J-C P, Star A and Gruner G 2003 Appl. Phys. Lett. 83 3821 [10] Wong S S, Joselevich E, Woolley A T, Cheung C L and Lieber C M 1998 Nature 394 52 [11] Staii C, Johnson A T Jr, Chen M and Gelperin A 2005 Nano Lett. 5 1774 [12] Zhang Y-B et al 2007 Nano Lett. 7 3086 [13] Zheng M, Jagota A, Semke E D, Diner B A, McLean R S, Lustig S R, Richardson R E and Tassi N G 2003 Nat. Mater. 2 338 [14] Johnson R R, Johnson A T and Klein M L 2008 Nano Lett. 8 69 [15] Patel D J, Suri A K, Jiang F, Jiang L, Fan P, Kumar R A and Nonin S 1997 J. Mol. Biol. 272 645 [16] Breaker R R 2004 Nature 432 838 [17] Jeng E S, Moll A E, Roy A C, Gastala J B and Strano M S 2006 Nano Lett. 6 371 [18] Star A, Tu E, Niemann J, Gabriel J-C P, Jr C S and Valcke C 2006 Proc. Natl Acad. Sci. 103 921 [19] Tang X, Bansaruntip S, Nakayama N, Yenilmez E, Chang Y L and Wang Q 2006 Nano Lett. 6 1632 [20] Martinez M T, Tseng Y C, Ormategui N, Loinaz I, Eritja R and Bokor J 2009 Nano Lett. 9 530 [21] Zheng M et al 2003 Science 302 1545 [22] Meng S, Maragakis P, Papaloukas C and Kaxiras E 2007 Nano Lett. 7 45 [23] Peng S and Cho K 2000 Nanotechnology 11 57 [24] Wong E W, Sheehan P E and Lieber C M 1997 Science 277 1971 [25] Lu J, Kopley T, Dutton D, Liu J, Qian C, Son H, Dresselhaus M and Kong J 2006 J. Phys. Chem. 110 10585 [26] Kim P, Shi L, Majumdar A and McEuen P L 2001 Phys. Rev. Lett. 87 215502 [27] Sedra A S and Smith K C 2004 Microelectronic Circuits (New York: Oxford University Press) [28] Soh H T, Quate C F, Morpurgo A F, Marcus C M, Kong J and Dai H 1999 Appl. Phys. Lett. 75 627 [29] Chen C-L, Lopez E, Jung Y-J, Muftu S, Selvarasah S and Dokmeci M R 2008 Appl. Phys. Lett. 93 093109 [30] Spotnitz M E, Ryan D and Stone H A 2004 J. Mater. Chem. 14 1299 [31] Song J-W, Kim J, Yoon Y-H, Choi B-S, Kim J-H and Han C-S 2008 Nanotechnology 19 095702 [32] Khanduja N, Selvarasah S, Chen C-L, Dokmeci M R, Xiong X, Makaram P and Busnaina A 2007 Appl. Phys. Lett. 90 083105 [33] Green N G, Morgan H and Milner J J 1997 J. Biochem. Biophys. Methods 35 89 [34] Hermanson K D, Lumsdon S O, Williams J P, Kaler E W and Velev O D 2001 Science 294 1082 [35] Pohl H A 1978 Dielectrophoresis: The Behavior of Neutral Matter in Nonuniform Electric Fields (Cambridge: Cambridge University Press) [36] Close G F, Yasuda S, Paul B, Fujita S and Wong H-S P 2008 Nano Lett. 8 706 [37] Chen C-L, Agarwal V, Sonkusale S and Dokmeci M R 2009 Nanotechnology 20 225302 In summary, we have demonstrated successful integration of ss-DNA-decorated SWNTs onto functional CMOS circuitry for chemical sensing applications. Two-terminal resistances of bare SWNTs and ss-DNA-decorated SWNTs were measured and it was found that decorating ss-DNA onto SWNTs increased the resistance between the SWNTs and the zinccoated electrodes by 57.02%, due to weak charge carrier scattering, as well as some displacement of a small number of the SWNTs during the decoration of ss-DNA and/or the drying process. Nonetheless, ss-DNA-decorated SWNTs remained sufficiently conductive for sensing applications. The chemical sensing properties have been tested for both bare SWNTs and ss-DNA-attached SWNTs on the CMOS chip with and without amplifier connections. Bare SWNTs were found to be sensitive to the vapors of methanol and isopropanol where an increase in resistance of 13.41 ± 1.03% and 3.23 ± 0.5% was measured, respectively. Ss-DNA decoration has enhanced the sensing response of the nanotube sensors to methanol by 37.43%, 332.66% and 84.19% for seq. 1, seq. 2 and seq. 3, respectively. With DNA decoration, the enhanced sensing response of the nanotube sensors to isopropanol alcohol was measured as 73.84%, 248.30% and 128.48% for seq. 1, seq. 2 and seq. 3, respectively. The initial response and the recovery of the bare and ss-DNA-decorated devices were fairly fast, within a few minutes of vapor exposure and removal. Moreover, ss-DNA-decorated SWNTs were successfully integrated onto CMOS circuitry and their sensing response with and without integration with the CMOS circuitry was in agreement with each other. The gain of the inverting amplifier integrated with ss-DNA-decorated SWNTs increased by about 20.71%, 55.00% and 31.19% for seq. 1, seq. 2 and seq. 3 when the devices were exposed to methanol, respectively, and 7.75%, 13.70% and 8.25% for seq. 1, seq. 2 and seq.3 when the devices were exposed to isopropanol vapors, respectively. This work demonstrated the first ss-DNA-decorated SWNTs integrated onto CMOS circuitry for sensing applications. The methodology presented is simple and versatile with potential applications in the realization of high sensitivity and low power nanotube-based biological and chemical sensors. Acknowledgments This work was supported by the National Science Foundation Nanoscale Science and Engineering Center (NSEC) for Highrate Nanomanufacturing (NSF grant 0425826). The authors would like to thank Nantero Inc for supplying us with the CMOS grade SWNT solution and Professor J Hopwood for valuable suggestions. This research was conducted at the George J Kostas Nanoscale Technology and Manufacturing Research Center at Northeastern University. References [1] Kong J, Franklin N R, Zhou C, Chapline M G, Peng S, Cho K and Dai H 2000 Science 287 622 [2] Kong J and Dai H 2001 J. Phys. Chem. B 105 2890 7 Nanotechnology 21 (2010) 095504 C-L Chen et al [41] http://www.gsi-net.com/en/publications/gsi-chemical-database/ single/324.html [42] Johnson A T C, Staii C, Chen M, Khamis S, Johson R, Klein M L and Gelperin A 2006 Semicond. Sci. Technol. 21 S17 [43] Razavi B 2001 Design of Analog CMOS Integrated Circuits (New York: McGraw-Hill) [38] White J E and Kauer J S 2004 US Patent Specification 2004/0101851 [39] Philip B, Abraham J K, Chandrasekhar A and Varadan V K 2003 Smart Mater. Struct. 12 935 [40] Mrazek R V, Wicks C E and Prabhu K N S 1968 J. Chem. Eng. Data 13 508 8