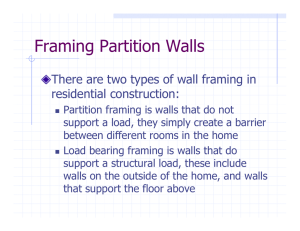

UNIT 2: FRAMING

advertisement

UNIT 2: FRAMING KEY CONCEPTS 1. Identify tools needed for wall framing and layout 2. Floor plans 3. Proper nails and lumber sizes 4. Wall components 5. Building and sheathing walls 6. Setting and plumbing walls at the site 7. Installation of top plate 8. Site Safety and Hazards INSTRUCTIONAL ACTIVITIES 1. Complete Follow-Up Worksheet from Unit 1 – Tools and Safety 2. Identify lumber sizes, lumber characteristics, and nails for wall framing 3. Identify wall components 4. Discuss wall markings and layout 5. Students build and sheet a wall section in lab 6. Discuss wall set up, bracing, and plumbing 7. Discuss top plate function and installation 8. Common framing hazards and safety issues 9. Summarize Key learning points ASSESS LEARNING OF KEY CONCEPTS Students will need to demonstrate proper building of wall section. Recognize lumber sizes and nails used in wall construction. Take written test on markings and wall components. 1 UNIT 2: FRAMING TOOLS USED E D B C A G K F I J H A. Pry Bar B. Cats Paw C. Hammer D. Circular Saw E. Power Miter Saw F. Reciprocating saw G. Speed Square H. Level I. Chalk Line J. Tape Measure K. Sledge Hammer MATERIALS USED A A B B C A. 8d nail – 2½" vinyl coated nail B. 16d nail – 3½" vinyl coated nail A. 2 X 12 B. 2 X 4 C. 4x8x½" O.S.B. 2 UNIT 2: FRAMING LUMBER SIZES Nominal Size 1x2" 1x3" 1x4" 1x6" 1x8" 1x10" 1x12" 5/4x6" Actual Size ¾ x 1½" ¾ x 2½" ¾ x 3½" ¾ x 5½" ¾ x 7¼" ¾ x 9¼" ¾ x 11¼" 1¼ x 5½" Nominal Size 2x2" 2x3" 2x4" 2x6" 2x8" 2x10" 2x12" Actual Size 1½ x 1½" 1½ x 2½" 1½ x 3½" 1½ x 5½" 1½ x 7¼" 1½ x 9¼" 1½ x 11¼" Actual lumber sizes do not match the size they are called due to additional planing and sanding in today’s lumber production. In the chart above you can see the difference. FLOOR PLAN The floor plan tells the story of a house before it is built. The walls, doors, and windows are all identified and located on the plans as well as kitchen and bath layout and dimensions for every room. Wall plates are built according to this “map” of the walls. This plan is an example, and not specific to our current house plan. 3 UNIT 2: FRAMING FRAMED WALL SECTION G B F D C E A F H A G A. B. C. D. E. F. G. H. Stud – the vertical 2x6s that are the strength of the walls. Header – the horizontal piece or pieces that carry the weight of windows or doors from above. King Stud – the studs that are next to a window or door and nail into the end of a header. Trimmer – a stud that is cut to fit underneath a header to act as the support for the header and is nailed to a king stud. Window Sills – two horizontal 2x6s for the window to sit on. Cripples – short 2x6s for under the window sills and 2x6s for above interior doors. Plates – the 2x6s that are the top and bottom of the walls and the “map” of where everything goes. Braces Additional term: Toe Nail- a nail driven at an angle of approximately 45 degrees. 4 UNIT 2: FRAMING EXTERIOR FRAMING 1. For ease in framing, the doors and windows need to go in first. On the plates locate where an X and an O are next to each other. The X is a king stud (92⅝") and the O is a trimmer (81⅛"). This is either a door or a window. The window or door size will be marked on the top plates that run the length of the wall. Please count how many of these you need and start nailing them together with 16d sinkers. The trimmer and king stud should be flush at one end and nailed together with 16d sinkers, two every 24". 2. While people are nailing the king studs and trimmers together, separate the plates and spread them apart. If you take the time to toenail the bottom plate down on the chalk line that was snapped 5½" in from the outside of the house you will accomplish two things: 1) When we start lifting the wall up after it is put together, the wall will not slide off of the deck. 2) When we square the wall before we put the plywood on, the bottom plate will be straight and will not move. 3. By now, enough king studs and trimmers have been nailed together to start framing the wall. Put these in place and attach them to the top and bottom plates with two 16d sinkers for 2x4 walls and three 16d sinkers in 2x6 walls. The next task is to put in the headers. These should be nailed in from the king studs with two 16d sinkers for every three inches of header height. Headers are nailed flush to the outside of the wall. Keep moving along by installing the cripples under the window and then the window sills. Then fill in the remaining X’s with single studs. 4. After you have double-checked the bottom plate to make sure it is straight and toe-nailed to the floor adequately, use tape measures to check the wall for square. To do this, hook the tapes on the corners of the bottom plate and run them to opposite corners of the top plate, creating an X. When the measurements are the same, the wall is square. Toe-nail a 16d sinker down through the top plate into the floor to hold the wall square. Now you are ready to sheet the wall. 5 UNIT 2: FRAMING 5. 4'x8'x7/16" O.S.B. sheathing is fastened to the wall framing with 8d sinker nails. Begin by aligning one corner and nailing, then align and nail a second corner, and finally a third corner to square the wall before nailing the middle part of the sheet. Avoid nailing in window or door openings. Edges of sheathing must fall on the center of a stud. The 8' sheets need to break in the middle of the bottom plate (¾") so that a piece of plywood can later be nailed from the center of the bottom of the plate and extend down to the pressure treated wood on top of the concrete foundation. Use 8d sinkers and place them every six inches around the exterior of the sheet of plywood. For the studs in the middle of the plywood, the nails should be placed every 12". You can use a chalk line to mark the nailing line in the middle of the sheets. 6 UNIT 2: FRAMING 6. Once the sheets are completely nailed off and the windows and doors are cut out, remove the 16d toe-nail that is in the top plate. Use a hammer or pry-bar to lift the wall at least 3 inches off the floor so everyone can get their hands underneath. Before lifting the wall, designate two people to nail braces to the wall after it is lifted. Make sure the braces will not be in the way of building the other exterior walls. Generally, a stud that is nailed to a 2x4 cleat attached to the floor on top of a floor joist, and then to a stud in the wall is sufficient. At least six braces are needed for the long walls of our house. If you plan ahead, the braces will not need to be moved to set interior walls. 7. Verify that the wall is on the chalk line and then nail the walls to the floor with two 16d sinkers between each stud. 8. After all of the walls are in place, fill in the remaining sheathing that will tie the corners of the walls together. At the same time, finish tying the corners together with the second 2x6 top plate. Make sure to leave a space where interior walls will intersect so the second top plate of interior walls will fit into the space you leave. An extra ¼" is helpful to ensure things will fit. Before leaving for the day, go around and wiggle the walls and add any braces that you think might be needed for the walls to be safe until the next workday. Be sure to leave the inside of the house clean of any lumber, as the interior wall plates will need to be laid out. 7 UNIT 2: FRAMING INTERIOR FRAMING 1. For ease in framing, the doors need to go in first. Locate where an X and an O are next to each other on the plates. This is a door. The door size will be marked on the top plates that run the length of the wall. Count how many of these you need and start nailing them together with 16d sinkers. The trimmer and king stud should be flush at one end and nailed together with 16d sinkers, two every 24". If you nail from the trimmer into the king stud, and nail at a slight angle the nails will not poke through into the door opening. 2. While some people are nailing the king studs and trimmers together, others can begin to separate the plates and spread them apart. Be careful not to turn them over or turn them around! 3. By now, enough king stud and trimmers have been nailed together to start framing the wall. Put these in place and attach them to the top and bottom plates with three 16d sinkers. The next task is to put in the headers. These should be nailed in from the king studs with two 16d sinkers for every three inches of header height. 4. After your wall is built, go put it on the floor where the chalk lines have been snapped. When attaching an interior wall to an exterior wall, be sure to use a level. Nail the wall to the floor with two 16d sinkers every 16 inches and next to doors. When attaching interior walls to each other, make sure the plates line up with each other and tie them together with the second top plates. The length of second top plates is determined by measuring wall lengths at the floor, and then adding or subtracting what is needed for intersecting plates. 5. After all of the walls are stood and have their second top plate on, it is time for a plumb and line. Check the corners of the house for plumb with a level and run a string line on the edge of the wall all the way around the house. Use braces to put the walls on the string line and use sufficient numbers to secure them in place. Generally you should put a brace on every interior wall that intersects with an exterior wall and any place there is a break in the first top plate on an exterior wall. 6. Cabinet and fixture blocking is installed between wall studs in areas where cabinets, shelving, or bathroom accessories will be used. 8 UNIT 2: FRAMING SAFETY GUIDELINES FOR FRAMING A. Proper footwear is important for your safety. Flip flops and sandals are not allowed. B. Use safety equipment such as glasses, earplugs, gloves, etc to minimize the risk of injury. C. Do not wear jewelry at the work site. Jewelry, long hair, and loose fitting clothes can get caught in saws. D. Use caution when lifting and get help with lifting heavy items. E. Use extreme caution on ladders and scaffolding; work at a height you are comfortable with. F. Immediately remove nails from used boards. G. Do not use unfamiliar power tools until you have received proper instruction. H. Be aware of your surroundings and watch for holes, trip hazards, and other people. 9 UNIT 2: FRAMING FOLLOW ALONG WORKSHEET Please use the area below to take notes about the major subject headings listed. NEW TOOLS: WALL COMPONENTS: MAJOR STEPS IN SETTING WALLS: ADDITIONAL NOTES: 10 UNIT 2: FRAMING FOLLOW UP WORKSHEET: Fill in the Blank: Please fill in the blank of each question with the corresponding answer from the key below. 1. A ____________ draws a straight line on the decking for wall alignment. 2. A special pry bar that is used to withdraw nails is called a ____________. 3. The ____________ is a print of the design of a house as viewed from above. 4. The second 2x4 that overlaps all top-plate connections is called a ________________. 5. ____________ ensures that all walls are perfectly vertical. 6. A__________________ is a stud that is cut to fit underneath a header to act as the support for the header and is nailed to a king stud. Double-Top Plate Cat’s Paw Chalk Line Plumbing Floor Plan Trimmer Describe the three ways that exterior walls are tied together: 1) 2) 3) Explain the following marks on the plates: X| |X X|O|C |C C|O|X |X |X |X |X X= O= C= Choose one safety precaution particular to this unit that you can implement either on the job site or in your home. In the area below describe why this precaution is necessary to ensure safety. 11