US Building Wire catalog PDF, Brochures

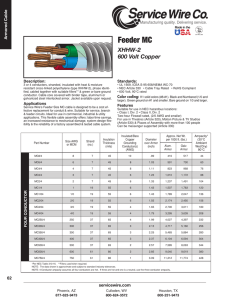

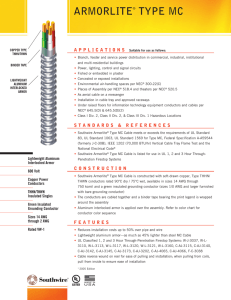

advertisement