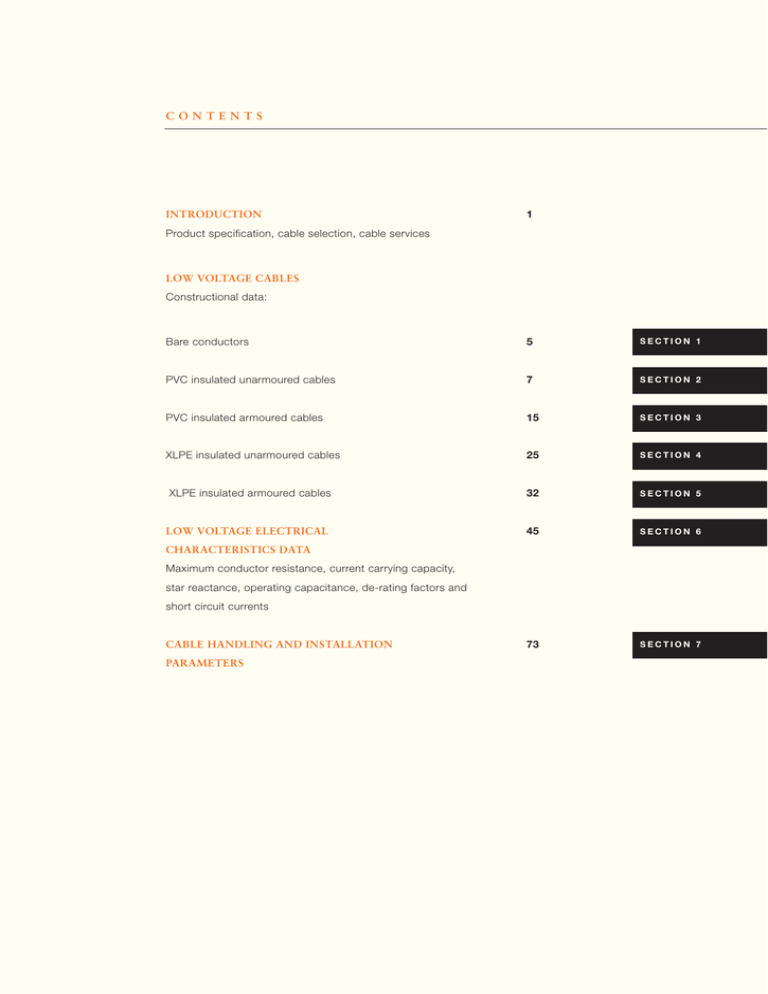

Low Voltage Cables - Saudi Cable Company

advertisement