FirePro® Xtinguish - Hochiki America Corporation

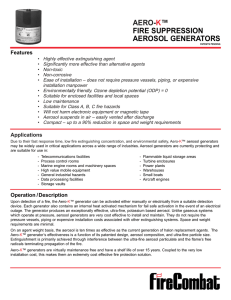

advertisement