Project`s Final technical report

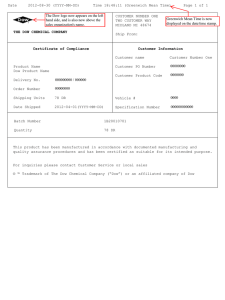

advertisement