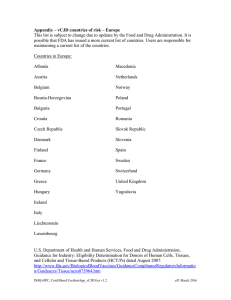

FDA

advertisement