1-70

advertisement

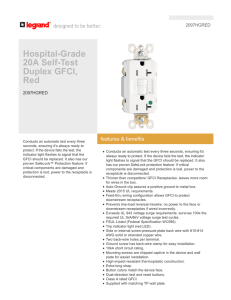

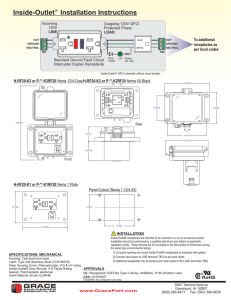

HUBBELL ShopTalk™ 2011 Workplace Safety Seminar Safety First with Hubbell Safety First with Hubbell • A safe work place can help reduce costly accidents and downtime • Hazards exist in every workplace • Hubbell products are designed to help maintain a safe work place • Hubbell is a recognized industry leader on code and regulation OSHA Safety Topics The following were the top 10 most frequently cited standards in fiscal year 2008* 1. Electrical Grounding 2. Ground Fault Protection 3. Strain Relief for Cords 4. Listed, Labeled, or Certified Equipment 5. Worn and Frayed Electrical Cables 6. Ground Fault Circuit Interrupters 7. Covers for Pull Boxes, Junction Boxes, Fittings, and Outlet Boxes 8. Electrical Equipment Fire Hazards 9. Guarding/Protecting Temporary Wiring Over 600 Volts 10. Access to Installations over 600 Volts *October 1, 2007 through September 30, 2008 OSHA Safety Topics The following were the top 10 most frequently cited standards in fiscal year 2010* 1. Scaffolding, general requirements, construction (29 CFR 1926.451) 2. Fall protection, construction (29 CFR 1926.501) 3. Hazard communication standard, general industry (29 CFR 1910.1200) 4. Ladders, construction (29 CFR 1926.1053) 5. Respiratory protection, general industry (29 CFR 1910.134) 6. Control of hazardous energy (lockout/tagout), general industry (29 CFR 1910.147] (#4 in Fines) 7. Electrical, wiring methods, components and equipment, general industry (29 CFR 1910.305) 8. Powered industrial trucks, general industry (29 CFR 1910.178) 9. Electrical systems design, general requirements, general industry (29 CFR 1910.303) (#2 In Fines) 10.Machines, general requirements, general industry (29 CFR 1910.212) *October 1, 2009 through September 30, 2010 UL - Underwriters’ Laboratories •A not-for profit corporation, operating as a testing facility and a developer of safety standards – not quality standards. •No Criteria established to differentiate terms of : Spec-Grade, Commercial, Industrial, heavy-duty, hard use. NEMA® National Electrical Manufacturers Association A standard of the National Electrical Manufacturers Association defines a product, process, or procedure with reference to one or more of the following: •Nomenclature •Composition •Construction •Dimensions •Tolerances •Safety •Operating characteristics •Performance •Ratings •Testing •The service for which it is designed •Defines configurations to prevent intermatability of voltages and amperages •General standards promote interchangeability between products of manufacturers with like product. •Standards related to product performance may be formulated by NEMA but are the exception, not the rule. Watertight vs. Weatherproof UL certifies that a product has been tested and meets the NEMA requirements. NEMA listings are self-certified by the manufacturer. i.e. UL 4X vs. NEMA 4X Wet & Damp Locations Watertight vs. Weatherproof UL 4X NEMA 4X NEMA 3R Weather Resistant Receptacles All 15 and 20 amp, 125 and 250 volt non-locking receptacles shall be listed as weather resistant type per NEC® Article 406.8, Receptacles in Damp and Wet Locations. • Receptacles installed outdoors and other wet /damp locations are subject to demanding temperature variations, direct sunlight and unusual mechanical abuse than those in a typical dry environments. • Weatherproof covers do not offer complete environmental protection. • Weather resistance increases corrosion resistance, cold impact, resistance to ultraviolet and water exposure and effects of aging. • Damp locations include receptacles installed outdoors and locations requiring a weatherproof enclosure. • Listed devices are required to have a “WR” marking on the face visible when installed. Corrosion Resistant Devices Marine Grade Devices • Nickel plated brass blades, contact • Stainless steel body assembly screws • UL Listed, CSA Certified UL 498 • NEMA 1, 4, 4X, 6, 6P environmental ratings • UL listed and CSA certified Watertight Devices •TPE (Rubber) molded body • Nickel plated brass blades, contact • Stainless steel body assembly screws • UL Listed, CSA Certified UL 498 • Rated NEMA 3R, 4, 4X, 6, 6P • Rain tested • Hose-down tested • Submersion tested in 6ft of water for 24 hrs Isolated Ground Receptacles • Ground terminal has insulating barrier from mounting strap • Work box must be grounded to electrical system to clear faults • Single ground path vs. redundant path of bonded box can pose a safety hazard • Triangle Identification SNAPConnect® Duplex Receptacles •No exposed live terminals on receptacle •Pigtails are finger safe if circuit is energized •Clear terminal housing for inspection of power contacts Receptacle Strap Composition • • • • • Ground Straps Ground wire attachment point All brass Nickel coated brass Brass contacts on steel straps Use in corrosive environment Receptacle Orientation Ground up or down? What is wrong with this picture? Tamper Resistant Devices • 406.1 amper T Resistant Receptacles in Dwelling Units. In all areas specified in 210.52, all 125 volt, 15-and 20-ampere receptacles shall be listed tamper resistant receptacles It is estimated that 2,400 children are injured annually by electrical outlet related incidents. Tamper Resistant receptacles incorporate internal mechanisms to limit access to energized internal components. Dwelling units are a single unit, providing complete and independent living facilities for one or more persons, including permanent provisions for living, sleeping cooking and sanitation. The new requirement applies to all dwelling unit outlets. Listed devices are required to have a “TR” marking visible when installed without the cover plate. • How TR Receptacles Work TR receptacles contain spring-loaded shutters that will lock out a single object, such as a hair pin or a key, effectively blocking the contacts. A plug, whether it is two prong or 3 prong will align the shutters and allow contact. Safety Grade Devices •Complies with 1993 NEC Article 517-18c •Electrically safe vs. mechanically safe – reciprocal contact energizing system •No exposed terminal screws if wall plate is removed NEMA Chart •Prevent intermatability of voltages and amperages 15a-30a, 125v – 600v •50amp – CS California Standard configurations NEMA vs. Non-NEMA Dual Voltage Rated Devices • Correct terminating • Identical configuration • Dual voltage 125/250v AC • Poles / Wires Safety-Shroud® Twist-Lock® • • • • • • • Protects against inadvertent contact with blades during mating Reduces exposure to arcing when connecting or disconnecting under load Protects blades from damage Provides mechanical support for plug and cable drag removing stress from power contacts Pad lockable keyway Provides additional locking stability Shroud can be added to old or new style Hubbell device Watertight Safety-Shroud® Twist-Lock® • • • UL 4X, 4 & 12 vs. Type 4x One-piece high impact body design – no boots required One–step integral Neoprene sealing gland Hubbellock® •Arcs are snuffed out by spring-loaded shutter doors when devices are mated or unmated under load •Safety is enhanced because access to live female contacts is restricted by shutter door •Prevents “lazy” connection as plug is rejected by spring door if not properly engaged and locked. What is a Ground Fault? An electrical current normally found on the hot & neutrals which is shunted undesirably to the ground path. Some portion of current is “derailed” Ground Fault Protection The Ground Fault Circuit Interrupter or GFCI will monitor the circuit’s Hot and Neutral conductors and constantly measure the outgoing current on the Hot conductor and compare it to the return current on the Neutral conductor. If the current is exactly the same, the circuit is OK. If it differs at all, there has been current faulted to ground or a Ground Fault has occurred. In the diagram at left the current delivered (blue) is more than the current returned (red). These two waves will not cancel. UL Standards for GFCI • UL 943 - Ground Fault Circuit Interrupters Class A: People Protection 4 to 6 mA trip level .025 trip time Class B: Equipment Protection 20 mA trip level .025 trip time • UL 498 - Wiring Devices GFCI Receptacles •Comprehensive diagnostics functionally test both the electronic components and the mechanical trip mechanism •Flashing RED led indicated device has lost capability to provide protection •Now power at the face if reverse wired •10kA short circuit current rating •Industrial models feature AUTOGUARD™ self test feature as well as a GREEN “ON” LED indication of power •Available in TR tamper resistant and WR weather resistant Testing GFCI Receptacles • Designed to measure the trip level of portable or “wired-in” GFCI’s in a range of 2-7mA. Leakage level can be adjusted from 2-7mA. • Will measure leakage level in small portable tools and appliances from 1-7mA. • Ideal for measuring leakage level of GFCI breakers,GFCI portables and GFCI receptacles. GFCI Receptacles 2011 NEC Code Change 210.8 GFCI Protection A new requirement addresses the accessibility of the test and reset functions of GFCI devices. •210.8 GFCI Protection. Ground-fault circuit interruption for personnel must be provided as required in 210.8(A) through (C). The Groundfault circuit-interrupter device must be installed at a readily accessible location to test on a monthly basis. •The Code previously didn’t address the accessibility of the test and reset functions of GFCI devices. Portable GFCI GFCI Portable Line Cords • Open neutral protection • Sealed electronics in watertight housing • Straight blade and TwistLock • Manual and Auto reset Safe Portable GFCI Protection Open Neutral Protection consists of the opening of both line contacts of a protective device when either line contact loses power. As an example, if the input neutral opens due to a broken conductor or loose plug connection, the GFCI circuitry would not receive power, and therefore would not provide protection. A current path from hot to ground could exist, under these circumstances; a person in contact with the live conductor could receive a shock or a faulty appliance that has an internal insulation failure could allow the case to become energized. Portable GFCI Manual Set •Required the GFCI to be manually set for use by pressing the reset button upon plug in and after loss of primary power (power failure or unplugging the device). •After a ground fault condition, the unit must be reset by pushing the reset button. •Ideal for applications where operator injury might occur if equipment were to restart after a power failure. i.e. power drills, saws, lathes, grinders etc. Portable GFCI Automatic Set •Automatically energizes or sets the GFCI for use upon plug in and after loss of primary power (power failure or unplugging the device). •After a ground fault condition, the unit must be reset by pushing the reset button. •Ideal for equipment where temporary power failure is likely and undesirable. i.e. Pressure washers, pumps, portable signs and lighting, engine heaters, etc. Hardwired GFCI • • • • • • Hard Wired Features Class A 5 milliamp protection NEMA 4x housing Available with audible alarm or 120v AC or 12v and 24v DC signal Open (lost) neutral relay Manual and Auto Reset 120v, 240v, 120/240v, 3Ø 250v, 3Ø 120/208v options What is wrong with this picture? This metal conduit box is being used in manner for which it was not designed. The box is intended to be mounted on a wall or other stationary object; it was not designed as a portable outlet box at the end of an extension cord. This piece of equipment is not being used in accordance with the manufacturer's intended use (violation of OSHA 29 CFR 1910.370(a) - (g) and NEC 1103(b)). Portable Outlet Boxes • UL listed as portable outlet boxes • Complies with NEC® 110.12 regarding unused cable openings in metallic boxes • High impact non- conductive corrosion resistant box • Provides 3R protection with weatherproof cover plates • Integral bonding strap GFCI Receptacle in Portable Use? Temporary Power Hubbell Spider® II Temporary Power Boxes • • • • • • UL 1640 listed for portable power distribution equipment Individual GFCI modules with N3-R gasketed covers Proprietary Supervisory circuit Twist-Lock® or straight blade models Field repairable Rugged abuse resistant housing IEC309 H.P. Rated Pin and Sleeve NEC Section 430.102(B) requires a separate disconnect means within sight of motor loads. NEC Section 430.109(F) permits the use of horsepower rated plugs and receptacles as a “line of sight” disconnecting means. Hubbell’s horsepower rated plugs and receptacles meet these requirements and are an approved “line of sight” disconnect means per the NEC 430.109(F). A motor controller is required in addition to H.P. rated plugs and receptacles to comply with NEC® Figure 430.1. (Traditional Motor Circuits and Controllers) NFPA 70E®: When servicing or changing out a plug connected motor, the motor controller must be turned to the “Off” position and the switch “Locked Out” per OSHA lock-out/tag-out regulations. Visual verification of motor de-energization requirements of NFPA 70E are met when the plug is separated from the mating connector. IEC 60309 H.P. Rated Pin and Sleeve • • • • Sequential contacts engagement during mating and un-mating IEC configurations specific to each voltage and amperage to prevent interchangeability of voltages Watertight 4X Nonmetallic Supertough® nylon body Color coded by voltage Applications Waste water Welders Computer rooms Outdoors Food processing Insulgrip® Pin and Sleeve • UL 1686-C1 configuration standard • Non-Metallic Insulated housing reduces the likelihood of electrical shock during mating and un-mating • UL Type 4X water tight • Corrosion and impact resistant • Interchangeable - Mates with Crouse-Hinds, Appleton and Killark devices Reverse Service Pin and Sleeve •Finger-safe installation for generators & portable power •Mechanical interlock to prevent plugging and unplugging while energized Arc Flash Safety Products •Mechanically interlocked devices eliminate breaking circuit under load providing safe connections to portable equipment •Hubbell Mechanical Interlock devices serve as both power source and disconnect •UL/CSA certified as a manual motor starter and also suitable as a disconnect Arc Flash Safety Products Mechanical Interlocks • • • • • • • • • Can not be plugged or unplugged while receptacle is energized No exposed “Hot” terminals UL certified for 4X application High impact Valox housing Pin & Sleeve outlet Provides Lock-out 20, 30, 60 and 100 amp Fused and Non-Fused IEC309, UL1686 C1 & Twist-Lock® Arc Flash Safety Products • • • NFPA require equipment enclosures to be accessed only by qualified personnel NFPA 70E: Electrical equipment enclosures can ONLY be accessed by qualified personnel with extensive protective clothing and equipment, including fire-resistant suits and hoods with nonconductive wands. NFPA 79: Electrical Standard for Industrial Machinery • ALL utility receptacles must be GFCI protected • ALL external utility receptacles must be covered • ALL covers must maintain enclosure rating Motor Disconnects and Compliance with NEC® 430 and NFPA 70E® Motor Controllers vs. Disconnect Switches NEC Section 430.102(B) requires each motor controller to have a disconnect within line of sight from the motor and driven equipment. NEC Section 430.109(A)(6) recognizes that a manual motor controller and disconnect can be the same unit. Hubbell’s Circuit-Lock® Unfused Disconnect Switches are UL listed as a manual motor controller and also “suitable as a motor disconnect” and meet these code requirements. In order to comply with the visual verification requirements of NFPA 70E without the need for PPE and FPB calculations, a H.P. rated plug and connector should be used in the circuit between the disconnect switch and the motor. Hubbell H.P. rated IEC pin & sleeve plugs and connectors can be used in conjunction with CircuitLock® Disconnect Switches to provide a visual verification of disconnecting means for servicing or changing out a plug connected motor. NFPA 70E®: When servicing or changing out a plug connected motor, the Circuit-Lock Disconnect switch’s red handle must be turned to the “Off” position and the switch “Locked Out” per OSHA lock-out/tag-out regulations. Visual verification of motor de-energization requirements of NFPA 70E are met when the plug is separated from the mating connector. Applications where motors are hard wired from the disconnect switch will require some level of PPE and FPB calculations. Circuit-Lock® Motor Disconnect Switches Modular Power - Linkosity® •NEC® Article 670 on Industrial Machinery refers to NFPA 79-2007, Electrical Standard for Industrial Machinery where sections 14.1.2.2 and 14.1.5.1 specifically indicate that molded connections factory-applied to cable and cords are to be permitted. •NEC® 336.10(7) Permits type TC-ER cable in transitions between cable trays and the utilization equipment or devices when secured at intervals not more than 6 ft without continuous support. •Sealed cable sets prevent condensation building up in raceway and penetrating the motor head MotorQuick™ Disconnect Switches MotorQuick™ Disconnect Switches are also UL listed as a manual motor controller and “suitable as motor disconnect.” When the switch is turned to the off position, the plug and play technology of the Linkosity™ power system can enable quick motor replacement. Motor change out time can be reduced by over 65%, minimizing production down time. NFPA 70E®: When servicing or changing out a Linkosity™ connected motor, turn the MotorQuick™ Disconnect switch’s red handle to the “Off” position and “LockOut” per OSHA lock-out/tag out regulations. Visual verification of motor de-energization requirements of NFPA 70E® are met when the Linkosity™ plug is separated from the mating connector. TredTrak® & TruckTrak® • • • • • • • Safety blue and yellow for high visibility TredTrak for pedestrian traffic (10,500 lb rating) TruckTrak for vehicular traffic (20,150 lb rating) 3’ Sections lock together Safety surface pattern UV stabilized for outdoor use Complies with NEC requirements (article 525) for insulating electrical cables for indoor and outdoor applications AccessTrak® System • • • AccessTrak® Meets ADA requirements 10,000 lb weight ratingwill protect cables and hoses up to 1.31” diameter Expandable by length and width Cable Management •UL Listed as type EF conduit •Meets NEC 356.10 applications •Non-metallic construction eliminates fatigue and separation at fittings •No metal core prevents potential energization Wire Management • NEC 400.1 Pull at joints and terminals • OSHA 29CFR 1926.405 Strain relief, Cords passing through holes • NEC 356.10 Liquidtight Flexible Non-metallic conduit 55 Cable Management •Support grips should have a 10 times the cable weight as a safety factor •Available in stainless steel for high corrosive areas •OSHA Regulation 29 CFR 1926.405(g)(2)(iv) Strain relief. Flexible cords shall be connected to devices and fittings so that strain relief is provided which will prevent pull from being directly transmitted to joints or terminal screws. Cable Management • NEC® 400.10 (Pull at Joints and Terminals) Flexible cords and cables shall be connected to devices and to fittings so that tension is not transmitted to joints or terminals. • OSHA 29CFR 1926.405(g)(2)(v) Cords passing through holes. Flexible cords and cables shall be protected by bushings or fittings where passing through holes in covers, outlet boxes, or similar enclosures. Lockout, Tagout Safety • Lockout/Tagout procedures safeguard people from unexpected startup of machinery or equipment • NFPA 70E-2004 LO/TO procedures 29CFR1910.147 (a) (3) (i) • Highly visible OSHA requirement Lockout, Tagout Safety • NFPA 70E-2004 LO/TO procedures: OSHA 29CFR1910.147 (a) (3) (i) This section requires employers to establish a program and utilize procedures for affixing appropriate lockout devices or tagout devices to energy isolating devices, and to otherwise disable machines or equipment to prevent unexpected energization, start up or release of stored energy in order to prevent injury to employees. • Highly visible OSHA requirement Hubbell SWITCHOUT® • • • • SwitchOut® Designed for toggle switch lockout Lighting fixture M&R Partially back out plate screws Slip on and tighten screws Hubbell PLUGOUT® Plug is closed, locked and tagged • Tag identifies user • Large size for welder plugs • High Impact plastic Hubbell Keyed PLUGOUT® Keyed PlugOut® • Easy to carry – fits in pouch or tool box • Fits over blade of 2 or 3 wire plug Circuit-Lock® Mechanical Interlocks NEC®: Hubbell’s Circuit-Lock Mechanical Interlocks allow an installation to comply with NEC Section 430.102(B), requiring each motor controller have a disconnect within line of sight from the motor and driven equipment. The NEC® also recognizes that a manual motor controller and disconnect can be the same unit [NEC Section 430.109(A)(6)]. Hubbell’s Circuit-Lock® mechanical interlocks are designed to comply with both the manual motor controller and disconnect requirements of the NEC®. In addition, Hubbell Mechanical Interlocks provide an extra measure of safety by preventing a plug connected motor load from being disconnected or connected live or under load. NFPA 70E®: When servicing or changing out a plug connected motor, the mechanical interlock’s combination motor controller/disconnect switch red handle must be turned to the “Off” position and the switch “Locked Out” per OSHA lock-out/tag-out regulations. Visual verification of motor de-energization requirements of NFPA 70E are met when the plug is separated from the mechanical interlock. Explanation of UL Standard Changes New UL Requirements for GFCI Cord Reels (Defined in UL 355 Standard for Cord Reels) Paragraph 1.5 – Cord Reels shall be permitted to employ Ground-Fault Circuit-interrupter(s) (GFCI) outlet(s). The Ground Fault Circuit Interrupters (GFCI) shall be investigated to the requirements in the Standard for Ground-Fault Circuit Interrupters, UL 943. Paragraphs 4.3, 4.4 – Cord Reels, that employ Ground-Fault Circuit Interrupter outlet(s) and are connected to the power supply by means of flexible cord with an attachment plug and/or that employ slip rings, shall be provided with open neutral protection as part of the GFCI. Definition Paragraph 2.7.1 - Open Neutral Protection consists of the opening of the line contacts of a protective device when either line contact loses power. As an example, if the input neutral opens due to a broken conductor or loose plug connection, the protective device circuitry would not receive power, and therefore would not operate to provide protection. A current path from line to ground could exist, under these circumstances; a person in contact with the live conductor could receive a shock. (A faulty appliance that has an internal insulation failure could allow the case to become energized.) Cable Management •Cable reels help eliminate unmanaged cords that would cause a trip hazard. •Types include UL type 4X weatherproof, industrial, commercial, static discharge and air and water hose reels SPD Surge Protection Devices SCCR Ratings •The NEC 2002 Code change states, “The TVSS shall be marked with a short circuit current rating (SCCR) and shall not be installed at a point on the system where the available fault current is in excess of that rating.” •The SCCR rating is the capacity of current with which the tested Surge Protected Device can withstand at the terminals where connected, without breaching the enclosure in any way. This change in the UL requirements is in response to NFPA (National Fire Protection Agency) 70, Article 285.6 of the 2002 National Electrical Code. •U.L. 1449-23 = Trace Fuse, Thermal Fuse and Overcurrent protection SPD Surge Protection Devices - UL 1449 3rd Edition • Effective September 29, 2009 • Name Change to Surge Protective Device • Type 1,2,3,4 defining installation locations in a facility • Nominal Discharge Current: I(n) • New product testing requirements SPD Surge Protection Devices Where does the Voltage and Current Go? •Current will flow through the path of least resistance. Simply put, the SPD becomes the path of least resistance and shunts the damaging energy before it is forced through the down stream equipment •Good grounding is critical for all SPD to function properly as spikes are shunted to ground SPD UL Type Classifications L 1 SPD 2 SPD SPD Distribution Permanently Connected Branch Permanently Connected 3 Loa d N Service Entrance Line Side of OCPD Load Side of OCPD Point of UsePlug-in protection Additional HubbellSafe Resources Website Landing Page Safety Application Guide Safety Evaluation E-learning Course Video-Demo 70