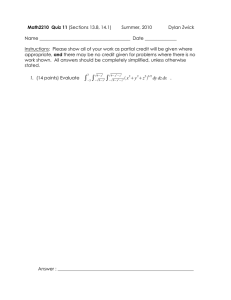

to view the Position Indicators catalogue

advertisement

4 Valve Monitoring Systems Rotary & linear visual indicators State-of-the-art switch technology Bus/network compatible Low power pilot valves www.ascovalve.com 4 Valve Monitoring Systems ASCO’s Valve Monitoring Systems (VMS) have revolutionized the concept of position indication by combining the technologies of visual indication and network communications. This catalog contains features, materials of construction, ambient temperatures, electrical information, specifications, ordering information, and dimensional drawings for the VMS line of products. If the information you are looking for is not here please call the contact information provided. All products are available in corrosion resistant low copper aluminum and resin constructions for hazardous environments. All rotary and linear products provide highly visible 360º indication. INDEX PAGE NR1 & NR2 Rotary Position Indicators Direct Mount for Rotary NAMUR Actuators 1-2 VR2 & VR3 Rotary Position Indicators Bracket Mounted for Rotary Actuators (Aluminum Body) 3-4 VR4 & VR8 Rotary Position Indicators Bracket Mounted for Rotary Actuators (Resin Body) 5-6 VR7 Rotary Position Indicators Bracket Mounted for Rotary Actuators (Div. 1/Div. 2) 7-8 Linear Position Indicators Bracket Mounted for Linear Actuators 9-14 DeviceNet™ Network Card 15-16 AS-interface® Network Card 17 FOUNDATION Fieldbus™ for NR and VR Series 18-19 Reed Switch Assembly VR Series Option 20 Potentiometer or Transmitter VR Series Option 21 3-Way Normally Closed Pilot Valves for Assembly to VMS Boxes 22-23 4-Way Pilot Valves for Assembly to VMS Boxes 24-25 Slip-Lok™ Connector 26 Network Junction Box for AS-interface and DeviceNet Networks 27 DeviceNet is a trademark of ODVA. AS-interface is a registered trademark of AS-International. Profibus is a registered trademark of Profibus International. FOUNDATION Fieldbus is a trademark of Fieldbus Foundation. CAUTION: Electrical load must be within range of the stated values in this catalog. Failure to stay within the electrical range of the switches may result in improper operation. Linear Position Indicator 4 Valve Monitoring Systems Bracket Mounted for Linear Actuators Aluminum Body Features SERIES HS1 % # • Explosion proof, Div. 1 rated aluminum housing for hazardous locations • Simple to install and adjust • Understroke compensating switch triggers • 12 mounting positions (in 30˚ increments) • No seal fittings required with reed switches in Class I, Div. 1, Group A, B, C, & D areas • One construction accommodates strokes up to 2 inches Construction Area Body Coating Switch Triggers Inner Frame Type 4, 4X Low Copper Aluminum Black Hard Anodized ABS Zytel™ Nylon Zytel is a registered trademark of DuPont Co. Ambient Temperatures Reed Switches: -4˚F to 150˚F (-20˚C to 65˚C) ASi, DeviceNet Bus Card: -4˚F to 140˚F (-20˚C to 60˚C) IS Profibus PA: 32˚F to 140˚F (0˚C to 60˚C) Mechanical Switches: -40˚F to 170˚F (-40˚C to 77˚C) (Contact ASCO for extended temperature range applications.) Electrical Mechanical Switches Gold Contacts Maximum 100mA@125/250VAC Minimum 4mA@5VDC Silver Contacts Maximum 15A@125/250VAC Minimum 125mA@125/250VAC Reed Switches Tungsten: 120VAC@3A or 24VDC@2A Maximum power allowable is 100 Watts or 100VA Minimum power required to ensure proper operation is 3W or 3VA Rhodium: 24VDC@1A Maximum power allowable is 25 Watts Minimum current required to ensure proper operation is 10mA@3VDC Rhodium (IS): 2mA to 1A@24VDC (suitable for IS applications) “IS”- Class I,II,III, Div. 1, Groups A,B,C,D,E,F, and G NOTE: ASCO requires 12VDC valves for DeviceNet Network Cards and 24VDC for AS-interface Network Cards. Approvals FM approved for “Hazardous (Classified) locations”; Class 3600, 3610, 3611, & 3615. CSA Certified to Standard C22.2 No. 142-M “Process Control Equipment”; Hazardous Locations, Class 2258-02, 04, 82 & 84. Optional Features • Low power pilot valve mounted to enclosure • Network Junction Box for hazardous locations • AS-interface, Profibus-PA, DeviceNet communication cards with 2 sensors to indicate stem position • 2 or 3 conduit entries in 3/4" FNPT See list price schedule for available mounting brackets and adapters. 9 SERIES 4 HS1 Valve Monitoring Systems Specifications Series Hazardous Classified Location Shaft Conduit Indicator Change Letter Explosionproof: with Switches Class1/Div.1/A,B,C,D/T6 Dust Ignition Proof: Class2,3/Div.1/E,F,G/T6 Ambient Temp. = 77˚C/170˚F HS1 Series Type 4,4X Indoor/Outdoor Explosionproof: with Switches Class1/Div.1/A,B,C,D/T6 Dust Ignition Proof: Class2,3/Div.1/E,F,G/T6 Ambient Temp. = 60˚C/140˚F Switches # of Switches Network/Bus Rev. A=Mech SPDT Silver 15A H=Mech SPDT Gold (IS) N=No Switch F=ITT(<1") G=Saunders(<1") H=ITT(1-1/4" to 2") K=ITT Series 47 (3" & 4") L=Gemu D6 (1/2" to 1") M=Gemu D6 (1-1/4" to 1-1/2") Q=ITT Series 33 (3" & 4") 2=(2) 3/4 FNPT 4=(3) 3/4 FNPT N=None A Explosionproof: with Bus Card Class1/Div.1/A,B,C,D/T6 Dust Ignition Proof: Class2,3/Div.1/E,F,G/T6 Ambient Temp. = 60˚C/140˚F G=Reed SPDT Rhodium (IS) R=Reed SPDT Rhodium 1A T=Reed SPDT Tungsten 3A W=Network Card HS1 F 2 N A A 0=None U=One Upper L=One Lower 2=Two NG=None A 0=None U=One Upper L=One Lower 2=Two AJ=ASI 2x1, v2.1, Std. Address AL=ASI 2x1, v2.1, Ext. Address 2=Two DC=DNET2x1 DE=DNET 2x1 Diagnostics 2 NG A Ordering Number Example: HS1F2NAA2NGA Dimensions Inches (mm) 4.25 (108) 5.94 (151) 3/4.NPT 2.13 (54) 4.25 (108) 1.55 (39) 10 3/4.NPT Linear Position Indicator 4 Valve Monitoring Systems Bracket Mounted for Linear Actuators Resin Body SERIES HS2 HS3 HS4 Features • Process valve body is serviceable without removing indicator box ) % # • Built-in understroke compensation • Simple to install and adjust • Designed for caustic washdown • One construction accommodates valve strokes up to 2 inches • Indicator visible from 360˚ Construction Area Classifications HS 2 HS 3 HS 4 Type 4, 4X Indoor Hazardous Location* IP66 Outdoor Hazardous Location* Type 4, 4X IP66 Indoor/Outdoor Non-Hazardous Location Switch Type Mechanical / Reed Body Valox 364 (Resilient PBT) Indicator Cover Polycarbonate (Makrolon Grade 2607™) UV Stabilized Switch Trigger ABS Inner Frame Zytel Nylon Mechanical SPDT gold plated switch is also available for intrinsically safe (IS) applications. * See Specifications Chart. Makrolon 2607 is a registered trademark of Bayer Inc. Ambient Temperatures Reed Switches: -4˚F to 150˚F (-20˚C to 65˚C) ASi, DeviceNet Bus Card: -4˚F to 140˚F (-20˚C to 60˚C) Profibus PA: 32˚F to 140˚F (0˚C to 60˚C) (Contact ASCO for extended temperature range applications.) Electrical Mechanical Switches Gold Contacts Maximum 100mA@125/250VAC Minimum 4mA@5VDC Silver Contacts Maximum 15A@125/250VAC Minimum 125mA@125/250VAC Reed Switches Tungsten: 120VAC@3A or 24VDC@2A Maximum power allowable is 100 Watts or 100VA Minimum power required to ensure proper operation is 3W or 3VA Rhodium: 24VDC@1A Maximum power allowable is 25 Watts Minimum current required to ensure proper operation is 10mA@3VDC Rhodium (IS): 2mA to 1A@24VDC (suitable for IS applications) “IS”- Class I,II,III, Div. 1, Groups A,B,C,D,E,F, and G Class I, Zone 0, AEx ia IIC T6 Class I, Zone 1, AEx ib IIC T6 ATEX category 1G, 2G Intrinsic Safety Only II 1G EEx i a IIC T6 KEMA 04 ATEX 1025X Ambient Temperature: -18 to 170˚F (-28 to 77˚C) NOTE: ASCO requires 12VDC valves for DeviceNet Network Cards and 24VDC for AS-interface Network Cards. Approvals FM approved for: “Hazardous (Classified) locations”; Class 3600, 3610 & 3611 (HS 2 & 3). Unclassified Locations (HS 4). CSA Certified to Standard C22.2 No. 142-M “Process Control Equipment”; Hazardous Locations, Class 2258-02, 04, 82 & 84 (HS 2 & 3), and General Requirements, Class 2252-01(HS 4), File 013976-0-000. CE Certified. Optional Features • Attached low power pilot valve or with integrated valve. • AS-interface, Profibus-PA, DeviceNet communication cards with 2 switches to indicate stem position. • Up to 2 conduit entries select from: 1/2" or 20mm. • Plug, cable gland, and network connectors. See list price schedule for available mounting brackets and adapters. 11 SERIES HS2 HS3 HS4 4 Valve Monitoring Systems Specifications Series Hazardous Classified Location Conduit / Connector Shaft Indicator Change Letter Intrinsically Safe: Class1,2,3/Div.1/A,B,C,D/T6 Class1/Zone 0/AEx ia IIC/T6 Class1/Zone 1/AEx ib IIC/T6 Ambient Temp. = 77˚C/170˚F Class2/Div.1/A,B,C,D,E,F,G Non-Incendive: with Reed SwitchesClass1/Div.2/A,B,C,D/T6 Class2/Div.2/F,G/T6 Except Dust HS2 Series Ambient Temp. = 65˚C/150˚F Special Protection: Indoor Only Type 4,4X Indoor D=10-24 Thread* 1=(2) 1/2 FNPT 9=(1) 1/2 FNPT Y=Yel/Black + (1) M20 x 1.5 C Non-Incendive: with Bus Card Class1/Div.2/A,B,C,D/T6 Class2/Div.2/F,G/T6 Ambient Temp. = 60˚C/140˚F Special Protection: Indoor Only Switches # of Switches N=None 0=None H=Mech SPDT Gold (IS) G=Reed SPDT Rhodium (IS) T=Reed SPDT Tungsten 3A R=Reed SPDT Rhodium 1A 0=None U=One Open Upper L=One Closed Lower 2=Two W=Network Card 0=None U=One Open Upper L=One Closed Lower 2=Two 2=Two HS2 Series Hazardous Classified Location D 1 Y C Shaft Conduit / Connector Indicator Change Letter T Switches N=None HS3 Series IP-66 Outdoor Intrinsically Safe: Class1,2,3/Div.1/A,B,C,D/T6 Class1/Zone 0/AEx ia IIC/T6 Class1/Zone 1/AEx ib IIC/T6 Ambient Temp. = 77˚C/170˚F Class2/Div.1/A,B,C,D,E,F,G D=10-24 Thread* 1=(2) 1/2 FNPT 9=(1) 1/2 FNPT Y=Yel/Black + (1) M20 x 1.5 C Series Hazardous Classified Location HS4 Series Type 4,4X Indoor Non-Hazardous IP-66 Indoor/ Outdoor 1 Y C Shaft Conduit / Connector Indicator Change Letter 1=(2) 1/2 FNPT D=10-24 Y=Yel/Black Thread* 9=(1) 1/2 FNPT + (1) M20 x 1.5 HS4 D 1 Y C C A=Threaded Conduit NG=None A=Threaded Conduit AJ=ASI 2x1, v2.1, Std Address B=M12 Pin AL=ASI 2x1, v2.1, Ext Address Connector for Bus Networks C=Mini (7/8) Pin DC=DNET2x1 Connector DE=DNET 2x1 Diagnostics for Bus Networks 2 NG A # of Switches Network/Bus Connector H=Mech SPDT Gold (IS) G=Reed SPDT Rhodium (IS) T=Reed SPDT Tungsten 3A R=Reed SPDT Rhodium 1A NG=None 0=None U=One Open Upper L=One Closed Lower 2=Two A=Threaded Conduit AJ=ASI 2x1, v2.1, Std Address B=M12 Pin AL=ASI 2x1, v2.1, Ext Address Connector for Bus Networks C=Mini (7/8) Pin DC=DNET2x1 Connector DE=DNET 2x1 Diagnostics for Bus Networks T Switches A=Threaded Conduit 0=None U=One Open Upper L=One Closed Lower 2=Two 2=Two D Connector 0=None W=Network Card HS3 Network/Bus 2 NG A # of Switches Network/Bus Connector A=Threaded Conduit B=M12 Pin Connector for Bus Networks C=Mini (7/8) Pin Connector for Bus Networks N=None 0=None A=Mech SPDT Silver 15A H=Mech SPDT Gold (IS) U=One Upper (open) NG=None L=One Lower (closed) 2=Two A 2 NG A M20 x 1.5 with PIN Connector required for Bus. * For correct operation, ASCO mouning bracket must be used. See ASCO VMS list price schedule for mounting kits. Ordering Example: HS2D1BYCT2NGA Dimensions: Inches (mm) 3.67 [93] 1/2 NPT OR M20 x 1.5 2 PLACES 3.73 [ 95] TOP VIEW 4.88 [124] 1.89 [48] 3.78 [96] 12 SIDE VIEW 1.08 [27] 1.08 [27] Linear Position Indicator 4 Valve Monitoring Systems Bracket Mounted with Integrated Valve for Linear Actuators Resin/Aluminum Body Indicator with Integrated Valve Features SERIES HS INTEGRATED % # • Simpler to order PENDING • Available in 0.3 Cv only PENDING • Solenoid valve is environmentally protected inside the housing • Reliable poppet construction • Built-in relief valve prevents pressurizing of internal indicator housing • External manual override Solenoid Valve Specifications • 1/4" NPT threaded ports • Cv flow factor of 0.3 • Medium - AIR or INERT GASES only • Pressure min. & max. - 30 to 120 psi Optional Features • Recommended filtration - 50 microns (50um) • AS-interface, DeviceNet communication cards with 2 switches to indicate stem position. • 2 conduit entries select from: 1/2" or 20mm. See list price schedule for available mounting brackets and adapters. • Coil wattage of 0.5 Watt in 24VDC or 1.0 Watt in 12VDC, 120/60 or 240/60 Integrated Valve Construction Body Anodized Aluminum Hardware Stainless Steel Popet Stainless Steel Sealing Material NBR Indicator Construction Area Classifications Switch Type HS 2 HS 4 Type 4, 4X Indoor Hazardous Location* Type 4, 4X IP66 Indoor/Outdoor Non-Hazardous Location Mechanical / Reed Body Valox 364 (Resilient PBT) Indicator Cover Polycarbonate (Makrolon Grade 2607™) UV Stabilized Switch Trigger ABS Inner Frame Zytel Nylon 13 SERIES HS 4 INTEGRATED Valve Monitoring Systems Specifications Hazardous ClassifiedLocation Series Conduit / Connector Shaft Indicator Change Letter Switches N=No Switch HS2 Series Type 4,4X Indoor Only # of Switches U=One Open/Upper T=Reed SPDT Tungsten 3A L=One Closed/Lower R=Reed SPDT Rhodium 1A 2=Two Non-Incendive Class1/Div. 2/A,B,C,D/T4 Class1/Div. 2/F,G/T4 D=#10-24 A=(1) 1/2 FNPT Y=Yel/Black Ambient Temp. = 60˚C/140˚F Thread* C=(1) M20 x 1.5 Special Protection: Indoor Only C W=Network Card U=One Open Upper L=One Closed Lower 2=Two 2=Two Intrinsically Safe: Class1,2,3/Div.1/A,B,C,D/T6 Class1/Zone 0/AEx ia IIC/T6 D=#10-24 A=(1) 1/2 FNPT Y=Yel/Black Class1/Zone 1/AEx ib IIC/T6 Thread* C=(1) M20 x 1.5 Ambient Temp. = 60˚C/140˚F Class2/Div.1/A,B,C,D,E,F,G U=One Open Upper G=Reed SPDT Rhodium (IS) L=One Closed Lower H=Mech SPDT Gold (IS) 2=Two C N=No Switch D=#10-24 A=(1) 1/2 FNPT Y=Yel/Black Thread* C=(1) M20 x 1.5 C W=Network Card U=One Open/Upper L=One Closed/Lower 2=Two 2=Two HS2 D C Y C Connector NG=None A=Threaded Conduit AJ=ASI 2x1, v2.1, A=Threaded Conduit Std Address AL=ASI 2x1, v2.1, B=M12 pin connector for Ext Address Bus DC=DNET2x1 C=Mini (7/8") pin DE=DNET 2x2 connector for bus Diagnostics NG=None A=Threaded Conduit NG=None A=Threaded Conduit 0=None A=Mech SPDT Silver 15A U=One Open/Upper H=Mech SPDT Gold (IS) L=One Closed/Lower T=Reed SPDT Tungsten 3A 2=Two R=Reed SPDT Rhodium 1A HS4 Series Type 4,4X Non-Hazardous Indoor IP-66 Indoor/Outdoor Network/Bus 0=None W 2 AJ=ASI 2x1, v2.1, A=Threaded Conduit Std Address AL=ASI 2x1, v2.1, B=M12 pin connector for Ext Address Bus DC=DNET2x1 C=Mini (7/8") pin DE=DNET 2x2 connector for bus Diagnostics DE C Ordering Example with valve: HS2DCYCW2DEC15F Description: (HS2 Series with #10-24 Shaft thread, (1) M20x1.5 threaded conduit, yellow/black indicator, (2) hall effect sensors, DNet Bus Card with diagnostics, Mini (7/8") pin connector, 3/2 NC 1/4 NPT valve, screw-in manual operator, 12VDC) * For correct operation, ASCO mouning bracket must be used. See ASCO VMS list price schedule for mounting kits. Integrated Solenoid Valve Ordering Valve Code 1 Manual Operator Operation Pipe 3/2 NC Code 1/4 NPT 5 Type Screw In 1 Voltages To Operate Code Voltage A 120/60 B 240/60 D 24/DC Screw Driver E IS F 12/DC 5 F Dimensions: Inches (mm) Construction Port #1 Port #2 Port #3 3/2 NC Pressure Cylinder Exhaust Ø3.57 [93] 3.73 [95] .409 [10.4] 4.88 [124] 1.89 [48] .610 [15.5] .39 [10] 5.007 [127.18] 14 1/2 NPT M20 x 1.5 THREAD .610 [15.5] 3.047 [77.4] .276 [7] .409 [10.4] 3/2 SERIES 8355 3-Way Normally Closed Pilot Valves 4 for assembly to VMS boxes Valve Monitoring Systems Features • Explosionproof, Type 4 & 4X and Intrinsically Safe solenoids • Poppet design provides durability and reliability in a wide range of ambient temperatures % # • Nickel plated brass, or 316 stainless steel bodies designed for harsh process conditions • Built-in speed controls and rebreather connection • High efficiency, low wattage coils (2 watt AC and .5 watt DC) • 1/4" NPT inline connection • Cv factor of 0.9 2 • Easy positioning with adjustable stainless steel conduit coupler 3 1 Construction Part Material Body Nickel Plated Brass, 316 Stainless Steel Solenoid Enclosure Ryton™ (Polyphenylene Sulfide) Seals and Disc Buna “N” Electrical DC Nominal Watt Rating Operating Current 120/60 AC 12V 24V IS 24VDC 2.0w .5w .5w .5w 25.3mA 30mA 15mA 29mA 12V compatible with DeviceNet, 24V compatible with AS-i See next page for IS Entity Parameters. Ambient Temperatures -20˚C to 70˚C (-4˚F to 158˚F) Solenoid Enclosures Enclosure Option Code EE Div. 1 with 3/4" MNPT connector B0 Type 4 & 4x with 20mm x 1.5 connector AS Intrinsically Safe with 3/4" MNPT connector BS Intrinsically Safe with 20mm x 1.5 connector Voltage Codes AG - 120/60 D2 - 24/DC AJ - 230/60 D1 - 12/DC For applications requiring a Cv greater then 0.9 consult ASCO. Ratings and Approvals B0 - Type 4 & 4X - (Indoor and outdoor locations) EE - Class I, Div. 1, Groups A,B,C, & D Class II, Div. 1, Groups E,F, & G Non-incendive Class I, Div. 2, Groups A,B,C, & D Class II, Div. 2, Groups F & G Hazardous locations Class I, Zone 1 AEx d m IIC T6 @ 70˚C AS, BS - Intrinsically Safe Class I, II, III, Div. 1, Groups A-G, Class I, Zone 0, AEx ia IIC T6 @ 70˚C ATEX category 1G, Operator Only II 1G EEx i a IIC T6 KEMA 03ATEX 1173X Ambient Temperature: -40 to 140˚F (-40 to 60˚C) Optional Features Specify suffix codes for manual operators MI - Momentary (push in & hold) MS - Sustained (push in & turn) 22 3/2 4 Valve Monitoring Systems SERIES 8355 Entity Parameters for Intrinsically Safe options AS & BS Groups A-G V max I max P max Capacitance Inductance Parameters 30 VDC 100 mA 0.75 w 0 nf 0 mH Specifications Pipe size (ins.) 1/4 Orifice Dia. (ins.) 1/4 Operating Pressure Differential (psi) Cv Flow 0.9 Max. AC/DC Min. 35 Air-Inert Gas 125 Enclosure Ordering Example: 8355A082 EE Media AIR Voltage AG Max. Fluid Temp.˚F 180 Nickel Plated Brass 8355A002 316 Stainless Steel 8355A082 Const. Ref. 1 Options MI Dimensions Inches (mm) Const. Ref. 1 END TOP .68 [17] SCREW 2.25 [57] 1.43 [36] .99 [25] .50 [13] NAMEPLATE .31 [8] 3.69 [94] SPEED CONTROL SIDE BOTTOM 1.25 [32] 2.97 [76] 1.43 [36] .38 [10] 1.63 [41] 23 4/2 SERIES 8455 4-Way Pilot Valves 4 for assembly to VMS boxes Valve Monitoring Systems Features • Explosionproof, Type 4 & 4X and Intrinsically Safe solenoids • Poppet design provides durability and reliability in a wide range of ambient temperatures % # • Nickel plated brass, or 316 stainless steel bodies designed for harsh process conditions • Built-in speed controls • High efficiency, low wattage coils (2 watt AC and .5 watt DC) • 1/4" NPT inline connection • Cv factor of 0.9 4 • Easy positioning with adjustable stainless steel conduit coupler 2 3 Construction Part Material Body Nickel plated brass, 316 Stainless Steel Solenoid Enclosure Ryton (Polyphenylene Sulfide) Seals and Disc Buna "N" Electrical DC Nominal Watt Rating Operating Current 120/60 AC 12V 24V IS 24VDC 2.0w .5w .5w .5w 25.3mA 30mA 15mA 29mA 12V compatible with DeviceNet, 24V compatible with AS-i See next page for IS Entity Parameters. Ambient Temperatures -20˚C to 70˚C (-4˚F to 158˚F) Solenoid Enclosures Enclosure Option Code EE Div. 1 with 3/4" MNPT connector B0 Type 4 & 4x with 20mm x 1.5 connector AS Intrinsically Safe with 3/4" MNPT connector BS Intrinsically Safe with 20mm x 1.5 connector Voltage Codes AG - 120/60 D2 - 24/DC AJ - 230/60 D1 - 12/DC For applications requiring a CV greater then 0.9 consult ASCO. 24 Ratings and Approvals B0 - Type 4 & 4X - (Indoor and outdoor locations) EE - Class I, Div. 1, Groups A,B,C, & D Class II, Div. 1, Groups E,F, & G Non-incendive Class I, Div. 2, Groups A,B,C, & D Class II, Div. 2, Groups F & G Hazardous locations Class I, Zone 1 AEx d m IIC T6 @ 70˚C AS, BS - Intrinsically Safe Class I, II, III, Div. 1, Groups A-G, Class I, Zone 0, AEx ia IIC T6 @ 70˚C ATEX category 1G, Operator Only II 1G EEx i a IIC T6 KEMA 03ATEX 1173X Ambient Temperature: -40 to 140˚F (-40 to 60˚C) Optional Features Specify suffix codes for manual operators MI - Momentary (push in & hold) MS - Sustained (push in & turn) 1 4/2 4 Valve Monitoring Systems SERIES 8455 Entity Parameters for Intrinsically Safe options AS & BS Groups A-G Parameters V max 30 VDC I max 100 mA P max 0.75 w Capacitance 0 nF Inductance 0 mH Specifications Pipe size (ins.) 1/4 Orifice Dia. (ins.) 1/4 Operating Pressure Differential (psi) Cv Flow 0.9 Max. Fluid Temp.˚F 180 Max. AC/DC Min. 35 Air-Inert Gas 125 Enclosure Ordering Example: 8455A082 Media AIR Voltage EE Nickel Plated Brass 8455A002 316 Stainless Steel 8455A082 Const. Ref. 1 Options D2 MI Dimensions Inches (mm) Const. Ref. 1 END TOP SCREW 1.0 [25] 1.16 [30] 2.25 [57] 1.45 [37] .99 [25] .40 [10] NAMEPLATE .40 [10] 3.47 [88] 3.69 [94] SIDE BOTTOM 1.28 [32] 1.93 [49] .39 [10] 1.30 [33] SPEED CONTROL 25 ASCO offers a complete catalog of products and accessories to satisfy any of your application needs. Visit us online at www.ascovalve.com to view our full line of products. Red-Hat Solenoid Valves The largest selection of 2, 3, and 4-way solenoid valves, designed to handle the most demanding fluid control applications. ASCO Scientific Highest quality micro-miniature solenoid valves for medical and analytical applications. Pneumatic Controls Directional control valves, air preparation equipment, actuators, and accessories for fluid power applications. Next Generation Solenoid Valves The Next Generation of solenoid valves provides lower operating cost, and represents an advancement in the performance, reliability, and ruggedness that you have come to expect from ASCO. Process Automation Pilot valves and control accessories for reliable process solutions. Pressure and Temperature Sensing Devices for pressure and temperature monitoring. ASCO S Series Compact valve solutions for commercial applications. www.ascovalve.com Canada Tel 519-758-2700 Australia Tel (61) 2-9-451-7077 Brazil Tel (55) 11-4208-1700 Germany Tel (49)-7237-9960 United Kingdom Tel (44) 1695-713600 China Tel (852) 2-343-8580 Mexico Tel (52) 55-3640-0200 France Tel (33) 1-47-14-32-00 Singapore Tel (65) 6556-1100 Japan Tel (81) 798-65-6361 A S C O Va l v e , I n c . • 8 0 0 . 9 7 2 . 2 7 2 6 • w w w. a s c o v a l v e . c o m V7380R3