S€Pt° 8, 1959 G. c. slTz 2903670

advertisement

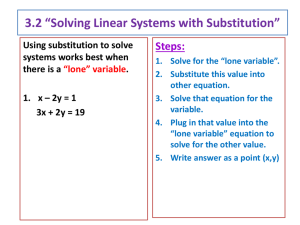

S€Pt° 8, 1959 G. c. slTz 2,903,670 PLUG TERMINAL l Filed March 24, 1954 a4 ’ INVENTÓR. Gilbert C. Sì’cz United States arent O rfice 2,9()131576l Patented Sept. 8, 1959 2 Other important features and objects of the invention .tto which reference has not been made hereinabove will ‘appear hereinafter when the following description and claims are considered with the accompanying drawings. 2,903,670 PLUG TERMINAL Gilbert C. Sitz, Paxtonia, Pa., assignor to Incorporated Application March 24, 1954, Serial No. 413,413 6 Claims. (Cl. 339-128) In this speciñcation and the accompanying drawings I have shownk and described a preferred embodiment of my invention, but it is to be understood that such embodi ment is not intended to be exhaustive nor limiting of the invention but, on the contrary, is given for purposes of 10 illustration in order that others skilled in the art may fully understand the invention and the principles there of and the manner of applying it in practical use so that they may modify and adapt it in various forms, each as may be best suited to the conditions of a particular This invention relates in general to plug contact as 15 semblies and more particularly to plug conductor termi use. Figure l is a fragmentary view in cross section of a nals of the snap-in lock type. In the conventional type of snap-in lock plug termi nals, a metallic pin contact element, usually formed by typical form of plug receptacle for the purpose of illus `trating the manner in which the plug terminal may be mounted therein; machining or casting is secured to the end of a lead 20 Figure 2 is a fragmentary plan view of the plug re conductor and inserted and retained in a plug receiving cep-tacle; and receptacle by means of a wire spring detent and co operating recess arrangement. Commonly, the recess takes the form of an annular groove on the pin element Figure 3 is a view in cross section of the plug terminal. In order to illustrate the objectives of the present in with «the detent being a wire spring mounted in the side 25 vention it will be described in connection with one par walls of the receptacle, although the reverse arrange ticular form the cooperating plug »and receptacle may ment wherein the spring detent consists of a wire insert take. It is to be understood, however, that the inven within the contact pin is also utilized. In either case the tion may be adapted to other forms of plugs and re inclusion of a Wire spring in the plug contact assembly ceptacles according to the applications and purposes for has 'several disadvantages, among these being that the 30 which the plug assembly is designed. Referring to Fig wire detent is particularly subject to distortion through ure l, generally designated at `ll is a plug receptacle in accidental mishandling or abuse, yor through acquisition which a plug terminal, generally `designated at 3, is in of a permanent set due -to continued use. Obviously, set ser-ted and thereby to be retained in electrical contact ting of the spring from its original character would im with a cooperating contact element, not shown, that may pair or perhaps destroy its effectiveness to hold the plug 35 be »an integral part of receptacle l or external thereto, terminal in place. the form of such contact element being immaterial. Plug terminals in the conventional form are generally While the contact portion of plug terminal 3 may take restricted to metallic construction which obviously re any convenient form, for purposes of illustration, how quires that the plug receptacle be of electrical insulating ever, plug 3 includes a pin contact nose 5 extending material even though a metallic structure may be pre 40 beyond the rear side of receptacle Il whereby to engage ferred as where strength is a design factor. In addition, with an external contact element which may be of the the conventional plug terminal has the further disad form shown and described in my copending application, vantage of not being wholly insertable in the receptacle, S.N. 411,969, filed February 23, 1954. Receptacle 1 the exposed portion including the point at which the lead may be of any suitable material, either electrical con conductor is a?xed to the terminal. In order to protect ducting or nonconduoting, and typically is provided with the plug terminal from short-circuiting and from break 45 a plug receiving aperture 2 into which projects a keeper `age at the point of connection, it has been the practice or detent 4 that serves to retain plug terminal 3 in the in many instances to provide for the assembly some form receptacle in a manner to be described. Detent 4, in the of covering, usually being either a separate covering ele embodiment disclosed, is simply formed by providing a ment placed over the assembly after connection, or a lip on the rear face of the receptacle which extends over molded insulation surrounding the exposed portion of 50 a small segment of aperture 2 as shown in Figure 2. the plug terminal, which ‘adds to the diñiculty and ex In the preferred embodiment of the invention plug 3 pense of manufacture. gener-ally includes a pin contact body 6 of any suitable It is, therefore, an object of the present invention to conducting material, which is mounted in a sleeve 8 of provide an improved plug terminal which is effective, 55 insulating material, such as nylon or other suitable plastic yet simple and inexpensive to produce by automatic material having sufficient resilience and ñexibility. It means. is contemplated that insulating sleeve S should substan Another object of Ithe present invention is to provide tially enclose pin Contact body 6 whereby upon insertion a plug terminal having an improved snap-in lock ar into the aperture 2 the engagement areas of receptacle rangement in which the taking of a permanent set is 1 and plug 3 will be between sleeve S and the side Walls 60 immaterial. of aperture 2, the conductive Contact body 6 being fully A further object of the present invention is to provide insulated from receptacle I. Contact body 6, however, a plug terminal in which the electrical connection be may be of sufficient length, as at pin 5, to project from tween the lead wire and terminal is inherently protected the insertion end of sleeve 8 a suílicient distance to pro by the arrangement of the plug elements. vide an external contact surface for the plug. 65 Still another object is to provide a plug terminal While sleeve 8 may be directly molded over contact »adapted for use with plug receptacles of any material of body 6, it is preferred that the elements be separately construction. formed to facilitate automatic manufacture, sleeve 8 be An additional objective resides in the provision of a ing separately molded and Contact body 6 being stamped commercially feasible organization which will be sub from sheet metal stock and rolled into tubular form as stantially foolproof in use and which overcomes certain shown in Figure 3. To maintain the elements assembled well-known disadvantages inherent in the prior art. a shank seciton 10 of contact body 6 is enlarged in diam-l 2,903,670 3 eter to provide a shoulder 11 which cooperates with an annular stop shoulder l2 within sleeve 8 and serves to limit the insertion of contact body 6 within the sleeve. Enlarged shank section l@ is provided with a flared end 14 which, by virtue of having a larger diameter than an internal annular bead 15 in the end of sleeve 8, snaps into a cooperating groove lo, after distending the end of sleeve 8 at bead l5, concomitant with shoulder 1l abutting shoulder l2. Bead l5, after contraction behind flared end i4, serves to retain contact body 6 within sleeve 8. A stop shoulder i7 formed by enlarging the end section 18 of sleeve 8 defines the limit of insertion of the plug into aperture 2 by engaging the face of receptacle 1. The plug is retained in the receptacle by means of an annular groove 2t) in the in insertion end of the sleeve 6, groove Z0 providing a recess for seating detent 4 coincident with shoulder 17 engaging the face of receptacle 1. lt is con templated, of course, that detent 4 shall extend suflicient ly far into aperture 2 so as to prevent free passage of the plug therethrough. Hence, to permit groove 2% to be moved into cooperative relationship with detent 4, the forward end of sleeve 8 is relieved from contact body 6, as by enlarging at 2l the inner diameter thereof, whereby as the plug is inserted into the receptacle, sleeve 8 may yield under pressure from detent 4. After detent 4 seats in groove 20, the forward end of sleeve 8 snaps back into its original shape thereby to maintain the plug in position. and so avoid taking a permanent set. Forces beyond a certain amount, however, will bring the shaft of the nose in the region Z7 into engagement with the nylon molding at its left hand end, as viewed in Figure 3, at the opening into the enlarged portion of diameter 21. This enlarged diameter 21 serves, therefore, not only to provide the de sired relief for detent 4 but also to inject a region of clearance for limited yielding movement of nose 5 when the plug is positioned in an aperture 2. The nylon skirt at 2l backs up the shaft of the nose, however, when ex cessive force is applied to it and provides a ñrm rein forcement against further disalignment of the metal con ductor within the dielectric sleeve. Changes in construciton will occur to those skilled in the art and various apparently different modifications and embodiments may be made without departing from the scope of the invention. The matter set forth in the fore going description and accompanying drawings is offered by way of illustration only. The actual scope of the in vention is intended to be defined in the following claims when viewed in their proper perspective against the prior art. I claim: l. A plug terminal for insertion in a plug receiving receptacle having a detent projecting therein comprising a contact member, a resilient sleeve fitted on said member, a recess in said sleeve for cooperating with the detent to retain said terminal in the receptacle, the forward end of The forward edge of sleeve 8 may be inclined to form said sleeve from said recess being spatially disposed and a ramp or camming surface Z2 to guide more efficiently 30 longitudinally fixed relative to said member for yieldably detent 4 to groove 20. impeding movement of said recess into and out of coopAs best shown in Figure 3, the plug 3 constitutes the eration with the detent for yieldably securing said terminal terminal of an electrical lead 23 which may be secured to contact body 6 by any suitable means. It is preferred, however, that the diameters of the insulated portion 24 and the stripped portion 25 of lead 23 be substantially the same as the diameters of enlarged shank 10 and nose 5, respectively, of contact body 6 which may thus be suitably crimped or swaged to lead 23, as by indentations 26, with in the receptacle. 2. A plug terminal for insertion in a plug receiving receptacle having a detent projecting therein comprising a contact pin, a resilient sleeve fitted on said pin, the insertion end of said sleeve being relieved from and longitudinally ñxed relative to Said pin and having an inclined edge, an annular groove in said end adjacent in that poriton of plug 3 which is received in recep-tacle l. As thus connected, when the plug is mounted in the re 40 said inclined edge for cooperating with the detent to maintain said terminal in the receptacle, said inclined ceptacle the points at which contact body 6 are secured edge engaging and snapping under the detent upon the to lead 23 are within the body of the receptacle, and hence, seating of the detent in said groove during insertion of are fully protected from external shock. said terminal in the receptacle. It will be evident that improved means are provided 3. A plug terminal `for insertion into a plug receiving whereby the failure of a plug of the snap-in type due to 45 setting or distortion of the snap member is minimized. Moreover, it is to be noted that even should the yieldable forward end of sleeve S become slightly distorted, no receptacle having a detent projecting therein comprising to conform to the desired shape in order to reenter aper enlarged sleeve retaining portion for snapping within said a contact member, a resilient sleeve fitted on said mem ber, a first portion of said sleeve having an enlarged in ternal diameter to define inwardly opposed stop shoulders impairment of the locking function thereof results since the forward end of sleeve 8, including ramp 22, is forced 50 at the ends thereof, said contact member including an sleeve and into engagement with said stop shoulders, a ture 2 during withdrawal of the plug from the receptacle. second portion of said sleeve being yieldably disposed In a typical application embodying the invention the relative to said member, a recess in said second portion multiple receptacle will take the form of a molded panel provided with apertures 2 and will be relatively rigid and 55 for cooperating with the detent to maintain said terminal in the receptacle, said second portion snapping under the unyielding. Sleeve S, of nylon or other suitable ma detent to bring said recess into cooperation with the terial, will be accurately molded to an external diameter detent upon insertion of said terminal in the receptacle. íitting within the interior surface defined by an aperture 2. 4. A plug terminal for insertion in a plug receiving The inner surfaces within sleeve 3 will make a nice force iit with shank section l0 of the metal plug. Thus the 60 receptacle having a detent projecting therein comprising a tubular contact member including a pin contact portion nose of the plug will be cushioned coaxially, with the and an enlarged shank portion having a flared end, said axis of aperture 2. The parts may, therefore, be mass portions forming a stop shoulder at the junction there produced and yet each nose, when the assembly is com between, a resilient insulating sleeve having first and plete, will be held by the nylon sleeve exactly where it should be with respect to its cooperating contact spring. 65 second opposed internal annular shoulders for cooperat ing with said stop shoulder and said flared end respec An advantage inherent in the present assembly arises tively to retain said sleeve on said member, the inside from the fact that the nylon possesses some natural resil~ diameter of said sleeve at said second shoulder being ience so that a bending force applied to the end of the nose of the plug can move the plug slightly, within the less than the diameter of said flared end so that upon yieldability of the nylon, to bring the axis of the nose 70 assembly of said sleeve on said member said iirst shoulder abuts said stop shoulder as said flared end snaps under to a slight angle with respect to the axis of the aperture and into engagement with said second shoulder, the for and in this manner the nose may accommodate itself ward end of said sleeve being yieldably dispose-d relative to a contact spring bearing up-o-n the nose with greater to said member, an annular groove in said forward end than normal pressure. Similarly the nose can yield under a blow, or through other unintended forces applied to it 75 for cooperating with the detent to maintain said terminal 2,903,670 5 in the receptacle, said forward end being arranged to behind said ramp to define a shoulder, said forward end snap under the detent upon the seating thereof in said groove when said terminal is inserted in the receptacle. 5. A plug terminal for insertion in a plug receiving being spatially disposed relative to said contact element, receptacle having a detent projecting therein comprising a contact member, a resilient sleeve secured on said member, the forward end portion of said sleeve being yieldably disposed relative to said member and con strained to Hex primarily about axes of flexure parallel a detent projecting from said body member and inter secting said passageway and cooperating with said shoul der for impeding movement of said plug thereby, the plug periphery at the high point of said ramp closely matching the conñguration of said passageway for A‘constraining said resilient member to flex abofut axes of ilexure parallel to the longitudinal aXis of said plug upon the ramp passing to the longitudinal axis of said plug terminal, the end 10 under said detent. of said sleeve being inclined to p-rovide an annular ramp References Cited in the ûle of this patent engaged by the detent upon insertion of said terminal into the receptacle, the external diameter of said sleeve behind UNITED STATES PATENTS said ramp being reduced for receiving the detent upon 2,142,818 Jacobson _____________ __ Jan. 3, 1939 forcing said ramp past the detent, said sleeve having lat 15 eral means on said sleeve for stopping insertion of the terminal within the receptacle upon movement of said ramp past said detent. 6. In combination, a body member having a passage way therein, a plug disposed in said passageway including 20 a contact element and a resilient member secured on said element, the forward end of said resilient member defining a ramp and being reduced in section immediately 2,205,146 2,330,948 2,383,909 2,469,397 2,689,337 2,694,798 2,695,394 2,711,522 2,774,810 Larkin ______________ „_ June 18, Brand ________________ __ Oct. 5, Buchanan ____________ __ Aug. 28, Mezek ______________ __ May 10, Burtt _______________ __ Sept. 14, Cole ________________ __ Nov. 16, Watts _______________ __ Nov. 23, Goodwin ____________ __ June 21, Ritter ______________ __ Dec. 18, 1940 1943 1945 1949 1954 1954 1954 1955 1956