Marathon Special Products Engineering Catalog - Fuse Holders & Blocks

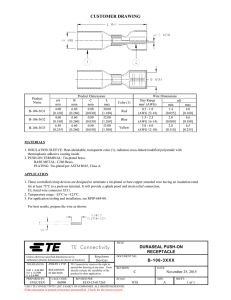

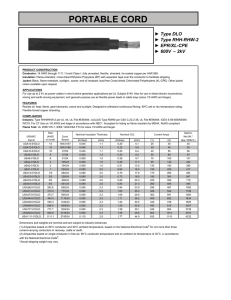

advertisement