SA060000 Install

advertisement

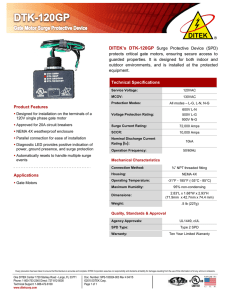

INSTALLATION MANUAL SA Series Residential Surge Protective Device (SPD) INTRODUCTION Thank you for choosing the surgeassureTM SA Series Residential Surge Protective Device. on electrical distribution equipment capable of delivering not more than 25,000 rms symmetrical amperes. Save this manual! It includes instructions for obtaining warranty service and for returning a defective device. During installation into an electrical system, the SA Series must NOT be energized until the electrical system is installed, inspected and tested. All conductors must be connected and functional. Please read and understand all information in this manual prior to installation. The procedures contained herein are not intended to supersede local or national electrical codes. Check all applicable electrical codes to ensure compliance. In all instances, local and national electrical code requirements are to be followed. Failure to follow the guidelines in this manual can lead to abnormally high voltage being applied to the SPD. This may cause the SA Series unit to become inoperative. The warranty does not cover an incorrectly installed device. This manual provides instructions for installing the SA Series Surge Protective Device (SPD). The SA Series SPD (Figure 1) can be mounted three ways. The preferred way is to mount the SPD directly to the outside of the electrical panel equipment using the chase nipple on the body of the SPD. It can also be installed against a panel/wall using installer supplied hardware, or it can be installed using an optional Flush Mount Kit. The latter two methods require use of additional conduit and hardware (not provided). The SA Series provides protection from damaging transient voltage surges and spikes. Proper installation is imperative to maximize the effectiveness and overall performance of this device. This device must be installed by a licensed electrician. The electrician should follow the steps outlined in this manual to insure proper installation. Note: surgeassureTM products are extensively tested to industry standards as set by ANSI/IEEE C62.41.12002, C62.41.2-2002 and C62.45-2002. The SA Series is listed to the most recent edition of UL 1449 Third Edition. This product is suitable for installation 14550 58th Street North Clearwater, Florida 33760 Do not high potential test the electrical system with the SPD connected. Failure to disconnect the SPD during elevated voltage testing will result in damage to the suppression components and/or other electronic components (see Safety Information). PARTS LIST AND INSPECTION Items included in the package consist of the following: 1 SA Series Surge Protective Device Data Sheet 1 User’s Manual (this document) ▪ ▪ ▪ If the Flush Mount Kit (Part #FMKITC) was ordered, additional parts are supplied as follows: ▪ 1 Flush Mount Plate ▪ 4 Pan-head Screws See Figure 3 for installation Carefully inspect each item in the package for signs of damage. If damage is found, please contact surgeassureTM Technical Support: 1-800-727-0669. For more information about this product or other surgeassureTM products, visit surgeassure.com. Tel: 1.800.727.0669 Fax: 727.539.8955 APTSurgeassure@Emerson.com www.surgeassure.com A Division of Advanced Protection Technologies, Inc. APT’s Quality Management System is ISO 9001:2008 Certified INSTALLATION The SA Series is a Type 2 SPD. The SA Series is suitable for use downstream of the service disconnect. Pre-Plan your installation. You need to accomplish the following: ▪ ▪ ▪ ▪ ▪ ▪ ▪ Meet all National and Local codes (NEC® Article 285 and UL 1449 address SPDs). Confirm System voltage to SPD voltage (120V SPD will fail instantly on 240V, 277V, etc.). Mount SPD as close to panel or equipment as possible to keep leads short. (long leads hurt performance). Ensure leads are as short and straight as possible, including neutral and ground. Use a breaker position that is close to the SPD and the panel’s neutral and ground. Recommended breaker size is 30A due to 10 AWG conductor. Make sure system is grounded per NEC® and clear of faults before energizing SPD. (inadvertent system problem may fail SPD). Never Hi-Pot test Any SPD. (will prematurely fail SPD). 1. Use voltmeter to check voltages and ensure correct SPD. See Data Sheet for specs and wire-outs. 2. Determine Mounting location – weather resistant equipment may be required. 3. If SPD has optional Dry Contact Flush Mount Kit, or Remote Indicator, pre-plan their installation. See Figure 3. (If flush mounting, be careful to not drop SPD into wall). 4. Remove power from panel/source. Confirm panel/source is deenergized. 5. Identify breaker location and SPD location. Position SPD such that LEDs are best visible. If Flush Mount Kit was ordered, follow Flush Mount instructions and then proceed at #6. 6. Mount SPD – weather resistant applications require additional sealing, etc. (not included) - Remove an appropriately sized knockout from panel. - Connect conductors as appropriate – short and straight as possible (Hi-Legs are Phase B). 7. Label or mark conductors as appropriate (neutral: white, ground: green, energized: black, hi-leg: orange). 8. Make sure system is bonded per NEC® and is clear of hazards or faults before energizing (N-G bonding not per NEC® will fail SPDs: #1 cause of SPD failures). 9. Energize and confirm proper operation of green LED indicators. If any connected phase LED does not illuminate, remove power, check all connections and test again. If any connected phase LED still does not illuminate, contact surgeassureTM Technical Support at: 1-800-727-0669. 10. The SPD is equipped with an audible alarm which will sound in the event of an alarm condition. This indicates a problem with the SPD which requires further evaluation. There is no test or silence switch. De-energizing the SPD will silence the alarm. TYPICAL PANEL INSTALLATION Figure 1 Figure 2 LEADS SHORT & STRAIGHT (T y p e 1 o r i n d i v i d u a l e q u i p m e n t i n s t a l l a t i o n s m a y v a r y ) Cu t o f f Exce s Le n g t h T o P r o t e c t e d Lo a d s ▪ ▪ A B ▪ BREAKER N ▪ G Use cl o se st b r e a ke Lo ca t e SP D lc o es i n t e n d e d b r e a ek r D o No t Lo o p o r Co i l r t o SP D to Sh o r t & St r a i g h t K e e p Le a d s Sh o r t a s P o si b l e Avo i d Sh a r p B e n d s ph 800.727.0669 • www.surgeassure.com 8815 Surge Protective Device ALARM ALARM 2 Green LEDs On = Full Protection 2 Green LEDs On = Full Protection Surge Protective Device ph 800.727.0669 • www.surgeassure.com ▪ ▪ 2 Ro t a t e SA u n i t s u c h t h a t LED i n d i c a t o r i s m o s t v i s i b l e Ou t d o o r i n st a p p r o p r ia te a t n i p p l e (g a co n d u i t , e t c. a lla tio n r e q u ir e s w e a t h e r se a l i n g ske t , se a l i n g ) V WARNING V ERIF Y T H AT ALL P OW ER CIRCUIT S ARE D EENERG IZ ED B EF ORE MAK ING CONNECT IONS All electrical connections should be performed by a qualified (l i ce n se d ) e l e ct r i ci a n o r t e ch n i ci a n . Al l w i r i n g m u st co m p l y w i t h t h e Na t i o n a l El e ct r i ca l Co d e (NEC® ) a n d a p p l i ca b l e l o ca l co d e s. FLUSH MOUNT INSTALLATION INSTRUCTIONS 1. Select the location where the SPD and Flush Mount Kit (XMFMKIT) will be mounted. Aesthetics may have to be sacrificed in order to achieve maximum surge protection. 2. Place the Flush Mount Kit plate where it will be mounted and trace the center hole and mounting holes. Cut this shape into the mounting surface and mount the XMFMKIT panel to the mounting surface 3. BE CAREFUL TO NOT DROP THE SPD INTO THE WALL. 4. Install the SPD to the back side of the Flush Mount Kit plate using the four 8/32 x 5/8” Thread Cutting Screws provided with the XMFMKIT kit. 5. Proceed with #6 on previous page. Figure 3 TYPICAL SA SERIES SPD INSTALLATION * SAFETY INFORMATION This section provides pertinent safety information that must be considered before installing the SPD. ▪ ▪ ▪ ▪ Do not install this device during a lightning storm. This device is rated NEMA 4X. Suitable for indoor and outdoor applications. The customer must seal the conduit nipple against the panel using watertight fittings (not supplied) to ensure a watertight connection. Do not install the surge protector in an excessively hot or moist location. Other safety considerations are listed on the previous page. CAUTION COND UCT ING D IELECT RIC AND / OR H IG H P OT ENT IAL T EST ING W ILL CAUSE INT ERNAL D AMAG E T O T H E SP D UNIT . D O NOT P ERF ORM D IELECT RIC OR H IG H P OT ENT IAL T EST S W IT H T H E P H ASE OR NEUT RAL SP D W IRES CONNECT ED . Insert flushmount screw through hole in each corner or punch a small starting hole in center of each translucent window (located in all 4 corners of the label). OPERATION The surgeassureTM Residential surge suppressor normally requires no remedial action. However in the event of a power anomaly or a malfunction, the operational status may change and may require action. The table below outlines the operating conditions of the SA Series and any correction action if required. Light 1 Light 2 Out Out Alarm Red Audible Alarm Corrective Action Out Off Reset Breaker if re-opens Replace Unit Replace Unit Green Green Out Green Blinks Sounds Green Out Blinks Sounds Replace Unit Sounds Check Neutral to Ground Connection before Replacing Unit Green Green No action Blinks This device features internal circuitry that will disconnect the surge protective component at the end of its useful life. Power will maintain to the load, however the load is now unprotected. Follow the manufacturer’s instructions for replacing the device. 3 Figure 4 WARRANTY & SERVICE DIMENSIONS & WEIGHT LIMITED WARRANTY 8.28 (210.31) 7.41 (188.21) 8.28 (210.31) ph 800.727.0669 • www.surgeassure.com 7.41 (188.21) 8815 ph 800.727.0669 • www.surgeassure.com 8815 Surge Protective Device 2 Green LEDs On = Full Protection Surge Protective Device ALARM 2.21 (56.13) 2 Green LEDs On = Full Protection 3.67 (93.22) ALARM 2.21 (56.13) ALARM 2 Green LEDs On = Full Protection ALARM 2 Green LEDs On = Full Protection Surge Protective Device Surge Protective Device ph 800.727.0669 • www.surgeassure.com ph 800.727.0669 • www.surgeassure.com 0.19 (4.83) T h e SA Se r i e s w e i g h t i s 4 l b s. XM SPECIFICATIONS Model LH LF DMP XM 3.67 (93.22) The company specifically disclaims all other warranties, expressed or implied. Additionally, the company will not be responsible for incidental or consequential damages resulting from any defect in any product or component thereof. 3.00 (76.20) 0.19 (4.83) surgeassureT M warrants it’s AC electrical distribution equipment protection products against defective workmanship and materials for 10 years. Liability is limited to the replacement of the defective product. A Return Material Authorization number (RMA #) must be given by the company prior to the return of any product. Returned products must be sent to the factory with the transportation charges prepaid. 10.7.13 10.7.13 10.7.13 8609 XM SERIES ENCLOSURE T surgeassure 05A8609 - M TECHNICAL SUPPORT & CUSTOMER SERVICE Voltage Rating & Service Type XM SERIES LH 10.7.13 LF SA 10.7.13 120/240V Single Phase DMP 10.7.13 ENCLOSURE 8609 05A86091.800.727.0669 - Specifications Temperature Operating -40°C (-40°F) to +60°C (+140°F) Temperature Storage -55°C (-65°F) to +65°C (+149°F) Audible Noise Service Clearance Installation Type Wire Length vs. Response Time and Let-Through Voltage Wire Size & Installation Torque Circuit Breaker Connection System Grounding None 36 in (94.1 cm) in front of the unit Chase Nipple 1 ft (31.7 cm) of wire = 1 nanosecond. 175 volts per foot (6kV,3kA, 8/20 microseconds) are added to the clamp voltage. in fo @ s u r g e a s s u r e .c o m T h is m a n u a l a s w e ll a s in fo r m a tio n a b o u t th e e n tir e M p r o d u c t l i n e a r e a v a i l a b l e o n t h e In t e r n e t a t : w w w .s u r g e a s s u r e .c o m . surgeassureT P r i o r t o c a l l i n g surgeassureT M f o r t e c h n i c a l s u p p o r t , p l e a s e h a v e th e fo llo w in g in fo r m a tio n a v a ila b le : Mo d e l Nu m b e r o f u n i t : _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Wire Size = #10 AWG, torque to 18 in. lbs. Ma n u f a c t u r e D a t e : 30 Amp P u rc h a s e D a te : Per IEEE STD 142-1991. For sensitive electronics/computer systems, the recommended ground impedance is 25 ohms or less. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ TROUBLESHOOTING & SERVICE Y o u r Or d e r Nu m b e r : _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Re t u r n Sh i p m e n t Ad d r e s s : surgeassureT M Please contact us for any service related issues. We want to take care of any problems. 14550 58t h St r e e t No r t h Cl e a r w a t e r , F L 33760 Quality SPDs withstand severe duty and attempt to protect their load until failure. There are electrical anomalies that SPDs cannot protect against. These are generally Sustained Overvoltages also known as Temporary Overvoltages (TOVs). In this context, Sustained Overvoltages may be only a few cycles. Failed SPDs tend to be symptoms, not root causes. We suggest treating a failed SPD as a ‘canary in the coalmine’ as there may be larger issues at play. As a generalization, the single largest ‘killer’ of SPDs is reference to ground issues. If the SPD shows problems on startup, there is reasonable chance of bonding/grounding/misapplication issue. This permanently damages the unit. If not corrected, it will happen again. At t n : RMA# _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Any returns need a Return Authorization (RA) number. 4 A Division of Advanced Protection Technologies, Inc. APT’s Quality Management System is ISO 9001:2008 Certified 14550 58th Street North Clearwater, Florida 33760 Tel: 1.800.727.0669 Fax: 727.539.8955 APTSurgeassure@Emerson.com www.surgeassure.com 2.17.15.lh #8817