GEOMETR

Manual TestsUsing the unit test switch, users can initiate different

Operation

duration

test cycles based on the following table:

Automatic Tests

Tests users can initiate different

Using the Manual

unit test switch,

The unit will automatically initiate a self-test/self-diagnostic

cycle based on the following table:

Manual TestsUsing the unit test switch, users can initiate different

duration test

cycles

on the

Initiating

Action

Cycle

duration

testbased

cycles based

on following

theTest

followingtable:

table:

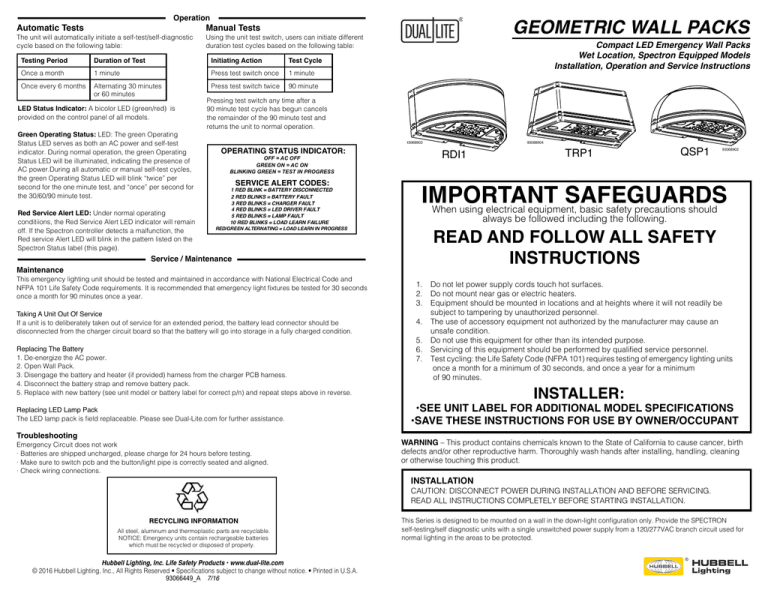

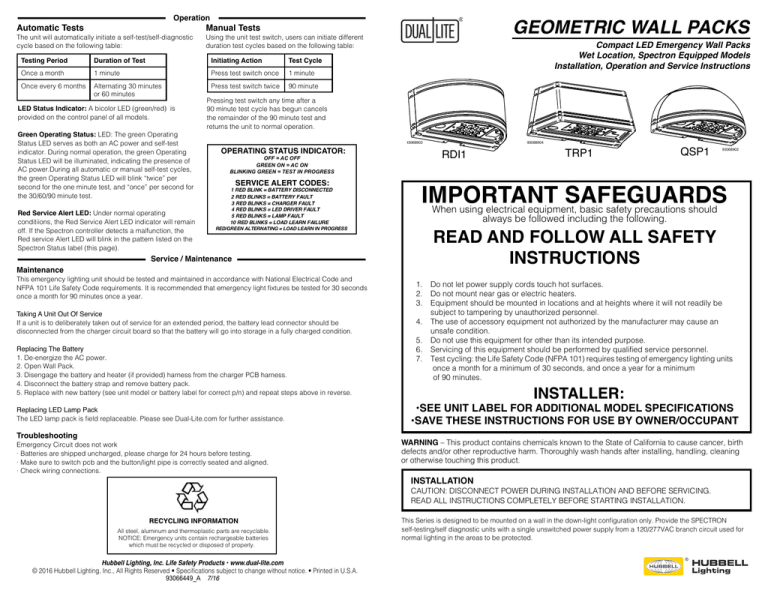

Compact LED Emergency Wall Packs

Compact LED Emergency Wall Packs

Wet

Location, Spectron Equipped Models

Wet Location, Spectron Equipped Models

Installation,

and

Service

Instructions

Installation,Operation

Operation, and

Service

Instructions

Press

test Action

switch

once

Initiating

Test Cycle 1 minute

Initiating Action

Test Cycle

Press

test

switch

twice

minute

Press

test switch

once 901minute

Press test switch

once

1 minute

Testing Period

Duration of Test

Once a month

1 minute

Once every 6 months

Alternating 30 minutes

or 60 minutes

Press test switch twice

Press test switch twice 90 minute

90 minute

Pressing test switch

any

time

after

Pressing test

switch

any time

after a

a

90 minute

cycle

has

cancels

Pressing test

switch

any test

time

after

a begun

90 minute

test

cycle

has

begun

cancels

the

remainder

of the

90 minute

test and

90 minute test returns

cycle has

cancels

the begun

unit

normal

operation.

the remainder

of the

90tominute

test and

the remainder of the 90 minute test and

returns

the

unit

to

normal

operation.

returns the unit to normal

operation.

OPERATING

STATUS INDICATOR:

LED StatusA

Indicator

LED Status Indicator:

bicolor LED (green/red) is

A bicolor LED (green/red) is provided on the control panel of all

provided on themodels.

control panel of all models.

on the control panelGreen

of all

Operating Status LED:

The green Operating Status LED serves as both an AC power and

Green Operating

Status:

self-test

indicator.LED:

During The

normalgreen

operation,Operating

the green Operating

Status LED will be illuminated, indicating the presence of AC power.

Status LED serves

asall both

anor AC

power

During

automatic

manual

self-test and

cycles,self-test

the green Operating

Status LED will blink "twice" per second for the one minute test, and

indicator. During"once"

normal

operation,

theminute

green

per second

for the 30/60/90

test. Operating

ves as both an AC power

and

LED will

be illuminated, indicating the presence of

eration,Status

the green

Operating

Red Service Alert LED:

ACpresence

power.During

automatic

Redall

Service

Alert LED: or manual self-test cycles,

ting the

of AC

power.

Under normal operating conditiions, the Red Service Alert LED

est cycles,

the green

Operating

the green

Operating

Status

LED

blink controller

“twice”detects

per a

indicator

will remain

off. If will

the Spectron

malfunction,

the Red service Alert LED will blink in the pattern listed

ond forsecond

the one

test,

and

forminute

the one

test,label

and

“once”

on theminute

Spectron Status

(this

page). per second for

inute test.

the 30/60/90 minute test.

OFF = AC OFF

GREEN ON = AC ON

BLINKING GREEN = TEST IN PROGRESS

OPERATING STATUS

INDICATOR:

OPERATING

STATUS

INDICATOR:

1 RED BLINK = BATTERY

DISCONNECTED

93068903

SERVICE ALERT CODES

OFF==AC

AC OFF

OFF

OFF

GREENON

ON == AC

GREEN

ACON

ON

BLINKING

GREEN

INPROGRESS

PROGRESS

BLINKING

GREEN== TEST

TEST IN

2 RED BLINKS = BATTERY FAULT

3 RED BLINKS = CHARGER FAULT

4 RED BLINKS = LED DRIVER FAULT

5 RED BLINKS = LAMP FAULT

10 RED BLINKS = LOAD LEARN FAILURE

SERVICE ALERT

SERVICE

ALERTCODES

CODES:

RED/GREEN ALTERNATING = LOAD LEARN IN PROGRESS

93068904

QSP1

TRP1

93068902

93068904

TRP1

RDI1 SAFEGUARDS

IMPORTANT

When using electrical equipment, basic safety precautions should

always be followed including the following.

the Red Service Alert LED

RED/GREEN ALTERNATING = LOAD LEARN IN PROGRESS

off. If thedetects

Spectron

detects

93044924

Taking

Unit Out Of

Servicea malfunction, the

ron controller

a Acontroller

service

will blink intaken

the pattern

listed

a unitLED

is tolisted

deliberately

out of service

foron

anthe

extended period, the battery lead connector

ED willRed

blink

in theIfAlert

pattern

shouldlabel

be disconnected

from the charger circuit board so that the battery will go into storage in a fully charged condition.

(this page).

ge). Spectron Status

Replacing The Battery

1. De-energize the AC power.

RDI1

93068903

93044924

1 RED BLINK = BATTERY DISCONNECTED

2 RED BLINKS = BATTERY FAULT

3 RED BLINKS = CHARGER FAULT

Maintenance

4 RED BLINKS = LED DRIVER FAULT

Red ServiceThis

Alert

LED: Under

operating

emergency

lightingnormal

unit should

be tested and maintained in accordance

with National

5 RED BLINKS

= LAMPElectrical

FAULT Code and NFPA 101 Life Safety

requirements.

It is recommended

thatwill

emergency

for 30 =seconds

once a

month for 90 minutes once a year.

conditiions, Code

the Red

Service Alert

LED indicator

remain light fixtures be

10 tested

RED BLINKS

LOAD LEARN

FAILURE

Maintenance

2. Open Wall Pack.

GEOMETRIC WALL PACKS

Installation

Compa

GEOMETRIC WALL PACKS

Wet Loc

Manual Tests

READ AND FOLLOW ALL SAFETY

INSTRUCTIONS

1.

2.

3.

Service / Maintenance

4.

3. Disengage

the battery

provided)

harnessin

from

the charger with

PCB National

harness. Electrical Code and

This emergency

lighting unit

shouldand

beheater

tested(ifand

maintained

accordance

4. Disconnect the battery strap and remove battery pack.

NFPA 101 Life5.Safety

requirements.

It ismodel

recommended

thatlabel

emergency

ReplaceCode

with new

battery (see unit

label or battery

for correctlight

p/n) fixtures be tested for 30 seconds

be

tested

accordance with National Electrical Code and NFPA 101

and

repeat

stepsonce

above

in

reverse.

once

a monthand

for

90maintained

minutes

ain

year.

5.

1. Do not let 6.power supply cords touch hot surfaces.

7.

uld

Life Safety

2. Do not mount

near gas or electric heaters.

3. Equipment should be mounted in locations and at heights where it will not readily be

mended that emergency

light

fixtures

be tested for 30 seconds once a month for 90 minutes once a year.

Replacing LED

Lamp

Pack

TheOf

LED

lamp pack is field replaceable. Please see Dual-Lite.com for further assistance.

Taking A Unit Out

Service

If a unit is to deliberately

taken out of service for an extended period, the battery lead connector should be

Troubleshooting

disconnected from

the charger

board

Emergency

Circuitcircuit

does not

workso that the battery will go into storage in a fully charged condition.

ut of service for· Batteries

an extended

period, the battery lead connector

are shipped uncharged, please charge for 24 hours before testing.

Make

sure so

to switch

and battery

the button/light

is correctly

seated and aligned.

e charger

circuit

board

thatpcbthe

willpipego

into storage

in a fully charged condition.

Replacing

The ·Battery

· Check wiring connections.

1. De-energize the AC power.

2. Open Wall Pack.

3. Disengage the battery and heater (if provided) harness from the charger PCB harness.

4. Disconnect the battery strap and remove battery pack.

5. Replace with new battery (see unit model or battery label for correct p/n) and repeat steps above in reverse.

heater (if provided) harness from the charger PCB harness.

p andReplacing

remove

battery pack.

LED Lamp Pack

ee unit

model

battery

label

for see

correct

p/n) for further assistance.

The LED

lamp label

pack isor

field

replaceable.

Please

Dual-Lite.com

everse.

ck

Troubleshooting

Emergency Circuit does not work

· BatteriesPlease

are shipped

please charge

for 24 hours

before testing.

placeable.

seeuncharged,

Dual-Lite.com

for further

assistance.

· Make sure to switch pcb and the button/light pipe is correctly seated and aligned.

· Check wiring connections.

93066449 4 2/11/16

ot work

arged, please charge for 24 hours before testing.

d the button/light pipe is correctly seated and aligned.

RECYCLING INFORMATION

All steel, aluminum and thermoplastic parts are recyclable.

NOTICE: Emergency units contain rechargeable batteries

which must be recycled or disposed of properly.

Hubbell Lighting, Inc. Life Safety Products • www.dual-lite.com

© 2016 Hubbell Lighting, Inc., All Rights Reserved • Specifications subject to change without notice. • Printed in U.S.A.

93066449_A 7/16

4.

5.

6.

7.

subject to tampering by unauthorized personnel.

The use of accessory equipment not authorized by the manufacturer may cause an

unsafe condition.

1.

Do not use this equipment for other than its intended purpose.

2. be performed by qualified service personnel.

Servicing of this equipment should

Test cycling: the Life Safety Code3.

(NFPA 101) requires testing of emergency lighting units once a month for a minimum of 30 seconds, and once a year for a minimum

4. INSTALLATION

of 90 minutes.

INSTALLER:

CAUTION: DISCONNECT POWER DURING INSTALLATION AND BEFORE SERVICING.

5.

BEFORE STARTING INSTALLATION.

READ ALL INSTRUCTIONS COMPLETELY

6.

•SEE UNIT LABEL FOR ADDITIONAL

MODEL SPECIFICATIONS

•SAVE

THESE

INSTRUCTIONS

USE

BYonly.

OWNER/OCCUPANT

This Series

is designed

to be mounted on a 7.

wall in theFOR

down-light

configuration

Provide the SPECTRON

self-testing/self diagnostic units with a single unswitched power supply from a 120/277VAC branch circuit

used for normal lighting in the areas to be protected.

WARNING – This product contains chemicals known to the State of California to cause cancer, birth

defects and/or other reproductive harm. Thoroughly wash hands after installing, handling, cleaning

or otherwise touching this product.

INSTALLATION

CAUTION: DISCONNECT POWER DURING INSTALLATION AND BEFORE SERVICING.

READ ALL INSTRUCTIONS COMPLETELY BEFORE STARTING INSTALLATION.

This Series is designed to be mounted on a wall in the down-light configuration only. Provide the SPECTRON

self-testing/self diagnostic units with a single unswitched power supply from a 120/277VAC branch circuit used for

normal lighting in the areas to be protected.

INSTALLATION

CAUTION: DISCONNECT POWER DURING INSTAL

INSTALLATION

NEUT

DIM +

LED +

RED

BLUE

BLUE

NEUT

RED

BUILDING AUTOMATION

DIMMING FUNCTION

WIRING

AC LED DRIVER

- INPUT -

LED +

RED

LED -

BLUE OR BLK

VIO

GRY

DIM +

DIM -

-OUT PUT -

LED +

RED

LED -

BLUE OR BLK

-OUT PUT -

- J1 BUILDING AUTOMATION

BLK

LINE

LED +

POS

YEL

BLUE

DIMMING FUNCTION

BLUE/W HT

WHT OR

NEUT

LED AC

LEDNEGDRIVER

LED DRV OUT AUTOMATION

LED DRV OUT - BUILDING

BLK

WIRING

RED

LED DRV OUT +

DIMMING

FUNCTION

LED DRV OUT +

EM LED +

YEL

WIRING

EM LED +

AC DRV SW

VIO

LINE

WHT

AC DRV LINE

BLUE

BLUE

LED +

- INPUT -

BLK

UNIT

GROUND

LINE

VIO

- INPUT -

BUILDING LED

AUTOMATION

BLUE OR BLK

AC LED DRIVER

UNIT

DIMMING FUNCTION

GROUND

WIRING

AC DRV SW

WHT

BLUE

AC DRV SW

BLK

BLK

BLUE

BLKWHT

WHT

GRN

BLK

LINE

BLUE

NEUT

GRN

NEUT

AC DRV LINE

GROUND

LINE SW ITCH

120VAC / 277VAC

WHT

BLK

NEUT

WHT

GRN

LINE

WHT

UNITBLK GRN 120VAC / 277VAC BLK

GROUND

120VAC

/ 277VAC

GROUND

BLK

WHT

NEUTLINE SW ITCH

WHT BLUE NEUT

WHT

120VAC / 277VAC

BLK

SURGE

UNIT

BLK SUPPRESOR

NEUT

WHT

UNSWITCHED

FIXTURE

UNSWITCHED

FIXTURE

BLK

SURGE

GROUND

SWITCHED

FIXTURE FIXTURE

UNSWITCHED

GROUND

GRN

GROUND

GRN

SUPPRESOR

BLK

UNIT

ITCH

BLUE

BUILDING

LINE SW ITCH SWITCHED

BLUE

FIXTURE LINE SW

GROUND

GROUND

GRN

BLK 120VAC

/ 277VAC

BLK

WIRING

120VAC / 277VAC

BLK

120VAC / 277VAC

WHT

BLK

AC DRV LINE

BLUE

BUILDING AUTOMATION

DIMMING FUNCTION

-OUT PUT WIRING -OUT PUT -

WHT

NEUT

LED - DRIVER

AC LED

BLUE OR BLK

AC LED

DRIVER

NEUT

-OUT PUT -

BLK

BLUEBLK LINE SW ITCH

LINE SW ITCH

- INPUT -

BLK

LINE

UNIT WHT

GROUND

SURGE

SUPPRESOR

LINE

GROUND

GRN

BLK

WHT

BLK

GRN

GROUND

GRN

SWITCHED

FIXTURE

GROUND

Wall Pack

Wiring Diagram

Geometric Geometric

Wall Pack Wall Pack

Wiring Diagram

Wiring

Geometric

WallDiagram

Pack

Geometric

Wall Pack

Wiring Diagram

Wiring Diagram

- INPUT BLK

WHT

BLK

SURGE

SUPPRESOR

BLK

BLK

BUILDINGGRN

LINE SW ITCH

WIRING BLUE

BUILDING

WIRING

BUILDING

BUILDING

WIRING

WIRING

BLK

GROUND

NEUT

UNIT

GROUND

BLUE

VIO

GRN

WHT

GRY

BLK

BLK

GROUND

NEUT

DIM -

120VAC / 277VAC

WHT

WHT

GRY BLK

BLUE

NEUT

LINE SW ITCH

DIM -LINE

BLK

GRN

NEUT

GRN

UNIT

SWITCHED UNIT

FIXTURE

LINE SW ITCH

BUILDING

GROUND

/ UNIT

277VAC

WIRING GROUND SWITCHED 120VAC

FIXTURE

Geometric Wall Pack

Wiring Diagram Geometric

BUILDING AUTOMATION

UNIT

FUNCTION

UNIT SURGEDIMMING

SUPPRESOR

WIRING

GROUND

GROUND

GROUND

WHT

120VAC / 277VAC

SURGE

SUPPRESOR

BLK

WHT

BLK

BLUE

NEUT

BUILDING

WIRING

LINE SW ITCH

BLK

BUILDING

WIRING

GRY

WHT

VIO +

DIM

NEUT

SURGE

SUPPRESOR

GRN

GRYDIM

WHT

BLK

GROUND

DIM +

NEUT

BLK

SWITCHED FIXTURE

SWITCHED FIXTURE

Geometric

Wall Pack

Geometric

Wall Pack

Wiring

Diagram

Wiring

Diagram

BUILDING AUTOMATION

BUILDING AUTOMATION

DIMMING FUNCTION DIMMING FUNCTION

WIRING

WIRING

BUILDING AUTOMATION

DIMMING FUNCTION

WIRING

DIM -

BLK

VIO

120VAC / 277VAC

GRY

BLK

DIM +

120VAC / 277VAC

DIM -

BLUE

VIO

GRN

LINE SW ITCH

WHT

GROUND

BLUE

GRN

GRN

YEL

RED

BLUE

BLUE

ORHT

BLUE/W

OR

BLUE ORLED

BLKDRV OUT BLK

BLK

GRY

BLK

GROUND

LINE SW ITCH

GRN

BUILDING

WIRING

SURGE

SUPPRESOR

SURGE

SUPPRESOR

BLK

BUILDING

WIRING

GRN

INSTALLATION

INSTALLATION

INSTALLATION

The Geometric

Wall

Pack is equipped

with intelligent

wiring. Connect

black

The Geometric

Wall Pack

is equipped

with intelligent

wiring. Connect

the blackthe

and

blueand blue

wires

unit to AC

building

(120 or 277VAC)

and the

white

wire to (com)

building

(com)

wires from

unitfrom

to building

(120 AC

or 277VAC)

and the white

wire

to building

wire

andwire and

green

wire to ground.

building ground.

green wire

to building

INSTALLATION

INSTALLATION

The

Geometric Wall Pack

is equipped with intelligent wiring. Connect the black and blue

Wall mounting

of unit

Wall mounting

of unit wires

from

unit to building

AC (120

or 277VAC)

and the

white wire the

to building

and

The Geometric Wall Pack

is equipped

with

intelligent

wiring.

Connect

black(com)

andwire

blue

green wire to building ground.

wires from unit to building AC (120 or 277VAC) and the white wire to building (com) wire and

Wallplate

mounting

of unit

1)

Affix mounting

(item

4)with

to J-box

with screws.

1) wire

Affixto

mounting

plate

(item

4) to

J-box

screws.

green

building

ground.

INSTALLATION

INSTALLATION

2)Wall

UsePack

approved

connectors

to

connect

wall

pack

tosupply

building

supply

leads,

2)

Use approved

connectors

to connect

wall

packwiring.

to

building

and

The

Geometric

is

equipped

with

intelligent

Connect

theleads,

black

and

blueand

The Geometric

Wall

Pack

is

equipped

with

intelligent

wiring.

1)

Affix

mounting

plate

(item

4) to J-boxConnect

with screws. the black and blue

Wall

mounting

of

unit

Insert

all AC

connections

into J-box.

Insert

alltoconnections

into

J-box.

wiresunit

from

unit

building

(120

277VAC)

and the

thetowhite

wire

to to

building

wireand

and

INSTALLATION

2) or

Use

approved connectors

connect

wall

pack

to building

building (com)

supply

leads,

wires from

to

building

AC

(120

or

277VAC)

and

white

wire

(com)

3) Affix

Wall

onto

Mounting

(item

4) and

secure

Pack usingwire and

3)wire

AffixtoWall

Packground.

ontoPack

Mounting

Plate

(itemPlate

4) and

secure

Wall

PackWall

using

green

building

Insert

all connections

into

J-box.

INSTALLATION

green wire

building

ground.

BUILDING

he Geometric

Wallto

Pack

is

equipped

with

intelligent

wiring.

Connect

the

black

and

blue

screws

(item

secure.

3)3)

Affix

Wallunit

Packisonto

Mounting Plate (item 4) and secure Wall Pack using

Set screwsSet

(item

3) until

unit

isuntil

secure.

WIRING

1) Affix

mounting

plate

(item

4)

to white

J-box

with

Wall

Pack

is ofequipped

with

intelligent

Connect

the

black

and blue

Wall

mounting

unit

iresThe

fromGeometric

unit to building

AC

(120

or

277VAC)

and

the

wire

tothe

building

(com)

wire

and

Set

screws

(item

3)wiring.

until

unit

isscrews.

secure.

4)

Loosen

screws

(item

2)

until

you

can

open

wall

pack

(item

1).

4)

Loosen

screws

(item

2)

until

you

can

open

the

wall

pack

(item

1).

Wall

mounting

of

unit

4)

Loosen

screws

(item

2)

until

you

can

open

the

wall

pack

(item

1).

2)

Use

approved

connectors

to

connect

wall

pack

to

building

supply

leads,

and

wires

from

unit

to

building

AC

(120

or

277VAC)

and

the

white

wire

to

building

(com)

wire

and

een wire to

building

ground.

5) Make

battery

connections

(asconnections

shown).(as shown).

5) Make

battery

connections

(as

shown).

4

3

2

1

5)

Make

battery

BUILDING

Insert all connections

into

J-box.

green wire

to building

ground.

WIRING

6)Before

Close

unit.

Note:

Before

closing

the unit,

extra

care must

be

to not

the

not not

beingbeing

6)

unit.

Note:

closing

the

unit,

care

must

be

to

thewires

wires

1) unit.

AffixClose

mounting

plate

(item

4) to

J-box

with

screws.

6) Close

Note:

Before

closing

the

unit,

extra

careextra

must

be

applied

to applied

theapplied

wires

being

- J1 -

- J1 -

YEL

POS

POS

BLUE/W HT

NEG

NEG

5

93068713

4

120/277VAC

Blue

Blue

4 Black

93068713

NOTE:

QSP1

IS SHOWN ABOVE BUT

Line

SWLine

IS SIMILARBlack

FOR ALL

MODELS.

White

1

SW

-OUT PUT BLUE OR BLK

BLUE

LED +

OR

EM LED -

RED/WHT

LED ARRAY +

RED BLUE/W HT

LED -

LED ARRAY +

RED/WHT

NEG

EM LED -

LED ARRAY +

EM LED +

EM LED -

BLK

LED DRV OUT +

RED

EM LED +

YEL

- J2 POS

EM LED -

OR HT

BLK/W

NEG

LED

ARRAY +

2

93068855

93068855

BLUE/W HT

BLK/W HT

BLK

RED

BLK

BLKBLK

RED

RED

BLK

- J1 - - J2 POS POS

NEG NEG

RED/WHT

- J1 BLK/W

POS HT

NEG

- J1 -

- J2 POS

NEG

RED/WHT

- J2 POS

BLK/W HT

NEG

- J1 POS

NEG

RED/WHT

- J2 POS

BLK/W HT

NEG

- J2 POS

Lockout cicuit, which prevents the emergency lights from illuminating when the battery is connected

and no AC is present.

BATTERY HEATER

BATTERY CONNECTION

BLK

Connect battery pack

to PCB battery harness

RED/WHT

BLUE/W HT

NEG

RED/WHT

YEL

BLK/W HT

BLUE/W HT

RED

LED ARRAY -

NEG

NEG

YELRED/WHT

BLUE/W

HT HT

BLK/W

BLUE/W HT

BLK/W HT

YEL

YEL

POS

BLUE/W HT

BLUE LED ARRAY

RED

OR

LED DRV OUT BLK

YEL

LED DRV OUT +

RED

BLUE/W HT

EM LED +

YEL

RED/WHT

BLUE/W HT

EM LED BLK/W HT

LED ARRAY +

RED/WHT

BLK

RED

LED DRV OUT +

LED DRV OUT -

BLUE

OR

BLK

RED/WHT

BLK

- J2 POS

LED ARRAY

EM -LED + BLK/WHT

YEL

POS

BLK/W HT

2

YEL RED/WHT

BLUE

OR

BLK/W HT

BLUE/WHT

BLK

- J1 POS

YEL

BLUE/W HT

LED

ARRAY

LED

DRV +OUT + RED/WHT

RED

- J1 -

BLUE OR BLK

BLK/W HT

RED/WHT

BLK/W HT

RED

LED DRV OUT +

LED ARRAY -

YEL

BLUE/W HT

BLUE/W HT

LED ARRAYBLUE

OR

BLK

LED DRV OUT -

BLK

DIM +

BLK

RED

YEL

LED ARRAY +

BLK

BLUE/W HT

EM LED

LED

DRV -OUT -

EM LED -

BLK

BLK

RED

BLK

YEL

RED/WHT

1

RED

WhiteWhite

Black

Neutral1

Neutral

Green

Ground

EM LED +

BLK/W HT

BLUE OR BLK

BLUE

RED

5

43

LED -

RED

EM LED +

LED ARRAY -

LED ARRAY RED

YEL

BLK

LED DRV OUT -

LED DRV OUT +

LED +

RED

EM LED +

LED ARRAY -

5

DIM -

DIM +

GRY

VIO

LED -

NEG

RED

LED DRV OUT +

DIM -

DIM -

DIM +

LED +

- J2 POS

RED

VIO

GRY

BLUE

WHT

BLUE

BLK

LINE

AC DRV LINE

NEUT

RED

-OUT PUT -

BLK

NEUT

BLUE

LINE

WHT

BLUE

BLK

LINE

NEUT

LINE

BLUE

BLK

BLUE

BLK

BLK

AC DRV SW WHT

NEUT

NEUT

BLK

NEUT

EM LED -

LED ARRAY +

-OUT PUT -

RED/WHT

BLK/W HT

LED DRV OUT -

AC DRV LINE

WHT

BLK

BLK

BLUE

RED

BLUE

- INPUT -

AC DRV SW

NEUT

AC DRV LINE

GRN

WHT

BLK

GRN

LINE

RED

WHT

- INPUT -

BLK

RED/WHT

BLK/W HT

BLUE OR BLK

LINE

BLUE

NEUT

RED

LED ARRAY -

- INPUT -

AC DRV SW

BLK

LED ARRAY +

LED +

LED -

WHT

BLUE

BLUE

LINE SW ITCH

120VAC / 277VAC

AC DRV SW

GRN

BLUE

GROUND

BLK

LINE SW ITCH

WHT

120VAC / 277VAC

NEUT

NEUT

BLUE/W HT

EM LED -

-OUT PUT -

WHT

GROUND

LINE

NEUT

LINE

WHT

BLK

WHT

GROUND

BLK

LINE SW ITCH

120VAC / 277VAC

BLK

AC DRV LINE

BLK

- INPUT -

BLK

WHT

WHT

WHT

BLK

BLK

NEUT

BLK

NEUT

BLUE

120VAC / 277VAC

120VAC / 277VAC

NEUT

GRN

BLUE

BLUE

BLK

GROUND

LINE SW ITCH

LINE SW ITCH

NEUT

WHT

LINE

BLK

AC DRV LINE

BLUE

AC DRV SW

AC DRV SW

BLUE

WHT

BLK

WHT

GRN

WHT

BLK

BLK

NEUT

NEUT

GROUND

LINE

NEUT

BLUE

AC DRV LINE

EC-150319002

LINE SW ITCH

WHT

120VAC / 277VAC

GRN

DESN CHCK

WHT

RECORD

GRN

DATE

DIM +

BUILDING

UNIT

Affix

Wall Pack

onto

Mounting

Plate

(item

4)

and secure

Wall

Pack

Wall mounting of unit 2)3)Use

1

9/29/15

WIRING

ALB ALB

crushed

bymating

the gasket

and

mating

die-cast

surfaces.

BUILDING

GROUND

connectors

to

connect

wall

pack

tosurfaces.

building

supply leads,

and using

crushed

by

the

gasket

die-cast

1) Affix

mounting

plate

(item

4)and

todie-cast

J-box

with

screws.

crushed

theapproved

gasket

and

mating

surfaces.

LED ASSY PACK

CHARGER PCB/ LED DRIVER

DAUGHTER/SWITCH PCB

UNSWITCHED FIXTURE

WIRING

Wall mounting

of by

unit

CHARGER

PCB/ LED DRIVER

7) Extra

weather

can be gained by application of silicon sealant between

LED ASSY PACK LED ASSY PACK

DAUGHTER/SWITCH

PCB

UNIT

CHARGER PCB/ LED

DRIVER

SWITCHED FIXTURE

Set screws

(item 3)

until

unit isproofing/sealing

secure.

DAUGHTER/SWITCH

PCB

Insert

allproofing/sealing

connections

into

J-box.

AC LED DRIVER

GROUND

7)

Extra

weather

proofing/sealing

can

be

gained

by

application

of

silicon

sealant

between

Useweather

approved

connectors

to

connect

wall

pack

to

building

supply

leads,

and

7)2)Extra

can

be

gained

by

application

of

silicon

sealant

between

Housing and Back Plate.

UNIT

SWITCHED FIXTURE

4)

Loosen

screws

(item

2)

until

you

can

open

the

wall

pack

(item

1).

D BUILDING

3) Affix

Wall Pack

onto

Mounting

Plate (item 4) and secure Wall Pack using

GROUND

UNSWITCHED FIXTURE

Housing

and

Back

Plate.

UNIT

Insert

all

connections

into

J-box.

Housing

and(item

Back4)Plate.

AC LED DRIVER

1) Affix mounting

to connections

J-box

withisscrews.

WIRING

GROUND

Set

screws

(item

3)

until unit

secure.

5)plate

Make

battery

(as shown).

UNIT

1) approved

Affix

mounting

plate (item

4) to

J-box

with

screws.

3) Affix

Wall

Pack

onto

Mounting

(item

4)the

andsupply

secure

Wall1).Pack

using

2

GROUND

2) Use

connectors

to Note:

connect

wallPlate

pack

to

building

leads,

and

BUILDING

LED ASSY PACK

CHARGER PCB/ LED DRIVER

4)6)

Loosen

(item

2) until

you

can

open

pack

(item

DAUGHTER/SWITCH PCB

Closescrews

unit.

Before

closing

the

unit,wall

extra

care

must

be applied to the wires not

being

UNSWITCHEDUNIT

FIXTURE

WIRING

GROUND

2) Use

approved

to connect

wall pack

to building

supply leads, and 1

Set5)screws

(item

3)

until

unit (as

is secure.

5die-cast

Insert

all connections

into

J-box.

4surfaces.

Makeconnectors

battery

connections

shown).

AC LED DRIVER

crushed

by the

gasket and

mating

2

BATTERY HEATER

2

BATTERY CONNECTION

LED ASSY PACK

CHARGER

WIRE LEADS

Insert

all

intoBefore

J-box.

4) Pack

Loosen

screws

(item

2)

until

you4)can

open

theWall

wallmust

pack

(item

1). to the wires not being

DAUGHTER/SWITCH

PCB

Black

TO BE CONNECTED

AC LED

DRIVER PCB/ LED DRIVER

6) connections

Close

unit. Note:

closing

the

extra

care

be

applied

3) Affix Wall

(item

andunit,

secure

Pack

using

UNSWITCHED

FIXTUREAT

(IF PROVIDED)

INSTALLATION

7)onto

ExtraMounting

weather Plate

proofing/sealing

can

be gained

by

application

sealant between BUILDING

120/277VAC

WIRING

1

1 usingof silicon

crushed

by

the

gasket

and

mating

die-cast

surfaces.

Affix

Wall

Pack

onto

Mounting

(item

secure Wall

Pack

54Plate

5) Make

battery

connections

(as

shown).

5

4 4) and

Set3)screws

(item

3) until

unit

isBack

secure.

BUILDING

LED ASSY PACK

CHARGER PCB/ LED DRIVER

DAUGHTER/SWITCH PCB

Housing

and

Plate.

BATTERY

HEATER

BATTERY

HEATER

WIRING

BATTERY

CONNECTION

BATTERY

CONNECTION

7) Extra

weather

proofing/sealing

be

gained

by(item

application

of silicon

sealant

BLACK

Set

screws

(item

3)until

until

unitcan

isclosing

secure.

6)screws

Close

unit.

Note:

Before

the

unit,

extra

care

must

be

applied

to thebetween

wires not being

WIRE LEADS

WIRE LEADS

4) Loosen

(item

2)

you

open can

the

wall

pack

1).White

Black

TO BE

Black

TO BE CONNECTED

AT CONNECTED AT

UNSWITCHED FIXTURE

120/277VAC

(IF PROVIDED) (IF PROVIDED)

Housing

and2)

Back

Plate.

INSTALLATION INSTALLATION

Neutral

4) Loosen

screws

you candie-cast

open

the

wall

pack (item

1).

crushed

by the(item

gasket

and

mating

surfaces.

UNSWITCHED FIXTURE

5) Make

battery

connections

(asuntil

shown).

120/277VAC

120/277VAC

WHITE

LED ASSY PACK

CHARGER PCB/ LED DRIVER

DAUGHTER/SWITCH PCB

BATTERY HEATER PACK

NEUTRAL

5) Make

battery

connections

7) Extra

weather

proofing/sealing

gained

silicon

between 2

(IF PROVIDED)

6) Close

unit.

Note:

Before

closing (as

the shown).

unit, can

extrabecare

mustbybeapplication

applied toof

the

wiressealant

not being

BATTERY CONNECTION

6)

Close

unit.

Note:

Before

closing

the

unit,

extra

care

must

be

applied

to

the

wires

not

being

Housing

and

Back

Plate.

TO

BE

CONNECTED

AT

2

White

White

crushed by the gasket and mating die-cast

surfaces.

BATTERY HEATER

1

INSTALLATION CHARGER PCB/ LED DRIVER

C

5

LED ASSY PACK

4 surfaces.

DAUGHTER/SWITCH PCB

WIRE LEADS CONNECTOR

crushed

by the

gasket and 5mating

Neutral

7) Extra

weather

proofing/sealing

can bedie-cast

gained

by

application

of silicon sealant

between

BATTERY HEATER

Neutral

1

BATTERY CONNECTION CHARGER PCB/ LED DRIVER

(IF PROVIDED) LED ASSY PACK

4

DAUGHTER/SWITCH PCB

93068855

WIRE LEADS

Black

TO BE CONNECTED

AT HEATER

BATTERY

BATTERY CONNECTION

Blue

7)

Extra

weather

proofing/sealing

can

be

gained

by

application

of

silicon

sealant

between

(IF PROVIDED)

BATTERY

HEATER PACK

Housing and Back Plate.

BATTERY HEATER

PACK

INSTALLATION WIRE LEADS

Black

TO BE CONNECTED AT

93068713

2

(IF PROVIDED)

PROVIDED)

120/277VACLine SW

INSTALLATION

PROVIDED)

illuminated when AC power is present.

NOTE:(IFAll

models(IFare

supplied with an AC

"AC ON" LED is

Housing and Back Plate.

120/277VAC

REV

NEG

RED/WHT

- J2 POS

BLK/W HT

NEG

BATTERY HEATER PACK

WIRE LEADS

(IF PROVIDED)

(IF PROVIDED)

circuit,

which

prevents damage

TO BE CONNECTED AT

with Low Voltage Disconnect

NOTE: All models are supplied

INSTALLATION

to the battery from deep discharge during prolonged

emergency operation.

BATTERY HEATER PACK

BATTERY HEATER PACK

BATTERY HEATER

BATTERY CONNECTION

TO BE CONNECTED AT

(IF PROVIDED)

WIRE LEADS

(IF PROVIDED)

93068858

NOTE:

THIS ILLUSTRATION IS USE ON INSTRUCTION SHEET 93066449.

UNSPECIFED TOLERANCES: INCHES

X.X= 0.02 X.XX= 0.01 X.XXX= 0.005

FRACTIONS= 1/32 ANGULAR TOLERANCE= .5

DRAWN BY:

DIMENSIONS IN INCHES

DIMENSIONS IN [ ] IN MM

CONFORMS TO ASME Y14.5M

DO NOT SCALE PRINT

This document contains confidential and proprietary information of Dual

Lite. Receipt or possession of this document does not convey any rights to

reproduce or disclose its contents, or to make, use , or sell anything it may

disclose. Reproduction, disclosure, or use of the document or its contents,

without the specific written authorization of Dual Lite, may violate the

intellectual property rights of Dual Lite.

CHECKED BY:

ENGINEERING:

CATALOG NO.

MATERIAL:

SCALE

---

SIZE

FINISH:

DRAWING NO.

---

PART NO.

---

REV.

THIRD ANGLE PROJECTION

4) This unit is capable of dimming, see wiring diagram and please contact Dual-Lite Inc for assistance

BLK

RED

BLK

BLK

RED

BLK

BLK

RED

BLK

BLK

BLK

RED

BLUE

LINE SWITCH

BLK

RED

GREEN

GROUND

RED

BATTERY HEATER

BATTERY

CONNECTION

(IF PROVIDED)

INSTALLATION

is illuminated

power

present.

NOTE:

All are

models

are supplied

with an AC

NOTE:

Batteries

areisoften

shipped

in awhen

discharged

state

- AC

this

normal.is

The

battery will

require

"AC

ON"

LED

illuminated

ACwhen

power

isisLEADS

present.

NOTE:

All

models

supplied

with an AC

"AC

ON"

LED

WIRE

TO BE CONNECTED AT

(IF PROVIDED)

charging. Allow

24 hours

of prevents

charging

testing

the

INSTALLATION

Lockout

cicuit,

whichbefore

prevents

theunit.

emergency

lights

from illuminating

theisbattery

is connected

Lockout

cicuit,

which

the

emergency

lights from

illuminating

when thewhen

battery

connected

B

and

AC is present.

and

no AC

isno

present.

All Models

have

SPECTRON

Self-Testing/Self-Diagnostic BATTERY

Circuitry

93068855

battery pack

Connect Connect

battery pack

3

HEATER PACK

3

93068855

Operation

(IF PROVIDED)

All Models have the SPECTRON Self-Testing/Self-Diagnostic electronics

system which provides:

93068713

to PCBharness

battery harness

to

PCB

battery

3 93068713

Allofare

models

supplied

with

Low Disconnect

Voltage

Disconnect

circuit,

which

All

models

with

Voltage

circuit,

which

damage damage

NOTE:

isNOTE:

illuminated

when

ACare

power

is Low

present.

NOTE:

All models

are

supplied

withprevents

an

AC prevents

"AC ON"

LED

-Visual

indication

AC supplied

power

status,

BATTERY HEATER

PACK

is

illuminated

when

AC

power

is

present.

NOTE:

models are supplied with an AC

"AC

ON"

LED

Lockout

which

the

emergency

lights(IFand

from

illuminating

when the

battery

isAll

connected

on

self-diagnostic

status

results.

toindication

theprevents

battery

from

deeptestdischarge

during

prolonged

emergency

operation.

to cicuit,

the-Visual

battery

from

deep

discharge

during

prolonged

emergency

operation.

PROVIDED)

Green

BATTERY HEATER PACK

IMPORTANT WIRING INSTRUCTIONS

Lockout

cicuit,

which

prevents

the

emergency

lights

from

illuminating

when

the

battery is connected

and

no

AC

is

present.

Connect battery pack

3

(IF PROVIDED)

NOTE:

IS SHOWN

ABOVE BUT Ground

Visual indication of any unit malfunctions includeNOTE: QSP1

ISQSP1

SHOWN

ABOVE BUT

Green

93068855

and

no

AC

is

present.

to PCB battery

harness

BlueGround

Disconnected,

Battery

Fault,

Charger

Fault,

LED

Driver

Fault,

Lamp

Fault

&

Load

Learn

Failure

Connect

batteryNOTE:

packBattery

NOTE:

Batteries

are

often

shipped

in

a

discharged

state

this

is

normal.

The

battery

will require

NOTE:

Batteries

are

often

shipped

in

a

discharged

state

this

is

normal.

The

battery

will

require

IS SIMILAR

FOR

ALL

MODELS.

IS SIMILAR

FOR3

ALL

MODELS.

All models are supplied with Low Voltage Disconnect circuit, which prevents damage

93068713

1) An un-switched AC power

of 120/277VAC is required for charger pcb black (120/277VAC)

CRITICAL

DIMENSIONS

Linesource

SW

to PCB battery harness

charging.

Allow

24

hours

ofAC

charging

before

testing

the unit.

charging.

Allow

24

hours

of

charging

before

testing

the

unit.

to the battery

from

deep

discharge

during

prolonged

emergency

operation.

ismodels

illuminated

when

power

isVoltage

present.

NOTE:

All circuit,

modelswhich

are supplied

with

an AC

"AC

ON"

LED

2) For a switched unit connect a switching device between 93068855

building (120/277VAC) power source and blue

The

Spectron

equipped

units

also

include:

All

are

supplied

with

Low

Disconnect

prevents

damage

NOTE:

u

u

u

(line switch

lead). (ref. to wiring

diagram)

NOTE: QSP1 IS SHOWN ABOVE

BUTBlue

u

u v

Brownout

protection:

unit

willfrom

automatically

transfer

to emergency

operation

upon

detection of low

Lockout

cicuit,

which

prevents

the

emergency

lights

from

illuminating

when

the battery is connected

93068855

to

the

battery

deep

discharge

during

prolonged

emergency

operation.

Green

93068713

3) Emergency charger

and AC LED Driver must be fed from the SAME BRANCH CIRCUIT

All

Models

have

SPECTRON

Self-Testing/Self-Diagnostic

Circuitry

Blue

All

Models

have

SPECTRON

Self-Testing/Self-Diagnostic

Circuitry

NOTE:

Batteries

are

often

shipped

in

a

discharged

state

this

is

normal.

The

battery

will

require

AC

power

(approximately

80%

of

nominal

line).

IS

SIMILAR FOR ALL MODELS.

Line

SWof dimming, see wiring

abrunelli 06/27/16

no AC

is present.

illuminated

when AC

power

is present.

NOTE: All models are supplied with an AC

Connect

battery

pack

"AC

ON"and

LED

3 93068713

4) This unit BUT

is capableGround

diagram and please contact

Dual-Lite

Inc

for assistance

NOTE: QSP1

IS SHOWN ABOVE

ILL-WALL

MTG QSP1

A charging.

AllowisAll

24

hours

of charging

before

testing

theSelf-Testing/Self-Diagnostic

unit.

Line

SW

ALB

10/6/15

Models

have

the

SPECTRON

electronics

system

which

provides:

isprevents

illuminated

when

AC

power

is

present.

NOTE:

All

are

supplied

with

an

ACrequire

Models

have

the

SPECTRON

Self-Testing/Self-Diagnostic

electronics

system

which

provides:

"ACAll

ON"

LED

Lockout

cicuit,

which

the

emergency

lights

illuminating

when

the

battery

isThe

connected

to PCB battery harness

NOTE:

Batteries

are

often

shipped

in from

a discharged

state

-models

this

is

normal.

battery

will

IS SIMILAR FOR ALL MODELS.

Green

All

models

are

supplied

with

Low

Voltage

Disconnect

circuit,

which

NOTE:

ALB

10/6/15

Lockout

cicuit,

which

prevents

thepower

emergency

lights

from

illuminating

when

the prevents

battery isdamage

connected

-Visual

indication

of

AC

power

status,

-Visual

indication

of AC

status,

Allno

Models

SPECTRON

Self-Testing/Self-Diagnostic

Circuitry

and

AC ishave

present.

charging.

Allow

24

hours

of

charging

before

testing

the

unit.

Connect battery packSHT 1

Green

3

Ground

to

battery

from deep

discharge

duringtest

prolonged

emergency

operation.

2 1 pack

1:2

93068713

SHTS

CConnect

--nothe

AC

isthe

present.

-Visual

indication

on self-diagnostic

test

status

and results.

battery

-Visual

indication

on

self-diagnostic

status

and

results.

3

to

PCB

battery

harness

Alland

Models

have

SPECTRON

Self-Testing/Self-Diagnostic

electronics

system

which provides:

Ground

NOTE:

QSP1

IS

SHOWN

ABOVE

BUT

All models

are supplied

with

Low Voltage

Disconnect circuit, which prevents

4

3INSTRUCTIONS

2

1

IMPORTANT

WIRING

All Models

have

SPECTRON

Self-Testing/Self-Diagnostic

Circuitrydamage

IMPORTANT

WIRING

INSTRUCTIONS

to PCB battery

harnessNOTE: -Visual

indication

of

AC

power

status,

Visual

of

any

unit

malfunctions

includeAllindication

models

areof

supplied

with

Low

Disconnect

prevents

damage

Visual

any

unit

malfunctions

includeNOTE:

Batteries

are

often

shipped

inVoltage

a discharged

state

-circuit,

this is which

normal.

The battery

will require

IS SIMILAR FOR ALL MODELS.

to theNOTE:

battery

deepindication

during

emergency

operation.

-Visual from

indication

ondischarge

self-diagnostic

testprolonged

status Self-Testing/Self-Diagnostic

and results.

93068858

All

Models

have

the

SPECTRON

electronics

system

which

provides:

93068858

to Battery

the

battery

from

deep

discharge

duringCharger

prolonged

emergency

operation.

Battery

Disconnected,

Battery

Fault,

Charger

Fault,

LED

Driver

Fault,Fault

Lamp

Fault

& Load

Learn Failure

charging.

Allow

24 hours

of charging

before

testing

the

unit.

Disconnected,

Battery

Fault,

Fault,

LED

Driver

Fault,

Lamp

& Load

Learn

Failure

OTE: QSP1 IS SHOWN

ABOVE

BUT

IMPORTANT

WIRING

INSTRUCTIONS

Visual

indication

of

any

unit

malfunctions

include-Visual

indication

of

AC

power

status,

1)

An

un-switched

AC

power

source

of

120/277VAC

is

required

for

charger

pcb

black

(120/277VAC)

1)

An

un-switched

AC

power

source

of

120/277VAC

is

required

for

charger

pcb

black

(120/277VAC)

NOTE:

QSP1

IS

SHOWN

ABOVE

BUT

NOTE:

Batteries

are

often

shipped

in

a

discharged

state

this

is

normal.

The

battery

will

require

ISCAUTION:

SIMILARDO

FOR

ALL

MODELS.

93068858

NOT

LET

WIRING

BECOME

PINCHED

Battery

Disconnected,

Battery

Fault,

Charger

Fault,

LEDthe

Driver

Fault,

Lamp

Fault

& Load

Learn Failure

All

Models

have

SPECTRON

Self-Testing/Self-Diagnostic

Circuitry

-Visual

indication

on

self-diagnostic

test

status

and

results.

2)

ForALL

a unit

switched

unita connect

a device

switching

devicebuilding

between(120/277VAC)

building (120/277VAC)

power

source

andNOTE:

blue

The

Spectron

equipped

also

include:

2) For a switched

connect

switching

between

power source

and

bluecharging.

Batteries

are

often

shipped

inunits

a

discharged

state

- this

is

normal.

The battery

will require

The

Spectron

equipped

units

also

include:

IS SIMILAR

FOR

MODELS.

Allow

24 hours

of

charging

before

testing

unit.

1)SEALING

An

un-switched

power

120/277VAC

BETWEEN

THE

BACK

PLATE

GASKET

AND THE is required for charger pcb black (120/277VAC)

WIRING

INSTRUCTIONS

(line

switch

lead).

(ref.

tosource

wiringofdiagram)

(lineIMPORTANT

switch

lead).

(ref.

to AC

wiring

diagram)

charging.

Allow

24

hours

of of

charging

before

testing

theto

unit.

Brownout

protection:

unitunit

will

automatically

transfer

to emergency

operation

uponprovides:

detection

Brownout

protection:

unit

will

automatically

transfer

emergency

operation

upon

detection

of low of low

All

Models

have

the

SPECTRON

Self-Testing/Self-Diagnostic

electronics

system

which

Visual

indication

any

malfunctions

include2)

For

a

switched

unit

connect

a

switching

device

between

building

(120/277VAC)

power

source

and

blue

The

Spectron

equipped

units

also

include:

DIE-CAST

HOUSING.

FAILINGand

TO

DOLED

SO

RESULT

INmust

3) Emergency

charger

andWILL

AC LED

Driver

bethe

fedSAME

from the

SAME

BRANCH

3) Emergency

charger

AC

Driver

must

be fed

from

BRANCH

CIRCUIT CIRCUIT All Models

have

SPECTRON

Self-Testing/Self-Diagnostic

Circuitry

AC

power

80%

of

nominal

line).

93068858

AC protection:

power

(approximately

80%

of

nominal

line).

-Visual

indication

of

ACBattery

power

status,

(lineINSIDE

switch lead).

(ref. toAND

wiringDAMAGING

diagram)

Battery

Disconnected,

Fault,

Charger

Fault,Circuitry

LED

Fault,

Brownout

unit

will(approximately

automatically

transfer

to emergency

operation

uponDriver

detection

of lowLamp Fault & Load Learn Failure

WATER4)

LEAKING

OFisofUNIT

All

Models

have

SPECTRON

Self-Testing/Self-Diagnostic

4)

This

unit

capable

of

dimming,

see

wiring

diagram

and

please

contact

Dual-Lite

Inc

for

assistance

This unit

is

capable

dimming,

see

wiring

diagram

and

please

contact

Dual-Lite

Inc

for

assistance

3)

chargerAC

andpower

AC LED

Driverof

must

be fed from the

SAME BRANCH

CIRCUIT

-Visual

indication

on

self-diagnostic

test status and

results. system which provides:

AllAC

Models

the SPECTRON

Self-Testing/Self-Diagnostic

electronics

1) Emergency

An un-switched

source

120/277VAC

is required

for charger

pcb black (120/277VAC)

power have

(approximately

80% of nominal

line).

THE ELECTRONICS.

4)

is INSTRUCTIONS

capableunit

of dimming,

wiring diagram

andbetween

please contact

Dual-Lite

Inc for assistance

All

Models

have

theofSPECTRON

Self-Testing/Self-Diagnostic

electronics system which provides:

IMPORTANT

WIRING

2)This

Forunit

a switched

connectsee

a switching

device

building

(120/277VAC)

power source and blue

The

Spectron

equipped

units also include:

-Visual

indication

AC

power

status,

Visual

indication

of

any

unit

malfunctions

include-Visual

indication

of AC power

status,

(line switch lead). (ref. to wiring diagram)

-Visual

indication

on

self-diagnostic

test

status and results.

Brownout

protection:

unit

will

automatically

transfer

to

emergency

upon

detection

low

93068858

Battery

Disconnected,

Battery Fault, Charger

Fault,

Driver

Fault, operation

Lamp Fault

& Load

LearnofFailure

-Visual

indication

on self-diagnostic

status

and LED

results.

3)INSTRUCTIONS

Emergency charger and AC LED Driver must be fed from the SAME BRANCH CIRCUIT

IMPORTANT WIRING

AC of

power

(approximately

80%includeoftest

nominal

line).

1) An

un-switched

AC power source of 120/277VAC is required for charger pcb black (120/277VAC) Visual indication

any

unit

malfunctions

IMPORTANT

WIRING

INSTRUCTIONS

4) This unit is capable of dimming, see wiring diagram and please contact Dual-Lite Inc for assistance

Visual

of

any unit

malfunctions

include2) For a switched unit connect a switching device between93068858

building (120/277VAC) power source and blue

Theindication

SpectronBattery

equipped

units

also include:

Battery

Disconnected,

Fault,

Charger

Fault,

LED Driver Fault, Lamp Fault & Load Learn Failure

(line switch

to wiring

diagram) is required for charger93068858

Battery

Disconnected,

Battery

Fault,

Charger Fault,

LED

Driver Fault,operation

Lamp Fault

& detection

Load Learn

Failure

1) An un-switched

AClead).

power(ref.

source

of 120/277VAC

pcb black (120/277VAC)

Brownout

protection:

unit will

automatically

transfer

to emergency

upon

of low

1)a An

AC

power

source

of

120/277VAC

required

for

charger

black

(120/277VAC)

3)un-switched

Emergency

charger

and

AC LED

Driver

mustisbe

fed from

the

SAMEpcb

BRANCH

CIRCUIT

2) For

switched

unit connect

a switching

device

between

building

(120/277VAC)

power

source

and blue

The Spectron

equipped

units also

include:

AC power

(approximately

80%

of nominal line).

2) For

aThis

switched

connect

a switching

building

(120/277VAC)

powerInc

source

and blue

4)lead).

unit

capable

of dimming,

seedevice

wiring between

diagram and

please

contact Dual-Lite

for assistance

The Spectron

equipped

units also include:

(line switch

(ref.istounit

wiring

diagram)

Brownout

protection:

unit will automatically

transfer to emergency operation upon detection of low

(line switch

lead). (ref.

to wiring

diagram)

3) Emergency

charger

and AC

LED Driver

must be fed from the SAME BRANCH CIRCUIT

Brownout

protection: 80%

unit will

automatically

AC power

(approximately

of nominal

line). transfer to emergency operation upon detection of low

3)

Emergency

charger

and

AC

LED

Driver

must

be

fed

from

the

SAME

BRANCH

CIRCUIT

4) This unit is capable of dimming, see wiring diagram and please contact Dual-Lite Inc for assistance

AC power (approximately 80% of nominal line).

120/277VAC

NeutralGreen

120/277VAC

Green

White Ground

Blue Ground

Blue

White Line SW

Neutral

4Neutral

Line SW

BLACK

SURGE

SUPPRESSION