3M™ Novec™ Engineered Fluids

Understanding solvent exposure guidelines

to protect worker health – and your profits

Because of growing public awareness and concern about the longterm health and environmental effects of many common industrial

solvents, regulations governing their use have become increasingly

restrictive. For users of these materials, coping with changing

regulations and guidelines is not only confusing, but can also

increase costs, while creating uncertainty about the sustainability

of their process.

For example, when n-propyl bromide (nPB) was first introduced as

a replacement for HCFC-141b, there was insufficient information

available to allow an accurate characterization of its toxicity. Based

on various studies conducted over the past ten years, however, the

8-hour time weighted average exposure guideline for nPB was

first downgraded from 200 ppm to 100 ppm; then further, to 50

ppm; and again down to 25 ppm. Today, the exposure guideline has

been established by the American Conference of Governmental

Industrial Hygienists (ACGIH) at 10ppm. And the California

OSHA has a rule proposal to set the exposure guideline at 5ppm

– a concentration that may be unachievable in vapor degreasing

operations.

In this atmosphere of uncertainty, how can you help ensure

the safety of your workers – while maintaining the long-term

sustainability of your process? A growing number of users are

making the switch from first-generation ozone-depleting solvent

(ODS) alternatives, such as nPB, to the dependable, sustainable

solution offered by 3M™ Novec™ Engineered Fluids.

The Once and Future Solvent

Novec fluids are a family of nonflammable, high performance

solvents based on 3M’s proprietary segregated hydrofluoroether

(HFE) technology. Novec fluids were developed in the mid

1990s as replacements for CFCs (chlorofluorocarbons), HCFCs

(hydrochlorofluorocarbons) and other ozone depleting materials.

Their unique balance of performance, safety and environmental

properties has made Novec fluids useful as cleaning solvents and

heat transfer fluids in a wide range of industrial and electronics

applications. These properties include low toxicity; low odor; nonflammability; zero ozone depletion potential; low global warming

potential and short atmospheric lifetimes. They are not classified

as hazardous air pollutants (HAPs), and in their pure (neat)

formulations, are exempt as volatile organic compounds (VOCs).

Novec fluids are non-corrosive and dry quickly, leaving no residue.

They also feature very low surface tension, making them more

effective at cleaning parts with complex geometries, blind holes

and tight spaces.

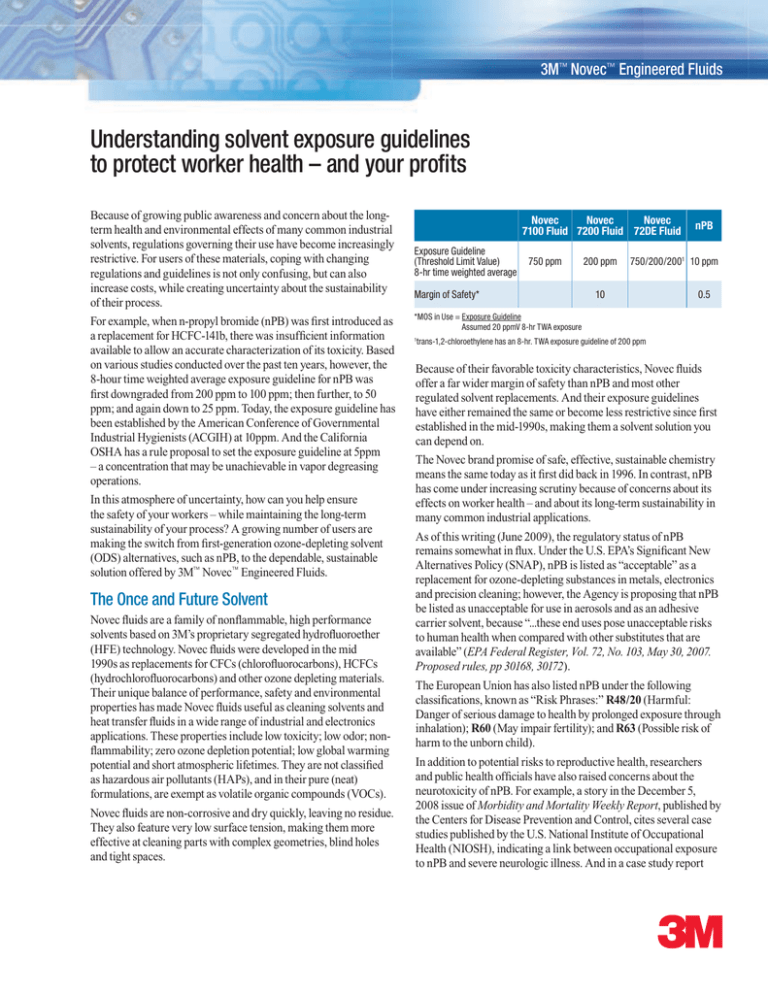

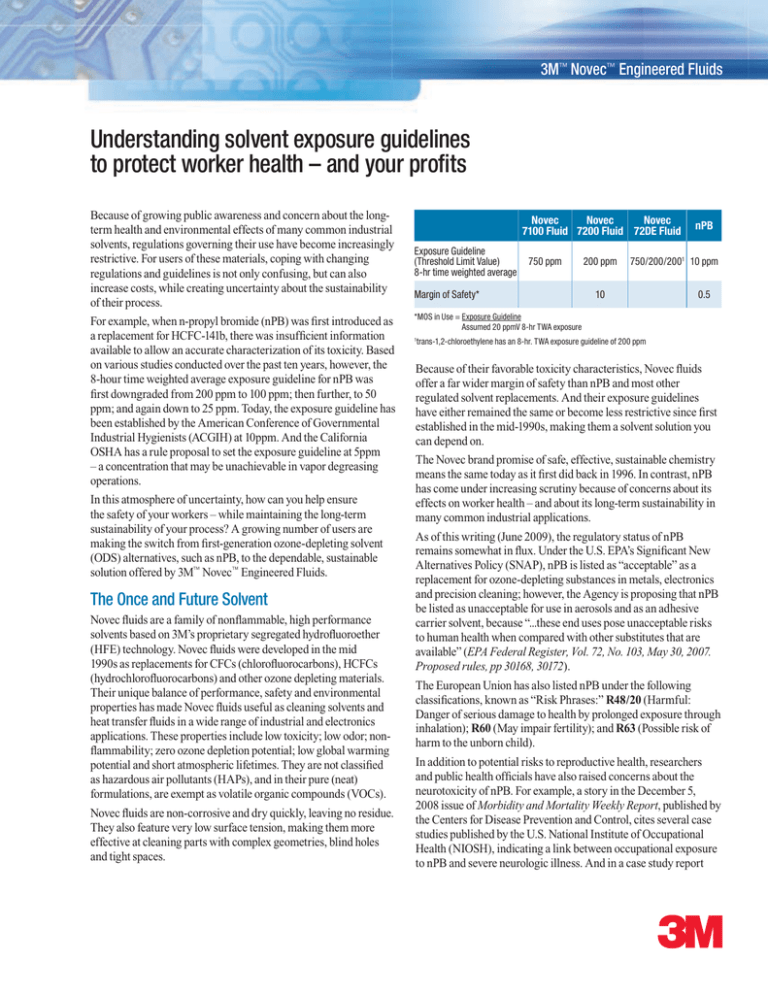

Novec

Novec

Novec

7100 Fluid 7200 Fluid 72DE Fluid

Exposure Guideline

(Threshold Limit Value)

8-hr time weighted average

750 ppm

Margin of Safety*

200 ppm

nPB

750/200/2001 10 ppm

10

0.5

*MOS in Use = E xposure Guideline

Assumed 20 ppmV 8-hr TWA exposure

trans-1,2-chloroethylene has an 8-hr. TWA exposure guideline of 200 ppm

1

Because of their favorable toxicity characteristics, Novec fluids

offer a far wider margin of safety than nPB and most other

regulated solvent replacements. And their exposure guidelines

have either remained the same or become less restrictive since first

established in the mid-1990s, making them a solvent solution you

can depend on.

The Novec brand promise of safe, effective, sustainable chemistry

means the same today as it first did back in 1996. In contrast, nPB

has come under increasing scrutiny because of concerns about its

effects on worker health – and about its long-term sustainability in

many common industrial applications.

As of this writing (June 2009), the regulatory status of nPB

remains somewhat in flux. Under the U.S. EPA’s Significant New

Alternatives Policy (SNAP), nPB is listed as “acceptable” as a

replacement for ozone-depleting substances in metals, electronics

and precision cleaning; however, the Agency is proposing that nPB

be listed as unacceptable for use in aerosols and as an adhesive

carrier solvent, because “...these end uses pose unacceptable risks

to human health when compared with other substitutes that are

available” (EPA Federal Register, Vol. 72, No. 103, May 30, 2007.

Proposed rules, pp 30168, 30172).

The European Union has also listed nPB under the following

classifications, known as “Risk Phrases:” R48/20 (Harmful:

Danger of serious damage to health by prolonged exposure through

inhalation); R60 (May impair fertility); and R63 (Possible risk of

harm to the unborn child).

In addition to potential risks to reproductive health, researchers

and public health officials have also raised concerns about the

neurotoxicity of nPB. For example, a story in the December 5,

2008 issue of Morbidity and Mortality Weekly Report, published by

the Centers for Disease Prevention and Control, cites several case

studies published by the U.S. National Institute of Occupational

Health (NIOSH), indicating a link between occupational exposure

to nPB and severe neurologic illness. And in a case study report

3

3M™ Novec™ Engineered Fluids

entitled, “Chronic Exposure to 1-Bromopropane Associated

with Spastic Paraparesis and Distal Neuropathy: A Report of Six

Foam Cushion Gluers,” researchers from the University of Utah

Neurology Department and the Utah Poison Control Center have

concluded that, “1-Bromopropane exposure is associated with

a neurotoxic syndrome consisting of subacute onset of spastic

paraparesis and distal sensory neuropathy.”

health effects of exposure to nPB, covering information

included on the appropriate MSDSs, as required by OSHA’s

Hazard Communication Standard (29 CFR 1910.1200).” If the

manufacturer or formulator of your nPB-based product does not

have an exposure monitoring program, the EPA recommends that

users of nPB start their own exposure monitoring program, and/or

request a confidential consultation from their State government.

Considering the Hidden Costs

of Solvent Alternatives

In the same Rule, the EPA recommends that, “...a medical

monitoring program should also be established for the early

detection and prevention of acute and chronic effects of exposure to

nPB. The workers’ physician(s) should be given information about

the adverse health effects of exposure to nPB and the workers’

potential for exposure.”

Although the cost-per-pound of nPB is relatively low, it’s important

to consider the total cost-in-use over time of any ODS alternative.

To attain the 10ppm TLV value set by the ACGIH, it may be

necessary for employers to invest in costly facility upgrades,

such as improved ventilation systems, equipment enclosures and

modifications to vapor degreasers in order to minimize emissions.

For example, to reduce worker exposure, the U.S. EPA’s nPB Final

Rule 12/40 CFR Part 82 suggests a number of workplace controls,

including, “...covers on cold-cleaning and vapor degreasing

equipment when not in use; devices to limit air movement over the

degreaser; and/or a lip-vent exhaust system to capture vapors and

vent them out of the room.” They add that,”...emissions from vapor

degreasers can be controlled both through improving equipment

(increasing the freeboard, adding cooling coils, or adding a lift that

raises cleaned pieces slowly) and through improved work practices

(leaving the vicinity of the vapor degreaser when done with

work, tipping work-pieces so they do not catch solvent, or lifting

cleaned pieces out slowly).” While all of these are considered

good practices for any type of solvent cleaning, they may not be

sufficient to meet the 10 ppm TLV in the work zone.

In their Final Rule, the EPA also states that “Workers should

receive safety training and education that includes potential

The 3M™ Novec™

Brand Family

The added cost of equipment and process modifications, training

and exposure monitoring can quickly negate the low purchase price

of some ODS replacement solvents. That’s why the outstanding

balance of performance, safety and environmental properties

of Novec Engineered Fluids can be an important competitive

advantage over nPB and other “low-cost” solvent alternatives.

With Novec fluids, you get more peace-of-mind, knowing that

your solvent choice provides a wide margin of worker safety; is

safe for your process; is not scheduled for regulatory restriction or

phaseout; and provides a sustainable, cost-effective solution to your

toughest production challenges.

Further Reading

Morbidity and Mortality Weekly Report, December 5, 2008

The U.S. Solvent Cleaning Industry and the Transition to Non

Ozone Depleting Substances, www.epa.gov/ozone/snap/solvents

nPB Final Rule 12, 40 CFR Part 82, U.S. Environmental

Protection Agency

The Novec brand is the hallmark for a variety of patented 3M compounds. Although each has its own unique formula and performance properties, all

Novec products are designed in common to address the need for safe, effective, sustainable solutions in industry-specific applications. These include

precision and electronics cleaning, heat transfer, fire protection, lubricant deposition and several specialty chemical applications.

3M™ Novec™ Engineered Fluids 3M™ Novec™Aerosol Cleaners 3M™ Novec™1230 Fire Protection Fluid 3M™ Novec™ Electronic Coatings 3M™ Novec™ Electronic Surfactants

■

United States

3M Electronics Markets

Materials Division

800 810 8513

China

3M China Ltd.

86 21 6275 3535

■

Europe

3M Belgium N.V.

32 3 250 7521

■

Japan

Sumitomo 3M Limited

813 3709 8250

■

Korea

3M Korea Limited

82 2 3771 4114

Singapore

3M Singapore Pte. Ltd.

65 64508888

Taiwan

3M Taiwan Limited

886 2 2704 9011

Product Use: All statements, technical information and recommendations contained in this document are based on tests or experience that 3M believes are reliable. However, many factors

beyond 3M’s control can affect the use and performance of a 3M product in a particular application, including conditions under which the product is used and the time and environmental

conditions in which the product is expected to perform. Since these factors are uniquely within the user’s knowledge and control, it is essential that the user evaluate the 3M product to

determine whether it is fit for a particular purpose and suitable for the user’s method of application.

Warranty and Limited Remedy: Unless stated otherwise in 3M’s product literature, packaging inserts or product packaging for individual products, 3M warrants that each 3M product

meets the applicable specifications at the time 3M ships the product. Individual products may have additional or different warranties as stated on product literature, package inserts or

product packages. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. User is responsible for determining whether the 3M

product is fit for a particular purpose and suitable for user’s application. If the 3M product is defective within the warranty period, your exclusive remedy and 3M’s and seller’s sole obligation

will be, at 3M’s option, to replace the product or refund the purchase price.

Limitation Of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental,

or consequential regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.

3

Electronics Markets

Materials Division

3M Center, Building 224-3N-11

St. Paul, MN 55144-1000

www.3M.com/novec

1-800-251-8634

Please recycle. Printed in USA.

Issued: 6/09 © 3M 2009.

All rights reserved. 6874HB

60-5002-0407-2

3M and Novec are trademarks of 3M.

Used under license by 3M subsidiaries and affiliates.