30 Cycle Rated Switchboards - Selectivity

advertisement

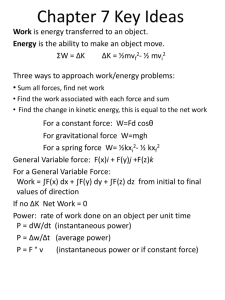

30-Cycle Rated Switchboards - Selectivity Tradeoffs By Rick Schlobohm, P.E. – Senior Specification Engineer, GE Franklin Bohac, P.E. – Specification Engineer, GE Increased focus on selective coordination has resulted due to requirements in the 2005 and 2008 editions of the National Electrical Code (NEC). These requirements, which focus on emergency systems (NEC Article 700), legally required standby systems (NEC Article 701), and Critical Operation Power Systems (NEC Article 708), have also led the electrical designer to pursue selective coordination for many other electrical systems. This paper will attempt to define and address the need for 30-cycle withstand ratings for distribution equipment, not only for low voltage switchgear, but also for low voltage switchboards when instantaneous selective coordination is specified. This paper will also address the consequences, such as increased arc flash hazard categories, that occur when a system is designed to achieve complete selective overcurrent protection through the instantaneous range. What is Selective Coordination? The NEC in Article 100 defines selective coordination as the “localization of an overcurrent condition to restrict outages to the circuit or equipment affected, accomplished by the choice of overcurrent protective devices and their ratings or settings”. A system designed to be selectively coordinated simply implies that the overcurrent device closest to a fault or overload will open the circuit before any upstream overcurrent device. An important aspect, which must be considered when designing and specifying a selectively coordinated distribution system, is the minimum time level for which selective coordination needs to be maintained and the maximum fault level at each piece of equipment in the system. The two most common time levels specified for selectively coordinated systems are 0.01 seconds and 0.1 seconds. The NEC Articles 700.27, 701.18, or 708.54 do not provide a definition for selective coordination and do not indicate a preference for one or the other common selectivity levels. This NEC selectivity requirement is generally, but not always, interpreted as meaning that selective coordination must extend throughout the instantaneous region (0.01 seconds) of the device’s trip curve. Other standards such as Florida’s Agency for Health Care Administration (AHCA) mandates selective coordination for time delays beginning at 0.1 seconds. The 0.1 second standard has been adopted by many other authorities having jurisdiction (AHJ) and is considered a good engineering compromise between the benefits of selective coordination and the associated increase of arc flash hazard levels resulting from the time delays needed to achieve complete selectivity among overcurrent devices. The 0.1 second standard will allow some overlap in the time bands for the devices in the instantaneous time region. These overlaps will occur at the higher fault levels. One item to understand in the selectivity discussion is the fact that even though the main device and feeder device both have an instantaneous trip function and their time bands overlap at high fault levels, they are selective up to the point of minimum instantaneous pickup for the upstream device (Reference Point A in Figure TCC-1). Even though the instantaneous time bands overlap for fault levels above Point A, the system is fully selective for faults and overloads below that level. Traditional switchboards and other distribution equipment can be utilized in designing to 0.1 second selective coordination if care is taken in the selection and adjustment of the overcurrent protective devices. When instantaneous selective coordination for the main distribution equipment is desired for time levels of 0.01 second and greater, selectivity is easily achieved throughout this instantaneous range by using conventional low voltage switchgear. This is accomplished by utilizing main devices without an instantaneous trip function. This feature is also available in some vendor’s switchboards, but the switchboards must be provided with internal bus that is braced for the available fault current for 30-cycles and not just the 3-cycles as defined in the UL 891 standard for switchboards. Without an instantaneous trip to isolate severe faults to a 3 cycle total clearing time, the bus withstand needs to be rated for 30-cycles. This is the maximum time delay permitted by the adjustment ranges of short-time and ground fault protection provided on fully adjustable UL 1066/ANSI rated low voltage power circuit breakers (LVPCB). When designing a project for selectivity, more thought and planning may be required to ensure selectivity throughout the distribution system in addition to the protective devices at the main distribution equipment. While perfect selectivity through the instantaneous range may be attained using ANSI rated switchgear for the main equipment, the switchgear feeder breakers may not be as selective with downstream molded case breakers as would be desired, or the large frame size may force the designer to add another level of overcurrent devices which would hamper the overall selective coordination of the system. Switchboards are available to achieve instantaneous selectivity with a low voltage power circuit breakers (LVPCB) main not utilizing an instantaneous trip function. These switchboards offer the designer the ability to have switchboard mounted feeder breakers utilizing molded case breakers. Many of these molded case breakers will provide selective coordination into the instantaneous range to higher fault values than can be obtained with breakers rated to the ANSI standards. The use of molded case breakers in the main distribution equipment as feeders can eliminate a layer of overcurrent devices that could be difficult to selectively coordinate. What is a 30-Cycle Withstand Rating? This term can be simply defined as the ability of the distribution equipment to withstand the mechanical and thermal stresses associated with a rated fault, for a time period of 30-cycles (0.5 seconds). The 30-cycle withstand rating has long been a requirement of low voltage switchgear designed and tested to the ANSI C37.20.1 standard and labeled to the UL 1558 standard. Switchgear short circuit ratings per these standards are based on two 30-cycle withstand tests with a 15-second interval in between tests performed at 15% power factor at 635VAC maximum. Switchboards however are only required to pass a single 3-cycle (0.05 second) short circuit test at 20% power factor and 600VAC maximum. Switchboards standards of UL 891 and NEMA PB-2 do not include requirements or testing procedures for a withstand test greater than 3-cycles since the circuit breakers used in these switchboards are UL 489 listed and all have an instantaneous trip function. With an instantaneous trip function, the breaker is expected to open within 3-cycles to prevent catastrophic damage to the distribution equipment. Figure TCC-2 references the 30-cycle time period (0.5 seconds) by Point B and the 3-cycle time period (0.05 seconds) by Point C. Even though UL 891 does not address a 30-cycle withstand rating, there are UL 891 listed switchboards available with this higher duration withstand rating. These switchboards are tested to the ANSI test standards and are witnessed by UL and thus can be labeled as suitable for applications requiring a 30-cycle withstand rating. When is a 30-Cycle Withstand Rating required? As mentioned previously, the 30-cycle withstand rating is required for some equipment by the standards for which they are designed and tested. The reason the ANSI standards for switchgear require the 30-cycle withstand rating is that this equipment is designed to accept UL 1066/ANSI C37 circuit breakers which are not required to have an instantaneous trip function. This is why any overcurrent device mounted in a traditional UL 891 switchboard with a 3-cycle withstand rating must have an instantaneous trip. Figures TCC-1 and TCC-2 below show typical time current curves for a main and feeder device. Figure TCC-1 shows a 4000A insulated case circuit breaker (ICCB) main and 1200A molded case circuit breaker (MCCB) feeder both with instantaneous trips. Figure TCC-2 shows the same main and feeder devices, however the main is now a low voltage power circuit breaker (LVPCB) without an instantaneous trip. In figure TCC-1 you can see that the main device will detect the faults greater than 33,000A at 0.01 seconds and due to the mechanical function of the breaker, will clear these faults within 3-cycles. In figure TCC-2 the same fault will continue until cleared by the short time function of the main device which will initiate breaker tripping in about 25-cycles (0.416 seconds) after the short-time pickup has been exceeded. Main 2 requires a switchboard with the 30-cycle withstand rating while Main 1 does not. CURRENT IN AMPERES CURRENT IN AMPERES 1000 1000 MAIN-2 ComponentName MAIN-1 GE PowerBreak II, EGTU SS Trip 4000.0 A Plug 4000.0 A Settings Phase LTPU/LTD (0.5-1 x In) 0.50X (2000A); Min CB STPU (1.5-9 x LTPU) 1.5X (3000A) STD (ST01 - ST11) ST02-Min (I^2t Out) INST (2-9 x In) 9X (36000A) Override (HSIOC) Fixed (50200A) 100 MAIN-1 100 FDR-1 10 B 1 0.10 0.01 C 0.5 1 10 100 1K 10K Figure TCC-1 A ComponentName FDR-2 GE SK, MVT Plus/PM SKL Trip 1200.0 A Plug 1200.0 A Settings Phase LTPU (0.5-1.0 x P) 0.5 (600A) LTD (1-4) 1 STPU (1.5-9 x LTPU) 1.5 (900A) STD (1-4) 1 (I^2t Out) INST (1.5-10 x P) 1.5 (1800A) 0.10 0.01 100K SWBD-1.tcc Ref. Voltage: 480V Current in Amps x 1 SWBD-1.drw 1 T IM E IN S E C O N D S 10 FDR-2 T IM E IN S E C O N D S ComponentName FDR-1 GE SK, MVT Plus/PM SKL Trip 1200.0 A Plug 1200.0 A Settings Phase LTPU (0.5-1.0 x P) 0.5 (600A) LTD (1-4) 1 STPU (1.5-9 x LTPU) 1.5 (900A) STD (1-4) 1 (I^2t Out) INST (1.5-10 x P) 1.5 (1800A) ComponentName MAIN-2 GE WavePro, EGTU WPS-40 Trip 4000.0 A Plug 4000.0 A Settings Phase LTPU/LTD (0.5-1 x In) 0.50X (2000A); C-1 STPU (1.5-9 x LTPU) 2X (4000A) STD (ST01 - ST11) ST11-Min (I^2t Out) 0.5 1 10 100 1K 10K 100K SWBD-2.tcc Ref. Voltage: 480V Current in Amps x 1 SWBD-2.drw Figure TCC-2 There are UL 489 listed breakers available on the market that are advertised with switchable instantaneous trip functions. When many of these breakers are investigated, the switchable function does not switch the instantaneous off, but simply increases the instantaneous pickup to a fixed high level setting. The reason these breakers are capable of being provided in a traditional UL 891 switchboard with only a 3-cycle fault withstand rating is that they continue to retain an instantaneous trip function. Breakers available without an instantaneous trip function are not listed to UL 489, but rather are low voltage power circuit breakers listed to UL 1066 and built per the standards of ANSI C37. These true UL 1066/ANSI rated low voltage power circuit breakers are available in GE Spectra and PowerBreak switchboards as main devices without instantaneous trip functions when these switchboards are provided with a 30-cycle withstand rating to accommodate these breakers. If the designer of an electrical system chooses to achieve the 0.01 second selectivity by eliminating the instantaneous function on the main device, he can choose to use UL 891 switchboards that are tested for a 30-cycle withstand. However, the designer must be aware of consequences of an increased arc flash hazard that is present with this design approach. How does meeting selectivity affect Arc Flash Hazard risk categories? The awareness of arc flash hazards has made tremendous strides in recent years. The standard for electrical safety in the workplace started in the 1970s when OSHA asked the NFPA to create a standard. This standard became NFPA 70E. Awareness in the general industry started increasing when the 2002 edition of the NEC was published requiring arc flash warning labels on equipment that was likely to be worked on or maintained while energized. Around the same time IEEE 1584 was published which provided calculations to quantify arc flash thermal energy release and the aid in the determination of appropriate personal protective equipment (PPE) to protect workers from arc flash. While this paper is not intended to be a tutorial on arc flash, there are a few facts that must be remembered. An arc flash is a violent event which releases thermal and mechanical energy from an arc, which can be as hot as the sun’s surface and can vaporize copper to 67,000 times its solid volume propelling from the incident area through a pressure wave with deafening sound. An arc flash energy magnitude is determined by the magnitude of the current in the arc, the time to clear the arc, and the distance of the worker from that arc, in addition to other variables which are not under the control of the designer. The hazard risk categories for personal protective equipment (PPE) are certified for the level of heat energy applied over a given area to allow the worker to survive the incident with no worse than “curable” (second degree) burns on his torso. Looking back at our examples in Figure TCC-1 and TCC-2 which show how removing the instantaneous trip function on the main can increase selectivity, we will now look at arc flash hazard categories for each of these main versus feeder protection schemes. For the simple system shown in Figure TCC-1 with a 4000A main with an instantaneous trip in a UL 489 switchboard and an available fault current of 65kA the arc flash level is calculated to 14 cal/cm², which would be within the capabilities of Category 3 PPE. Category 3 PPE consists of cotton underwear, flame resistant (FR) shirt and pant and flame resistant (FR) coveralls. This same piece of equipment shown in Figure TCC-2 designed for instantaneous selectivity (0.01 second) with a main device without instantaneous trip protection would have an arc flash level of 73 cal/cm² which exceeds the capabilities of all hazard risk categories. There is no appropriate PPE recommended by NFPA 70E for arc flash energies that exceed 40 cal/cm², because the blast effects of arc flash are a bigger concern than the thermal effects and there is no recognized protection against the blast effects of an arc flash for these high levels. Reference Figures AFL-1 and AFL-2 for respective Arc Flash and Shock Hazard equipment labels for the examples in TCC-1 and TCC-2. The electrical designer now has a tough decision to make with regard to the need for instantaneous selectivity and the corresponding increase in the arc flash hazard category for the equipment. The scenario presented in the example of TCC-2 and AFL-2 utilized a switchboard with a 30 cycle bus withstand rating, an ANSI rated main circuit breaker without instantaneous and a molded case circuit breaker feeder rated at 1200A. Many designers would consider true ANSI rated switchgear construction for this type of application instead of a rated and tested switchboard. Using switchgear does not necessarily solve the selectivity or the arc flash hazard risks. Most circuit breaker manufacturers have published tables and guidelines that list the various combinations of overcurrent protection devices whose instantaneous trips have been found to be selective with each other along with the corresponding maximum fault values for which the combinations achieve instantaneous selectivity. Many of the combinations require the use of molded case feeders because the same level of selectivity is not achieved with the ANSI rated devices. Using switchgear could hinder the ability to selectively coordinate the downstream combination of devices. The arc flash incident energy will be different when switchgear is applied due to the difference in the input data used in the calculations for low voltage switchgear versus switchboards. The gap measurement (conductor phase spacing gaps) used for switchboard construction is 25mm but increases to 32mm for switchgear. The working distance measurement used in the calculations also is different between the equipment types. For switchboards the input data is 18” while for switchgear the data used is 24”. While these differences in input data for the different types of equipment do change the calculated incident energy, the low voltage switchgear does not present a lower hazard risk category. The incident energy available when utilizing switchgear in lieu of a switchboard for the scenario presented in TCC-2 is 43 cal/cm². This value is still greater than the thermal energy rating of Category 4 PPE and so no suitable PPE is available. The electrical designer has options, but must weigh the benefits of instantaneous selectivity with corresponding arc flash hazards of each design option. Figure AFL-1 Figure AFL-2 What does this all mean? When an electrical designer makes a decision to have a selectively coordinated system, he must first decide what level of selectivity is required. If selectivity is desired beginning at 0.1 seconds, then traditional switchboards can be utilized with careful selection and specification of the overcurrent protective devices. If the design requires selectivity through the instantaneous range beginning at 0.01 seconds, the designer must then be aware of requirements in equipment selection when the instantaneous trip function is eliminated for the main device. If the main device does not have an instantaneous trip function, a 30-cycle withstand rating must be specified for the distribution equipment. With true 30 cycle rated switchboards now available, the designer is not required to specify ANSI rated switchgear to apply main breakers without instantaneous trips. One must also consider the safety aspects of the design and the corresponding differences in arc flash hazard categories for the various types of distribution equipment to be utilized for the project. The designer must work with the owner, architect and AHJ and make them aware of the consequences of the deign criteria. They should work as a team to provide the best compromise between the benefits of selective coordination and arc flash safety hazards that increase with some designs.