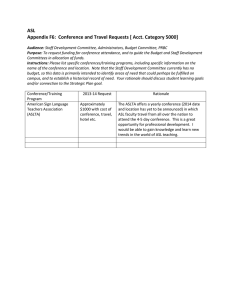

TemBreak Plus

advertisement

Innovators in Protection Technlogy TemBreak Plus For High Demand Applications Ics=Icu=50kA & 85kA, Selectivity with 3:1 MCCB ratio Powerful interrupting Capacities Limitation of System Damage Unique Contact Structure Selectivity Enhanced Switchgear Innovators in Protection Technology High Demand Applications TemBreak TemBreak Plus Plus Marine systems with high demand loads and short cable runs, high fault service rated switchboards, fully selective secure supplies..... .....highly rated electrical installations need highly rated MCCB protection. TemBreak Plus meets this need, with frame sizes and accessories which are completely compatible with the well established TemBreak range. Together TemBreak and TemBreak Plus offer a massive choice of ratings one for every application! Contact your local office for sales, service and application support. (Addresses on rear cover). Innovators in Protection Technology 2 Section Contents Product Features ON F OF Page 5-10 IEC 7 8 4 1 0 N 9 5 2 . + 6 Ratings and Specifications 11-16 Thermal Magnetic Characteristics 17-20 Microprocessor Based Characteristics 21-24 Optional Accessories 25-32 Outline Dimensions 33-42 Selectivity Table 43-44 – 3 X = S 3 4 Section Product Features ON F OF 5 Product Features TemBreak Plus High Demand Applications PowerBreaker Series Ics = 50kA Type XH160PJ XH250PJ XH400PJ XH400PE XH630PJ XH630PE XH800PJ No. of poles XH125PJ 3,4 3,4 3,4 3,4 3,4 3,4 3,4 3,4 3,4 Ampere Frame 125 160 250 400 400 630 630 800 800 20,32,50,63 160 160,250 250,400 250,400 400,630 630 800 800 Rated Current In (Amp) XH800PE 100,125 Rated AC breaking capacity 690V 8/4 15/7.5 18/9 18/9 20/10 45/23 20/10 45/23 20/10 IEC 60947-2 500V 25/13 25/13 42/21 42/21 42/21 65/33 42/21 65/33 42/21 Icu/Ics kA 440V 42/35 42/35 65/50 65/50 65/50 85/43 65/50 85/43 65/50 415V 50/50 50/50 65/50 65/50 65/50 85/50 65/50 85/50 65/50 400V 50/50 50/50 65/50 65/50 65/50 100/50 65/50 100/50 65/50 • • • • Thermal magnetic Microprocessor • • • • • Dimensions 4P 120x155x86 140x165x103 185x260x103 185x260x103 185x260x103 280x273x103 280x273x103 280x273x103 280x273x103 Dimensions 3P 90x155x86 105x165x103 140x260x103 140x260x103 140x260x103 210x273x103 210x273x103 210x273x103 210x273x103 XH125NJ XH250NJ XS400NJ XS400NJ XH400NE XS630NJ XH630NE XS800NJ XH800NE Reference MCCB for accessories LimitorBreaker Series Ics = 65~85kA Type TL-100NJ TL-250NJ TL-400NE TL-630NE TL-800NE TL-1250NE No. of poles 3,4 3,4 3,4 3,4 3,4 3,4 Ampere Frame 100 250 400 630 800 1250 160,250 400 630 800 Rated Current In (Amp) 20,32,50, 63,100 1000 1250 Rated AC breaking capacity 690V - - 25/25 25/25 45/34 45/34 45/34 IEC 60947-2 500V - - 70/70 70/70 75/57 75/57 75/57 Icu/Ics kA 440V 85/85 85/85 85/85 125/70 125/70 125/65 415V 85/85 85/85 85/85 125/70 125/70 125/65 400V 85/85 100/100 100/100 125/70 125/70 125/65 • • Thermal magnetic • • • • Dimensions 4P 120x235x86 185x360X103 185x360x103 280X370X140 280X370X140 280x370x140 Dimensions 3P 90x235x86 140x360x103 140x360x103 210x370x140 210x370x140 210x370x140 XH400NJ XS400NE XS1600NE XS1600NE XS1600NE Microprocessor Reference MCCB XH125NJ for accessories Selectivity Series 3:1 Selectivity Type XS400SE XH400SE XS630SE XH630SE XS800SE XH800SE XS1250SE XH1250SE No. of poles 3,4 3,4 3,4 3,4 3,4 3,4 3,4 3,4 Ampere Frame 400 400 630 630 800 800 1250 1600 250,400 250,400 630 630 800 800 1000 1600 Rated Current In (Amp) 1250 Rated AC breaking capacity 690V 18/9 20/10 20/10 20/10 20/10 20/10 25/19 45/34 IEC 60947-2 500V 30/15 42/21 35/18 42/21 35/18 42/21 45/34 65/49 Icu/Ics kA 440V 42/21 65/33 50/25 65/33 50/25 65/33 65/49 85/64 415V 50/25 65/33 50/25 65/33 50/25 65/33 65/49 65/49 400V 50/25 65/33 50/25 65/33 50/25 65/33 85/64 100/75 • • • • • • • • Dimensions 4P 185x260x103 185x260x103 280x273x103 280x273x103 280x273x103 280x370x120 280x370x120 280x370x140 Dimensions 3P 140x260x103 140x260x103 210x273x103 210x273x103 210x273x103 210x273x103 210x370x120 210x370x140 XS400NE XH400NE XS630NE XH630NE XS800NE XH800NE XS1250NE XS1600NE Microprocessor Reference MCCB for accessories 6 Product Features TemBreak Plus High Demand Applications Limitation of System Damage Powerful Interrupting Capacities I peak kA Plus Plus XH125PJ XH125NJ 50 TL100NJ Icu = 85kA Ics = 85kA Conventional MCCB 2 It 9 Icu = 50kA Ics = 50kA TemBreak Plus Icu = 50kA Ics = 25kA 2 It t The majority of distribution systems are designed to an ultimate short circuit rating (Icu). An Icu rated MCCB provides the optimum protection in terms of safe and economical selection. Certain applications may require protection which is designed to the more onerous service short circuit rating (Ics). Terasaki's TemBreak Plus range can provide a wide choice of MCCBs with superior Ics ratings up to 85kA at 440V AC. Icu=o-co 2 Full Short Circuits Ics=o-co-co 3 Full Short Circuits Unique Contact Structure During a fault condition, a circuit breaker with excellent current limiting ability such as TemBreak Plus, can substantially reduce damage to the electrical system and thus minimise downtime. This current limiting feature reduces the peak let through current (Ipeak) and energy let through (I2t) during fault conditions. Selectivity Enhanced Switchgear T LONG TIME I1 SHORT TIME INSTANTANEOUS GROUND FAULT T1 0.9 CURR. 0.85 SETTING IG I2 T2 I3 I1 I CT RATED CURRENT In 1250 A 1.0 1250 TIME A SETTING 10 0.63 T1 0.8 1.0 x In I2 PICK UP x I0 30 SEC at 6 x I1 0.15 x I0 SHORT TIME IG 0.4 X In 0.3 0.4 0.2 0.3 SEC 0.3 0.1 I2t 0.25 0.1 T2 12 3 I3 0.2 20 5 TEST IN Terasaki's TemBreak Plus MCCBs achieve this exceptional current limiting performance by utilising a unique contact structure which we call the Fast Break Mechanism (FBM). The U-Shaped contact of this mechanism assists in the electromagnetic repulsion of the contact tips for fast arc extinction.The 50kA PowerBreaker Series uses one FBM per pole whilst the LimitorBreaker Series uses two FBM per pole to achieve its rating of 85kA. xI0 RATED CUR. (A) 10 0.2 9 6 8 2 15 BASE CUR. IC 4 0.95 0.8 TG 6 0.1 OFF ON TG 0.8 SEC T2 SEC at 10 x I0 The need for a continuous and reliable power supply places increased emphasis on selectivity requirements in today's electrical distribution system. The Selectivity Series utilises microprocessor based protection, giving enhanced selectivity. This ensures 3:1 ratio between the upstream and downstream MCCBs. For further details please refer to the selectivity table on page 31 of this catalogue. 7 Product Features TemBreak Plus High Demand Applications Very often, MCCBs must grade with other protective devices that may not have adjustable characteristics. This could be either a downstream fuse or an upstream electricty authority relay. Each microprocessor based TemBreak Plus can achieve as standard over 200,000 independant time current characteristics. This unique curve flexibility enables TemBreak Plus to achieve full selectivity even in the tightest of grading systems. Microprocessor Time Current Characteristics 4 0.9 0.7 1.0 0.3 0.3 0.4 0.2 0.4 0.1 IG 0.1 0.8 SEC TG X In Ground fault trip (GFT) Characteristics xI0 I1 30 5 T1 SEC at 6 x I1 Long time-delay (LTD) trip characteristic 10 8 6 5 4 6 0.2 4 3 2 2 I2 8 0.15 10 x I0 0.25 0.3 0.1 T2 SEC Short time-delay (STD) trip characteristic 1 50 40 30 Tripping time 1.0 0.8 20 minute 0.2 20 10 2 30 Pre-trip alarm (PTA) characteristics 0.95 0.85 1 50 40 x I1 IP 15 0.9 3 hour 0.8 20 10 8 6 5 4 OFF ON T2 SEC at 10 x I0 3 Short time-delay I2t ramp selector switch second 2 1 0.8 0.6 0.5 0.4 0.3 0.2 0.1 0.08 0.06 0.05 0.04 0.03 9 6 0.02 0.01 0.008 12 3 I3 Percent x[In] 2000 1500 700 800 900 1000 600 500 400 300 250 200 150 125 60 70 80 90 100 70 80 90 100 60 50 40 30 25 20 15 8 9 10 0.006 0.005 Percent x[Io] x I0 Instantaneous (INST) trip characteristic Microprocessor Adjustment Facia TRIP INDICATORS RESET T LONG TIME I1 SHORT TIME INSTANTANEOUS GROUND FAULT PRE TRIP ALARM T1 0.9 CURR. 0.85 SETTING IG I2 T2 0.8 TG I3 I1 I CT RATED CURRENT In 1250 A 1250 1.0 xI0 RATED CUR. (A) TIME A SETTING 10 T1 0.8 1.0 x In PICK UP 10 x I0 30 SEC at 6 x I1 0.15 x I0 SHORT TIME IP X In 0.3 0.4 0.1 TG 0.8 SEC T2 SEC at 10 x I0 Example XS1250SE 8 1.0 0.4 0.2 OFF ON 0.9 0.8 0.7 IG 0.3 SEC 0.3 0.1 I2t 0.25 0.1 T2 12 3 I3 0.2 20 5 TEST IN 0.63 I2 0.2 9 6 8 2 15 BASE CUR. IC 6 4 0.95 x I1 Product Features TemBreak Plus High Demand Applications Adjustable Time Settings Flexibility In addition to TemBreak microprocessor MCCBs being the most flexible on the market, a number of important features are available as STANDARD! Most other MCCB manufacturers offer these relevant features at a premium price. Provision of adjustable LTD T1 settings and STD T2 setting are important to match the protective characteristic to the load requirement. It is also extremely useful to provide flexible grading with other devices. 30 sec T1 5 sec When co-ordinating between MCCB and fuses, it can often be difficult to obtain the required selectivity due to the different shape of the time current curves. With a flick of a switch the I2t ramp can be enabled to make grading easier. 300 msec Inductive loads such as motors often produce a transient inrush on initial switching. In this application it is important to have an adjustable instantaneous trip to set above this inrush current. 2 Adjustable I T Ramp T2 100 msec Adjustable Inst. Trip motor starting curve L.V. fuse downstream I3 300% 1200% 9 Product Features TemBreak Plus High Demand Applications Pre-Trip Alarm Function (Optional) High Frequency Harmonics Detected 50 Conventional r.m.s. Output contact (1a) of the pre-trip alarm TemBreak detection can ignore % higher frequency harmonics Total SHT SHT Harmonic Distortion 3 Computer Essential Load Non-essential Load Non-essential Load Electronic office equipment is being increasingly used in today's buildings and factories. The power demand at peak time can reach overload levels of the breakers installed in the system. If such a situation continued a sudden trip may be generated by the long time-delay trip function of the breaker. The pre-trip alarm prevents this 'sudden trip' by tripping out non-essential loads thus ensuring an uninterrupted supply to essential loads. 400A TemBreak MCCBs employ a True R.M.S. detection through a process of sampling and integrating. Even those MCCBs that claim True R.M.S. may only do so up until the 3rd or 5th Harmonic. Ignoring higher frequency harmonics can lead to 'under protection' of the conductor. By utilizing a high sampling rate of 500 µsec TemBreak microprocessor MCCBs detect up until and including the 19th Harmonic. Choice of Protection Suitable for Isolation I (ON) 5 7 9 11 13 15 17 19 Frequency spectrum TRIP 400A O (OFF) 400A 0.8 Ir Im 0.63 1 xIn Thermal Adjustment 63% - 100% x In TemBreak Plus MCCBs from 125AF to 1600AF are suitable for isolation as defined by IEC 947-2. Positive Contact Indication (PCI) is achieved via the toggle mechanism. Padlocks can only be installed if the contacts are fully open. 10 8.5 6 OFF O ON I 7.1 10 5 xIn Magnetic Adjustment 500% - 1000% x In As well as microprocessor MCCBs from 125A to 1600A, Terasaki is one of the few manufacturers who can still offer a complete range of Thermal Magnetic MCCBs up to 800AF. The thermal adjustment of the TemBreak Plus range, 63% to 100% of the nominal rating, is one of the biggest on the market. This proven form of electromechanical technology still represents by far the largest type of MCCBs sold on the European Market. Wouldn't you prefer the choice? Section Ratings and Specifications IEC 7 8 4 1 0 9 5 2 . + 6 – 3 X = 11 Ratings and Specifications TemBreak Plus PowerBreaker Series Ampere Frame Type 125 XH125PJ Number of poles RATED CURRENT (A). [In] Calibrated at 45°C 3 NRC RATED IMPULSE WITHSTAND VOLTAGE Uimp [kV] AC RATED INSULATION VOLTAGE [Ui] AC RATED BREAKING CAPACITY sym. r.m.s. [kA] IEC 947-2 [Icu] IEC 947-2 [Ics] BS EN 60947-2 [Icu] BS EN 60947-2 [Ics] CEI EN 60947-2 [Icu] CEI EN 60947-2 [Ics] 690V 500V 440V 415V 400V 380V 240V 240-690V 250V 125V Without Inst. DC RATED BREAKING CAPACITY [kA] RATED SHORT TIME CURRENT r.m.s. [kA] [Icw] UTILIZATION CATEGORY OUTLINE DIMENSIONS (mm) w h d1 d2 Weight (kg) marked standard type CONNECTIONS AND MOUNTINGS Front Terminal screw (FCS) connected (FC) Attached flat bar (BAR) Solderless terminal (PWC) Rear Bolt stud (REB) connected (RC) Flat bar stud (REF) Plug-in (PM) For switchboard (PRC/PMB) For distribution board Draw-out (DO) STANDARD FEATURES ON-OFF colour indication Trip button PROTECTIVE FUNCTIONS Electronic type Adjustable LTD, STD & INST. Adjustable GFT or Adjustable PTA (option) Trip Indicators (option) Thermal-magnetic type Thermal and fixed magnetic trips – Thermal and adjustable magnetic trips Adjustable thermal and fixed magnetic trips Adjustable thermal and magnetic trips CODE ACCESSORIES (option) AX,AXE Internally Auxiliary switch AL,ALE mounted Alarm switch SHT Shunt trip UVT Undervoltage trip 3 MOT Externally Motor operator OHE mounted Handle Panel mounted type OHJ operating Breaker mounted type OHH mechanism Variable depth type EHA Handle extension MIF Mechanical Front type MIB interlock Rear type HH Handle holder HL Handle lock TCF Terminal Front conn. type TCR cover Rear conn./ plug-in type TBA Interpole barrier 5 LTF Accessory lead terminal 5 LTS D.F Door flange IP20 IP20 Protection (Plug-in type) 20 32 50 63 100 125 8 690 160 XH160PJ 4 3 4 ASR NRC ASR min. max. min. max. 13 20 160 100 160 20 32 32 50 40 63 63 100 80 125 8 690 8/4 25/13 42/35 50/50 50/50 50/50 85/50 – 40 40 – A 90 155 86 104 1.3 1 1 120 1.6 15/7.5 25/13 42/35 50/50 50/50 50/50 85/50 – 40 40 – A 105 165 103 124 2.1 1 1 140 2.6 250 XH250PJ 400 XH400PJ 3 NRC 4 ASR min. max. 160 100 160 250 160 250 3 NRC 4 3 4 ASR NRC ASR min. max. min. max. 250 160 250 400 200 400 400 250 400 8 690 8 690 18/9 42/21 65/50 65/50 65/50 65/50 85/50 – 40 40 – A 140 260 103 131 4.7 1 1 185 145 6.1 400 XH400PE 8 690 18/9 42/21 65/50 65/50 65/50 65/50 85/50 – 40 40 – A 140 260 103 131 4.7 1 1 185 145 6.1 1 20/10 1 42/21 65/50 65/50 65/50 65/50 100/50 5 – – 5 (0.3 sec) B 140 185 260 103 131 145 4.8 6.2 • • – O O – O O – O O – O O – O • • • • • • • • • • – – – – – – – – – – – – • • (PTA only) – – – • – – – • – – – – • – – – • – – – – •(AXE) •(ALE) • • • • • • – • • • • • • • 4 • – • • •(AXE) •(ALE) • • • • • • – • • • • • • • 4 • – • • •(AX) •(AL) • • • • • • – • • • • • • • 4 • – • • •(AX) •(AL) • • • • • • – • • • • • • • 4 • – • • •(AX) •(AL) • • • • • • – • • • • • • • 4 • – • • • (BAR) 2 O O – O O – O • • (BAR) 2 O O – O O – O (BAR) 2 O O – O – – O (BAR) 2 Notes: NRC : Nominal Rated Current ASR : Adjustable Setting Range : Standard. This configuration is used unless otherwise specified. • : Optional. Specify when ordering. : Yes or available. • – : No or not available. 12 1 2 3 4 5 : : : : : The application on IT systems on this voltage is not available. Available on request, contact Terasaki for details. For AC UVT, a UVT controller is mounted externally Line side interpole bariers supplied as standard. Draw out leads horizontally. Ratings and Specifications TemBreak Plus PowerBreaker Series Ampere Frame Type 630 XH630PJ 630 800 XH630PE XH800PJ 800 XH800PE Number of poles RATED CURRENT (A). [In] Calibrated at 45°C 3 NRC RATED IMPULSE WITHSTAND VOLTAGE Uimp [kV] AC RATED INSULATION VOLTAGE [Ui] AC RATED BREAKING CAPACITY sym. r.m.s. [kA] IEC 947-2 [Icu] IEC 947-2 [Ics] BS EN 60947-2 [Icu] BS EN 60947-2 [Ics] CEI EN 60947-2 [Icu] CEI EN 60947-2 [Ics] 8 690 8 690 8 690 8 690 1 45/23 1 65/33 85/43 85/50 100/50 100/50 125/63 – 40 40 – A 210 280 273 103 145 9.0 11.5 1 20/10 1 42/21 65/50 65/50 65/50 65/50 100/50 10 – – 10 (0.3 sec) B 210 280 273 103 145 9.0 11.5 1 45/23 1 65/33 85/50 85/50 100/50 100/50 125/63 – 40 40 – A 210 280 273 103 145 9.0 11.5 1 20/10 1 42/21 65/50 65/50 65/50 65/50 100/50 10 – – 10 (0.3 sec) B 210 280 273 103 145 9.0 11.5 – – – – 4 3 4 3 4 3 4 ASR NRC ASR NRC ASR NRC ASR min. max. min. max. min. max. min. max. 400 250 400 630 315 630 800 500 800 800 400 800 630 400 630 690V 500V 440V 415V 400V 380V 240V 240-690V 250V 125V Without Inst. DC RATED BREAKING CAPACITY [kA] RATED SHORT TIME CURRENT r.m.s. [kA] [Icw] UTILIZATION CATEGORY OUTLINE DIMENSIONS (mm) w h d1 d2 Weight (kg) marked standard type CONNECTIONS AND MOUNTINGS Front Terminal screw (FCS) connected (FC) Attached flat bar (BAR) Solderless terminal (PWC) Rear Bolt stud (REB) connected (RC) Flat bar stud (REF) Plug-in (PM) For switchboard (PRC/PMB) For distribution board Draw-out (DO) STANDARD FEATURES ON-OFF colour indication Trip button PROTECTIVE FUNCTIONS Electronic type Adjustable LTD, STD & INST. Adjustable GFT or Adjustable PTA (option) Trip Indicators (option) Thermal-magnetic type Thermal and fixed magnetic trips Thermal and adjustable magnetic trips – Adjustable thermal and fixed magnetic trips Adjustable thermal and magnetic trips ACCESSORIES (option) CODE Internally Auxiliary switch AX,AXE mounted Alarm switch AL,ALE Shunt trip SHT Undervoltage trip 3 UVT Externally Motor operator MOT mounted Handle Panel mounted type OHE operating Breaker mounted type OHJ mechanism Variable depth type OHH Handle extension EHA Mechanical Front type MIF interlock Rear type MIB Handle holder HH Handle lock HL Terminal Front conn. type TCF cover Rear conn./ plug-in type TCR Interpole barrier TBA 5 Accessory lead terminal LTF LTS Door flange D.F IP20 Protection (Plug-in type) IP20 • • • • O – O O – • O – O O – • O – O O – • O – O O – • 2 2 2 2 • • • • • • • • – – – • • • – – – • • • – – – • – – – – – – – • – – – – •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • • • • • – • • 2 2 Notes: NRC : Nominal Rated Current ASR : Adjustable Setting Range • : Standard. This configuration is used unless otherwise specified. : Optional. Specify when ordering. : Yes or available. • – : No or not available. 1 2 3 4 5 : : : : : The application on IT systems on this voltage is not available. Available on request, contact Terasaki for details. For AC UVT, a UVT controller is mounted externally Line side interpole bariers supplied as standard. Draw out leads horizontally. 13 Ratings and Specifications TemBreak Plus LimitorBreaker Series Ampere Frame Type Number of poles RATED CURRENT (A). [In] Calibrated at 45°C 100 400 400 1600 1600 1600 TL-100NJ TL-250NJ TL-400NE TL-630NE TL-800NE TL1250NE 3 NRC 4 ASR min. max. 160 100 160 250 160 250 3 NRC 4 3 4 3 4 ASR NRC ASR NRC ASR min. max. min. max. min. max. 250 160 250 630 315 630 800 400 400 400 250 400 3 4 NRC ASR min. max. 1000 500 1000 1250 630 1250 8 690 8 690 8 690 – – – – 85/85 85/85 85/85 85/85 100/100 – 40 40 – A 90 120 235 86 104 2.2 2.7 1 25/25 1 70/70 85/85 85/85 100/100 100/100 130/130 – 40 40 – A 140 185 360 103 145 7.1 9.1 25/25 70/70 85/85 85/85 100/100 100/100 130/130 15 – • • • 3 NRC 20 32 50 63 100 RATED IMPULSE WITHSTAND VOLTAGE Uimp [kV] AC RATED INSULATION VOLTAGE [Ui] AC RATED BREAKING CAPACITY sym. r.m.s. [kA] IEC 947-2 [Icu] IEC 947-2 [Ics] BS EN 60947-2 [Icu] BS EN 60947-2 [Ics] CEI EN 60947-2 [Icu] CEI EN 60947-2 [Ics] 690V 500V 440V 415V 400V 380V 240V 240-690V 250V 125V Without Inst. DC RATED BREAKING CAPACITY [kA] RATED SHORT TIME CURRENT r.m.s. [kA] [Icw] UTILIZATION CATEGORY OUTLINE DIMENSIONS (mm) w h d1 d2 Weight (kg) marked standard type CONNECTIONS AND MOUNTINGS Front Terminal screw (FCS) connected (FC) Attached flat bar (BAR) Solderless terminal (PWC) Rear Bolt stud (REB) connected (RC) Flat bar stud (REF) Plug-in (PM) For switchboard (PRC/PMB) For distribution board Draw-out (DO) STANDARD FEATURES ON-OFF colour indication Trip button PROTECTIVE FUNCTIONS Electronic type Adjustable LTD, STD & INST. Adjustable GFT or Adjustable PTA (option) Trip Indicators (option) Thermal-magnetic type Thermal and fixed magnetic trips Thermal and adjustable magnetic trips – Adjustable thermal and fixed magnetic trips Adjustable thermal and magnetic trips ACCESSORIES (option) CODE Internally Auxiliary switch AX,AXE mounted Alarm switch AL,ALE Shunt trip SHT Undervoltage trip 3 UVT Externally Motor operator MOT mounted Handle Panel mounted type OHE operating Breaker mounted type OHJ mechanism Variable depth type OHH Handle extension EHA Mechanical Front type MIF interlock Rear type MIB Handle holder HH Handle lock HL Terminal Front conn. type TCF cover Rear conn./ plug-in type TCR Interpole barrier TBA 5 Accessory lead terminal LTF LTS Door flange D.F IP20 Protection (Plug-in type) IP20 4 ASR min. max. 12.5 20 20 32 32 50 40 63 63 100 1 1 15 (0.3 sec) B 140 185 360 103 145 7.1 9.1 8 690 8 690 8 690 1 45/34 1 75/57 125/70 125/70 125/70 125/70 150/113 15 – – 15 (0.3 sec) B 210 280 370 140 191 25.8 33.5 1 45/34 1 75/57 125/70 125/70 125/70 125/70 150/113 15 – – 15 (0.3 sec) B 210 280 370 140 191 25.8 33.5 1 45/34 1 75/57 125/65 125/65 125/65 125/70 150/113 15 – – 15 (0.3 sec) B 210 280 370 140 191 26.0 33.7 – – • – – • • – – – – – – – – – – – – – – – • • • • • • • • • • – – – – – – • • (PTA only) – • • • • • • • • • – – • – – – – • – – – – – – – – – – – – – – – – •(AXE) •(ALE) • • • – • • – • • • • • • • 4 • – • • •(AX) •(AL) • • • – • • – • • • • • • • 4 • – • • •(AX) •(AL) • • • – • • – • • • • • • •4 • – • • •(AX) •(AL) • • • • • • • • • • • • – • • – • • •(AX) •(AL) • • • • • • • • • • • • – • • – • • – – 2 – – 2 Notes: NRC : Nominal Rated Current ASR : Adjustable Setting Range • : Standard. This configuration is used unless otherwise specified. : Optional. Specify when ordering. : Yes or available. • – : No or not available. 14 1 2 3 4 5 : : : : : The application on IT systems on this voltage is not available. Available on request, contact Terasaki for details. For AC UVT, a UVT controller is mounted externally Line and load side interpole bariers supplied as standard. Draw out leads horizontally. Ratings and Specifications TemBreak Plus Selectivity Series Ampere Frame Type Number of poles RATED CURRENT (A). [In] Calibrated at 45°C RATED IMPULSE WITHSTAND VOLTAGE Uimp [kV] AC RATED INSULATION VOLTAGE [Ui] AC RATED BREAKING CAPACITY sym. r.m.s. [kA] IEC 947-2 [Icu] IEC 947-2 [Ics] BS EN 60947-2 [Icu] BS EN 60947-2 [Ics] CEI EN 60947-2 [Icu] CEI EN 60947-2 [Ics] Without Inst. DC RATED BREAKING CAPACITY [kA] RATED SHORT TIME CURRENT r.m.s. [kA] [Icw] UTILIZATION CATEGORY OUTLINE DIMENSIONS (mm) 690V 500V 440V 415V 400V 380V 240V 240-690V 250V 125V w h d1 d2 Weight (kg) • marked standard type CONNECTIONS AND MOUNTINGS Front Terminal screw (FCS) connected (FC) Attached flat bar (BAR) Solderless terminal (PWC) Rear Bolt stud (REB) connected (RC) Flat bar stud (REF) Plug-in (PM) For switchboard (PRC/PMB) For distribution board Draw-out (DO) STANDARD FEATURES ON-OFF colour indication Trip button PROTECTIVE FUNCTIONS Electronic type Adjustable LTD, STD & INST. Adjustable GFT or Adjustable PTA (option) Trip Indicators (option) Thermal-magnetic type Thermal and fixed magnetic trips Thermal and adjustable magnetic trips Adjustable thermal and fixed magnetic trips Adjustable thermal and magnetic trips CODE ACCESSORIES (option) AX,AXE Internally Auxiliary switch AL,ALE mounted Alarm switch SHT Shunt trip UVT Undervoltage trip 2 MOT Externally Motor operator OHE mounted Handle Panel mounted type OHJ operating Breaker mounted type OHH mechanism Variable depth type EHA Handle extension MIF Mechanical Front type MIB interlock Rear type HH Handle holder HL Handle lock TCF Terminal Front conn. type TCR cover Rear conn./ plug-in type TBA Interpole barrier LTF 5 Accessory lead terminal LTS D.F Door flange IP20 IP20 Protection (Plug-in type) 400 400 400 630 XS400SE-C XS400SE XH400SE XS630SE-C XS630SE 3 NRC 4 ASR min. max. 250 125 250 400 250 400 8 690 3 NRC 4 ASR min. max. 250 125 250 400 250 400 8 690 3 NRC 4 3 4 ASR NRC ASR min. max. min. max. 250 125 250 630 400 630 400 200 400 8 8 690 690 3 NRC 16/8 22/11 30/15 35/18 35/18 35/18 50/25 5 – – 5 (0.3 sec) B 18/9 30/15 42/21 50/25 50/25 50/25 85/43 5 – – 5 (0.3 sec) B 20/10 42/21 65/33 65/33 65/33 65/33 100/50 5 – – 5 (0.3 sec) B 16/8 25/13 30/15 35/18 40/20 40/20 50/25 10 – – 10 (0.3 sec) B 20/10 35/18 50/25 50/25 50/25 50/25 85/43 10 – 10 (0.3 sec) B 140 260 103 131 4.8 140 260 103 131 4.8 140 260 103 131 4.8 210 273 103 145 9.6 210 273 103 145 9.6 185 145 6.2 145 6.2 (BAR) O O – O O – 185 145 6.2 – • • • O O – O O – 185 (BAR) O O – O O – (BAR) 630 280 12 4 ASR min. max. 630 400 630 8 690 280 12 – • • O – O O – O – O O – • • • • • • • • • • • • (PTA only) • 2 • • (PTA only) • 2 • • (PTA only) • 2 • • • • • • – – – – – – – – – – – – – – – – – – – – •(AX) •(AL) • • • • • • • • • • • • • • 4 • • • • •(AX) •(AL) • • • • • • • • • • • • • • 4 • • • • •(AX) •(AL) • • • • • • • • • • • • • • 4 • • • • •(AX) •(AL) • • • • • • • • • • • • • • • • • • •(AX) •(AL) • • • • • • • • • • • • • • • • • • 2 2 Notes: NRC : Nominal Rated Current ASR : Adjustable Setting Range : Standard. This configuration is used unless otherwise specified. • : Optional. Specify when ordering. : Yes or available. • – : No or not available. 2 3 4 5 : : : : Available on request, contact Terasaki for details. For AC UVT, a UVT controller is mounted externally. Line side interpole barriers are supplied as standard. Draw-out leads, horizontally. 15 Ratings and Specifications TemBreak Plus Selectivity Series Ampere Frame Type Number of poles RATED CURRENT (A). [In] Calibrated at 45°C RATED IMPULSE WITHSTAND VOLTAGE Uimp [kV] AC RATED INSULATION VOLTAGE [Ui] AC RATED BREAKING CAPACITY sym. r.m.s. [kA] 690V IEC 947-2 [Icu] IEC 947-2 [Ics] 500V BS EN 60947-2 [Icu] BS EN 60947-2 [Ics] 440V CEI EN 60947-2 [Icu] CEI EN 60947-2 [Ics] 415V 400V 380V 240V 240-690V Without Inst. 250V DC RATED BREAKING 1 125V CAPACITY [kA] RATED SHORT TIME CURRENT r.m.s. [kA] [Icw] UTILIZATION CATEGORY OUTLINE DIMENSIONS (mm) w h d1 d2 Weight (kg) • marked standard type CONNECTIONS AND MOUNTINGS Front Terminal screw (FCS) connected (FC) Attached flat bar (BAR) Solderless terminal (PWC) Rear Bolt stud (REB) connected (RC) Flat bar stud (REF) Plug-in (PM) For switchboard (PRC/PMB) For distribution board Draw-out (DO) STANDARD FEATURES ON-OFF colour indication Trip button PROTECTIVE FUNCTIONS Electronic type Adjustable LTD, STD & INST. Adjustable GFT or Adjustable PTA (option) Trip Indicators (option) Thermal-magnetic type Thermal and fixed magnetic trips Thermal and adjustable magnetic trips Adjustable thermal and fixed magnetic trips Adjustable thermal and magnetic trips ACCESSORIES (option) AX,AXE Internally Auxiliary switch AL,ALE mounted Alarm switch SHT Shunt trip UVT 3 Undervoltage trip MOT Externally Motor operator OHE mounted Handle Panel mounted type OHJ operating Breaker mounted type OHH mechanism Variable depth type EHA Handle extension MIF • Mechanical Front type MIB interlock Rear type HH Handle holder HL Handle lock TCF Terminal Front conn. type TCR cover Rear conn./ plug-in type TBA Interpole barrier LTF 5 Accessory lead terminal LTS D.F Door flange IP20 IP20 Protection (Plug-in type) 630 800 800 1250 XH630SE XS800SE XH800SE XS1250SE XS1600SE 1600 3 4 3 4 3 4 3 4 NRC ASR NRC ASR NRC ASR NRC ASR min. max. min. max. min.max. min.max. 630 315 630 800 400 800 800 400 800 1000 500 1000 1250 630 1250 8 8 8 8 690 690 690 690 3 4 NRC ASR min.max. 1600 800 1600 20/10 42/21 65/33 65/33 65/33 65/33 100/50 10 – – 10 (0.3 sec) B 20/10 35/18 50/25 50/25 50/25 50/25 85/43 10 – – 10 (0.3 sec) B 20/10 42/21 65/33 65/33 65/33 65/33 100/50 10 – – 10 (0.3 sec) B 25/19 45/34 65/49 65/49 85/64 85/64 100/75 15 – – 15 (0.3 sec) B 45/34 65/49 85/64 85/64 100/75 100/75 125/94 20 – – 20 (0.3 sec) B 210 273 103 145 9.6 210 273 103 145 9.7 210 370 103 145 9.7 210 370 120 171 22.0 210 370 140 191 27.0 280 12.0 – • O – O O – – 2 • • • • • 280 12.5 12.5 28.0 – • • • • O – O O – – O – O O – – O – O O – – – – O – – – 2 • • • – 280 – • • 2 280 8 690 2 • • 2 2 • • • 35.0 – 2 • • • • • 280 2 • • 2 • • • – – – – – – – – – – – – – – – – – – – – •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • • • • • – • • •(AX) •(AL) • • • • • • • • • • • – – • • – • • •(AX) •(AL) • • • • • • • • • • • – – • • – • – Notes: NRC : Nominal Rated Current ASR : Adjustable Setting Range • : Standard. This configuration is used unless otherwise specified. : Optional. Specify when ordering. • : Yes or available. – : No or not available. 16 2 3 5 : Available on request, contact Terasaki for details. : For AC UVT, a UVT controller is mounted externally. : Draw-out leads, horizontally. Section Thermal Magnetic Characteristics N S 17 Thermal Magnetic Characteristics Time/Current Curves XH125PJ, XH160PJ Time/current characteristic curves Time/current characteristic curves XH160PJ XH125PJ Rated curr.(A) NRC 20 32 50 63 100 125 1 50 40 30 20 minute 4 3 hour Magnetic trip current 2 10 8 6 5 4 3 Mag. trip curr. (A) 260±52 420±84 650±130 820±164 1300±260 1550±310 10 8 6 5 4 3 2 1 50 40 30 1 50 40 30 Max. 10 8 6 5 4 3 Min. 2 1 0.8 0.6 1 0.8 0.6 0.5 0.4 0.3 second 2 0.5 0.4 0.3 Min. 20 Tripping Time Tripping Time Mag. trip curr. (A) 1760±176 Max. 20 second Rated curr.(A) NRC 160 20 2 10 8 6 5 4 3 Magnetic trip current 2 1 50 40 30 minute hour 4 3 20, 32, 50, 63, 100A 0.2 0.2 125A Percent Rated Current Percent Rated Current Ambient compensating curves Ambient compensating curves 150 50A, 20A(min.) 63A(min.) 130 140 125A(min.) 130 Calibrated temperature Percent current rating 120 Calibrated at 40°C 45°C 50°C 18 110 Percent current rating 100, 32A(min.) 50, 20A(max.) 100, 32A(max.) 100 63A(max.) 125A(max.) 90 80 0 5 10 160A(max.) 120 Calibrated temperature 110 160A(min.) 100 90 10 20 30 40 15 25 35 45 20 30 40 50 Ambient temperature (°C) 50 55 60 60 65 70 Calibrated at 40°C 45°C 50°C 0 5 10 10 15 20 20 30 40 25 35 45 30 40 50 Ambient temperature (°C) 50 55 60 60 65 70 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 250 200 80 90 100 8000 6000 7000 5000 4000 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 80 90 100 250 0.01 0.008 0.006 0.005 0.006 0.005 200 0.01 0.008 150 0.02 125 0.02 150 0.1 0.08 0.06 0.05 0.04 0.03 125 0.1 0.08 0.06 0.05 0.04 0.03 Thermal Magnetic Characteristics Time/Current Curves XH250PJ, XH400PJ, XH630PJ, XH800PJ Time/current characteristic curves Time/current characteristic curves XH630PJ, XH800PJ XH250PJ, XH400PJ 4 3 Magnetic trip current hour 2 Rated curr.(A) NRC 160 250 400 1 50 40 30 20 Mag. trip curr. (A) 1660±160 2500±250 4000±400 Magnetic trip current 2 Rated curr.(A) NRC 400 630 800 1 50 40 30 20 2 10 8 6 5 4 3 2 Min. Min. 30 1 50 40 30 20 20 Tripping Time 10 8 3 10 8 6 5 4 3 2 2 1 0.8 0.6 0.5 0.4 0.3 1 0.8 0.6 0.5 0.4 0.3 second 0.2 0.2 X10 110 250A max. 400A max. 90 Calibrated at 40°C 45°C 50°C 0 5 10 10 15 20 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 130 Calibrated temperature Percent current rating Percent current rating Ambient compensating curves 120 100 600 Percent Rated Current Ambient compensating curves 250A min. 400A min. 500 300 250 Percent Rated Current 130 X10 X5 200 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 600 500 80 90 100 400 0.01 0.008 0.006 0.005 300 0.01 0.008 250 0.02 200 0.02 150 0.1 0.08 0.06 0.05 0.04 0.03 125 0.1 0.08 0.06 0.05 0.04 0.03 150 X5 125 second 6 5 4 80 90 100 Tripping Time 1 50 40 0.006 0.005 Mag. trip curr. (A) 4000±160 6300±250 8000±400 Max. 10 8 6 5 4 3 minute minute Max. 400 hour 4 3 20 30 40 50 25 35 45 55 30 40 50 60 Ambient temperature (°C) 60 65 70 Calibrated at 40°C 45°C 50°C 120 Calibrated temperature 800A (min) 630A (min) 400A (min) 110 800A (max) 630A (max) 400A (max) 100 90 0 5 10 10 15 20 20 25 30 30 35 40 40 45 50 50 55 60 60 65 70 Ambient temperature (°C) 19 Thermal Magnetic Characteristics Time/Current Curves TL-100NJ, TL-250NJ Time/current characteristic curves Time/current characteristic curves TL-250NJ TL-100NJ 10 8 6 5 4 3 2 1 50 40 30 1 50 40 30 20 20 10 8 6 5 4 0.1 0.08 0.06 0.05 0.04 0.03 0.1 0.08 0.06 0.05 0.04 0.03 0.02 0.02 0.01 0.008 0.006 0.005 0.01 0.008 0.006 0.005 700 800 900 1000 x10 600 500 400 300 250 200 150 125 80 90 100 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 250 200 150 125 80 90 100 x5 Percent Rated Current Percent Rated Current Ambient compensating curves Ambient compensating curves 150 160 63A min 150 140 250A min Calibrated temperature 20A min Calibrated temperature 32.50A min Percent current rating Percent current rating 140 100A min 130 120 110 130 160A min 120 110 250A max 63A max 20A max 100 160A max 100 32.50A max 100A max 90 o Calibrated at 40 C 45oC 20 80 90 o 0 5 10 20 30 40 15 25 35 45 Ambient temperature ( C) 50 55 Calibrated at 40 C 45oC 50oC 0 5 10 10 20 30 40 15 25 35 45 20 35 40 50 Ambient temperature ( C) 50 55 60 6000 7000 8000 0.2 5000 0.2 4000 1 0.8 0.6 0.5 0.4 0.3 3000 1 0.8 0.6 2500 2 2000 3 2 second 3 0.5 0.4 0.3 Mag. trip curr. (A) 1600±160 2500±250 20 2 10 8 6 5 4 Rated curr.(A) NRC 160 250 1 50 40 30 Tripping Time minute 10 8 6 5 4 3 Mag. trip curr. (A) 260±52 420±84 650±130 820±164 1300±260 Magnetic trip current 2 1500 Rated curr.(A) NRC 20 32 50 63 100 20 Tripping Time hour 2 1 50 40 30 second 4 3 Magnetic trip current minute hour 4 3 Section Microprocessor Based Characteristics 21 Microprocessor Based Characteristics Time/Current Curves PowerBreaker and Selectivity Series Time/current characteristic curves Time/current characteristic curves XS400SE, XS400SE-C, XH400SE, XH400PE, IP T 4 3 I1 T1 2 hour hour 4 3 XS630SE, XS630SE-C, XH630SE, XH630PE, XS800SE, XH800SE, XH800PE IP T1 IG I2 1 50 40 30 I1 T 2 T2 1 50 40 I3 I I2 T2 TG I3 I 30 curves based on standard settings Curves based on standard settings 20 minute 10 8 6 5 4 6 5 4 3 2 2 1 50 40 30 1 50 40 30 20 20 10 8 6 5 4 3 10 8 6 5 4 3 2 1 0.8 0.6 1 0.8 0.6 0.5 0.4 second 2 0.5 0.4 0.3 Percent rated current of base current (I0) Overcurrent tripping characteristics CT rated current (A) (In) Base current setting (A): (Io) Long time-delay pick-up current (A): (I1) 250,400 (In) x (0.63-0.8-1.0) (Io) x (0.8-0.85-0.9-0.95-1.0) Non-tripping at (I1) setting x 105% and below. Tripping at 125% and above. Long time-delay time settings (S) (T1) (5–10–15–20–30) at (I1) x 600% current. Setting tolerance ± 20% Short time-delay pick-up current (A): (I2) (Io) x (2-4-6-8-10) Setting tolerance ± 15% Short time-delay time settings (S) (T2) Opening time (0.1, 0.15, 0.2, 0.25, 0.3) in the definite time-delay. Total clearing time is + 50 mS and resettable time -20mS for the time-delay setting Instantaneous trip pick-up current (A) (I3) Continuously adjustable from (Io) x (3 to12) Setting tolerance ± 20% * Pre-trip alarm pick-up current (A) (IP) (I1) x (0.7, 0.8, 0.9, 1.0) Setting tolerance ±10% * Pre-trip alarm time setting (S) (TP) 40 fixed definite time-delay.Setting tolerance ±10% Note: * Optional Note: The underlined values will be applied as standard ratings unless otherwise specified when ordering. Percent rated current of CT rated current (In) 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 250 200 150 125 50 80 90 100 20 40 15 8 9 10 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 80 90 100 600 0.01 0.008 0.006 0.005 0.006 0.005 500 0.01 0.008 400 0.02 300 0.02 250 0.1 0.08 0.06 0.05 0.04 0.03 200 0.1 0.08 0.06 0.05 0.04 0.03 150 0.2 12.5 0.3 0.2 125 second 10 8 3 Tripping Time Tripping Time minute 20 Percent rated current of base current (I0) Overcurrent tripping characteristics CT rated current (A) (In) Base current setting (A): (Io) Long time-delay pick-up current (A): (I1) 630,800 (In) x (0.63-0.8-1.0) (Io) x (0.8-0.85-0.9-0.95-1.0) Non-tripping at (I1) setting x 105% and below. Tripping at 125% & above. Long time-delay time settings (S) (T1) (5–10–15–20–30) at (I1) x 600% current. Setting tolerance ± 20% Short time-delay pick-up current (A): (I2) (Io) x (2-4-6-8-10) Setting tolerance ± 15% Short time-delay time settings (S) (T2) Opening time (0.1, 0.15, 0.2, 0.25, 0.3) in the definite time-delay. Total clearing time is + 50 mS and resettable time -20mS for the time-delay setting. Instantaneous trip pick-up current (A) (I3) Continuously adjustable from (Io) x (3 to12) Setting tolerance ± 20% * Pre-trip alarm pick-up current (A) (IP) (I1) x (0.7, 0.8, 0.9, 1.0) Setting tolerance ±10% * Pre-trip alarm time setting (S) (TP) 40 fixed definite time-delay.Setting tolerance ±10% * Ground fault trip pick-up current (A): (IG) Continiuously adjustable from (In) x (0.1 to 0.4) Setting tolerance ± 15% * Ground fault trip time setting (S): (TG) Opening time (0.1-0.2-0.3-0.4-0.8) in the definite time-delay. Total clearing time is + 50mS and resettable time is - 20mS for the time-delay settings Note: * Optional Note: The underlined values will be applied as standard ratings unless otherwise specified when ordering. Microprocessor Based Characteristics Time/Current Curves LimitorBreaker Series Time/current characteristic curves Time/current characteristic curves TL-400NE TL-630NE, TL-800NE, TL-1250NE IP T 4 3 I1 I1 T1 2 hour hour 4 3 I2 1 50 40 30 T2 T1 IG 1 50 40 30 I3 I Curves based on standard settings 20 IP T 2 I2 T2 TG I3 I 20 minute 2 1 50 40 30 1 50 40 30 20 20 10 8 6 5 4 3 2 1 0.8 0.6 0.5 0.4 0.3 1 0.8 0.6 Percent rated current of base current (I0) Overcurrent tripping characteristics CT rated current (A) (In) Base current setting (A): (Io) Long time-delay pick-up current (A): (I1) 400 (In) x (0.63-0.8-1.0) (Io) x (0.8-0.85-0.9-0.95-1.0) Non-tripping at (I1) setting x 105% and below. Tripping at 125% and above. Long time-delay time settings (S) (T1) (5–10–15–20–30) at (I1) x 600% current. Setting tolerance ± 20% Short time-delay pick-up current (A): (I2) (Io) x (2-4-6-8-10) Setting tolerance ± 15% Short time-delay time settings (S) (T2) Opening time (0.1, 0.15, 0.2, 0.25, 0.3) in the definite time-delay. Total clearing time is + 50 mS and resettable time -20mS for the time-delay setting Instantaneous trip pick-up current (A) (I3) Continuously adjustable from (Io) x (3 to12) Setting tolerance ± 20% * Pre-trip alarm pick-up current (A) (IP) (I1) x (0.7, 0.8, 0.9, 1.0) Setting tolerance ±10% * Pre-trip alarm time setting (S) (TP) 40 fixed definite time-delay.Setting tolerance ±10% Note: * Optional Note: The underlined values will be applied as standard ratings unless otherwise specified when ordering. Percent rated current of CT rated current (In) 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 250 200 150 125 50 80 90 100 0.006 0.005 8 9 10 6000 7000 8000 5000 4000 3000 2500 2000 1500 700 800 900 1000 600 500 0.01 0.008 400 0.01 0.008 0.006 0.005 300 0.02 250 0.02 200 0.1 0.08 0.06 0.05 0.04 0.03 150 0.1 0.08 0.06 0.05 0.04 0.03 125 0.2 80 90 100 0.2 20 40 0.5 0.4 0.3 15 second 2 12.5 10 8 6 5 4 3 second 10 8 6 5 4 3 2 Tripping Time Tripping Time minute Curves based on standard settings 10 8 6 5 4 3 Percent rated current of base current (I0) Overcurrent tripping characteristics CT rated current (A) (In) Base current setting (A): (Io) Long time-delay pick-up current (A): (I1) 630, 800, 1000, 1250 (In) x (0.63-0.8-1.0) (Io) x (0.8-0.85-0.9-0.95-1.0) Non-tripping at (I1) setting x 105% and below. Tripping at 125% & above. Long time-delay time settings (S) (T1) (5–10–15–20–30) at (I1) x 600% current. Setting tolerance ± 20% Short time-delay pick-up current (A): (I2) (Io) x (2-4-6-8-10) Setting tolerance ± 15% Short time-delay time settings (S) (T2) Opening time (0.1, 0.15, 0.2, 0.25, 0.3) in the definite time-delay. Total clearing time is + 50 mS and resettable time -20mS for the time-delay setting. Instantaneous trip pick-up current (A) (I3) Continuously adjustable from (Io) x (3 to 12) Setting tolerance ± 20% * Pre-trip alarm pick-up current (A) (IP) (I1) x (0.7, 0.8, 0.9, 1.0) Setting tolerance ±10% * Pre-trip alarm time setting (S) (TP) 40 fixed definite time-delay.Setting tolerance ±10% * Ground fault trip pick-up current (A): (IG) Continiuously adjustable from (In) x (0.1 to 0.4) Setting tolerance ± 15% * Ground fault trip time setting (S): (TG) Opening time (0.1-0.2-0.3-0.4-0.8) in the definite time-delay. Total clearing time is + 50mS and resettable time is - 20mS for the time-delay settings Note: * Optional Note: The underlined values will be applied as standard ratings unless otherwise specified when ordering. Microprocessor Based Characteristics Time/Current Curves Selectivity Series Time/current characteristic curves XS1250SE, XS1600SE hour 4 3 I1 IP T 2 T1 1 50 40 IG I2 T2 30 TG I3 I Curves based on standard settings minute 20 10 8 6 5 4 3 2 1 50 40 30 Tripping Time 20 10 8 6 5 4 3 second 2 1 0.8 0.6 0.5 0.4 0.3 0.2 0.1 0.08 0.06 0.05 0.04 0.03 Percent rated current of CT rated current (In) 3000 2500 2000 1500 700 800 900 1000 600 500 400 300 250 200 150 125 50 80 90 100 40 20 15 8 9 10 0.01 0.008 0.006 0.005 12.5 0.02 Percent rated current of base current (I0) Overcurrent tripping characteristics CT rated current (A) (In) Base current setting (A): (Io) Long time-delay pick-up current (A): (I1) 1000, 1250, 1600 (In) x (0.63-0.8-1.0) (Io) x (0.8-0.85-0.9-0.95-1.0) Non-tripping at (I1) setting x 105% and below. Tripping at 125% & above. Long time-delay time settings (S) (T1) (5–10–15–20–30) at (I1) x 600% current. Setting tolerance ± 20% Short time-delay pick-up current (A): (I2) (Io) x (2-4-6-8-10) Setting tolerance ± 15% Short time-delay time settings (S) (T2) Opening time (0.1, 0.15, 0.2, 0.25, 0.3) in the definite time-delay. Total clearing time is + 50 mS and resettable time -20mS for the time-delay setting. Instantaneous trip pick-up current (A) (I3) Continuously adjustable from (Io) x (3 to 12) Setting tolerance ± 20% * Pre-trip alarm pick-up current (A) (IP) (I1) x (0.7, 0.8, 0.9, 1.0) Setting tolerance ±10% * Pre-trip alarm time setting (S) (TP) 40 fixed definite time-delay.Setting tolerance ±10% * Ground fault trip pick-up current (A): (IG) Continiuously adjustable from (In) x (0.1 to 0.4) Setting tolerance ± 15% * Ground fault trip time setting (S): (TG) Opening time (0.1-0.2-0.3-0.4-0.8) in the definite time-delay. Total clearing time is + 50mS and resettable time is - 20mS for the time-delay settings Note: * Optional Note: The underlined values will be applied as standard ratings unless otherwise specified when ordering. 24 Section Optional Accessories 25 Optional Accessories Internally Mounted Accessories Overview Shunt Trip (SHT) Auxiliary Trip (AX, AXE) Remote tripping of the breaker Electrically indicates On/Off status of the breaker. Undervoltage Trip Alarm Switch (UVT) Automatically trips the breaker when the circuit breaker falls below pre-set value. Remote tripping of the breaker is also possible. Note: The UVT controller is installed externally, when provided with AC UVT. (Refer to page 23) (AL,ALE) Electrically indicates when the breaker is in the “Tripped” state. Note: The SHT and UVT cannot be mounted in the same breaker. Operation of AX, AXE and AL, ALE Switch type Breaker 'ON' AXb1 AXa1 Breaker 'OFF' AXb1 AXa1 Breaker 'TRIP' Switch type AXb1 AXa1 AX, AXE AL, ALE AXc1 AXc1 AXc1 Breaker 'ON' Breaker 'OFF' Breaker 'TRIP' ALb1 ALa1 ALb1 ALa1 ALb1 ALa1 ALc1 ALc1 ALc1 Ratings Auxiliary switches (AX,AXE) and alarm switches (AL,ALE) ratings Applicable breakers Switch type AC 250AF or smaller *AV39052(AXE, ALE) 480 250 125 Resistive load 0.4 3 3 Lamp load 0.05 0.3 0.5 Inductive load 0.25 2 2 Motor load 0.1 0.5 0.7 DC Voltage (V) 250 125 30 Current (A) Resistive load 0.2 0.4 3 Lamp load 0.03 0.05 1 Inductive load 0.03 0.05 2 Motor load 0.03 0.05 2 Note:* For use in the micro current (mA) range. Contact Terasaki for details. 26 Voltage (V) Current (A) 400AF or larger (including:XH250PJ and TL250NJ) *V-10(AX, AL) 480 250 3 5 0.3 1.5 2 5 0.4 2 250 125 0.3 0.6 0.05 0.1 0.3 0.6 0.05 0.1 125 5 2 5 3 30 5 3 4 3 Optional Accessories Internally Mounted Accessories Ratings Shunt trip (SHT) rating Series Breaker PowerBreaker LimitorBreaker Selectivity Rated Exciting coil current [ peak value (A)] Values at the highest voltage (60Hz for AC use) voltage:110-115VAC 200-480VAC 24VDC 48VDC 100-115VDC 200-230VDC XH125PJ XH160PJ XH250PJ XH400PJ, XH400PE XH630PJ, XH630PE XH800PJ, XH800PE TL-100NJ TL-250NJ TL-400NE TL-630NE TL-800NE TL-1250NE XS400SE, XS400SE-C, XH400SE XS630SE, XS630SE-C, XH630SE XS800SE, XH800SE XS1250SE XS1600SE 3.4 0.83 1.6 0.71 0.4 - 1.1 0.93 2.52 1.55 0.67 0.35 3.4 1.1 0.83 0.93 1.6 2.52 0.71 1.55 0.4 0.67 0.35 1.1 0.93 2.52 1.55 0.67 0.35 Note: AC rated, permissible operating voltage range is 85 to 110%. DC 75 to 125%. Note: *Applicable to 200V and 400V class only. Note: Special voltages available on request. Contact Terasaki for details. Note: Shunt trip is provided with anti-burnout switch. Undervoltage trip (UVT) ratings Series Breaker PowerBreaker LimitorBreaker Selectivity Rated Power supply, VA (with UVT controller) voltage:100-120VAC 200-480VAC 300-450VAS XH125PJ XH160PJ XH250PJ XH400PJ, XH400PE XH630PJ, XH630PE XH800PJ, XH800PE TL-100NJ TL-250NJ TL-400NE TL-630NE TL-800NE TL-1250NE XS400SE, XS400SE-C, XH400SE XS630SE, XS630SE-C, XH630SE XS800SE, XH800SE XS1250SE XS1600SE Exciting coil current (MA) 24DC 110-115VDC 200-230VDC 5VA 5VA 5VA 18.2 4.8 *- 2VA 2VA 2VA 86.5 21.2 5VA 2VA 5VA 2VA 5VA 2VA 18.2 86.5 4.8 21.2 *12.1 2VA 2VA 2VA 86.5 21.2 12.1 12.1 Note: Tripping voltage is 35-70% of the rated voltage. Resettable voltage is 85% or less, of the rated voltage. Note: *200V DC application available on request as a special specification and equipped with resistor. Contact Terasaki for details. Note: Special voltages available on request. Contact Terasaki for details UVT controller If the UVT is for AC use a UVT controller must be installed. Standard installation of the UVT controller is on the left side of the breaker. However, this may be installed in a separate location (please specify). Separate installation is standard for breakers fitted with Mechanical Interlocks. A time-delay UVT controller is available with the same outside configurations (please contact Terasaki for details). For the UVT controller mounting position and accessory lead terminal block arrangement refer to pages 74-75 of catalogue ‘98-I20E. 88 100 18 6 10 16 7.8 15 80 15 16 10 6 UVT controller 22 Undervoltage trip (UVT) ratings 9 Small type of breaker or fuse ON Terminal screw *1 OCR 9 Terminal screw 83 81.5 69 400A-2500A XCU 4JS XCU 4JD 59 50A-250A XCU IS XCU ID 57.5 Frame size Instantaneous type Time delay type ON support P2 P1 UC2 UC1 P2 P1 UC2 OFF UC1 UVT controller 21 Controller Designations 45 Small type of breaker or fuse 6 25 NOTE: Terminals UC1 and UC2 are already connected UVT controller 50A to 250A frame support 400A to 2500A frame OFF * Configuration is for simultaneous mounting with OCR controller, for details on OCR controller refer to page 38 of catalogue ‘98-I20E. 27 Optional Accessories Externally Mounted Accessories Overview MIB REB PFB REF PMB MIF PRC LTP ON F ON OF F OF MIW PRC REB Designation Description FCS PWC BAR REF REB PRC PFB LTP LTF LTS PMB TCF TCR TBA XCU ELB EHA HL MOT OMM OHE OHJ MIF MIB MIW Front connect screw Solderless terminal Attach bar Rear connection flat bar Rear connection bolt stud Plug-in rear connection Plug-in attach bar Plug-in lead terminal Accessory lead terminal Accessory lead terminal (angled entry) Plug-in mounting base Terminal cover (front connected) Terminal cover (rear connected) Interpole barrier UVT controller Earth leakage block * Extension handle Handle lock Motor operator Operating handle, variable depth Operating handle, panel mounted Operating handle, breaker mounted Front mechanical interlock Rear mechanical interlock Wire mechanical interlock * Available for MCCB types XH125PJ and XH160PJ only 28 REF Optional Accessories Externally Mounted Accessories Overview ON F OF TCR OHJ TCF I TR IP. 0 OHH PWC OHE TBA AL NU MA N IO AT ER OP FCS T AC N NT COCATIO DI IN ON D PE TRIPFF O ON I LTP BAR O ak Bre m Te R TO R MO ATO R PE pe Ty XM D4 E 0N 40 XH l ria Se 0A In E 40 ns ctio ne Con On P2 P1 Off ce ur so TE NO E N TIO CAU P2 Off P1 On LTF/LTS TO SH PU IP TR ON DF MOT F OF XCU K LOC OCK UNL HL EHA BAR PWC ak Bre Tem ELB AD LO T 29 Optional Accessories Externally Mounted Accessories Motor Operators (MOT) ON/OFF indicator Padlocking Device Motor driven type 1 Ratings and specifications Type of Motor Operators Applicable Breakers PowerBreaker Series Rated Operating Voltage 1 Automatic Reset Steady-state r.m.s. Amp/inrush Amp (A) 5 6 Type of operation Operating Time(s) XH125PJ XH160PJ TL-100NJ Limitor Series AC 100-110V 200-220V DC 100-110V Yes 2 No AC100 50Hz -110V 60Hz AC200 50Hz -220V 60Hz DC 100V 110V • • – • • 1 7 2.0/4.5 2.0/4.5 1.0/2.0 1.0/2.0 7 – 7 – Motor driven type 1 0.85 250V, 5A 100 AC100V 1.8 ON OFF, RESET Control Switch Ratings Power Source Capacity (VA) Dielectric withstand voltage Weight (kg) Note: • Yes or available, 2 Requires breaker’s auxiliary switch (1bcontact). This will be wired at the factory (on request) when the breaker/motor operator assemblies are ordered. However, when all the auxiliary switch contacts are specified for other purposes, an external auxiliary relay (not supplied) is required to be controlled by the auxiliary a-contact of the breaker and use the relay’s normally closed contact (b-contact) for automatic reset. 3 Time values at the rated operating voltage. Allow a longer time for the motor operator to complete the operation, at lower operating voltage. 4 The motor operator is of a short time duty. Do not subject it to more than 10 continuous ONOFF operations. If this occurs, allow the motor operator to cool for at least 15 minutes. – No or not available Control circuit AC and DC Power Supply OFF RESET ON B A 5 D C 6 7 AUTO RESET SW (OPTION) X X1 E Note Maximum values at 110V AC Maximum values at 220V AC Special specification, available on request. CAUTIONARY NOTES If the motor operator is turned ON with the breaker OFF and the UVT de-energised, apply the power and complete one ON-OFF operation. (The breaker cannot be turned ON). Then complete one ON operation again (The breaker can be turned ON) LIMIT SW X2 Reference Notes Permissible operating voltage range as follows: AC rated, 85 to 110% of the rated voltage DC rated, 75 to 110% of the rated voltage Note: AC rated operating voltage 380V or 400460V a power transformer is available (optional) • •••: Resistor is fitted for AC200-220V motor X : Relay Y : Motor When the breaker is ON and is then tripped, the ON/OFF indicator on the motor operator will be indicating ON until the breaker is reset. Note: The breaker’s condition may differ. Note: Allow several minutes to cool when a thermal-magnetic breaker is tripped by a thermal overload trip, then reset the breaker. Optional Accessories Externally Mounted Accessories Motor Operators (MOT) Manual operating handle Manual operating handle Indicator Indicator Lock plate Lock plate Control circuit terminals Trip button Control circuit terminals Trip button Type XMD4 Positive contact indication Colour coding indicates the true position of the contacts clearly: ON (red), OFF (green), TRIP (white). Type XMD6, XMD9 Fast closing operation Easy maintenance Breaker mounting, removal, and even setting changes can be done without removing the motor operator. Closing in 60ms or less. The closing time remains constant over repeated operations. Lock Plate The breaker can be padlocked in the “OFF” position by pulling out the lock plate, and locking it with a padlock. When the breaker is “ON”, the lock plate cannot be pulled out. Up to three locks can be used. Padlocks not supplied. Manual ON/OFF operation with one stroke ø5.5 mm padlock Lever pumping is no longer required. Ratings and Specifications Type of Motor Operators PowerBreaker Series Applicable Breakers LimitorBreaker Series Selectivity Series AC 100-115V 50/60Hz 200-230V 50/60Hz DC 100-110V 24V Lock in "OFF" position (standard) Manual Trip Button AC100 ON Steady-state r.m.s. -115V OFF, RESET Amp/inrush Amp (A) AC200 ON -230V OFF, RESET DC100 ON -110V OFF, RESET DC24V ON OFF, RESET Type of operation ON (Maximium values) Operating Time(s) OFF, RESET Control Switch Ratings Power Source Capacity (VA) Dielectric withstand voltage The value in brackets for 24V DC Weight (kg) Rated Operating Voltage (V) XMD4 XH250PJ, XH400PJ XH400PE TL-250NJ TL-400NE XS400SE,XS400SE-C XH400SE • • • • • • –/3.1 1.2/5.7 –/1.2 0.7/3.0 –/0.8 1.0/4.0 –/4.5 4.0/12.0 Spring Charged 0.06 3 250V, 5A 300VA AC1500V (AC500V) 4.7 NOTE • : Yes or available 1 : Maximum values at AC115V, 50Hz 2 : Maximum values at AC230V, 50Hz 3 : Maximum values at DC110V 4 : Maximum values at the rated operating voltages XMD6 XH630PJ, XH800PJ XH630PE,XH800PE - XMD9 TL-630NE, TL800NE TL-1250NE XS630SE,XS630SE-C XS1250SE XH630SE,XH800SE XS1600SE – • • • • • • • • • • * * –/3.1 –/3.1 1.8/6.0 1.8/6.0 –/1.2 –/1.2 1.0/3.2 1.0/3.2 –/0.8 –/0.8 1.1/4.2 1.1/4.2 –/4.5 –/4.5 4.0/12.0 4.0/12.0 Spring Charged Spring Charged 0.06 0.06 3 3 250V, 5A 250V, 5A 300VA 300VA AC1500V (AC500V) AC1500V (AC500V) 6.4 5.6 Control circuit AC and DC + _ _ + 32 Section Outline Dimensions 33 Outline dimensions (mm) TemBreak Plus XH125PJ ASL: Arrangement Standard Line HL : Handle Frame Centre Line Front connected Interpole barrier (removable) Drilling plan Mounting hole 3P 4P 3P 4P HL HL 30 30 Preparation of conductor M8 Screw 67 HL 24 9 60 102 155 134 N ASL ASL 27 30 90 17(max.) 132 8.5(max.) HL ASL M4 x 0.7 Mounting screw 6 M4 x 0.7 Tapped hole 79 90 4 120 86 104 Rear connected with motor operator 4P 90 3P HL Mounting plate Insulated stud block Panel cutout Drilling plan 3P 4P HL M4 x 0.7 Tapped hole HL padlock operating handle facility 30 30 30 15 134 30 60 60 15 15 15 Plug-in 31.5 29 29 30 M8 Screw 132 21.5 ASL 86.5 66.5 31.5 51.5 54.5 ASL 134 121 86 57.5 207.8 18 90 15 for accessory wiring when necessary Mounting block Drilling plan 4P Preparation of conductor 90 30 89 119 15 ø6 13 10(max.) 45 134 25 194 107 22 2 121 18.5 13 35 30 ASL HL HL ø6.5 15(max.) 86 ASL 28 M5 x 0.8 Mounting screw 15 30 86 60 4P 3P HL Details of connection M6 Mounting screw 3 24 52 Panel cutout dimensions shown give an allowance of 1.0 mm around the handle R1 escutcheon Conductor 24 34 100 HL 25 ASL 4P 3P 75 18.5 60 HL 27 3P Outline dimensions (mm) TemBreak Plus XH160PJ Front connected ASL: Arrangement Standard Line H L : Handle Frame Centre Line Interpole barrier (removable) Drilling plan With terminal bars (optional) Preparation of conductor M8 Screw M4 x 0.7 Mounting screw M4 x 0.7 Tapped hole Conductor overlap max. Note: Breakers with terminal bars available on request Rear connected with motor operator Mounting plate max. 5t Drilling plan Stud can be turned 90º M4 x 0.7 Tapped hole Conductor overlap max. for accessory wiring when necessary Plug-in Mounting block Drilling plan M5 x 0.8 Mounting Screw Mounting plate Accessory connection block Details of connection Mounting plate Panel cutout Panel cutout dimensions shown give an allowance of 1.0 mm around the handle escutcheon R1 25 Max.conductor width M8 Screw 35 Outline dimensions (mm) TemBreak Plus TL-100NJ ASL: Arrangement Standard Line H L : Handle Frame Centre Line Front connected Pan head screw Preparation of Conductor 4P HL 30 30 66 ø9 ASL 3P HL 132 ASL ASL (max.) 80 157.5 143.5 17 147 Drilling plan 8.5 (max.) 51 77.5 67 M8 screw 67 Interpole barrier (removable) Mounting hole 4P HL 3P HL 24 M4x0.7 Mounting screw 27 60 6 M4x0.7 Tapped hole 30 79 90 90 4 86 120 104 Rear connected with motor operator 4P Bolt stud:type XRD2 Panel cutout 3P 4P HL 3P HL HL 1 ASL 80 R 29 29 86.5 52 31.5 66 21.5 66 188 4P HL ASL 86 51.5 ASL 66.5 77.5 157.5 31.5 67 147 54.5 57.5 Insulated stud block 3P 132 214 Mounting plate 30 30 30 30 30 24 ø18 M8 screw 15 ø15 for accessory wiring when necessary 60 15 60 15 90 15 M4x0.7 Tapped hole Panel cutout dimensions should give an allowance of 1.0mm around the handle escutcheon. Note: Panel cutout shown for MCCB without motor operator. Plug-in Preparation of Conductor (max.) M6 mounting screw Conductor 3 24 36 13 HL 27 35 22 2 121 M5X0.8 Mounting screw 18.5 25 80 180 75 86 ASL 37.5 147 177 Details for connection ø6 4P 37.5 18.5 15 214 45 3P HL 53.5 25 67 97 30 ASL ASL 15 HL 274 30 HL Drilling plan 133.5 60 10 ø6.5 4P 90 67 3P (max.) (XDM2LS) Mounting block 89 30 28 15 119 86 60 Mounting plate Outline dimensions (mm) TemBreak Plus TL-250NJ, TL-400NE ASL: Arrangement Standard Line H L : Handle Frame Centre Line Front connected Hexagon socket head screw Preparation of Conductor 4P 120 28 ø11 3P H L H L 20 44.5 M10 screw mounting hole Drilling plan 14.5 H L 10 H L With Terminal Bars (Optional) t=8 3P 12.5(max.) 4P 110 Interpole barrier (removable) 3P 107 ASL ASL ASL 28 14.7 M6 mounting screw 7 44.5 23 69 100 214 230 360 56 ASL 214 46 114 130 25 (max.) 7.5 90 45 140 45 60 145 M6 tapped hole 45 14.5 52.5 103 45 70 23.5 ø14 28 60 115 60 4P 185 Values for conductors or optional terminal bars Rear connected with motor operator Flat bar stud : type XRP4 Panel cutout Drilling plan 4P 3P 345 4P 3P 4P H L H L 3P HL 328 92 29 25 110 45 4.5 45 45 45 45 M6 tapped hole 100 15 214 230 R6.5 30 ø13 30 max.11 ASL 15 360 ø13 214 ASL 70 ASL 107 103 Conductor overlap,max. 25 114 130 8 8 Mounting plate 115 64 8 33 90 Stud can be turned 90 214.5 33 33 45 45 45 33 Panel cutout dimensions shown give an allowance of 1.0mm around the handle escutcheon. ø36 337 NOTE: ø15 for accessory wiring when necessary In the standard shipment made, both terminals on the line side and the load side are in a horizontal direction. Note: Panel cutout shown for MCCB without motor operator. Plug-in Mounting block 47 35 (XDM4LS) 3P 4P H L H L Drilling plan H L 4P 11.5 18 3P 142 60 18 25 27 27 90 20 72 10 148 45 45 119 45 11.5 Conductor width, 35 max. 121 234 42 20 ASL 382 167 ASL 20 20 67 114 141 Auxiliary circuit terminal 214 241 Details for connection M8 Mounting screw ASL 25 54 Mounting angle 60 ø9 hole 74 47 35 M10 screw 37 Outline dimensions (mm) TemBreak Plus XH250PJ, XH400PJ, XH400PE, XS400SE, XS400SE-C, XH400SE ASL: Arrangement Standard Line H L : Handle Frame Centre Line Front connected With terminal bars (optional) 120 69 7.5 28 20 23 14.7 ø14 103 185 ASL ASL 214 56 46 ASL M6 Mounting screw 45 115 25(max.) 28 145 52.5 60 60 44.5 45 45 70 ASL 14.5 90 140 260 228 ASL HL 44.5 11 N 4P 3P 7 M10 Screw On side 8 10 On side 31 Off side 30 On side 28 HL 12.5(max.) HL HL Preparation of conductor Drilling plan 39 14.5 4P 23.5 3P 110 Interpole barrier (removable) 45 8 38 Off side M6 Tapped hole Off side 60 Note: Breakers with terminal bars available on request Rear connected with motor operator 4P 3P Mounting plate Drilling plan HL 3P 4P Stud can be turned 90º ø36 ø13 M6 Tapped hole 103 29 214.5 8 HL ASL ASL 4.5 45 45 45 13 33 45 ø36 90 33 8 110 25 30 214.5 15 max.11 15 28.5 30 70 25 ASL Conductor overlap max. 228 203 8 28.5 HL 214 345 228 Lock plate 45 33 45 45 45 33 334 max Conductor overlap max. Note: In the normal shipment mode, both terminals on the line side and the load side are in the horizontal direction. 15 for accessory wiring when necessary Plug-in Drilling plan 4P Mounting block 3P 4P HL HL 84 ASL 54 25 134 ASL 60 282 ASL 20 ASL 282 228 20 25 54 HL 9 72 10 148 45 45 119 Mounting angle Accessory connection block Panel cutout Motor operator Panel Cutout Details of connection 47 4P Panel cutout dimensions shown give an allowance of 1.0 mm around the handle escutcheon 3P H L 18 R3 20 35 60 74 104 ASL 4P 3P HL ASL 92 121 45 11.5 90 R6.5 35 max. conductor width M10 Screw 122 64 38 134 3P 11.5 M8 Mounting screw Outline dimensions (mm) TemBreak Plus XH630PJ, XH630PE, XS630SE, XS630SE-C, XH630SE, XH800PJ, XH800PE, XS800SE, XH800SE ASL: Arrangement Standard Line HL: Handle Frame Centre Line Front connected Drilling plan 3P 4P A 13 4P HL 3P 80 13 6 ASL 6 14 8 8 80 M8 Mounting screw 140 105 70 15 40 70 70 A Conductor overlap max. 175 280 210 117 132 28 32 25 57 ASL 273 ASL 126 141 N ASL HL Extension handle (removable) 45 HL 32 7.5 B 103 145 80.5 70 M8 Tapped hole (Neutral: N) Note: Breakers with terminal bars available on request Breaker type A B N XH630PJ 8 34 36 XH630PE, XS/XH630SE, XS630SE-C 8 36 36 XH800PJ 10 35 36 XH800PE, XS800SE, XH800SE 10 36 36 Rear connected with motor operator Drilling plan 4P 13 3P 3P HL 5 13 214.5 70 70 70 43 140 5 70 70 4.5 43 43 70 127 117 122 13 136 126 ASL 55 7 25 85 20 8 32 132 42 75.5 117 ASL max 11 M8 Tapped hole H L 214.5 141 126 10 102 31.5 HL Stud can be turned 90º Lock plate 40 173.5 24 Mounting plate 4P 48 70 70 43 Max. 310 Note:In the normal shipment mode, both terminals on the line side and the load side are in the horizontal direction. Conductor overlap max. 15 for accessory wiring when necessary Drilling plan Plug-in 4P Mounting block 3P HL 3P Mounting angle 4P HL 25 303 67 25 90 ASL 67 90 76 76 ASL 62 117 147 ASL 18 ASL 18 156 126 62 M10 Mounting screw HL 62 45 70 210 90 105 280 Panel cutout 4P Motor operator Panel Cutout 47 11 70 175 Accessory connection block Details of connection 70 18 4P Panel cutout dimensions shown give an allowance of 1.0 mm around the handle escutcheon 3P H L 21 17.5 86.5 R3 60 ASL ASL R6.5 40 max. conductor width M16 Screw 3P HL 92 140 121 168 64 39 Outline dimensions (mm) TemBreak Plus XS1250SE ASL: Arrangement Standard Line HL : Handle Frame Centre Line Front connected Rear connected with motor operator Panel Cutout Plug-in 40 Outline dimensions (mm) TemBreak Plus TL-630NE, TL-800NE, TL-1250NE, XS1600SE ASL: Arrangement Standard Line HL : Handle Frame Centre Line Front connected Rear connected with motor operator Motor operator panel cutout (*) * Panel cutout dimensions shown give an allowance of 1mm around the handle escutcheon or 1.5mm around the motor operator frame Draw-out 41 42 Section Selectivity Table 43 Application TemBreak Plus Selectivity Table for 415V and 400V Downstream Upstream Icu @ 415 400 XS400SE XH400SE XS630SE XH630SE XS800SE XH800SE XS1250SE XS1600SE 50 50 65 65 50 50 65 65 50 50 65 65 65 85 85 100 XE100NS 10 15 T T T T T T T T T T T T T T T T XS125CJ 14 18 T T T T T T T T T T T T T T T T XS125NJ 25 30 T T T T T T T T T T T T T T T T XH125NJ 50 50 35 35 35 35 T T T T T T T T T T T T XH125PJ 50 50 35 35 35 35 T T T T T T T T T T T T XS160NJ 25 35 15 15 15 15 T T T T T T T T T T T T XH160NJ 50 50 35 35 35 35 T T T T T T T T T T T T XH160PJ 50 50 25 25 25 25 T T T T T T T T T T T T XE225NS 15 18 T 15 T 15 T T T T T T T T T T T T XS250NJ 25 35 15 15 15 15 T T T T T T T T T T T T XS250PJ 35 35 15 15 15 15 T T T T T T T T T T T T XH250NJ 50 50 25 25 25 25 T T T T T T T T T T T T XH250PJ 65 65 ** ** ** ** 10 10 10 10 25 25 25 25 50 50 50 50 XH250PE 65 65 ** ** ** ** 10 10 10 10 25 25 25 25 50 50 50 50 XE400NS 25 25 ** ** ** ** 10 10 10 10 T T T T T T XS400CJ 35 35 ** ** ** ** 10 10 10 10 25 25 25 25 T T T T XS400NJ 50 50 ** ** ** ** 10 10 10 10 25 25 25 25 T T T T XH400PJ 65 65 ** ** ** ** 10 10 10 10 25 25 25 25 50 50 50 50 XS400SE-C 35 35 ** ** ** ** 10 10 10 10 25 25 25 25 T T T T XS400SE 50 50 ** ** ** ** 10 10 10 10 25 25 25 25 T T T T XH400SE 65 65 ** ** ** ** 10 10 10 10 25 25 25 25 50 50 50 50 XH400PE 65 65 ** ** ** ** 10 10 10 10 25 25 25 25 50 50 50 50 XE600NS 25 25 ** ** ** ** ** ** ** ** ** ** ** ** 20 20 20 20 XS630CJ 35 45 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XS630NJ 50 65 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XH630PJ 85 100 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XS630SE-C 35 40 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XS630SE 50 50 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XH630SE 65 65 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 XH630PE 65 65 ** ** ** ** ** ** ** ** ** ** ** ** 30 30 30 30 Notes: 1. The letter 'T' denotes Total Selectivity up to the breaking capacity of lower rated Icu MCCB. 2. The symbol '**' denotes that selectivity is only obtained up to the level of the upstream instantaneous trip 3. All pick-up current and time delay settings are to be set at maximum for upstream MCCBs T T Notes: 4. The above table is in accordance with IEC-947-2 Appendix A 5. Figures are shown with 415v information in white and 400v information in black 6. Selectivity figures for the XH-PE series are the same as the XS-SE. Please contact Terasaki for further details. OVERSEAS NETWORK TERASAKI (EUROPE) LTD. 80 Beardmore Way, Clydebank Industrial Estate, Clydebank, G81 4HT. SCOTLAND (U.K.) Telephone: 44-141-941-1940 / Fax: 44-141-952-9246 web: www.terasaki.com TERASAKI ITALIA s.r.l. Via Campania 4/6, 20090 Segrate, Milano, ITALY Telephone: + 39-02-2137574 / Fax: + 39-02-26922931 web: www.terasaki.it TERASAKI ESPAÑA, S.A. Roma Street, s/n 08400 Granollers, Barcelona, SPAIN Telephone: +34-93-8796050 / Fax: +34-93-870-3905 web: www.terasaki.es TERASAKI CIRCUIT BREAKERS (S) PTE. LTD. 51 Tannery Lane #10-02, Sharely Warehouse, Singapore 1334, SINGAPORE Telephone: +65-7449752 / Fax: +65-7487592 TERASAKI ELECTRIC (M) SDN. BHD. Lot 3 Jalan 16/13-D, 40000 Shah Alam,Selangor, MALAYSIA Telephone: +60-3-5510-3820 / Fax: +60-3-55103763 TERASAKI DO BRASIL S.A. Rua Campo Grande No. 3700, Campo Grande, Rio de Janeiro, BRAZIL Telephone: 021-413 4222 / Telex: 2123178 TBRJ BR / Fax: 21-3941875 ELECTRIC CO., LTD. Head Office: 7-2-10 Hannancho, Abenoku, Osaka, JAPAN Telephone: 81-6-692-1131 / Telex: 526-7749 TTSAKI / Cable: TERASAKI OSAKA Circuit Breaker Division: 7-2-10 Kamihigashi, Hiranoku, Osaka, JAPAN Telephone: 81-6-692-1134 / Telex: 526-7769 TSKNFB / Fax: 81-6-695-2296 web: www.terasaki.jp JUNE 2000 CATALOGUE No. '00 - I26E Ratings and specifications covered in this catalogue may be subject to change without notice.