Chemical Engineering Science 59 (2004) 247 – 258

www.elsevier.com/locate/ces

The impact of external electrostatic #elds on gas–liquid

bubbling dynamics

Sachin U. Sarnobata , Sandeep Rajputa , Duane D. Brunsa;∗ , David W. DePaolib ,

C. Stuart Dawc , Ke Nguyend

a Department

of Chemical Engineering, University of Tennessee, 436 Dougherty Engr Bldg, Knoxville, TN 37996, USA

and Materials Research Group, Oak Ridge National Laboratory, P.O. Box 2008, Oak Ridge, TN 37831-6181, USA

c Engineering Technology Division, Oak Ridge National Laboratory, P.O. Box 2009, Oak Ridge, TN 37831-8088, USA

d Department of Mechanical Engineering, University of Tennessee, Knoxville, TN 37996, USA

b Separations

Received 2 June 2003; received in revised form 20 August 2003; accepted 16 September 2003

Abstract

The e9ect of an applied electric potential on the dynamics of gas bubble formation from a single nozzle in glycerol was studied

experimentally. Dry nitrogen was bubbled into glycerol through a nozzle having an electri#ed tip while pressure measurements were

made upstream of the nozzle. As the applied electric potential was increased from zero, bubble size reduced, bubble shape became more

spherical, and bubbling frequency increased. At constant gas ;ow, bubble-formation exhibited a classic period-doubling route to chaos with

increasing potential. We de#ned an electric Bond number assuming that both the liquid and gas phases are conducting. This is in contrast

to previous studies where one phase was considered a perfect conductor and the other one a perfect nonconductor or insulator. Although

electric potential and gas ;ow appear to have similar e9ects on the period-doubling bifurcation process for this system, the relative impact

of electrostatic forces, as measured in terms of electric Bond number for conducting liquid and gas phases, is smaller. However, the

relative impact of electrostatic forces for the case of insulating liquid and conducting gas phases is comparable to ;ow forces. Further

data collection is required for di9erent nozzle geometries and liquid column heights in order to verify the relative impacts of electrostatic

and ;ow forces, and would allow us to ascertain if electrostatic potential is a feasible manipulated variable for controlling this system.

? 2003 Elsevier Ltd. All rights reserved.

Keywords: Multiphase ;ow; Nonlinear dynamics; Bubble formation; Separations; Electrostatic spraying

1. Introduction

Although gas–liquid bubbling can seem to be a simple

phenomenon, it actually involves complex dynamical interactions. Such bubbling is a major component of a wide range

of chemical and environmental processes. Typically, one expects that the most eAcient gas–liquid processes have small

bubbles, since greater interfacial area increases inter-phase

heat and mass transfer. One might also expect that bubbles are of uniform size which will simplify control and

predictability. However, in reality, gas–liquid bubbles generally have broad size distributions and complex property

variations over time (e.g., Kikuchi et al., 1997; FDemat et al.,

1998; Luewisutthichat et al., 1997).

∗

Corresponding author. Tel.: +1-865974-5317; fax: +1-865974-7706.

E-mail address: dbruns@utk.edu (D.D. Bruns).

0009-2509/$ - see front matter ? 2003 Elsevier Ltd. All rights reserved.

doi:10.1016/j.ces.2003.09.001

Bubble formation has been the subject of numerous studies (e.g., Tsuge, 1986; Deshpande et al., 1991;

Longuet-Higgins et al., 1991; DrahoHs et al., 1992; Terasaka

and Tsuge, 1993). One key #nding from those studies is that

bubble-to-bubble interactions create instabilities leading to

bifurcations and chaos. At low gas ;ow rates, bubbling is

regular and periodic, but it becomes increasingly irregular

with increasing ;ow. In their classic paper, Davidson and

SchJuler (1960) were among the #rst to use high-speed photography to study the interaction and coalescence between

leading and trailing bubbles. More recently Leighton et al.

(1991) illustrated the complicated hydrodynamic phenomena present in bubbling through high-speed imaging and

acoustic signatures. Other investigators identi#ed di9erent

regimes of bubbling, de#ned by dimensionless groups and

characterized by di9erent amounts of interactions between

forming bubbles (Miyahara et al., 1984; Tsuge, 1986).

Predictive models have been developed based on a simple

248

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

description of the interaction between a primary bubble and

subsequent bubbles at higher gas ;ow rates (Deshpande

et al., 1991; Ruzicka et al., 1997; Ruzicka, 2000).

With the availability of better experimental measurements

and improved nonlinear dynamics analysis tools, additional

progress has been made in understanding the nature of bubbling instabilities. Deterministic chaos in bubbling was #rst

reported by Tritton and Egdell (1993), who studied air injected from a single submerged ori#ce in water–glycerol

mixtures. In these studies, Tritton and Egdell reported a

period-doubling bifurcation with increasing air ;ow. Mittoni

et al. (1995) subsequently reported deterministic chaos in

a similar system under a range of conditions by varying

chamber volume, injection nozzle diameter, liquid viscosity and gas ;ow rate. Nguyen et al. (1996) further identi#ed the spatio-temporal aspect of chaotic bubbling; noting

that bubble-to-bubble interactions propagate long distances.

This research clearly observed period-8 behavior. A simple

model was also used that gave a good representation of the

attractor behavior. Such spatial interactions reduce the directness of the analogy between bubbling and the classical

dripping faucet.

In other studies, the e9ects of external perturbations, such

as ;ow and acoustic pulsations, have been examined (e.g.,

Fawkner et al., 1990; Cheng, 1996). In some cases such

perturbations have led to control schemes. Most notably,

Tufaile and Sartorelli (2000, 2001) reported the capability

to transform a chaotic bubbling state to a periodic state by

the application of a synchronized sound wave.

Zaky and Nossier (1977) #rst reported the e9ect of an

electric #eld on bubbling, noting a decrease in bubble size

and an increase in pressure with increasing voltage for bubbling of air into transformer oil and n-heptane through an

electri#ed needle. Further studies by Ogata et al. (1979,

1985), Sato et al. (1979) and Sato (1980) showed that by

the application of a few kilovolts, bubble size can be reduced from a few mm to less than 100 m in many liquids,

including nonpolar ;uids like cyclohexane and polar compounds such as ethanol and distilled water. Sato et al. (1993)

reported similar results for liquid–liquid systems in which

the time scale of electrical charge relaxation (i.e., permittivity/conductivity) of the injected ;uid is greater than that

of the continuous ;uid. This type of dispersion has been

termed inverse electrostatic spraying (Tsouris et al., 1998)

to di9erentiate it from the well-studied normal electrostatic

spraying (Grace and Marijnissen, 1994). Several practical

applications have been suggested for this type of spraying, including generating #ne bubbles for ;ow tracers (Sato

et al., 1979), enhancing gas–liquid reactions (Tsouris et al.,

1995), and producing uniform microcapsules (Sato et al.,

1996).

Two main contributing phenomena have been identi#ed

for bubble formation in the presence of electric #elds, electric stress and electrohydrodynamic ;ow. Electric stress acts

directly at the gas–liquid interface of growing bubbles and

is directed inward (Tsouris et al., 1994). This force is man-

ifested by an increase in nozzle pressure with an increase in

applied voltage. Above a critical voltage (that depends on

nozzle geometry and ;uid properties), electrohydrodynamic

;ows are induced in the bulk ;uid (Sato et al., 1979, 1993,

1997). These ;ows have a toroidal shape with a high magnitude near the injection nozzle and move outward from the

points of highest #eld gradient. Under conditions of electrohydrodynamic ;ow, a signi#cant decrease in nozzle pressure

is exhibited with increasing voltage (Tsouris et al., 1998).

The dynamics of electri#ed bubbling are complicated by

the interactions of these mechanisms. Sato et al. (1979) described three regimes of bubbling: periodic bubbling, dispersed bubble production, and a high-voltage region characterized by sparking and larger bubble production. Similarly,

Shin et al. (1997) outlined three bubbling modes—dripping,

an erratic mixed mode, and a spraying mode.

To date, no detailed study of the dynamics of electri#ed

bubbling has been conducted. For example, it has not been

veri#ed that the regimes characterized as periodic are truly

periodic, nor are there any detailed analyses and/or means

of prediction of the transitions from periodic bubbling. Beyond its intrinsic scienti#c value, such information would

be highly valuable in guiding the development of methods

for controlling bubbles size distribution.

In the present study, the e9ects of an applied electrostatic

potential on bubbling dynamics were determined experimentally. Bubbles were formed in a viscous liquid (glycerol) such that electrohydrodynamic ;ows were negligible

and the main electrostatic mechanism a9ecting bubbling

was the electric stress at the gas–liquid interfaces of the

forming bubbles. To keep the analysis reasonably straightforward, bubble formation from only one submerged nozzle was examined. The dynamics were characterized using

pressure measurements upstream from the injection nozzle.

The combined e9ects of gas ;ow and applied voltage were

evaluated.

In the following section we describe the experimental

setup. Subsequently, we show results from the data analysis

and discuss their implications. Finally we o9er conclusions

and propose future directions for research.

2. Experimental setup

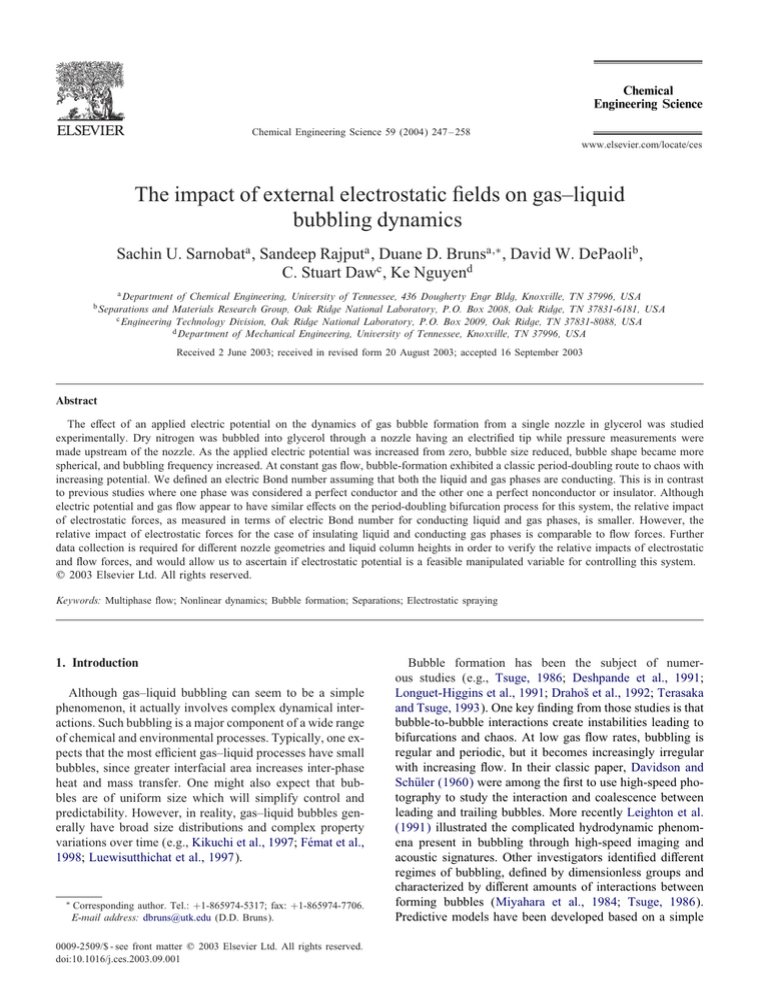

A schematic of the experimental apparatus (Sarnobat,

2000) is shown in Fig. 1. The apparatus consisted of a

glass bubbling column, a gas metering system, a pressure

transducer for monitoring the response of the system, a

high-voltage, direct-current power supply for maintaining

a potential di9erence between the nozzle and a ground

electrode immersed in the liquid, and a data acquisition

system.

The experiments were conducted in a square glass column (4 cm × 4 cm in cross-section, 27 cm in height) into

which gas was injected through a central vertical nozzle

having an electri#ed metal tip. The column was #lled with

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

249

Time series for pressure

1.5

(14)

1

Pressure

(2)

0.5

0

-0.5

-1

8.2 8.25 8.3 8.35 8.4 8.45 8.5 8.55

time

x104

(12)

(6)

(1)

(3)

(5)

(4)

(7) (8) (9)

(10)

(11)

(13)

Fig. 1. Schematic of experimental bubble system: (1) High-voltage power supply; (2) ground electrode; (3) electri#ed nozzle; (4) drain valve; (5) metering

valve; (6) pressure transducer; (7) rotameter; (8) pressure reducer; (9) pressure regulator; (10) nitrogen gas cylinder; (11) data acquisition system.

99.98% pure glycerol to a level 21:6 cm above the tip of

the nozzle which protruded 3:5 cm from the column base.

Dry nitrogen from a compressed gas cylinder formed the

bubbles. The column was operated at atmospheric conditions, and the gauge pressure measured in the tubing immediately upstream of the nozzle served to characterize the

bubbling.

The gas train used in the experiments was similar to those

used in previous studies (Nguyen et al., 1996). It consisted

of two pressure regulators, a rotameter with a stainless-steel

;oat (Shor-Rate II, tube number R-2-15-D, Brooks Instruments), piezo-electric valve (MaxTek MV-112), ;ow

sensor (Cole-Parmer 8168), high-speed pressure transducer

(Setra Systems 228), a Nupro double cross metering valve

(with a maximum Cv of 0.004 for ;ow control), and a

ball valve connected in series. This system supplied measured gas ;ow rates covering a range of 10 –500 cc=min.

The tubing volume from the piezo-electric valve to the

nozzle was minimized to reduce the dynamics of gas

compression.

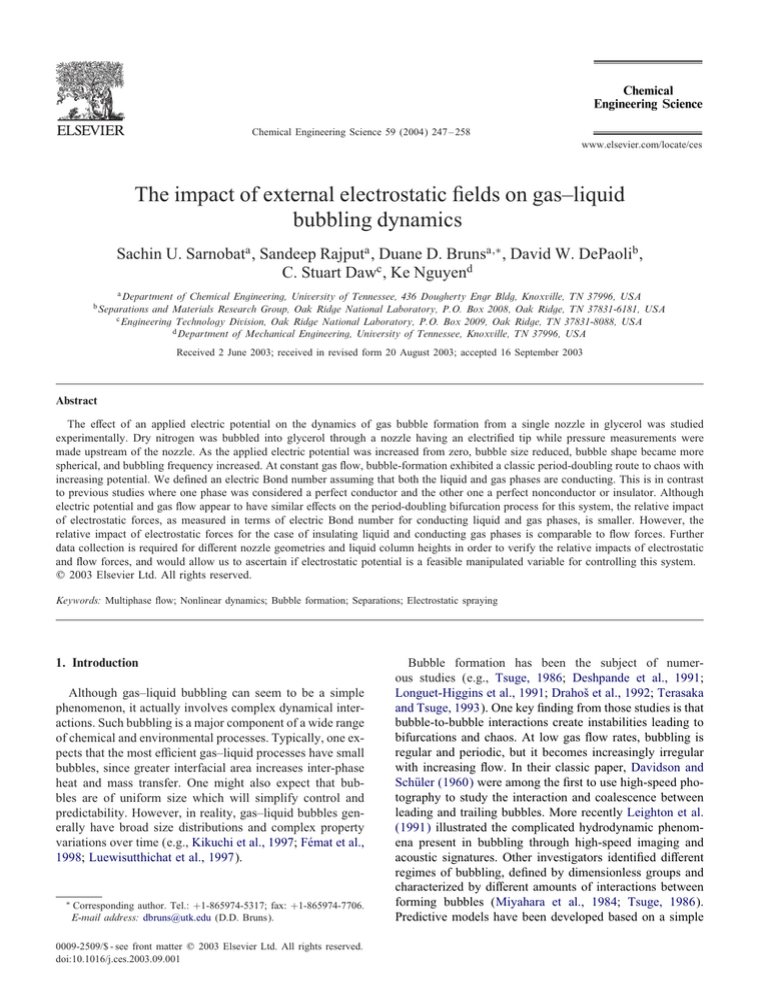

Details of the nozzle design are shown in Fig. 2. The

nozzle was constructed from 6.35-cm-o.d. Lucite tubing. A

6.35-cm-o.d., 1.0-mm thick brass ori#ce plate was secured

at the end of the nozzle. This plate could be electri#ed by

a 22-gauge, uninsulated copper wire passing through the

nozzle to a connector on the gas inlet line.

An ori#ce diameter of 0:75 mm was used to avoid indistinct return maps that have been obtained with larger ori#ce diameters (Mittoni et al., 1995). Preliminary experiments with applied electrostatic potential conducted in this

study using a 1.0-mm ori#ce obtained results with irregular

spikes and peaks in the pressure time series. Three design

features allowed the system to be operated such that liq-

uid that may have weeped through the ori#ce during setup

could not adversely a9ect the results by causing intermittent

bubbling. These were the relatively large inside diameter

of the nozzle tube, a tee-bend in the gas inlet, and a drain

valve.

A high-voltage, direct current power supply (model

225-50R, Bertan High Voltage Corp.) was connected to the

nozzle tip with positive polarity. A 3.2-mm-diameter stainless steel rod immersed 2:5 cm into the upper surface of the

glycerol served as the counter electrode and was connected

to electrical ground. The electrode was not inserted farther

into the liquid in order to minimize the electrode surface

area in contact with the liquid. With this con#guration, a

potential of approximately 13 kV could be attained at the

nozzle tip before the 0.3-mA current safety limit of the

power supply was reached.

A capacitive transducer (model 228, Setra Systems Inc.)

having a range from 0 to 1 psig was used to measure the

pressure in the gas line upstream of the nozzle. The output from the pressure transducer was a 0 –5 V DC analog signal, which was fed through a signal conditioning

card signal ampli#er to a data acquisition board (models

SC-2043-SG and PCI-MIO-16E-50, National Instrument) in

a 300-MHz Pentium IITM -based personal computer. National

Instruments LabviewTM 5.1 was used as the data acquisition

software.

For consistent experimental results, a fresh batch of glycerol was used for each run. Each run consisted of data collected at a speci#c ;ow rate and changing the applied voltage

in increments of 1 kV from 0 V to 10 kV. Time intervals

of 300 s were provided between successive readings. The

pressure data were collected for 50 s at 2000 or 5000 Hz at

each set of experimental conditions.

250

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

(9)

(8)

(4)

(5)

(10)

(2)

(6)

(1)

(3)

(7)

Fig. 2. Details of bubble nozzle construction: (1) Gas inlet; (2) ball valve; (3) connection for wire to nozzle tip; (4) glass column; (5) nozzle tip;

(6) liquid drain; (7) drain for accumulated glycerin; (8) metal cap; (9) 0.75-mm-i.d. ori#ce; (10) copper wire.

3. Data analysis

The following data analysis techniques were used for the

characterization of nonlinear bubble-formation dynamics.

Power spectra: The classical linear method of Fourier

analysis was used to transform the time-series information

into the frequency domain, which has been shown to be

sensitive to changes in periodicity (FDemat et al., 1998). Although not de#nitive for nonlinear time series, the power

spectra yield useful information for continuous physical systems as a pointer to the relevant time scales and the choice

of parameters in nonlinear time-series analysis.

Delay embedding: We used the delay embedding

(Takens, 1981) of pressure measurements to characterize the attractor. Given the set of measurements

{xi |i = 1; : : : ; n}, the sequence of vectors formed as

xj = [xj ; xj+

; xj+2

; : : : ; xj+(m−1)

]T (where j is a time index)

can be used to reconstruct the dynamic trajectory of the

system. Takens (1981) proved that if some m is suAciently

large, the embedding vectors preserve the geometrical properties and invariants of the system. Our observations indicated that typically an embedding dimension of 5 and delay

of 35 are appropriate embedding parameters for resolving

the injected bubble patterns. We also apply local principal

component analysis (PCA) to the embedded data to allow

the resulted to be projected into two or three dimensions

for easier viewing.

Period-doubling bifurcation and route to chaos: Bifurcation plots have been widely used (e.g., Nguyen et al., 1996;

Tufaile et al., 1999; Tufaile and Sartorelli, 2001) to illustrate the onset of complex dynamics as a result of variation in some process input variable. For the bubbling process, the changes were quanti#ed in terms of the period

of formation of the bubble. In the context of this experiment, a plot of bubbling rate (or period of bubble formation)

against the gas ;ow rate or the electrostatic potential is a

bifurcation diagram. We also generated three-dimensional

bifurcation plots involving both system variables—gas ;ow

rate and electrostatic potential—to illustrate the simultaneous e9ect of electrostatic potential and ;ow rate on bubble

formation.

Time return maps: Time return maps (Moon, 1992) were

used to condense the information of time series and to help

determine the periodicity of the system. Period-of-formation

intervals were generated by measuring the peak-to-peak time

intervals of the pressure time-series data. A peak in the pressure trace corresponds to the beginning of bubble growth at

the nozzle, and the peak-to-peak time-interval corresponds

to the bubble formation time.

4. Results and discussion

Previous experimental work (e.g., Mittoni et al., 1995;

Tritton and Egdell, 1993; Nguyen et al., 1996; Tufaile and

Sartorelli, 2000) has shown that as gas ;ow is increased,

bubble formation undergoes a bifurcation process that is

readily detected by observing variations in bubble size and

speed. At low ;ow, it is observed that a regular train of identical bubbles is produced. In addition to being of equal size,

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

(a)

(b)

(c)

Fig. 3. Bubble interaction with increase in ;ow rate: (a) No interaction;

(b) slight interaction; (c) signi#cant interaction in period-2 bubbling.

the bubbles are formed and released in equal time intervals.

In our apparatus, the sequence of identical bubbles produces

a train of identical pressure peaks in the nozzle (Fig. 3a).

Increasing gas ;ow increases the frequency of bubbling and

leads to interaction between bubbles (Fig. 3b). Speci#cally,

trailing bubbles are accelerated by the wakes of preceding

bubbles. At the nozzle, this gives rise to the formation of

two alternating size bubbles (period-2), and the pressure

pulses contain two distinct alternating peaks (Fig. 3c).

With still greater gas ;ow, the system enters a state in

which four distinct bubble types are formed (period-4).

This period-doubling process continues progressively

with increasing ;ow rate, #nally leading to deterministic

chaos.

Fig. 4 shows examples of pressure time-series data for

four di9erent ;ow rates that resulted in periods 1, 2, 4 and

chaos. Subplots 4 (a) – (d) contain 2-s pressure traces. As

the ;ow rate is increased, the bubbling frequency increases,

and the number of distinct peaks appearing in the pressure

trace increase. In 4(d), the number of distinct peaks has become e9ectively in#nite due to the onset of deterministic

251

chaos. Under these conditions, there are never two bubbles

produced with exactly the same characteristics. Figs. 4(e)–

(h) show the three-dimensional delay embedding formed

with the time-series segments shown in Figs. 4(a) – (d), with

embedding delay of 35. The single band in Fig. 4(e), gives

way to two distinct bands in 4(f)—leading from period-1 to

period-2 behavior. Fig. 4(g) has four distinct bands, indicating period-4, and Fig. 4(h) has many bands with fractal

structure—a sign of chaotic dynamics.

When an electrostatic potential is applied to the injection

nozzle, electric stresses cause a “pinching” action on the

bubbles during formation (Tsouris et al., 1994). The visual

e9ects of applied voltage in our experiments are illustrated

in Fig. 5, which compares the images of bubbles formed at

a #xed ;ow rate under applied potentials of 0 and 12:5 kV.

The images shown are at a point in time 4 ms before the

bubbles detached from the nozzle. It is seen that the bubble

formed with an applied voltage is smaller and more spherical. Increasing electrostatic potential hastens the detachment

of bubbles, which leads to greater and more signi#cant interactions between bubbles. These results demonstrated how

increasing gas ;ow a9ects the bubbling dynamics. Now we

examine the impact of increasing the electrostatic potential

at a given ;ow rate.

Fig. 6 shows pressure traces collected at 2 kHz for

bubbling at constant gas ;ow of 335 cc=min and multiple applied potentials of 1–9 kV (increments of 1 kV).

A subtle variation can be observed in the time series in

terms of an increase in the number of peaks observed, a

decrease in the peak heights, and increasing irregularity in

the peak heights with increasing potential. On average, the

bubbling frequency also increases with increasing potential. The system is chaotic in subplots (h) and (i). Fig. 7

shows the local principal component scores for the time

series in Fig. 6. Note that with increasing electrostatic potential, the banding in the plots becomes more complex and

the system is chaotic for potentials of 8 and 9 kV. Fig. 8

shows the spectral densities for the time series shown in

Fig. 6. The distribution becomes broader with increasing

potential.

Fig. 9 illustrates an alternative approach for observing the

dynamic changes induced by the electric potential in terms

of the characteristic intervals between bubbles. In this #gure,

successive time interval values between bubbles are plotted

as two-dimensional ‘return maps’ for the same conditions in

Fig. 6. Initially (at low potential) we observe four distinct

points corresponding to the four di9erent bubble periods—

thus the system is exhibiting period-4 behavior. As the potential increases, we observe the four points merge into a

curve, representing the chaotic state. It should be noted that

this curve is actually a trace of the dynamic ‘map’ of this

system. In fact, a function #t through this map can provide

an approximate model of the bubbling dynamics. The bubble

formation interval continues to wander along this line due

to the continuous state of instability driving the deterministic chaos. Although not obvious, the average inter-bubble

252

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

Fig. 4. Typical pressure traces for di9erent levels of bubbling instability. Period-1 (a, e), Period-2 (b, f), Period-4 (c, g) and Chaos (d, h).

Fig. 5. E9ect of electrostatic potential in bubble formation dynamics

and bubble shape. Images of bubbles formed at a #xed ;ow rate under

conditions of no voltage (left) and with an applied potential of 12:5 kV

(right).

interval decreases from 0.11 to 0:08 s as the voltage transition is made, indicating that the bubbles produced in the

chaotic state are smaller.

Fig. 10 is a bifurcation plot in which bubble formation

intervals are plotted as a function of applied potential. In

these experiments, gas ;ow was held constant, and voltage

was gradually increased in steps of 1 kV. At low values of

the applied potential, the system exhibits period-4 behavior

as indicated by the four distinct bands of observed intervals.

With increasing voltage, the period of formation of bubbles decreases and bubble size distribution becomes broader.

At applied voltages between 7 and 8 kV, the bubbling becomes chaotic and there is almost a continuous range of

values along a wide band. Fig. 11 shows a similar bifurcation diagram obtained at a lower gas ;ow. Note that although the same general trends are apparent at the two ;ows,

the details of the bifurcations with applied potential are

di9erent.

To illustrate the combined e9ects of electrostatic potential

and gas ;ow, data collected from experimental runs at different ;ow rates and di9erent applied potentials were plotted

on the same graph to generate a co-dimension bifurcation

plot. Fig. 12 illustrates such a plot showing bubble interval

as a function of the applied voltage and ;ow rate.

Perhaps a more useful way of mapping the twodimensional bifurcations is to use the appropriate dimensionless ;ow and potentials. Tsuge’s ;ow number represents

a ratio of the combined mechanical disruptive forces—

inertia and buoyancy—to surface tension, and is de#ned as

(Tsuge, 1986)

Nw = Bo Fr 0:5 ;

(1)

where

Bo =

d2i g

and

Fr =

u2

di g

(2)

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

253

Fig. 6. Pressure traces for various potentials at a #xed gas ;ow rate. Subplots (a) – (i) refer to potentials of 1–9 kV in increments of 1 kV. The gas ;ow

rate was 335 cc=min.

Fig. 7. Principal component scores for various potentials at a #xed gas ;ow rates. Subplots (a) – (i) refer to potentials of 1–9 kV in increments of 1 kV.

The gas ;ow rate was 335 cc=min.

254

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

Fig. 8. Power spectral density for various potentials at a #xed gas ;ow rate. Subplots (a) through (i) refer to potentials of 1–9 kV in increments of

1 kV. The gas ;ow rate was 335 cc=min.

Fig. 10. Bifurcation of bubbling intervals with increasing applied potential

at a constant gas ;ow rate of 335 cc=min.

Fig. 9. Bubbling interval return maps for various potentials at a #xed gas

;ow rate. Subplots (a) – (i) refer to potentials of 1–9 kV in increments

of 1 kV. The gas ;ow rate was 335 cc=min.

and di is the inside diameter of the nozzle ori#ce, is the

liquid density, g is the gravitational acceleration constant, is the liquid surface tension, and u is the gas velocity through

the ori#ce. Bo and Fr refer to Bond and Froude numbers,

respectively. However, electric forces are also acting on the

bubbles, and should be taken into account.

Now we consider the electric stress tensors, assuming the

;uids are linearly polarizable (Landau and Lifshitz, 1960).

If Ea is the electric #eld though the ambient liquid and Eg

is the electric #eld across the gas phase, we have

Ea a = Eg g ;

(3)

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

255

where da is the distance from the submerged electrode tip to

the nozzle and L is the permittivity of glycerin. Assuming

g ∼

= 0 where 0 is the permittivity of air, Eq. (5) reduces to

Eg =

1

V

di [1 + (da =di )1=K]

Ea =

1

V

;

di K [1 + (da =di )1=K]

and

(6)

where K = g =a g =0 is the dielectric constant of the

ambient phase.

If the ambient (liquid) phase is a perfect conductor, i.e.,

K ≈ ∞, and the electric #eld in the liquid will be zero

and the liquid would be isopotential. In that limiting case,

Eq. (6) becomes

Fig. 11. Bifurcation of bubbling intervals with increasing applied potential

at a constant gas ;ow rate of 290 cc=min.

Eg = lim

V

V

1

=

di [1 + (da =di )1=K] di

Ea = lim

V

1

= 0:

di [K + da =di ]

K→∞

K→∞

be

and

(6a)

The jump in the electric stress tensor at the interface would

(g − a =K 2 )

1

V2

Te = (g Eg2 − a Ea2 ) = 2

2

2di [1 + (da =di )1=K]2

=

V 2 g

(1 − g =a )

:

2d2i [1 + (da =di )1=K]2

(7)

Note that if a g and K 1, Eq. (6) reduces to

Te =

lim

g a ; K→∞

1

= g

2

Fig. 12. Co-dimension bifurcation diagram of bubbling for changes in

voltage and ;ow rate.

where g is the permittivity of the gas and where a is the

permittivity of ambient phase. Since

Ea =

V − Vi

da

and

Eg =

Vi

di

(4)

where Vi is the potential at the interface. Eliminating Vi from

Eqs. (3) and (4), we obtain

Eg =

V

[di + da g =a ]

Ea =

1

V

;

di [a =g + da =di ]

and

(5)

V

di

Te =

2

≈

V 2 g

2d2i

1

g Eg2 :

2

(7a)

A ratio of this stress to the stress caused by surface tension

forces can be constituted as

Be =

V 2 g

(1 − g =a )

2Te

=

;

=di

di [1 + (da =di )1=K]2

(8)

which is the electric Bond number for this setup.

In the limiting case of the liquid being a perfect conductor,

Eq. (8) reduces to

Be =

lim

g a ;K→∞

Be =

di g Eg2

V 2 g

=

:

di

(8a)

The di9erence in Eqs. (8) and (8a) (or in Eqs. (6) and

(6a)) is a factor for given values of K, di and da . However,

the de#nition in Eq. (8) allows us to compare the impact

of electric stress as compared to surface tension for all nozzles. For low to moderately conducting liquids, placing the

ground electrode closer to the nozzle (decreasing da ) would

allow one to achieve higher electric stresses given the same

potential di9erence.

256

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

Fig. 13. Bubbling stability map as correlated with Tsuge ;ow and electric

Bond numbers. Legend: open circle (period-1), plus sign (period-2), open

square (period-4) and #lled circles (chaos).

Note that in this derivation, we have assumed that the

electric #eld is normal to the interface, and the tangential

components have been omitted. Regardless of the polarity, the electric #eld is normal to the interface and is directed inward towards the gas phase. Ideally, we should

have conducted the experiment with a very small da so that

the gas phase would be the dominating resistance. However, that could not be performed as our intention was to

reduce the electrode area in contact with the liquid. We also

ignored the aspect ratio, as the #eld is normal to the interface, and the shortest path through the gas phase is the

nozzle i.d.

Fig. 13 presents the bifurcation plot as a stability map

in terms of dimensionless variables; speci#cally, the Tsuge

;ow number and the electric Bond number. Since both

dimensionless groups are scaled against surface-tension

forces, they allow comparison of the relative e9ect of forces

caused by gas ;ow and those caused by the applied electric

#eld. We note that for chaotic dynamics, the Tsuge number

was 16.4 and the electric Bond number was greater than

0.2. This may indicate that electrostatic forces have greater

impact on bubbling dynamics than ;ow forces; however,

further data obtained at larger electric Bond numbers and

smaller Tsuge ;ow numbers would be necessary to verify

this assertion.

It would be desirable to de#ne a system variable incorporating the e9ects of both applied voltage and ;ow rate that

could be used as a predictor of bubbling regime. In order

to capture the collective e9ect of electrostatic and inertial

forces on bubble formation from an electri#ed nozzle, Shin

et al. (1997) suggested a modi#ed Weber number that is the

ratio of the sum of the electrostatic and inertia forces to surface tension forces. That modi#ed Weber number (simply

the sum of electrical Bond number and Weber number) is

Fig. 14. Bubbling stability map as correlated with Tsuge ;ow and modi#ed

Weber numbers. Legend: open circle (period-1), plus sign (period-2),

open square (period-4) and #lled circles (chaos).

Fig. 15. Bubbling stability map as correlated with Tsuge ;ow number and

electric Bond number (in limiting case, assuming the liquid phase is a

perfect conductor). Legend: open circle (period-1), plus sign (period-2),

open square (period-4) and #lled circles (chaos).

de#ned as

d i a E 2 + u 2 d i a

;

(9)

where a is the gas density. Fig. 14 replots Fig. 13 with

modi#ed Weber number replacing the electric Bond number as the ordinate. The derivation in Eqs. (7) and (8) is a

very important correction in estimating electric stresses at

the interface. If we had assumed the liquid phase to be perfectly conducting, the electric Bond numbers would have

reached up to 20, compared to the maximum value of 0.33 in

Fig. 13. Fig. 15 replots Fig. 13 but replaces the electric Bond

WeS =

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

number de#ned in Eq. (8) by that de#ned in Eq. (8a). Under this scaling, it is apparent that electrostatic forces have

much lower impact on bubbling dynamics than ;ow-related

forces.

5. Conclusions and recommendations

Our results demonstrate that, at constant ;ow rate, bubble formation dynamics from an electri#ed nozzle exhibits

the classic signs of a period-doubling bifurcation to chaos

with increasing applied potential. With increasing voltage,

the bubble frequency increases and the bubbling undergoes

period-doubling bifurcations to become chaotic, similar to

that for increasing ;ow rate. Similar behavior has been observed in liquid–liquid systems under electrostatic spraying (Tsouris et al., 1994). Although the basic type of bifurcation is similar for applied voltage and ;ow, voltage

has a proportionally smaller e9ect than ;ow. Application

of voltage also reduces bubble size, apparently by promoting early bubble release. The smaller bubbles have higher

interfacial surface area for heat and mass transfer, and this

might have bene#cial applications in gas–liquid contacting

devices.

Use of applied electrical potential for bubble size control

should be further investigated because it would be possible to manipulate this variable very quickly and thus provide very fast feedback perturbations (e.g., much faster than

can be obtained with gas ;ow perturbations). A possible

limitation is the relatively large voltage amplitude needed

to achieve signi#cant e9ects. This study is the #rst one to

consider the case where both the ambient and gas phases

were conducting. Other studies have assumed both of these

to be either perfect conductors or perfect nonconductors.

An expression for electric Bond number was derived for

the current apparatus, and it was shown that it reduces

to the expression for other, limiting cases studied in the

literature.

In the present study, the e9ects of electro-hydrodynamic

(EHD) ;ows were assumed to be negligible and were not

studied. Future studies should include EHD ;ows induced

with di9erent shapes of nozzles, various chamber sizes and

changing the nozzle diameter. The particular liquid used

is another important parameter, and consideration should

be given to similar studies in immiscible liquid–liquid

systems.

Acknowledgements

This work was supported by the Division of Chemical

Sciences, OAce of Basic Energy Sciences, US Department of Energy, under contract DE-AC05-00OR22725 with

UT-Battelle, LLC. The authors thank Costas Tsouris of

ORNL for helpful comments.

257

References

Cheng, Y., 1996. Characterization and control of chaotic bubble behavior.

M.S. Thesis, The University of Tennessee, Knoxville.

Davidson, J.F., SchJuler, B.O.G., 1960. Bubble formation at an ori#ce in

a viscous liquid. Transactions of the Institution of Chemical Engineers

38, 335.

Deshpande, D.A., Deo, M.D., Hanson, F.V., Oblad, A.G., 1991. A model

for the prediction of bubble size at a single ori#ce in two-phase gas–

liquid systems. Chemical Engineering Science 47 (7), 1669–1676.

DrahoHs, J., Bradka, F., Puncochar, M., 1992. Fractal behavior of pressure

;uctuations in a bubble column. Chemical Engineering Science 47

(15/16), 4069–4075.

Fawkner, R.D., Kluth, P.P., Dennis, J.S., 1990. Bubble formation at

ori#ces in pulsed, ;owing liquids. Transactions of the Institution of

Chemical Engineers 68 (Part A).

FDemat, R., Alvarez-Ramirez, J., Soria, A., 1998. Chaotic ;ow structure

in a vertical bubble column. Physics Letters A 248, 67–79.

Grace, J.M., Marijnissen, J.C.M., 1994. A review of liquid atomization

by electrical means. Journal of Aerosol Science 25, 1005–1019.

Kikuchi, R., Yano, T., Tsutsumi, A., Yoshida, K., Punchochar, M., DrahoHs,

J., 1997. Diagnosis of chaotic dynamics of bubble motion in a bubble

column. Chemical Engineering Science 52 (21/22), 3741–3745.

Landau, L.D., Lifshitz, E.M., 1960. Electrodynamics of Continuous Media.

Pergamon, New York, NY.

Leighton, T.G., Fagan, K.J., Field, J.E., 1991. Acoustic and photographic

studies of injected bubbles. European Journal of Physics 12, 77–85.

Longuet-Higgins, M.S., Kerman, B.R., Lunde, K., 1991. The release of

air bubbles from an underwater nozzle. Journal of Fluid Mechanics

230, 365–390.

Luewisutthichat, W., Tsutsumi, A., Yoshida, K., 1997. Chaotic

hydrodynamics of continuous systems. Chemical Engineering Science

52 (21/22), 3685–3691.

Mittoni, L.J., Schwarz, M.P., La Nauze, R.D., 1995. Deterministic chaos

in the gas inlet pressure of gas–liquid bubbling systems. Physics of

Fluids 7 (4), 891–893.

Miyahara, T., Iwata, M., Takahashi, T., 1984. Bubble formation pattern

at a submerged oriface. Journal of Chemical Engineering Japan, 17

(6), 592–597.

Moon, F.C., 1992. Chaotic and Fractal Dynamics. Wiley, New York, NY.

Nguyen, K., Daw, C.S., Chakka, P., Cheng, M., Bruns, D.D., Finney,

C.E.A., 1996. Spatio-temporal dynamics in a train of rising bubbles.

Chemical Engineering Journal 65, 191–197.

Ogata, S., Yoshida, T., Shinohara, H., 1979. Small air bubble formation

in insulating liquids under strong non-uniform electric #eld. Japanese

Journal of Applied Physics 18, 411–414.

Ogata, S., Tan, K., Nishijima, K., Chang, J.-S., 1985. Development of

improved bubble disruption and dispersion technique by an applied

electric #eld method. A.I.Ch.E. Journal 31, 62–69.

Ruzicka, M.C., 2000. On bubbles rising in a line. International Journal

of Multiphase Flow 26, 1141.

Ruzicka, M.C., DrahoHs, J., Zahradnik, J., Thomas, N.H., 1997. Intermittent

transition from bubbling to jetting regime in gas–liquid two phase

;ows. International Journal of Multiphase Flow 4, 671.

Sarnobat, S., 2000. Modi#cation, Identi#cation and Control of Chaotic

Bubbling with Electrostatic Potential. M.S. Thesis, The University of

Tennessee.

Sato, M., 1980. Cloudy bubble formation in a strong nonuniform electric

#eld. J. Electrostatics 8, 285–287.

Sato, M., Kuroda, M., Sakai, T., 1979. E9ect of electrostatics on bubble

formation. Kagaku Kogaku Ronbunshu 5, 380–384.

Sato, M., Saito, M., Hatori, T., 1993. Emulsi#cation and size control

of insulating and/or viscous liquids in liquid–liquid systems by

electrostatic dispersion. Journal of Colloid Interface Science 156,

504–507.

Sato, M., Kato, S., Saito, M., 1996. Production of oil/water type uniformly

sized droplets using a convergent AC electric #eld. IEEE Transactions

on Industry Applications 32, 138–145.

258

S.U. Sarnobat et al. / Chemical Engineering Science 59 (2004) 247 – 258

Sato, M., Hatori, T., Saito, M., 1997. Experimental investigation of droplet

formation mechanisms by electrostatic dispersion in a liquid–liquid

system. IEEE Transactions on Industry Applications 1527–1534.

Shin, W.-T., Yiacoumi, S., Tsouris, C., 1997. Experiments on electrostatic

dispersion of air in water. Industrial and Engineering Chemistry

Research 36, 3647–3655.

Takens, F., 1981. Dynamical systems and turbulence. In: Rand, D., Young,

L.S. (Eds.), Lecture Notes in Mathematics, Vol. 898. Springer, Berlin,

p. 366.

Terasaka, K., Tsuge, H., 1993. Bubble formation under constant ;ow

conditions. Chemical Engineering Science 48 (19), 3417–3422.

Tritton, D.J., Egdell, C., 1993. Chaotic bubbling. Physics of Fluids A 5

(2), 503–505.

Tsouris, C., DePaoli, D.W., Feng, J.Q., Basaran, O.A., Scott, T.C., 1994.

Electrostatic spraying of nonconductive ;uids into conductive ;uids.

A.I.Ch.E. Journal 40, 1920–1923.

Tsouris, C., DePaoli, D.W., Feng, J.Q., Scott, T.C., 1995. An experimental

investigation of electrostatic spraying of nonconductive ;uids into

conductive ;uids. Industrial and Engineering Chemistry Research 34,

1394–1403.

Tsouris, C., Shin, W., Yiacoumi, S., 1998. Pumping, spraying and mixing

of ;uids by electric-#elds. Canadian Journal of Chemical Engineering

76, 589–599.

Tsuge, H., 1986. In: Cheremisino9, N. (Ed.), Hydrodynamics of

Bubble Formation from Submerged Ori#ces in Encyclopedia of Fluid

Mechanics, Vol. 3. Gulf Publications, Houston, pp. 191–232.

Tufaile, A., Sartorelli, J.C., 2000. Chaotic Behavior in bubble formation

dynamics. Physica A 275, 336–346.

Tufaile, A., Sartorelli, J.C., 2001. The circle map dynamics in air bubble

formation. Physics Letters A 287, 74–80.

Tufaile, A., Pinto, R.D., GonZcalves, W.M., Sartorelli, J.C., 1999.

Simulations in a dripping faucet experiment. Physics Letters A 255,

58–64.

Zaky, A.A., Nossier, A., 1977. Bubble injection and electrically induced

hydrostatic pressure in insulating liquids subjected to non-uniform

#elds. Journal of Physics D 10, L189–L191.