r-ffi1 - Gavatec A/S

advertisement

SEALED TIGHT!

w

?w

G-ST-Flange Gaskets

G-ST-Profite Gaskets

G-ST-Wedge Rings

QN,4-System

zertilizlert dLrrch

r-ffi1

\cemryZ

iso

9001

G-ST-Ftange Gaskets

G-ST-Profile Gaskets

G-ST-Wedge Rings

Rubbersteel flange gaskets and

adiustable wedge rings have been

proven in use over many years in all

areas of pipeline construction.

Sleel n

ll'. powe pld -\.

pelro

cheriro pl orr o( eutir dl industri"s

as wetl as numerous gas and

water companies at home and

abroad value the advantages of

Kro[[ & Zitler sealing products.

Product Range

Page

G-ST

For

various appLications.

G-Sr/GUSS

ln special dimensions.

For

total covering offlange face.

G-sr-P/s

For various applications, top choice

for ioints connecting non-metallic

(ptastics or GRP) and steelflanges.

G-ST-P/K

suit ftange ioints connecting

pairs of plastic stub ends.

To

G-ST-P/Kl{

For various applications, top choice

for partialLy coated flanges

and heavy duty services.

G.ST-P/HTB

For stee[ flange connections in

Fire Safe pipelines.

G-ST-P/OE

FLexible design gasket with

visible stainless steel insert.

c-sr-P/GR

To suit pipework

with soft rubber

lining and flange faces with

soft/hard rubber coating.

IF

lF-

F=

I--r|H

T

G-ST-Profile Gaskets

With *o yea ,- o'expel op6p ;n .o1u-

ing individual sealing probtems,

With steel insert

Flange bolts center the gaskets

we can provide you with a range of

lange gaske : olexteplio ol oper

ating reLiability. With Kroll & Ziller

gaskets you can be sure of:

.high efficiencV due to

reduced

operating costs

'reduced fugitive

em issio ns

Growing international competi-

tion rnal(es cost

rn in

imisation

t

I

in all areas of production nec-

essary. Production d isru p

tions and rejections, main-

e and repa,'ro\ts

must be prevented by

renanc

choosing the best possi

ble construction m ateriaLs. The risk of possibLe

environmentaI poLtution

The

rnüst be elirninatecl.

policy of Kroll & Ziller

\

over the last 15 years

has been specialisation,

research and develop-

ment in close coLtabora'

tion with a [arge number of

customers.

The wide range

of

standard

gaskets available for sealing

flanges allows top quality stan

dardisarion. H;qh ef''rie"cV .. com

bined with superb handling. The

ease of instalLation to the rigid

steel is attributed core even with

ld ge nomindl w dlh\ dnd Jnder:'

able

stresses.

lf you have a probLem in choosing

suitable gaskets, the experienced

KROLL & ZILLER sales team is here

to assjst you.

G

.

ST

-

5

for SteeIpipes

K

for Plastic pipes

KN

for non load bearing

flafge

jo

irts

OE

vlsibLe SS lnsert

HTB

for Flre saie

GR

ior Rubber lined p ipes

P

ST

with Steelinsert

G

for

R u

bber maierial

G-ST-Profile Gaskets

Proven in practice

Reliable sealing of flanged joints

on p peli-es has been rrade po:si

bLe by the developrnent of KR0LL &

ZILLER G ST gasl(ets. Vutcanization

p-ovidos a- exl-erlV good adhesion between the steel insert and

the rubber sheath. Even when

stressed to extrernes, separation

or blow out' are ror po\\ible.

Dimensions in accordance with

slandd'ds prevents Ln-ecessary

llowrale redurtions dJe to pdrlbLocked cross-sections. Additionatly,

there is optimum handLing during

ilsldlldliol, since the gas\et

is self

centering on the bolt circLe. The

l:

rl;

'-#.

combination of these features

makes the G-ST gasket the right

choice for you.

The new generation

The G ST P profile gasket range

ilrustrdtes the techr ological p'ogress of KR0LL & ZILLER. The basic

concept is very ctear in the graphic

illJsträrion of rhe gacket rro<s\e( lion.l he G 5T rnain body is con

bined with a round cord ring. This

"O-ring" is the most static sealing

etement. The performance of this

0-ring is almost miracutous even

without a (osr-intensive g'oove.

The G ST P profiLe gasket combines

the advantages of its individual

pa'ts. ligh sL'lace pressures transmitted from the main force of the

fLow are absorbed by the rigid body

o' lhe c 5l gaskel. he 'lal

s[eel-

ring, corrosion protected by being

vulcanized in, absorbs with ease

lhe reqlircd 1e<l pressure. Tl'e 0ring lying paratteI to the main force

of the flow is ideatly compressed

against the sealing faces even at

low surface pressures. lrregularties

and grooves, even slight misalign-

ments are compensated. As well,

the gasket shows insensitivity to

lhe minimJm torq-es required dL'

ing installation which spares the

material. A degree of operating

reliability - never before reached is

assured. Once in position it is

seated tight! These advantages are

especially important

for

flange

ioints of thermoplastics (PVC, PE, Pq

PVDF). The special KROLL & ZILLER

gasket G-ST-P/S has the fotlowing

advantages:

.

wlde seaLing surface area

'rectangular instead

of

round

cross section near the 0-ring

-hese all ributes prevent deforration of the flange adapters. The

round cord ring reLiabLy fills the

enlarged gap. Minimum req u ired

tighlen "g torqJes proLect tha join;ng elenents from being over

Loaded.

G-ST-Profile Gaskets

Benefits linked to G-ST-P gasket applications:

.sealing u nder minimum bott

.angte differences are more

tighten ing

'

com pensation

im perfections

easily compensated com pared

to sim ple ftat gaskets

of surface

.ftange and bolt designs can

be more lightweight

.

expensive machining of a 0-ring

groove on the flange is unnec'

essary

. higher durabiljty of plastic

ftange ioints

Sealing thro ugh

round cord ring

system

Absorption of

Absorption of

surface pressure

in

ner pressure

by steel ring

G-ST-profile gasket

Electric characteristics of

material used for gaskets

The surface resistance Ro and the

isolation resistance PD has been

determined accordlng to DIN

53482, arrangement of electrodes

styLe,,C".

The desruptive voltage U6 has been

tested due to DIN lEc 243-zlvDE

o303, part 22 with direct current.

(An electrode with a diameter of 25

nn

conbined with grexnis6 p|a.trode with a diameter of 75 mm in

accordance

part

with

D

N VDE oj03,

21.)

The tests envolved items with

thickness of r and 5 mm.

(O)

1mm

EPDM

0.45 x 103

NBR-DUO

3.30

(o)

po

5mm

1mm

5mm

0.85 x 103

0.5 x 103

0.6 x 103

x 103 5.35 x

103

2.45 x 1011 2.35 x

101

1.5 x

2.55x1012 1.15x 1012 5.5 x

FPM-S

(o)

Ro (O)

Ro

material

a

10r0

1010 6.2 x

1o'g

Po

Test vottage (V)

3.2 x 101

8.9 x

(kv)

1mm

ud

ud (kv)

5mm

10

10rD

100

7 4x1Oe

100

>15

>15

>15

nb = without results

Gasket parameters

due

to DIN 28 o9o-1

due to ASME

Code Section Vlll Div.r

Tabte UA. 49.1

materials

G-ST, P/S

G-sT, P/5

P/K, Pi

P/K, Pi 0E

OE

NBR

FPM-S,

CR, NR,

EPDM, IIR

CSM

Pi KN

P/KN

c-5T, P/S,

P

NBR, CR, NR

EPDM, IIR

lK,P loE

FPM-S,

NBR, CR

CSM

NR, EPDM

R, CSM

FPM-S

recommended flange

face roughness

Ra

surface pressure N/mm2

imits for 20' C

sudace

I

pressure

mlts for 150' C

160

R.

2

15

m

9

4s0

v

öeut

(:2)

öeo

(5)

(15)

(435)

Lrm

N/mm2

övulr

6vo

160

160

2

10

p

inch

500

psi

1.00

200

G-ST-Profile Gaskets

Extra retiability

The KROLL & ZiLLER gasket range

was proven in the testing.

1

|

,.,.,

Test parameters:

I

9o

. medium: water

85

.temperature: zo'C I 680

8o

F

?

z

.test pressure: ro bar / r43 psi

-o

Test sam ptes

2o" Gasket

70

=

g60

a = G-ST ftange gasket

b:

NBR-DUO

G ST P/S-proflle flange gasket

NBR-DUO

'E

lo

c = Flat rubber gasket with textiLe

insert NBR

The resLlt

ol lhe iest series

is

shown in the graph:

Witl^ a pres\ure of ro oar / r43 psi

o-lv a lrac lio r of t're req L red tightening torque calculated for the G'ST

flange gasket is necessary for the

6-51-o/$ p'ofile gacket. H owever.

use of the G-ST gasket with the

higher vaLue is recommended during

inslallation. lhe extra reliabilily ollsets nany Ln(erlainlies i- prarticp.

lnner pressure p

Water at 2oo C

(bar) .+

a. = G-ST-Flange Gaskets

b. = G-ST-Profile Gaskets

für Zwei

NBR.DUO

zuqel. + gcprüft

o.Ä

&rr.*rd

SUDDEUTSCH LAND

Materials:

CSM = Chlorosulphonated Monomer rubber

NR = Natural rubber

Temp. tmax.'3o...+ 60o C, Shore A hardness 6o

Temp. Trnax. -22...+ r|ao

r

5

F

Temp. trnax. 2a...+ 72aa C, Shore A-hardness 7o

Temp. tmax. -4...+ z48" F

r

5

EPDM* = Ethylene Propylene Diene Monomer rubber

NBR-DUO = Acrylonitrile Butadiene rubber

-KTW recommendation 1.3.13 in the areas D1 and D2,

DIN'DVGW test mark, reg.no. NV 52614P1125

FDA approved acc.to 21 CFR Ch.I

DR]NK NG WATER

-KTW recommendation 1.3.13 in the areas D1 and D2,

we as hVgienic test in accordance with DVGW

code of practice W 2/o

'FDA, 21 CFR Ch.l (o4l2ooo), 5 177.26ao

(o4/zooo), $ t77.z6oo

t

5

FPM-S* = Fluorinated rubber acid proof

Temp. tmax. 2o...+ 2ooo C, Shore-A hardness 8o t

5

Temp. tmax.-3o...+ rzoo C, Shore A-hardness 7o

Temp. tmax. '22...+ 248o F

as

Temp. tmax, -4,.,+ 392"

NATU RAL GAS

Test approval by DVGW in accordance

EN 3535, Part 3 (prEN 682)

llR:

with DIN

no. NG 51134P1125

Temp. tmax. 25...+ 7ao C, Shore-A hardness Bo 1

HNBR

:

5

F

Steel lnsert

Hydrogenated Acrylonitrile Butadiene rubber

Ternp. tmax. -25...+ 15oo C, Shore A hardness 75

Temp. tmax. -13... + 302'F

CR:

lsobutene soprene rubber (Butyte rubber)

Temp. tmax. -25...+ 12aö C, Shore A-hardness 55

Temp. tmax.-1j...+ 248o F

reg.

Temp. tmax. -13...+ 15Bo

F

loroprene ru bber

Temp. tmax. -25...+ g5o C, Shore-A-hardress

Temp. tmax. -73...+ 2oj" F

r

5

Standard: Carbon Steel

Optional: Slainless Steel

* also available

Ch

5j I

as

"HP" (high purity)

5

t

5

G.ST

EN 1514-1

slmitar to

G-ST,Flange Gaskets

Nominal

Diameter

Nominal

Pressure

DN

15

20

40

50

65

BO

100

100

100

125

125

150

150

200

200

200

250

250

250

250

300

300

300

300

300

350

400

400

400

400

500

500

600

700

800

T 000

1200

1200

1200

1200

1600

1600

1800

2000

Nomina

DN

Dimensions in mm

Diameter

drxdzxsj

10-40

22 x

10-40

27 x

10-40

34 x

10-40

43 x

1040

49 x

1040

61 x

1040

77 x

1040

Bg x

6

115 x

10-T6 1'15 x

25-44 115 x

10-16 141 x

25-40 141 x

1016

169 x

25-40 169 x

1016

220 x

25220x284x6

40220x290xG

10273x328x6

16273x329x6

25273x340x6

40273x352x6

6324x373x6

10

324 x

16

324 x

25324x400x6

40324x417x6

10

356 x

10

407 x

16

407 x

25

407 x

40407x546x7

10

508 x

40508x628x7

10610x695x7

1A

712 x

10813t917xB

10

1016 x

1-2.5 1220 x

6

1224 x

1A

122A x

16

122A x

2,5

1620 x

10

1620 x

10

1820 x

10

2o2A x

51

61

71

82

92

107

127

142

152

162

168

192

194

218

224

273

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

378 x

384 x

438

489

495

5'14

x

x

x

x

594 x

810 x

1124

1290

1307

1341

1342

1700

1772

1972

2182

x

x

x

x

x

x

x

x

x

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

6

6

6

7

7

7

7

7

8

B

B

B

B

B

8

8

B

B

50

100

100

125

125

150

150

175

175

200

200

250

300

350

350

350

350

350

400

400

400

400

400

450

500

500

500

500

600

600

600

600

700

700

800

800

800

800

900

900

900

900

1000

1000

1000

1000

1000

1100

1100

1200

1200

Nornina

Pressure

PN

10-40

10-16

25 40

6

10 16

6

10-16

10-16

40

10 16

25

10

'10

6

'10

16

25

4A

6

10

16

25

4Q

10

6

10

16

25

10

16

25

40

6

10

6

10

16

25

6

T0

16

25

6

10

16

25

40

16

25

25

40

1300

1400

T

.i1

G-

500

10

Dimensions in mm

drxdz\s1

57x107x4

108 x 162 x

108 x 167 x

141 x 1B2x

133x192x5

169x207x5

159x218x5

195x248x5

195x267x5

216x273x6

216 x 285 x

261 x328x

3'18x378x6

368x423x7

368x438x7

368x445xl

368x458x1

368x475x7

42O v. 473 x

42Ax4g0xl

42Ox497x7

420x515x7

420x547x7

470 x. 540 x

520x575x7

520x595x7

520 x 618 x

520x625x7

620x695x7

620x735x7

620x730x7

620x745x7

72OX7B5XB

l2Ox810xB

820x890x8

820 x 915 x

820 x 910 x

B20x940xB

92Ax990xB

920 x 10T5 x

920x1010x8

920 x '1040 x

1020x1090x8

1020x1120xlB

'1020 x 1125 x

1020x1150x8

1020x1190x9

1120x1225x9

1120 x T260 x

1220 x T360 x

1220x1395x8

1320 x 1435 x

1420 x 1545 x

1520 x 1645 x

5

5

5

6

6

7

7

7

B

B

B

I

8

B

8

8

B

B

DIN z69o

Quatity requested by

the trained Technicans

QuaLity for skiLled technotogical

progress does not stop in front of

the pipe trench. However the stakes

of an assemb[y job of a flange joint

are stilt high. That is why the

approved rubber steeL gasket concept cannot be matched by alterna-

tive products.

G-ST

G-5T-Flange Gaskets

in specialdimensions

Nominal

Diameter

DN

15

20

20

25

25

25

25

25

25

40

40

40

40

50

50

50

50

50

50

50

50

50

50

65

65

65

65

80

BO

BO

80

80

BO

BO

100

100

100

100

Dimens ons n mm

drxdzxsl

'15 x 54

23x54x3

23x60x3

28x43x3

28x53x3

28x65x3

30x48x4

30x

71

33x70x3

36x50x5

3BxA2x4

43x55x3

45x85x4

45x92x4

45x1O2x4

50 x 100

52x7Ax3

52x78x3

55x69x3

55x112x4

57x87x3

57x95y.4

57 x 118

62 x 118

63x75x4

65x85x4

l0x1O7x4

11 \

9T

71 x 137

80x104x3

B0 x 118

85 x 147

87 x 105

92x124x3

95 x 121

100 x 148

102x138x3

105 x 127

10B x 149

108 x 173

Nominal

Diameter

DN

x

3

x4

x

x

x

8

100

100

100

100

100

100

125

125

125

125

125

150

150

150

150

150

150

150

150

150

150

150

3

3

150

150

150

150

x

x

x

x

x

x4

x

x

x

x

115

3

4

115

175

190

3

5

190

204

3

204

200

5

204

204

204

4

200

4

5

20a

20a

Dirnens ons n

Nominal

ameter

mTn

D

drxdzxsl

DN

110x150x4

110 x 160 x

115 x 149 x

116 x 218 x

124 x 17O x

125x174x4

125x172x5

130 x T51 x

132x175x5

133 x 210 x

150 x 208 x

150 x 210 x

150x212x5

152 x 177 x

152 x 194 x

152 x 210 x

'154x258x5

156 x 177 x

158 x 188 x

159 x 203 x

160x215x3.5

16Ox247x5

169x203x5

170 x 195 x

170x285x5

175 x 228 x

180 x 240 x

1A7x23Bx6

192x228x4

192 x 217 x

243x239x5

243x273x6

204 x 305 x

2ASx270x5

2QBx242x5

21Ax25Ax6

215x270x4

224x259x5

220 x 309 x

225x239x5

'10

4

5

5

4

5

5

5

5

3

3.5

4

4

5

5

5

5

5

6

6

G-ST-Flange Gaskets

in speciaI dime nsion s, to suit pressure class PN 10

Outer diameter according to DIN 2590, special inner diameter

Nom nal

D arneter

DN

4A

50

65

BO

100

125

150

200

250

12

Dimensions in mm

Nominal

Diameter

drxdzxsl

17v.70x4

34x92x4

44x147x4

61 x 127 x

72x142x4

97x162x5

121 x 192 x

149x218x5

196x273x6

250x328x6

4

5

Dimensions in mm

DN

dr x

300

350

400

500

600

700

800

900

1000

299 x

329 x

378 x

485 x

587 x

687 x

786 x

884 x

986 x

d2

XSr

374

,<7

x7

xl

x7

x7

XB

xB

XB

xB

438

490

595

695

810

915

1015

1120

225

225

250

250

250

300

300

300

300

300

300

300

350

350

350

350

400

400

400

450

450

450

450

500

500

500

500

500

550

600

600

650

650

650

700

700

800

950

D

riens ons n rnrn

dtxd2xsl

225x2BOx5

230x267x5

255 x 295 x

255x312x5

267x342x6

274x364x6

300 x 345 x

300x349x6

300 x 365 x

300 x 378 x

307 x 353 x

310x35BxB

310 x 363 x

344x403x6

350 x 410 x

350x435x7

370x450x5

400x490x6

400x455x5

42Ax47Ax6

474x570x7

4BAx574x7

485x535x7

490x540x5

500x580x7

504t542x7

508x585x7

520x585x6

552x625x6

595x643x6

620x71Ax7

622x674x7

650 x 710 x

676x736x8

650 x 810 x

704x146x8

720x895x8

800x840x8

982 x 1050 x

4

6

6

5

5

5

7

B

8

8

G-ST/GUSS

G-ST/GUS5-Flange Gaskets

in special dimensions. For total covering of flange face.

The right gasket

for utility

Flange gaskets for flange joints

used in pipetine and facitity con

struction works had been produced

to match standards and

directives

precisely naming dirnensions for

in

ner and outer diameter.

The way to determlne the inner

diameter generalLv means that due

1o ils size a ronsiderabely big parli-

tion olthe [ace will not be roverec.

TypicaI scenery:

. FFG-Pipe made

of ductile cast

iron with casted flanges and

cement coating according to DIN

28 614, DN 8o, PN 10-25

. l/D pip": 78 mm

' O/D

pipg=

rll

mm

. area of ftange J66s= 9.rr5 mm'

. Flange gasket DN 80, PN 1o-4o

according to DIN EN 1514-1

' l/D oio" oio"= 89 mm

' O/D p1p"= 1{2 mm

. contact face with O lD pip" : 7 .672 mm'

Naturally there are no additional

restrictions caused by substitution.

0f course the gaskets will be made

Rdsum6: approx. 16% of the flange face

will not be covered!

of

N

BR'DUO.

This material

is

approved for water and natural gas

Due to insufficient corrosion protection especially to be found in otd instaL

tations an agglomeration of rust might occur occasionally whiLe deating with

aggressive water q uality.

The usage of KROLL & ZILLER-gaskets style TYP G-sT/GU55 shoots that

or

application (seeDVGW

othe r

international documents).

A

stressmark

is

linl<ed

to

the

extended KTW requirements.

problem!

The worksheet W 2Zo "Approvai

The in ner diameter will be determined by the nominal pipe size of commod-

against microbiological disease" is

ity pipe and fltting:

mandatoryl

KROLL

Nominal

Diameter

Nom nal

Pressure

DN

PN

40

50

60

10-40

10 40

65

10-40

65

BO

10-40

100

125

150

200

10 16

250

10 16

300

400

500

10

80

100

125

150

206

250

300

400

500

D Tnens

10

10

&

ZILLER again

is offering

the taitor made solution.

drxdzxsl

40

50

'10-40

10-16

10-16

10-16

ons n mm

x91

x4

x '106 x

x117x4

/, 126x4

x 142 x

x162x5

x 192 x

x21Bx5

x273x6

x32Bx6

x37Bx7

x4Bgxl

x594x7

4

4

5

d2

d1

lt

G-ST-P/S

DIN 2690

EN 1514-1

G-ST-P/5-Profile Gaskets

na

DN

Nom

Diameter

Nominal

Pressure

PN

15

10-40

20

20

6

10-40

25

32

32

10-40

6

10-40

40

50

50

10-40

65

6

65

80

100

100

100

125

125

125

10-40

T 0-40

10 16

25,40

'150

6

150

150

200

200

6

10-40

6

10-16

25-40

6

10 16

25 40

6

10-16

2AO

200

250

250

250

250

250

300

300

300

300

300

350

350

400

400

450

450

500

500

600

600

700

700

800

800

900

900

1000

1000

T 200

1200

1200

1200

1400

40

6

10

16

25

40

6

10

16

25

40

10

16

10

16

10

16

10

16

10

16

10

16

10

16

10

16

10

16

2.5

6

10

16

25

Dimens

aF_

ons n mm

d1 x d2 x s1/s2

22x 51 x 3/4

27x54x3/4

27 x 61 x 3/4

x 3/4

34x71

43x76x3/4

43x82x3/4

49x92x3/4

61 x96 x 4/5

61 x 107 x 4/5

77 x 116 x 4/5

77 x 127 x 4/5

89xT42x4/5

115 x 152 x 5/6

115 x T62 x 5/6

115x168x5/6

141 x 182 x 5/6

141 x. 192 x 5/6

141 x 194 x 5/6

169 x 2A7 x 6/8

169 x 218 x 6/8

169 x 224 x 6/8

220 x 262 x 6/8

220 x 213 x 6/8

22O x 284 x 6/8

220 x 290 x 6/8

273 x 317 x 6/8

273 x 328 x 6/8

273 x 329 x 6/8

273 x 340 x 6/8

273 x 352 x 6/8

324 x 373 x 6/8

324 x 378 x 6/8

324 x 344 x 6/8

324 x 40O x 6/8

324 x 417 x 6/8

356 x 438 x 7/10

356 x 444 x 7/10

407 x 4Bg x 7/10

407 x 495 x 7/10

458 x 539 x 7/10

458 x 555 x 7/10

508 x 594 \ 7/10

508x617x7/10

610 x 695 x 7/1O

610 x 734 x 7/1O

712 x 81A x B/T

712 x. 804 x B/11

813 x 9T7 x B/11

813 x 9T1 x 8/11

915 x 10T7 x B/T1

915 x10T1 x 8/11

1016 x1124 v. 8/11

1016 x 1128 x 8111

122A x129A x 8/11

122A x13O7 x 8/1

122A x1311 x 8/11

122A x1342 x B/11

142a x149O x 8/11

1

G-ST-P/S-Profi le Gaskets

Nomina

Diameter

Nominal

Pressure

DN

PN

350

350

350

350

350

400

400

400

400

400

450

450

450

450

450

500

500

500

500

500

600

600

600

600

600

6

10

16

dixd2xsr/s2

368 x 423 x. 7/10

368x43Bx7/10

368 x 445 x 7/10

368 x 458 x 7/10

368x475x7/1O

424 x 473 x 7/14

424x490x7/10

424 x 497 x 7/10

42O x 515 x 7/1A

42A x 547 x 7/1A

470 x 528 x 7/14

474x540x7/14

470 x 557 x 7/14

47Ox565x7/14

47O x 572 x 7l1A

52Ox57Ax//14

520 x 595 x 7/10

520 x 618 x 7/10

52O x 625 x 7/1A

52Ox62Ax//1A

620x680x7/10

620x695x//1A

620x735x7/1A

620x73Ox7/1A

620 x 745 x 7/14

720 x 785 x B/11

720 x 810 x B/11

720 x 805 x B/11

72O x B3A x B/11

720 v. 85A x B/11

B20xB90xB/11

B20x915xB/11

820 x 910 x B/11

820x940x8/11

82Ox97Ax8/11

920 x 990 x 8/'11

920 x 1015 x B/11

920 x 1010 x B/11

920 x 1040 x 8/11

920 x 1080 x B/11

1020 x 1090 x 8/11

102A x1120 x A/11

102A x1125 x A/11

1020 x T190 x B/17

1120 x 1215 x B/17

1215 x 1285 x 5.5/7

122A x 1395 x B/11

1280 x T380 x 8/17

1454 x 1540 x 8/11

6

10

16

25

40

6

10

16

25

4A

6

10

T6

25

40

6

TO

T6

25

700

700

loo

25

700

800

800

800

800

800

900

900

900

900

900

1000

1000

1000

40

'1000

Dimens ons in rnrn

25

40

4A

6

10

16

700

6

10

16

25

40

6

10

16

25

40

6

10

16

40

1100

1204

1204

@

40

1204

'1400

d2

d1

G-ST-P/S

ASME

G-5T-P/S

G-ST-P/S-Profile Gaskets

Nominal

Pipe

Size

Dimensions in mm

Pressure Class 150 lbs

NPS di x d2 x

1/2" 21 x 45

3/"" 2t x s4

1" 33x 64

1 1/4" 42 x 73

1 1/t" 48 x 83

2" 60 x 102

2 1/2" 73 x 121

3

89 x 133

3 1/2" 102 x 159

4" 115 x 171

5" T40 x 193

6" T68 x 219

8" 219 x 276

10" 273 x 337

12" 325 x 406

14" 356 x 448

16' 406 x 5T2

T8' 457 x 547

2A" 508 x 604

/,

x

x

x

x

x

x

x

x

x

x

x

x

D

rnensions n

Pressure C ass

si/s2

drx

3/4

3/4

3/4

3/4

3/4

4/5

4/5

4/5

4/5

5/6

5/6

6/B

6/8

2Ax

27x

33x

12x

48 x

60 x

73x

Bgx

1A2 x

T15 x

140 x

168 x

219 x

273 x

325 x

356 x

406 x

457 x

508 x

x 6/8

x7/10

x7/1O

v.7/10

x7/14

d2x

rn Tn

300 bs

s1/s2

x 3/4

64x 3/4

70x.3/4

80 x 3/4

92 x 3/4

108 x 4/5

127 x 4/5

146 x 4/5

162 x 4/5

178 x 5/6

213 x 5/6

2,17 x 6/B

305 x 6/8

359 x 6/8

4'19 x 6/8

51

482 x7110

537 x7/10

594 x7/10

651 x 7/10

Nominal

P pe

Size

Dlmens ons n rnm

Dimensions in mm

Pressure Class 150 lbs

Pressure Class

300 bs

NPS di x d2 x si/s2

di x d2 x s1/s2

24"

26"

28"

30'

32"

34'

36"

38'

40"

42"

44"

46"

48'

50'

52'

5,1'

56"

58'

60'

x 772 x7/10

665v.832x7/1O

720 x 895 x8/11

770 x 949 x8/17

820x1003x8/17

865 x 1054 x B/11

g20x1114xB/11

965 x 1051 xB/11

61A

x 115xl/1O

x7/14

665 x 771

720 x 829

770 x BB0

820 x 937

865 x 987

920 x 1045

965 x 1T0B

1020 x'1159

x B/11

x B/11

xBl11

x 8/T1

x 8/1'1

x B/11

x B/1'1

T070 x 1216 x 8/11

1120 x1273 x B/11

1170 x 1324 x B/11

122A x 13A1 x B/ 11

127A x 1132 x 8/ 11

1320 x 1489 x B/11

1370 x 1546 x 8/11

1430 x 1603 x B/11

112A x1273 xB/11

1530 x 1711 x 8/11

610

xB/T1

x 8/T'1

x B/11

1170x1270x8/11

1220 x 1321 x B/11

1270 x 1375 x B/11

1320x1425x8/11

1370x14BgxB/11

1430x1540x8/11

1475 x 1590 x B/11

530 x'1641 x B/11

1020 x1111

1070 x 1162

1T20 x T216

T

G-ST-P/S

G-ST-P/S-Profi le Gaskets

special dimensions

Nominal

Diameter

DN

40

50

65

80

B0

100

125

150

'150

150

175

2OA

204

250

250

300

Dimensions in mm

drx d2 x

si

38x 92x 3/4

50x T07 x

66x 127 x 4/5

76x 142 x 4/5

81 x 142 x 4/5

100 x 162 x 4/5

125 x 192 x 5/6

150 x 2T8 x 5/6

156 x 218 x 6/B

114 x 218 x 6/B

T75 x 235 x 6/B

182 x 275 x 6/B

240 x 273 x 6/8

228 x 328 x

250 x 328 x 6/B

275 x 3/8 x 6/B

nal Dimens ons in mm

DNdrxd2xsl

Norn

D arneter

300 300 x

350 285 x

350 330 x

350 340 x

350 340 x

350 396x

400 372 x

:100 324 x

400 400 x

500 465 x

600 589 x

600 630 x

700 661 x

700 690 x

800 745 x

378

438

x 6/8

x7/1A

438 x 7/10

490 x 7/10

x 7/10

x 6/8

490 x1/1O

617

,144

490 x7/14

490 x7110

595 x 7/10

695 x 7/T0

680 x 7/10

810 x 8/11

755 x B/11

915 \. A /11

G-ST-P/5-Profile caskets

Dimensions for flanges of VCI-tanks,

in accordance with code of practice C2.1.1

Nominal

Dimensions in mm

Diameter

DNdixd2xsl

500 51A x 577 x

600 61A x 677 x

600 610 x 711 x

700 710 x 782 x

800 810 x BB7 x

7/1A

7/14

7/14

8/11

8/11

15

G-ST-P/K

G-sr-P/K

G-ST-P/K to suit flange ioints made of thermoplastics

(PVC, PB PE, PVDF)

For pressure piDeLines mrde oi FVC w th solventcemented flanse adaptors and ba.kine flanees, maiulartured in ac.ordance

w lh D N 306l part 4, and aLso tor pressure pipeLines made of PE, PP and PVDFwith eLe.trofused nnnge adaptors and backing

fLangesmanuiacturedina..ordan.cwlthDN16g62parrD(PP)andDN1696tpartfl(PE),akousabGrornxedflangesmade

of PVC, PP afd PVDF. Can aLro be !5ed for intermedlate fLanee vaLves. D mensions ac.odife to DIN lS0 2io1PN 10.

Outer O of pipe

Flange

ot,l ')

Dimensions mm

d1 x d2x

(mm)

10

16

'15

20

25

32

20

25

x

x

x

x

0x

50 x

x 3/4

x 3/4

x 3/4

x 3/4

x 3/4

x 3/4

63 x 1Q7 x 4/5

75 x 127 x 4/5

90 x 142 x 4/5

110 x 162 x 5/6

125 x 192 x 5/6

140 x 192 x 5/6

160x218x 6/8

204 x273 x 6/8

225 x273 x 6/8

250 x 303 x 6/8

25A x32B x 6/8

2BA x32B x 6/8

315 x 378 x 6/B

355x438x7/10

4oo x 489 x 7 /1O

16

20

25

32

40

40

50

50

65

75

80

90

100

125

125

150

'110

125

140

160

200

200

200

225

250

250

250

250

250

300

350

400

sr/s2

280

3'15

355

400

DrN

G-ST-P/K-Profi le Gaskets

l-

46

51

61

71

82

92

/ rso (PVDF)

For pressure pipelines made of PVDF with butlfused flange adaptors and

backing flanges. Flange dimensions according to DIN ISO z5or PN ro.

F

ange

otrr ')

20

25

40

50

65

65

BO

100

100

125

125

150

150

150

200

200

200

200

250

t6

Outer O of pipe

PN

(mm)

16

16

16

'16

16

16

10

r 0-16

16

10

10

16

10

16

10

T0

16

1A

16

10

25

32

4A

50

63

75

75

90

110

125

140

140

160

160

180

200

200

225

225

280

Dimensions in mm

SDR

21

21

21

21

21

21

33

33

21

33

33

21

33

21

33

33

21

33

21

33

a

djx

24

30

37

46

61

73

69

84

x

x

x

x

x

d2x

sj/s2

61 x

71 x

82 x

92 x

3/4

3/4

3/4

3/4

4/5

4/5

4/5

4/5

5/6

5/6

5/6

5/6

6/8

6/8

6/8

6/8

6la

6/a

6/8

6/8

x

x

x 127 x

x 142 x

1O4 x 162 x

123 x162 x

137 x 192 x

127 x 192 x

156 x21Bx

146 x 218 x

177 x 218 x

196 x 273 x

181 x 273 x

22O x 273 x

203 x 273 x

274 x 32A x

107

v. 127

O-

G-ST-P/K

DIN 16962 part + (PP)

DIN 1696j part 4 (PE)

G-ST-P/K Profile Gaskets

G-ST-P/K Profi le Gaskets

For pressure pipelines made of PE and PP with buttfused flange adaptors and bacl<ing ftanges to suit DIN

ß962 paft 4 (PP) and DIN 16963 part 4 (PE). FLange

dimensions according to DIN LSO 2501 PN10.

F

ange Outer

Dimensions in mm

O

ofooe

DN') (nT;)

sDn':)

'11

20

20

25

25

25

25

7.4

32

1.4

32

40

11

32

40

50

50

50

63

63

63

75

15

75

90

90

90

110

110

110

7.4

1T0

7.4

33

40

4A

40

50

50

50

65

65

65

BO

BO

80

100

'100

100

100

100

100

100

100

125

125

125

11

125

125

125

125

140

140

140

17

11

7.4

17

11

7.4

17

11

7.4

1l

11

7.4

33

17

11

17

'11

7.4

33

17

11

dl x d2 x

22x61

24x61

2a v. 71

23x71

34x82

29x82

46x92

42x92

36x 92

58 x 107

53 x 107

45 x 107

69 x 127

63 x 127

54 x 127

A4 x 142

76 x 142

65 x '142

1O4 x 162

T00 x 162

93 x 162

B0 x 162

123 x 162

114 x '162

'105 x 162

90 x 162

137 x 192

127 x 192

117 x 192

DIN 16962 part 4 (PP)

DIN 16963 part 4 (PE)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Flange Outer

D mensions in mm

O

of oioe

sr/s2

3/4

3/4

3/4

3/4

314

3/4

3/4

3/4

3/4

4/5

4/5

4/5

4/5

4/5

4/5

4/5

4/5

x 5/6

x

x

x

x

x

For pressure pipelines made of PE and PP with buttfused flange adaptors and backing flanges to suit DIN

ß962 paft 4 (PP) and DIN 16963 part a (PE).

5/6

5/6

5/6

5/6

5/6

x 5/6

x 5/6

x 5/6

DNrr (;;)

125

150

150

150

150

150

150

150

150

200

200

200

200

200

200

140

160

160

160

160

180

180

180

180

200

200

200

204

225

225

200

sDF'r

7.4

33

11

11

7.4

33

17

11

7.4

33

17

11

7.4

17

11

250

250

254

254

254

254

17

250

280

33

250

280

280

315

315

315

1l

355

400

400

450

450

500

500

560

560

560

630

630

11

254

300

300

300

350

350

400

400

500

500

500

500

600

600

600

600

600

11

T1

33

17

11

17

'11

11

17

11

17

11

11

17

11

drxd2xsj/s2

x192 x5l6

156x218x6/B

146 x 218 x 6/B

135 x 218 x 6/8

116x218x6/B

171 x 218 x 6/8

164x218x6/8

151 x21B x6/B

130x218x6/B

196x273x6/B

181 x 273 x 6/8

168x273x6/B

145x273x6/8

220 x 273 x 6/a

2A3 x 273 v, 6 /B

188x273x6/8

243 x 32a x 6/A

226 x 328 x 6/8

208 x 328 x 6/8

214t328x6/8

252 x 328 x 6/8

233 x 328 x 6/B

306 x 378 x 6/8

283 x 378 x 6/8

262 x 378 x 6/8

319 x 435 x 6/B

294 x 438 v. 6/8

359 x 4Bg x 6/B

331 x4Bg x6/B

403 )< 594 x 7/1O

372x594x7/1O

447x594x7/10

413x594x7/10

494x695x7/10

462x695x7/1a

451 x 695 x 7/10

555x695x7/10

519x695x7/10

101

\omi-al f.angp si,,e nay not

be siTilar lo nom ina I pipe

size.

')SDR: Standard Dimension Ratio (ratio between outer

@ of pipe I wall thickness)

d2

.11

77

G-ST'P/KN for non-[oad bearing flange joints

G-ST-P/KN for non-load bearing

flange ioints

The successfut merging of two

opposing sealing philosophies.

The c ST profile gasl<et exhibits

de[orn ing and no: ld ing rharac [erislit: wiIh nin ru-n su lare pressu re.

When extreme stresses occur during

instaLlation, the G-ST-P/KN offers the

best solution.

The outer steeL ring on the outside

boxes in the surface lip and protects

it fully.

F_

ligh ,: fare p.e\<L e\ on 1l-e rubber lip or blow-outs under high

'FF'

operaling pre\sJ'e are nor pos' ble.

€

kkF-

FF-E--

the case of partcoated fLanges the

sensitive faces are protected.

n

E

Typical applications are therefore:

Systems operating at high pressure

or

Rubber-coated sub-assem bLies

i-

ci-enicol wo'1.: and powe' sto

tio

n

s.

Soft rubber

0-R in g

Flatt ring section

Steel support ring

19

c-sr-P/KN

DIN 2690

G-ST-P/KN

c-ST-P/KN for non'load bearing

flange ioints

PN

10

PN 1oo

Dimensions in rnm

100

10

16

d1

d,

d.1

d4

d1

d.1

d.1

si/s2

10

18

56

56

50

61

61

20

25

2A

45

50

60

45

22

45

50

60

70

45

15

5/3

5/3

5/3

70

7A

82

82

32

43

49

82

82

82

82

s2

147

127

92

147

127

92

107

142

142

162

192

162

192

21A

T68

103

113

137

148

174

195

210

225

267

292

353

418

475

547

572

247

277

309

364

424

486

543

103

119

143

154

180

217

257

287

628

657

764

879

DN

35

40

50

65

77

90

11s

BO

100

125

141

'150

169

195

220

274

325

368

420

470

520

175

200

254

300

350

400

450

500

600

700

800

900

1000

1204

1400

1600

'1800

2000

2204

2404

2600

2800

3000

620

120

820

920

020

1220

T

1420

1620

1420

2420

2220

2424

2620

2B2A

3020

214

248

273

324

438

490

540

595

695

810

915

1015

1120

T 340

1545

1770

1970

2180

2380

2590

2790

3010

3225

50

60

10

248

273

330

385

445

497

557

618

735

805

910

10T0

1125

1340

1540

'1760

1960

2165

2375

2585

2745

127

142

168

195

255

245

342

402

458

515

565

625

730

830

940

1040

1150

1360

1575

1795

2000

2234

60

92

147

127

142

745

850

970

1080

T 190

1395

1615

1830

9BB

1108

1220

1452

397

4sB

512

512

744

813

950

5.5/3.5

5.5/3.5

5.5/3.5

5.5/3.5

5.5/3.5

5.5/3.5

B/5

B/5

B/5

B/5

8/5

B/5

a/5

8/5

8/5

10/6.5

10/6.5

10/6.5

10/6.s

10/6 5

10/6.5

10/6.5

10/6.5

12/8

12/8

12/A

12 /B

12/B

12/B

12/8

12/A

12/8

d4

d1

c-sr-P/KN

similartoASME B 16.zr for ASME B 16.47 Series A flanges

(previous MSS 5P - 44)

F:

G-5T-P/KN for non-load bearing

flange ioints

CLass 15o Ibs -

600 lbs

Dimensions in mm

Class

NPS

26"

28"

30"

32"

34"

dl

46"

720

770

820

865

920

965

1020

1070

1120

1170

4B'

50"

1224

1274

52',

1324

1370

1430

1475

1530

38"

40"

44"

54"

56"

58"

60"

150

d4

d4

d4

d4

774

835

898

952

1006

1057

1117

1054

1114

1165

1219

1273

831

866

914

971

1422

1073

1130

1104

1155

831

882

939

990

1447

111

1

1162

1219

1276

1327

1384

1435

1492

1549

1606

1663

1714

1323

1378

1428

1492

1543

1593

1644

G-ST-P/KN

892

946

1003

1054

1117

1073

1132

1118

1231

1289

1346

1403

1454

1517

1568

'1619

16A2

simitarto ASME B

1215

1270

1327

1390

1447

1498

1555

1612

1663

1120

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

12/8

12/B

12/8

12/B

12/B

12/A

16.zr für ASME B 16.47 Series B flanges

(previous API 605)

F=r

G-ST-P/KN for non-load bearing

flange ioints

Class r5o lbs -

6oo bs

Dimensions in mm

NPS

dl

d1

d,

d4

d,

s1/s2

26"

28"

665

720

770

820

865

725

776

827

771

746

800

857

88'1

939

993

1047

10s8

1149

1200

765

819

879

933

997

1441

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

10/6.5

T 0/6.5

10/6.5

T 0/6.5

10/6.5

10/6.5

32"

34"

920

38"

40"

42"

44"

965

1020

1070

1124

46',

1174

48"

50'

1224

1274

52',

1324

54"

1370

1430

1415

1530

56',

58'

60"

935

987

1044

1095

1146

1196

1255

1306

1357

1408

1463

1514

1579

1630

825

BB6

12s1

1317

1368

1419

1470

1555

1593

911

962

1022

12/B

12/8

12/8

12/B

'1655

12/8

1104

12/A

G-ST-P/Kl{

simitar to ASM E B

non-loät

bearirir$;,''

16.zr for ASM E B 16.5 flanges

:

!l

Ctass r5o lbs - 9oo lbs

Dlmensions in mm

'150

Class

400

600

900

d4

d4

s1/s2

63

5/3

5/3

5/3

NPS

d1

d4

d4

d4

1/2"

22

47

3/4',

1"

27

34

43

49

57

53

66

66

82

82

a2

79

88

95

95

95

9B

111

111

111

142

130

149

165

180

130

149

162

177

212

247

130

149

168

1 1/4"

73

21/2"

74

90

76

85

104

124

136

3 1/2"

102

162

115

141

169

220

274

174

196

222

279

11t2',

2"

5"

6"

8"

10"

12"

14"

'18"

20"

6S

409

450

356

407

458

508

610

514

549

606

717

215

251

307

422

485

539

596

654

774

162

193

241

266

304

320

358

419

482

536

593

647

400

457

492

565

612

682

790

206

247

289

358

434

498

520

574

638

698

838

5.5/3.5

5.5/3.5

5.5/3.5

5.5/3.5

5.5/3.5

a/5

a/5

a/5

a/5

a/5

al5

8/5

8/5

B/5

10,/6.5

10,i6.5

10/6.5

Available materials

EPDM

N

BR-DUO

FPM.S

Thrust Ring

Stainless SteeI

t.43ot I AlSl 3o4

Low Carbon Steel

1.oc:.9 l st 37

zincplated and gatvanized

other materials on request

+

i

G-ST-P/HTB

VP 4o1l DIN EN 682

G-ST-P/ HTB

G-5T-Profile Gaskets

Designed for steel flange joints in Fire

nected fire fighting systerns.

-

Thrustringstyte"KammprofiL",t.r+SZtlASl316Ti,

te on both faces. Sealing lip made of

Nominal Nom na

ameter Pressure Class

DN

PN

D

D

d1

25

32

10,40

10 40

34

4A

10-40

10-40

10-40

10 40

100

125

150

10-16

N B R-D

Xdrx

s1/s2

71

49

92

X

6T

77

107

127

B9

142

162

X

10-16

10-16

115

141

169

214

x

240

10-16

22A

200

250

25

224

273

BO

'16

layers of expanded graphi-

mensions n mm

X

65

DVGW approved up

U0.

a2

50

to 5 bar

accordlng to VP 4o1

Safe pipesystems as well as con'

273

284

329

5.5/4.5

5.5/4.5

5.5/4.5

5.5/4.5

5.5/4.5

5.5/4.5

a/6

8/6

a/6

a/6

a/6

a/6

d1

' F-r^

G-ST-P/OE

G-ST-P/OE

G-ST-P/OE:Profi le Gaskets

Proflles availäble currently

Due to their innovative design, profiLe gaskets are the first choice to provide retiabte sealing for flange joints with low

static capacity.

For example, the construction of an apparatus and containers will often combine sLim flange faces with a small amount

of botts.

Those and similar applications are perfectly covered by the type G'ST'P/OE.

We will match your request through the right combination of elastornerlips and stainless steel inserts.

Profiles

Elastomerlips

'18

10

=l

F:s-l

Available materia[s

EPDM NBR-DUO

FPM-S

Steel insert made of r.43or/AlSl 3o4

Others on req uest

.. 'lt r-

25

_

13,U

_

-Y^

35

=l

ts:N?^

45

33.5

-Y^

24

Minimum inner diameter = 2oo mm

'l'o'

G-ST-P/GR

G-sT-P/G

R

G'5T-P/GR-Profi le Gaskets

in accordance with directive FDG - ol89

to suit flange joints with soft/hard rubber lining.

Nom nal Diameter

Dimensions in mm

xd3xsr/sz

DN

25

32

40

50

65

BO

100

125

150

200

250

300

350

400

500

600

700

800

s00

1000

1200

2a x

37x85

43x95

54 x

7A x

82 x

101 x

132 x

159 )<

207 x

264 x

310 x

341 x

392 x

494 x

595 x

695 x

800 x

BS5 x

1000 x

12AO x

74

110

130

145

165

195

221

276

330

380

440

491

596

698

813

920

1020

1127

1344

x54x3.5/3

x64x3.5/3

x70x3.5/3

x

82 x

x 102 x

x114x4.5/4

x 140 x

x 163 x

x 192 x

x24Ax5.5/5

x293x5.5/5

x342x5.5/5

x373xB/l

x430xB/l

x532x8/7

x635xB/7

x735x9/8

xB40x9/B

x940x9/B

x 1040 x

x1245x9/B

4.5 /

4.5 /

4

4.5 /

5.5 /

5.5 /

4

9 /

4

5

5

B

d2

d3

d1

25

G-ST-Wedge Ring

G-ST-Wedge

Ring

Outer diameter accord ing to

DIN 2632, ASME B 16.5

PN 10

Wedge Ring

infin itly variable

na Diameter

Norn

DN

D rnensions in mm

sat0'

d2

89x

142

127

142

162

152

218

273

328

378

438

490

595

695

810

917

1015

4A

50

65

BO

100

125

150

200

250

300

350

400

500

600

700

800

900

weight

x

45

58

x

x

B9

x

108

x

x

133

71

x

163

216

267

318

368

420

520

622

x

710

x

x

808

910

x

x

x

x

x

x

x23

x24

x25

x27

x27

x30

x33

x37

x41

x45

x53

x57

x66

x73

x84

x92

x

satS'

kg

29

31

0.6

0.8

37

1.7

3B

2.0

1.4

43

4B

4.1

56

5.4

7.7

9.7

17.6

64

71

a4

91

19.3

108

120

32.1

141

'156

100

171

40.3

76.0

99.0

121.0

The quicl< answer to

sealing problems

The Kroll & Zilter G-ST wedge ring is

ideally suited for solving alignment

problems during assembly or for filting

large gaps in installation. The shell

structure with inner elastomeric flat

gasket - combined into one unit with

pins provides the posibility to solve

misalignments from oo to B" without

ste ps.

The ideaL com binatio n with

G-ST-P gaskets is approved for gas and

drinking water and is a must for the

practical engineer.

Time is saved during assembly and

flanges can be reliably sealed for

service.

G-ST-Wedge Ring

Class r5o

Wedge Ring

infinitLy va riable

Nominal Pipe Size

Dimens ons tn mm

NPS

1O2

121

133

111

219

276

337

406

2"

2 1/2"

4"

6'

B'

10,,

12"

x

x

x

x

x

x

x

x

55

68

84

weight

sat0'

satB'

24

27

31

kg

0.92

1.39

1.54

28

35

37

110

29

41

2.61

163

214

35

50

39

5B

268

43

49

67

3.89

6.16

9.50

T 5.90

320

77

Materialr Carbon steeL (1.ool7), galvanized, electro coatecl with epoxy polyester powder

coating (potäble water approvaL), colour acc. to RAL 501o, blue.

I

26

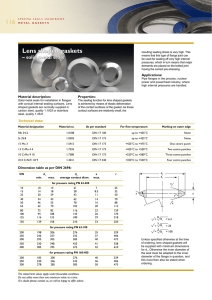

The companies within the ZILLER-Group

NILtrs

NILOS@ HANS ZILTER GMBH

& CO. KG

Conveyor belt - equipment

Conveyor belts and connections, vulcanising equipment, coLd bonding

adhesives TOPGUM, NIL0S friction, reflex and wear protection coatings,

knife cteaning devices, moutded articles, sieve ftoors, sieve machines with

new processing technoLogy, planning and supply of complete conveyor

belt repair worksho ps.

NII.OS.HINE

ZILLER GMBH & CO. KG

Ro[ler bearing gaskets

NIL0S rings for ball and roLLer bearings, Z and RS bearings, labyrinth

gaskets NlL05 ring LSTO, spacer rings.

KROLL & ZIttER GMBH & CO. KG

G-ST ftange and profile gaskets, other flange

KB0L[aZlil.EB

gaskets and packings

Ask for the complete brochure.

1üB qel'fur

F*fk

t

t

a

,

t

-->

-.: -

$s's

$*-t,il'

KROLT & ZlttER GmbH & Co.KG

Reisholzstrasse 15

D-40721 Hilden/Germany

lnland/Domestic:

Tet: +49 (0)2103.951-516, .5o7

Fax +49 (o)21o3-95i-5o8, -5o9

Ausland/Expod:

Te[: +49 (o)zro3-95r-5u, -5r5

Fa* +49 (o)2103-951"510

info@kroll.ziller.de

www.Krolt-Zilter.de