Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers

advertisement

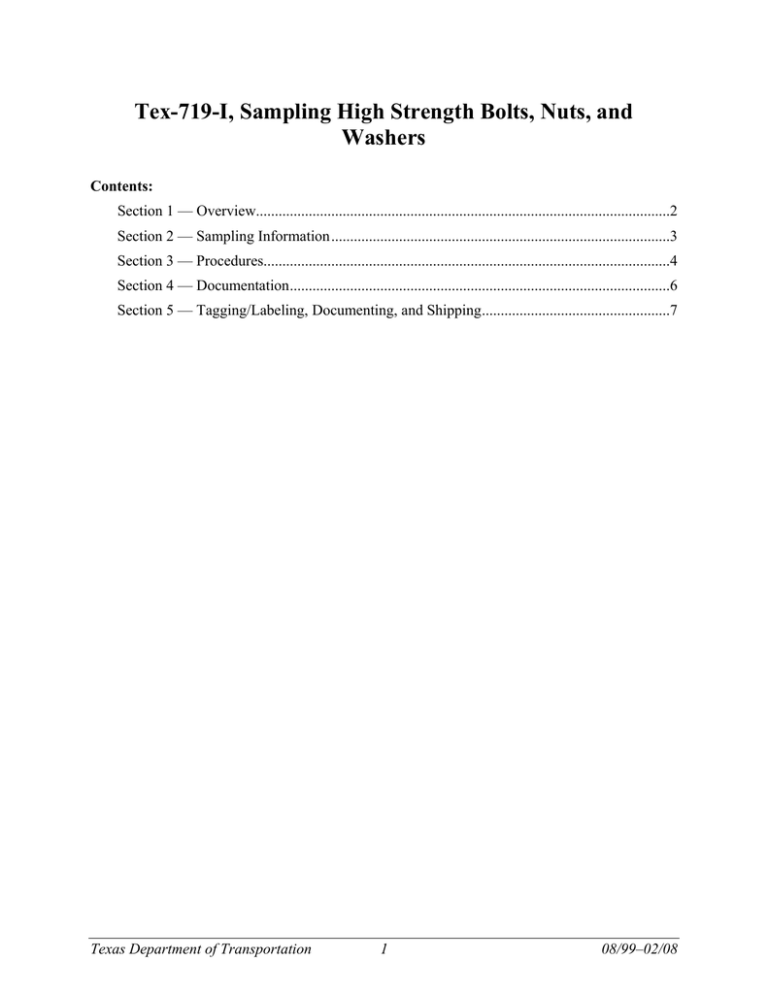

Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Contents: Section 1 — Overview..............................................................................................................2 Section 2 — Sampling Information..........................................................................................3 Section 3 — Procedures............................................................................................................4 Section 4 — Documentation.....................................................................................................6 Section 5 — Tagging/Labeling, Documenting, and Shipping..................................................7 Texas Department of Transportation 1 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 1 — Overview Section 1 Overview Effective dates: August 1999–February 2008. This method outlines the procedure for sampling ASTM A 325 and ASTM A 490 bolts, nuts, and washers used as high strength fasteners. Units of Measurement The values given in parentheses (if provided) are not standard and may not be exact mathematical conversions. Use each system of units separately. Combining values from the two systems may result in nonconformance with the standard. Texas Department of Transportation 2 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 2 — Sampling Information Section 2 Sampling Information Sampling shall be done by lot and by an authorized representative of TxDOT. Texas Department of Transportation 3 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 3 — Procedures Section 3 Procedures Visual Inspection The sampler shall perform a visual inspection of the bolts for head bursts (an open break in the metal which can occur on the flats or corners of bolt heads). A defective bolt, for the purpose of visual inspection for bursts, is any bolt that contains a burst on the flat of the head which extends into the crown surface of the head (chamfer circle) or the under-head bearing surface, or at the intersection of two wrenching surfaces. A lot, for the purpose of visual inspection, consists of all bolts of one type having the same nominal diameter and length offered for inspection at one time. A representative sample quantity shall be picked at random from each of the bolt lots and visually inspected for bursts. The sample size shall be as shown in the following table. If the number of defective bolts is greater than the acceptance level cited in the table, the lot shall be subject to rejection and shall not be sampled for mechanical testing. Lot Quantity 2 to 8 9 to 15 16 to 25 26 to 150 151 to 280 281 to 500 501 to 1,200 1,201 to 3,200 3,201 to 10,000 10,001 to 35,000 ASTM A325/A490 Bolts Number of Samples 2 3 5 20 32 50 80 125 200 315 Acceptance Level 0 0 0 1 2 3 5 7 10 14 Mechanical Testing ASTM A 325 High Strength Bolts – A lot, for the purpose of selecting samples for mechanical testing, is defined as that quantity of bolts of the same nominal diameter and length necessary to fill the requirements of a single purchase order. From each lot, the minimum number of samples is indicated in the following table. ASTM A325 Bolts Lot Quantity Number of Samples 500 or less 3 501 to 1,200 5 1,201 to 3,200 8 3,201 to 10,000 13 10,001 and over 20 Texas Department of Transportation 4 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 3 — Procedures ASTM A 490 High Strength Bolts – A lot, for the purpose of selecting samples for mechanical testing, is defined as that quantity of bolts of the same nominal diameter and length necessary to fill the requirements of a single purchase order. From each lot, the minimum number of samples is indicated in the following table. ASTM A490 Bolts Lot Quantity Number of Samples 150 or less 3 151 to 1,200 5 1,201 to 10,000 8 10,001 to 35,000 13 35,001 to 150,000 20 150,001 and over 32 ASTM Nuts for use with ASTM A 325 High Strength Bolts and ASTM A 490 High Strength Bolts – A lot, for the purpose of selecting test samples for mechanical testing, consists of all material offered for inspection at one time with the following common characteristics: the same nominal size, grade, type, style, thread series, class, and surface finish. From each lot, the minimum number of samples is indicated in the following table. Nuts Lot Quantity Number of Samples 8,000 or less 2 8,001 to 22,000 3 22,001 and over 5 Washers for use with ASTM A 325 High Strength Bolts and ASTM A 490 High Strength Bolts shall be sampled at the same rate as nuts. Texas Department of Transportation 5 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 4 — Documentation Section 4 Documentation All samples shall be accompanied by the original signed and notarized Form D-9-USA-1, "Material Statement," with mill test reports and certifications attached (reference 'Buy America Documentation Program' section of the CST/M&P 'Material Inspection Guide'). Texas Department of Transportation 6 08/99–02/08 Tex-719-I, Sampling High Strength Bolts, Nuts, and Washers Section 5 — Tagging/Labeling, Documenting, and Shipping Section 5 Tagging/Labeling, Documenting, and Shipping Follow the 'General Requirements' as detailed in "Tagging/Labeling, Documenting, and Shipping General Requirements." In addition: ♦ provide name of producer, size, grade, type, heat or sample number ♦ carefully wrap samples ♦ wrap completed packages to prevent damage during transit. Texas Department of Transportation 7 08/99–02/08