Catalog GK-1

Eighth Edition

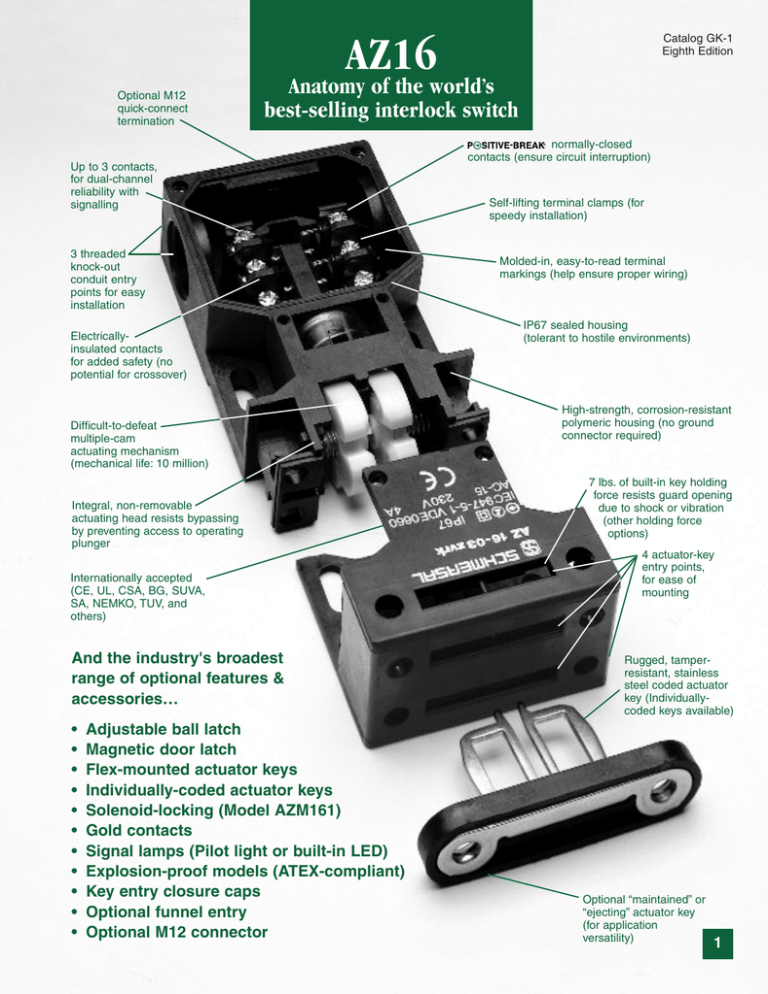

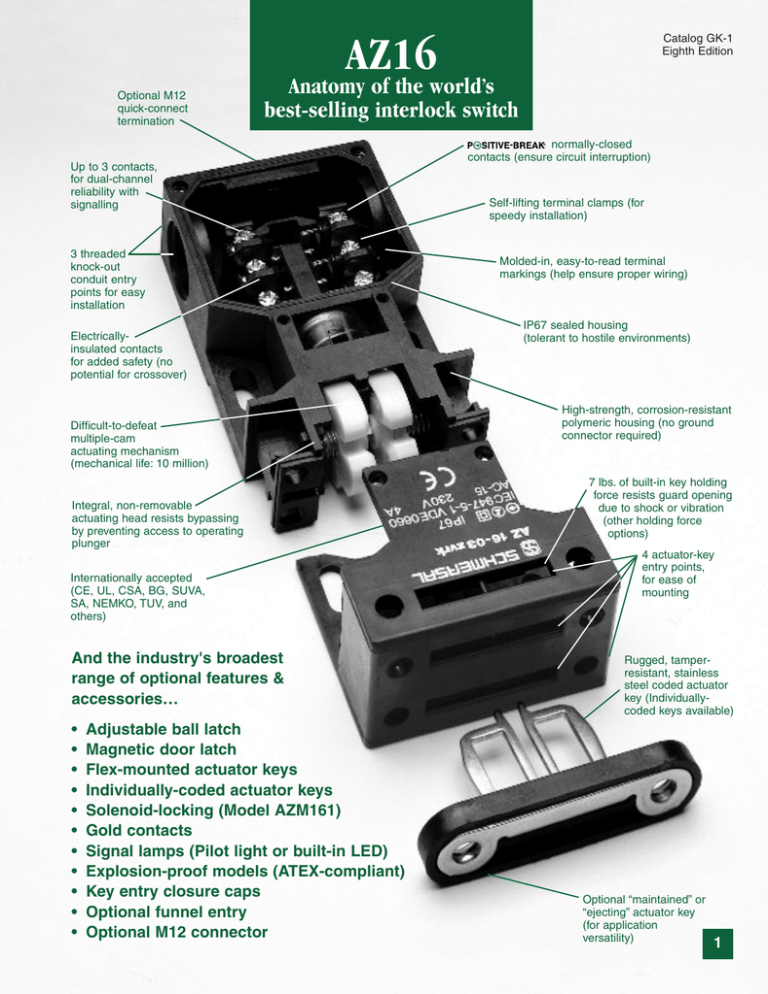

AZ16

Optional M12

quick-connect

termination

Anatomy of the world’s

best-selling interlock switch

normally-closed

contacts (ensure circuit interruption)

®

Up to 3 contacts,

for dual-channel

reliability with

signalling

3 threaded

knock-out

conduit entry

points for easy

installation

Electricallyinsulated contacts

for added safety (no

potential for crossover)

Difficult-to-defeat

multiple-cam

actuating mechanism

(mechanical life: 10 million)

Integral, non-removable

actuating head resists bypassing

by preventing access to operating

plunger

Internationally accepted

(CE, UL, CSA, BG, SUVA,

SA, NEMKO, TUV, and

others)

And the industry's broadest

range of optional features &

accessories…

•

•

•

•

•

•

•

•

•

•

•

Adjustable ball latch

Magnetic door latch

Flex-mounted actuator keys

Individually-coded actuator keys

Solenoid-locking (Model AZM161)

Gold contacts

Signal lamps (Pilot light or built-in LED)

Explosion-proof models (ATEX-compliant)

Key entry closure caps

Optional funnel entry

Optional M12 connector

Self-lifting terminal clamps (for

speedy installation)

Molded-in, easy-to-read terminal

markings (help ensure proper wiring)

IP67 sealed housing

(tolerant to hostile environments)

High-strength, corrosion-resistant

polymeric housing (no ground

connector required)

7 lbs. of built-in key holding

force resists guard opening

due to shock or vibration

(other holding force

options)

4 actuator-key

entry points,

for ease of

mounting

Rugged, tamperresistant, stainless

steel coded actuator

key (Individuallycoded keys available)

Optional “maintained” or

“ejecting” actuator key

(for application

versatility)

1

TABLE OF CONTENTS

Topic

Page

Alphanumeric Product Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pictorial Product Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 5

About Schmersal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Man-Machine Safeguarding Products

Selection Guides

• Keyed Interlock Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• Keyed Interlock Switches with Solenoid Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

• Application Accessories

(Safety Door Handles, Enabling Devices, Safety Foot Control, Two-Hand Controls) . . . 105

• Emergency Cable-Pull Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

• Non-Contact Safety Sensors & Compatible Safety Controllers . . . . . . . . . . . . . . . . . . . . 153

• Hinged Safety Interlock Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

• Safety-Rated Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

• Safety Light Curtains & Beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

• Safety Pressure Mats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

• Fail-to-Safe Safety Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

• Safety Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Appendices

• Frequently Asked Questions Regarding Man-Machine

Safeguarding Requirements & Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .352

• Frequently Asked Questions Regarding Safety Light Curtains . . . . . . . . . . . . . . . . . . . . .380

• Selected Machine Safeguarding Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .401

• Machine Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

• Selected Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

• NEMA, UL, CSA & IEC Ingress Protection Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .412

Copyright © 2007 by SCHMERSAL All Rights Reserved.

SCHMERSAL is continuously working to improve our product designs. Therefore we reserve the right to change product specifications/ratings and

other information contained in this catalog without notice. Proper installation and use of our products remains the customer’s responsibility.

2

ALPHANUMERIC PRODUCT INDEX

Product

Series

Page

Product

Series

Page

AES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

SDG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

AZ15/16 . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SHGV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

AZ16zi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

AZ17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SEPK(G) . . . . . . . .e.w. . . . . . . . . . . . . . . . . . 122

AZ17zi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SLC, SLG & SLB . . . . . . . . . . . . . . . . . . . . 263

!

AZ200 . . . . . . . .e.w. . . . . . . . . . . . . . . . . . . . . 32

N

SMS3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

AZ335 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SRB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

AZ415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ST14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

AZM161 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

STS . . . . . . . . . . . e. w

. . . . . . . . . . . . . . . . . . 106

AZM170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

T.C 235/236 . . . . . . . . . . . . . . . . . . . . . . . . 214

AZM200 . . . . . .e.w. !. . . . . . . . . . . . . . . . . . . . 70

TESF . . . . . . . . . . e. w

. . . . . . . . . . . . . . . . . . .220

AZM415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

TESZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

AZS2305 . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

TFA/TFI . . . . . . . . e. w

. . . . . . . . . . . . . . . . . . .124

N

!

!

N

!

N

!

N

!

N

B25 . . . . . . . . . .e.w. . . . . . . . . . . . . . . . . . . .112

TG-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

BNS16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

TKF/TKM . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

BNS33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

TV8S-521 . . . . . . . . . . . . . . . . . . . . . . . . . .212

N

!

BNS33S . . . . . . .e.w. . . . . . . . . . . . . . . . . . . .162

TVS335 . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

BNS250 . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

TZF/TZM . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

BNS260 . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

TZG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BNS30 & BNS300 . . . . . . . . . . . . . . . . . . . .166

TZK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

BNS303 . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Z332 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

BNS333 . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Z/T235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

!

BNS-B20 . . . . . e

.w

. . . . . . . . . . . . . . . . . . . . 174

N

Z/T236 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

BZ16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Z/T335 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

C50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Z/T336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

!

CSS 34 . . . . . . . e. w

. . . . . . . . . . . . . . . . . . . .184

N

CSS 180 . . . . . . .e.w. !. . . . . . . . . . . . . . . . . . 176

N

ZS71 & ZS71NA* . . . . . . e. w

. .! . . . . . . . . . . . 126

ES95 SB . . . . . . . . . . . . . . . . . . . . . . . . . . 208

ZS75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

FWS1205/2205 . . . . . . . . . . . . . . . . . . 100/102

ZS75S (Bidirectional) . . . . . . . . . . . . . . . . . 142

GFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

ZS80 . . . . . . . . . . . e. w

. . . . . . . . . . . . . . . . . . 146

N

!

N !

w

S900 . . . . . . . . . e

N . . . . . . . . . . . . . . . . . . . . .150

MZM100 . . . . . . e. w

. . . . . . . . . . . . . . . . . . . . .76

*

N

ZS73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

!

N

ZS441 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

ZSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3

PICTORIAL PRODUCT INDEX

ST14

AZ17 & AZ17zi

AZ15/16 & AZ16zi

Page 12

Page 14 & 18

Page 22 & 28

AZM170

AZM161

Page 60

Page 66

Keyed

Interlock Switches

w!

Ne

AZ 200

Selection Guide:

Page 11

Keyed

Interlock Switches

with SolenoidLatching

Selection Guide:

Page 59

w!

Ne

AZM 200

w!

Ne

MZM 100

B25

Page 76

TG-1

Page 106

Page 112

Page 114

ZS71

ZS73

ZS75

Page 126

Page 130

Page 134

BNS250 & BNS260

BNS33 & BNS33S

BNS303

BNS30 & BNS300

Pages 154 & 156

Pages 158 & 162

Page 164

Page 166

ES95 SB & TVS 335

TV8S-521

T.C 235/236

Pages 208 & 210

Page 212

Page 214

Application Accessories

(Safety Door Handles, Enabling

Devices, Safety Foot Switches)

w!

Ne

STS

Page 70

Page 32

w!

Ne

Selection Guide:

Page 105

Emergency Cable-Pull Switches

Selection Guide:

Page 125

Non-Contact

Safety Sensors &

Compatible

Safety Controllers

Selection Guide:

Page 153

Hinged Safety Interlock Switches

Selection Guide:

Page 207

Safety Light Curtains & Beams

Selection Guide:

Page 273

4

w! SLC, SLG & SLB

Ne

Safety Category 3

Pressure Mats &

Fail-to-Safe

Safety Edges

Page 263

SMS3 Series

Page 311

PICTORIAL PRODUCT INDEX

TZG

SDG

SHGV

AZ335

AZ415

1

Page 40

Page 44

Page 48

TZF/TZM

TKF/TKM

TZK

Page 54

Page 52

AZM415

AZS/FWS

2

Page 82

ZSD

Page 86

Page 94

Page 90

w! SEPK(G)

Ne

GFS

w!

Ne

Page 98

TFA/TFI

3

Page 116

Page 118

Page 122

ZS441

ZS75S Bidirectional

w!

Ne

ZS80

Page 124

w!

Ne

S900

4

Page 138

Page 142

BNS333

BNS16 & BZ16

Page 146

w!

Ne

BNS-B20

Page 150

w!

Ne

CSS 180

w!

Ne

CSS 34

5

Page 168

w! TESF & TESZ

e

N

Pages 170 & 172

Page 174

Page 176

Page 184

Z/T235/236 & Z/T335/336

Z332

C50

Safety-Rated

Limit Switches

6

Selection Guide:

Page 227

Pages 220 & 224

Pages 228, 236, 244, & 250

Page 256

SE Series

AES

SRB “Protect”

General &

Specific

Purpose Safety

Controllers

Page 317

Page 260

7

Page 189

Page 327

5

Turning Workplaces Into Safeplaces®

6

ABOUT SCHMERSAL

K.A. SCHMERSAL GmbH & Co. was founded as a family

business in 1945. The firm initially focused on the design

and manufacture of electromechanical switches for

industrial applications.

Our first products included heavy-duty, cast-encapsulated

limit switches for (post-war) civil engineering and

construction applications. This program quickly expanded

to include:

•

•

•

•

•

•

•

•

•

grey cast iron limit switches

light metal limit switches

robust precision limit switches

spindle limit switches

gear motor switches

elevator switch gears

CENELEC position switches

miniature snap-acting switches, and

command devices for machine and crane control

systems.

With this early post-war product program, the firm quickly

established itself as a specialist in monitoring, switching,

and controlling elevators, material handling systems,

machine tools, and other industrial equipment.

Many of these initial products satisfied unique requirements for safety switches. Such products included:

• explosion-proof switches for gasoline pumps

• door contacts and locks for personnel/freight

elevators

• cable monitoring switches for mountain cablecar

systems, and

• snap-acting limit switches featuring positive-opening

contacts for lignite diggers, construction cranes, and

other machinery.

Today the product range has expanded to include a

broad selection of non-contact electronic presence/position sensing sensors and switches. These are designed

using state-of-the-art inductive, capacitive, magnetic and

photoelectric technologies.

Armed with diverse electronic and electromechanical

capabilities, the firm has continued to welcome unique

customer-specific problems. Operating from their modern headquarters in Wuppertal, Germany, an industrial

suburb of Dusseldorf with a population of 400,000, the

firm’s 400 employees maintain close contact with their

worldwide customer base.

This close contact, coupled with a commitment to

respond to the needs of their customers, continues to

serve as a basis for continued new product development

to meet the constantly changing market.

By 1953 the company had established a reputation as a

leading producer of innovative machine guarding safety

switches.

SYSTEM SAFETY: PROTECTION

FOR MAN AND MACHINE

Recent trends for a safer workplace in many industries

have led the company to give this field even greater

attention. Newest product developments have focused

on advanced safety switches which satisfy the stringent

requirements of the harmonized European Economic

Community and its regulatory agencies.

GLOBAL COVERAGE:

Technical support and

inventory in more than

22 countries.

7

MAN-MACHINE SAFETY

THE SCHMERSAL SYSTEM:

A 360° APPROACH

CHANGING MAN-MACHINE

SAFEGUARDING RULES

For more than 50 years SCHMERSAL has dedicated

itself to understanding machine safety hazards. We have

made it our mission to develop defeat-resistant, fail-tosafe solutions using advanced safety switch technology. This catalog-handbook is a compilation of information that addresses the latest and most stringent industry safety

standards and regulations matched

with a broad selection of dependable solutions.

Today worker safety is an issue of major concern to manufacturers worldwide. OSHA guidelines, more stringent

ANSI standards, and the recently (1996) adopted

European Machinery Directive (EMD) are

evidence of the increased emphasis being

given to employee safety in the

workplace.

The day-to-day study of modern workplace safety is filled

with the minutiae of industry

regulations and standards. But

philosophically we look to a

higher standard in the work of

one of the world’s greatest

engineers, Leonardo da Vinci. A

true Renaissance genius, he was

a man whose fascination for the

human body and the principles of

physics resulted in his meticulous

anatomical drawings, numerous intricate

machines, and even a robotic knight that consisted of a system of cables and pulleys that controlled

the movement of articulated limbs. Arguably the world’s

first ergonomic engineer, Leonardo truly understood man

and his physiological relationship to machinery.

Like Leonardo, we at SCHMERSAL take a 360degree approach to safety. We evaluate

from every angle the potential for accidents and their prevention. We recognize the wide differences in each

work station. We take into account

specific guard design, as well as

the environmental and physical

considerations necessary to support machinery operation and

provide maintenance. We even

understand the frustrations and

all-too-human temptation some

machine operators feel to override

(bypass) the safety system.

Selected industry standards and

guidelines aimed at achieving

higher levels of safety are

reviewed in the section of this

Handbook/ Catalog entitled

“Safety Standards.” Each

defines

minimum

safety

requirements to which manufacturers and employees must

comply.

In so doing, they present new

challenges to the plant safety

specialist and equipment designer

…especially where safety guards

ancillary to the production equipment’s

functional design are required.

NEW SAFETY CONCEPTS

AND TECHNIQUES

The goal of these new and emerging guidelines is to provide heightened levels of

protection to machine operators,

helpers, and maintenance personnel. Toward this goal they have

embraced several new safety

system concepts including:

• positive-break contacts

• greater tamper-resistance

• positive-guided relays

• fault detection

• single component failure

control reliability

Conventional limit switches, proximity

sensors, magnet switches and

Different dynamics mean different soluother

classical

position-sensing and

tions. Different markets are subject to difcontrol

devices

traditionally

used as safety

ferent regulations. Our system of more than

interlocks

do

not

meet

contemporary

require200 interlock, magnetic and rope-pull switches

ments.

Consequently,

when

used

in

such

has earned SCHMERSAL a world-wide

International symbol for

applications,

they

are

regarded

as

unsafe.

reputation for reliability, flexibility, and

Positive-Break contacts

dependable quality.

8

“SAFETY-SPECIFIC” COMPONENTS

New switches, sensors and controls have been designed

specifically for safety applications. Each is intended to

overcome one or more of the limitations of conventional

“non-safety” components … and to satisfy one or more of

the current safety requirements inherent in the latest

industry standards and guidelines.

GUIDE TO APPLICATION SYMBOLS USED

THROUGHOUT THE CATALOG

These safety-specific components are the subject of this

catalog. They include:

• keyed interlock switches

• keyed interlock switches with solenoid latching

• sealed non-contact safety sensors

• safety foot switches

• push/pull operated emergency cable-pull switches

• two-hand controls

Sliding Guard Applications

• positive-break hinged safety switches

• safety light curtains/beams

• fail-to-safe safety edges

• safety pressure mats

• safety-rated limit switches

• safety controllers

Each of these components is designed to help the safety specialist and equipment designers to better address

their responsibility … to ensure that machinery, built or

purchased, does not expose the operators, helpers or

maintenance personnel to hazards.

SATISFYING YOUR NEEDS

We trust that this Catalog-Handbook, its companion catalogs, and our tutorial Manual and videos, will be useful

tools in the selection of suitable components to satisfy

your unique application requirements.Your needs are our

most important concern.

Hinged Guard Applications

We welcome your questions and comments, and would

appreciate your making us aware of any machine safeguarding requirements which cannot be satisfied with

available components.

Lift-off Guard Applications

9

Safer

by

Design

10

KEYED INTERLOCK SWITCHES

1

SELECTION GUIDE

Switch

Series

Housing

Material

Envelope

Dimensions

Contact

Configurations

Catalog

Page

ST14

Glass-fiber,

reinforced thermoplastic

⁄4" × 11⁄4" × 2"

1 NO & 1 NC

2 NC

12

AZ17

AZ17zi

Glass-fiber,

reinforced thermoplastic

11⁄4" × 11⁄4" × 21⁄2"

1 NO & 1 NC

2 NC

14

18

Glass-fiber,

reinforced thermoplastic

11⁄4" × 2" × 3"

1 NC

1 NO & 1 NC

2 NC

1 NO & 2 NC

3 NC

22

28

Glass-fiber,

reinforced thermoplastic

11⁄2" × 83⁄4" × 11⁄2"

2 PNP Safety Outputs

1 or 3 Diagnostic

Outputs

32

TZG

Glass-fiber,

reinforced thermoplastic

13⁄4" × 2" × 33⁄4"

1 NO & 1 NC

2 NC

40

SDG

Die-cast aluminum

13⁄4" × 2" × 6"

1 NO & 2 NC

2 NO & 1 NC

3 NC

44

48

AZ15/16

AZ16zi

New!

AZ200

3

AZ335

Die-cast aluminum

11⁄2" × 13⁄4" × 41⁄2"

1 NO & 1 NC

2 NC

1 NO & 2 NC

3 NC

SHGV

Die-cast aluminum

13⁄4" × 13⁄4" × 4"

1 NO & 1 NC

52

2 NO & 2 NC

54

(Key Transfer System)

AZ415

Die-cast aluminum

13⁄4" × 31⁄2" × 4"

11

SERIES ST14

Sub-Compact, Tamper-Resistant Movable

Machine Guard Safety Interlock Switch

Features & Benefits

®

• Compact design … only 3⁄4" × 11⁄4" × 2". Ideal where space

is limited.

• “Positive-break” NC contacts … assure circuit interruption

upon actuator key removal.

• Tamper-resistant design … difficult to defeat with simple

tools, tape, bent wires, etc. Reduces liability exposure.

• Watertight design … meets NEMA 4 (IP67) washdown

and immersion requirements.

• High-strength, stainless-steel actuator key … tolerant to

mechanical abuse without damage.

• Rugged, corrosion-resistant housing … tolerates the

most hostile environments.

• Top and side key-entry locations … provide installation

flexibility.

• Optional key designs … to meet diverse application

requirements.

• Meets rigid safety agency standards … IEC, BG, VDE,

UL and CSA.

• Optional “side-entry” cable … please consult factory.

Description

The ST14 Series is designed for use with movable machine

guards which must be closed for operator safety. Their twopiece, tamper-resistant design, and positive-opening NC

contacts, provide a significantly higher level of safety than

conventional, spring-driven switches whose contacts can weld

or stick shut. Their NEMA 4 (IP67) rating make them ideal for

interlocking safety guards in hostile environments. Their

compact design allows use in applications where space is

severely limited.

AVAILABLE STANDARD MODELS

(Actuator key must be ordered separately)

Please see below.

Contacts

Part Number

(with key inserted)

ST14-10/1SK

1 NO & 1 NC

ST14 interlock switch (Sealed

switch. Contact mechanism

embedded in resin.)

2 NC

ST14 interlock switch (Sealed

switch. Contact mechanism

embedded in resin.)

Optional right-angle keys, close-radius keys and mounting

brackets provide application versatility.

Operation

The ST14 is a two-piece, electromechanical safety interlock

switch. It consists of a rugged, sealed switch mechanism and

a geometrically-unique actuating key. The actuating key is

typically mounted to the movable machine guard or access

gate. Upon opening of the guard the NC contact(s) are forced

to open by a direct (non-resilient) mechanical linkage with the

actuating key. These positive-break contacts assure circuit

interruption (and machine stoppage) upon removal of the

actuator key. (The NO contact closes upon key removal.)

When the guard is closed, the actuating key forces the NC

contact(s) to close, and the NO contact to re-open. Their

tamper-resistant design prevents bypassing with simple tools,

bent wires or other readily available means.

Typical Applications

The ST14 is intended for use as a safety interlock switch on

movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Their

compact, sealed (NEMA 4) design makes them ideal where

space is severely limited and/or where equipment is washeddown or subject to other hostile environments (i.e. business

machines, medical equipment, food processing machinery, et

al). Typical applications are the interlocking of protective

gratings, access doors/guards, hinged covers, access panels

and other movable guards.

ST14-20K

Note: All actuator keys feature integral vibration-tolerant mounting

washers.

ACTUATOR KEYS & ACCESSORIES

Part Number

Description

ST14-B1

Standard B1 actuator key

ST14-B3

Close-radius actuator key (for mounting key

close to door hinge)

ST14-B5

Right-angle actuator key

ST14-Bracket

Optional switch or key mounting bracket

Note: All actuator keys feature integral vibration-tolerant mounting

washers.

®

12

Description

is a trademark of SCHMERSAL

ST14 TECHNICAL DATA

MECHANICAL SPECIFICATIONS

Housing

Actuator Key

Degree of Protection

Operating Temperature

Mechanical Life

Conformity to Standards

Minimum Closing Radius

ELECTRICAL SPECIFICATIONS

Glass-fibre reinforced, selfextinguishing thermoplastic

Stainless steel

(defeat-resistant design)

IP67

Actuation Head: IP 20

–4°F to +175°F

> 106 operations

IEC 947-5-1

EN 60947-5-1

DIN VDE 0660-200

BG-GS-ET-15

UL

CSA

5.9" (with ST14-B1 and ST14-B5

actuator key)

1.97" (with ST14-B3 actuator key)

Contacts

Contact Configuration

Fine silver

Double-pole, double-break with

electrically separated contact

bridges

6A (250VAC)

0.25A (220VDC)

Slow-action, positive-break NC

contacts

Fuse 6A (time-delay)

Prewired with sealed PVC

UL-style 2464 4x20 AWG

cable one meter long*

Contact Rating

Switching Action

Short Circuit Protection

Electrical Connection

1

*Other cable lengths available. Please consult factory.

DIMENSIONS

ST 14-B1 (Standard key)

Right Angle Key

ST 14-B5

Minimum key entry

closing radius 150mm.

ST 14-Bracket Switch or

Key Mounting Bracket

mm

inch

Note: Side-entry cable available

(Please consult factory)

Angle view

24

0

36

1.42

7

.28

16

.63

9

23-24

11-12

5

8

5

8

ø 4,2

.17

ø8

.31

23

.91

ST14-10/1S

11 = red

12 = orange

23 = black

24 = brown

26

1.02

37

1.46

12

23

3,5

.14

ST 14-B3

Close Radius Key

SWITCHING SYMBOLS & CONTACT SCHEMATICS

(Colors identify factory prewiring)

11

Side view

11

12

21

22

ST14-20

11 = red

12 = orange

21 = black

22 = brown

0

11-12

21-22

5

8

10°

11

.43

For close radius keys for mounting key

close to (within 50 mm) door hinge, order ST 14-B3.

13

SERIES AZ17

Compact Tamper-Resistant Movable

Machine Guard Safety Interlock Switch

Features & Benefits

®

• Compact design … only 11⁄4" × 11⁄4" × 3". Ideal where space

is limited.

• Insulation Displacement Connector (IDC) … facilitates

fast, easy installation.

• Watertight design … meets IP67 washdown requirements.

• Eight optional key entry locations … depending upon

mounting arrangement.

• Highly tamper-resistant … difficult to defeat with simple

tools, tape, bent wires, etc. Reduces liability exposure.

• “Positive-break” NC contacts … assure interruption of

safety circuit upon actuator key removal.

• High-strength, stainless-steel actuator key … tolerant to

mechanical abuse without damage.

• Rugged, corrosion-resistant, high-impact glass-fibre

reinforced housing … tolerates the most hostile

environments.

• “Padlockable” key for added security during

maintenance.

• Meets rigid IEC, BG, VDE, UL & CSA standards.

• Three styles of actuator key … accommodates a wide

variety of movable guards.

Description

The compact Series AZ17 is designed for use with movable

machine guards/access gates which must be closed for

operator safety. Their positive-opening NC contacts provide a

significantly higher level of safety than conventional springdriven switches whose contacts can weld or stick shut. And

their tamper-resistant design prevents bypassing with simple

tools, bent wires or other readily available means. Their IP67

rating makes them ideal for interlocking safety guards in

hostile environments.

SPACE-SAVING

IDC CONTACTS

& CONNECTOR

Operation

The AZ17 electromechanical safety interlock switch consists

of a rugged switch mechanism and a geometrically-unique

actuating key. The key is mounted to the movable guard. Upon

opening of the guard the NC contact(s) are forced to open

through a direct (non-resilient) mechanical linkage with the

actuating key. These positive-break NC contacts assure circuit

interruption (and machine stoppage) upon removal of the

actuator key. (The NO contact closes upon key removal.)

Note: Available with optional M12x1 quick-connect.

When the guard is closed, the actuating key forces the NC

contacts to close and the NO contacts to re-open.

Typical Applications

The AZ17 is intended for use as a safety interlock switch on

movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Typical

applications are the interlocking of protective gratings, access

doors/gates, hinged covers, access panels and other movable

guards.

®

14

is a trademark of SCHMERSAL

AZ17 AVAILABLE MODELS AND ACCESSORIES

AVAILABLE STANDARD MODELS

(Actuator key must be ordered separately)

Part Number

Contacts (with

actuator key inserted)

ACTUATOR KEYS & ACCESSORIES

Part Number

Description

AZ17/170-B1

Standard key (7.87" minimum closing radius)

AZ17/170-B5

Right-angle key (7.87" minimum closing

radius)

AZ17-B6

Flexible, close-radius key (1.97" minimum

closing radius)

AZ17/170-B11

Elongated standard straight key (7.87" minimum closing radius)

Individually-coded key models available (Model AZ17zi)

(For extra security in “high-risk” applications)

AZ17/170-B15

Elongated right-angle key (7.87" minimum

closing radius)

Note: Pre-wired (5 meter length) cable entry models available. Add

suffix “2243” for front of unit cable entry or suffix “2243-1” for

rear cable entry.

AZ17/170-B1-2245 Standard straight key with vibration-resistant

mounting (7.87" minimum closing radius)

Note: Optional “quick-connect” ... add suffix “ST”

(e.g. AZ17-11zk-ST).

MS AZ 17-P

(See installation

on Page 20)

Adjustable mounting kit for parallel mounting.

AZ17-B6 key required.

MS AZ 17-R/P

(See installation

on Page 20)

Adjustable mounting kit for parallel or

perpendicular mounting. AZ17-B6 key

required.

Suffix “-ST”

Optional M12x1 quick-connect

AZ17-11zk

1 NO & 1 NC

AZ17-11zrk

1 NO & 1 NC

AZ17-02zk

2 NC

AZ17-02zrk

2 NC

Solenoid-latching models available. (Model AZM170)

1

SELECTED ACTUATOR KEYS

AZ17/170-B1

AZ17/170-B5

AZ17-B6

15

AZ17 TECHNICAL DATA

MECHANICAL SPECIFICATIONS

Housing

Actuator Key

Degree of Protection

Holding Force

Travel for Positive-Break

Closing Force

Operating Temperature

Mechanical Life

Conformity to Standards

Minimum Closing Radius

ELECTRICAL SPECIFICATIONS

Glass-fibre reinforced, selfextinguishing thermoplastic

Stainless steel, 1.4301

IP67

zk models: 1.2 pounds

zrk models: 7 pounds

8 mm (0.315 inches)

Approx. 12N (2.7 pounds)

–22°F to +175°F

> 106 operations

IEC 947-5-1

EN 60947-5-1

DIN VDE 0660-200

BG-GS-ET, pr EN 1088

UL & CSA

1.97" (with AZ17-B6 actuator key)

7.87" (with B1, B5, B11 and B15

actuator key)

Contacts

Contact Configuration

Fine silver

Double-pole, double-break with

electrically separated contact

bridges

4A/230VAC

2.5A/230VA (with “ST” quickconnect)

Slow-action, positive-break NC

contacts

6A (time-delay)

250V

Insulation displacement contacts

& connector for 18AWG flexible

stranded wire (0.75 mm2)

Contact Rating

Switching Action

Short Circuit Protection

Rated Isolation Voltage

Type Terminals

SWITCHING DIAGRAMS & CONTACT SCHEMATICS

AZ17-11z

AZ17-02z

13

21

0

4,2

7,6

13-14

21-22

8

11

MS AZ 17 ADJUSTABLE MOUNTING KIT

16

11

21

14

22

0

12

22

4,2

8

11

11-12

21-22

8

11

AZ17 TECHNICAL DATA

DIMENSIONS

24

.94

1

23

.91

31

1.22

Switching Symbols (Colors identify -2243 factory prewired models)

8,2

.32

22

.87

60

2.36

ø 4,2

.17

22

.87

ø 19

.75

8

.31

BLUE

BROWN

BROWN

BLUE

BLACK

BLACK

AZ17-02z

Connections

AZ17-11z

AZ17-02z

AZ17-11z

same polarity; type four enclosure

30

1.18

22

.87

BLACK

20

.79

5

.2

M169

Pg

BLACK

0.

67

(1 0"

7)

ø 4-8

.16-.31

mm

inch

30

1.18

(Remove outer sleeve

from cable)

ACTUATOR KEYS

30

1.18

22

.87

20

.79

22

.87

20

.79

12

.47

37,5

1.48

33

1.30

60,5

2.38

33

1.30

36

1.41

10

.40

13

.51

4,3

.17

7,5

.30

20

.79

4,3

.17

22

.87

AZ17/170-B11

AZ17/170-B5

30

1.18

5,5

.27

30

1.18

4,3

.17

AZ17/170-B1

2

.08

8

.31

23

.91

2

.08

23

.91

2

.08

23

.91

20

.79

ø11

.43

ø 4,2

.17

12

.47

18

.71

6

.24

12

.47

4,3

.17

36

1.42

11

.43

2

.08

23

.91

a

b

28

1.10

20

.79

22

.87

30

1.18

13

.51

a

7

.28

b

23

.91

30

1.18

48

1.89

24

.94 8

.31

25

.98

22

.87

AZ17/170-B1-2245

8

.31

AZ17-B6

30

1.18

16

.63

30

1.18

4,2

.18

AZ17/170-B15

23

.91

17

SERIES AZ17zi

Individually-Coded Movable

Machine Guard Safety Interlock Switch

Features & Benefits

®

INDIVIDUALLY-CODED

ACTUATOR KEYS

(15,000 CODES)

• Highly tamper-resistant actuating mechanism … difficult

to defeat with simple tools, tape, bent wires, etc. Reduces

liability exposure.

• Individually-coded actuator key (15,000 codes) …

provides extra security in high-risk applications.

• Compact design … only 11⁄4" × 11⁄4" × 3". Ideal where space

is limited.

• Non-removable actuating head … heightens tamperresistance.

• Four optional key entry locations … provide installation

flexibility.

• “Positive-Break” NC contacts … assure circuit

interruption upon actuator key removal.

• Watertight design … meets IP67 washdown requirements.

• High-strength, stainless-steel actuator key … tolerates

mechanical abuse without damage.

• Rugged, corrosion-resistant housing … tolerates the

most hostile environments.

• Wide selection of accessories … to meet diverse

application requirements.

• Padlockable key … for added security during equipment

maintenance.

• Meets rigid safety agency standards … BG, UL and

CSA.

Description

The compact Series AZ17zi are designed for use with

movable machine guards which must be closed for operator

safety. Their tamper-resistant design, and positive-opening NC

contacts, provide a significantly higher level of safety than

conventional spring-driven switches whose contacts can

weld/stick shut. Their IP67 rating makes them ideal for

interlocking safety guards in hostile environments.

Operation

SPACE-SAVING

IDC CONTACTS

& CONNECTOR

The AZ17zi is a two-piece, electromechanical safety interlock

switch. It consists of a rugged switch mechanism and an

individually-coded, geometrically-unique actuating key. The

key must be directly hard-mounted to the movable guard.

Upon opening of the guard, the normally-closed (NC)

contact(s) are forced to open through a direct (non-resilient)

mechanical linkage with the actuating key. The positive-break

NC contacts assure circuit interruption (and machine

stoppage) upon removal of the actuator key. (The NO

contacts close upon key removal.)

When the guard is closed, the actuating key forces the NC

contacts to re-close, and any NO contacts to re-open. The

tamper-resistant design prevents bypassing with simple tools,

bent wires or other readily available means.

Typical Applications

The AZ17zi is intended for use as a safety interlock on

movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Typical

applications are the interlocking of protective gratings, hinged

covers, access panels and other movable guards.

®

18

is a trademark of SCHMERSAL

AZ17zi AVAILABLE MODELS AND ACCESSORIES

AVAILABLE MODELS

(Includes Individually-Coded Actuator Key and

1

⁄2" NPT Plastic Adapter)

Part Number

AZ17-11zi-B1

Description

Standard unit

Contacts (with

actuator key inserted)

1 NO & 1 NC

AZ17-11zi-B5

AZ17-11zi-B6R

AZ17-11zi-B6L

AZ17-02zi-B1

Standard unit

2 NC

AZ17-02zi-B5

OPTIONAL ACCESSORIES

Part Number

Description

MS AZ 17-P

(See installation

on Page 20)

Adjustable mounting kit for parallel

mounting

MS AZ 17-R/P

(See installation

on Page 20)

Adjustable mounting kit for parallel or

perpendicular mounting

1

Mounting kits require use of the -B6 key

AZ17-02zi-B6R

AZ17-02zi-B6L

Note: Standard units feature 1.2 pounds of key retention force. For

unit with 7 pounds of key retention force, please add suffix “r”

to part number. Example: AZ17-11zir-B1

19

AZ17zi TECHNICAL DATA

MECHANICAL SPECIFICATIONS

Housing

Actuator Key

Degree of Protection

Key Retention Force

Travel for Positive-Break

Closing Force

Operating Temperature

Mechanical Life

Conformity to Standards

Minimum Closing Radius

ELECTRICAL SPECIFICATIONS

Glass-fibre reinforced, selfextinguishing thermoplastic

Stainless steel, 1.4301

IP67

zi models: 1.2 pounds

zir models: 7 pounds

8 mm (0.315 inches)

Approx. 12N (2.7 pounds)

–22°F to +175°F

> 106 operations

IEC 947-5-1

EN 60947-5-1

DIN VDE 0660-200

BG-GS-ET, pr EN 1088

UL & CSA

1.97" (with B6L or B6R actuator key)

7.87" (with B1 or B5 actuator key)

Contacts

Contact Configuration

Contact Rating

Switching Action

Short Circuit Protection

Rated Isolation Voltage

Type Terminals

Fine silver

Double-pole, double-break with

electrically separated contact

bridges

4A/230VAC

Slow-action, positive-break NC

contacts

6A (time-delay)

250V

Insulation displacement contacts

& connector for 18AWG flexible

stranded wire (0.75 mm2)

Note: Pre-wired (5 meter length) cable entry models available. See

optional accessories.

SWITCHING DIAGRAMS & CONTACT SCHEMATICS

AZ17-11zi

13

21

14

22

0

4,2

7,6

13-14

21-22

8

11

8

11

AZ17-02zi

11

21

MS AZ 17 ADJUSTABLE MOUNTING KIT

(Eases installation and facilitates

adjustments due to guard misalignment)

MS AZ17-P

(for parallel

mounting)

20

MS AZ17-R/P

(for parallel or

perpendicular mounting)

12

22

0

4,2

11-12

21-22

8

11

AZ17zi TECHNICAL DATA

DIMENSIONS

1

Rm

in.

5.5

1" (

140

0.866"(22)

)

0.078"

(2)

0.216"

(5.5)

0.905"

(23)

22

.89

60

2.36

8,2

.32

B5 Actuator Key

0.314"

(8)

Rm

in.

5.5

1" (

140

1.18"(30)

0.866"(22)

0.787"(20)

)

8

.31

0.472"

(12)

0.169"

(4.3)

Rm

in.

7.87

" (2

00)

20

.79

5

.20

M169

Pg

0.59"

(15)

1.42" (36)

0.177"

(4.5)

ø 19

.75

0.216"

(5.5)

22

.87

0.511

(13)

23

.91

ø 4,2

.17

31

1.22

24

.94

0.787"(20)

0.169"

(4.3)

0.314"

(8)

0.393"

(10)

0.59"

(15)

1.18"(30)

Rm

in.

7.87

" (2

00)

1.30" (33)

0.177"

(4.5)

B1 Actuator Key

0.078"

(2)

30

1.18

mm

inch

30

1.18

0.787"(20)

0.866"(22)

0.169"

(4.3)

0.314"

(8)

22

.87

0.905"

(23)

ø 4-8

.16-.31

1.18"(30)

B6L Actuator Key

Switching Symbols (Colors identify -2243 factory prewired models)

B6R Actuator Key

0.866"(22)

GRN

RED

WHT

BLK

WHT

BLK

AZ17-02zi

Connections

0.165"

(4.2)

0.433"

(11)

0.944" (24)

0.905"

(23)

0.078"

(2)

AZ17-11zi

0.236"

(6)

GRN

0.157"

(4)

RED

0.787"(20)

0.314" 0.472" (12)

(8)

0.944"(21)

1.18" (30)

0.590"

(15)

AZ17-02zi

7

0.433"

(11)

Rm

1.9

in.

)

50

"(

Rm

1

in.

.97

50

"(

0.590"

(15)

)

R

mi

n.

1.9

7"

(50

)

0.314"

(8)

R

mi

n.

1.9

7"

(

50

)

0.314"(8)

AZ17-11zi

same polarity; type four enclosure

67

0.

(1

7)

0"

(Minimum radius: 50mm)

(Remove outer sleeve

from cable)

All dimensions in

inches (mm)

21

SERIES AZ15/16

Tamper-Resistant Movable

Machine Guard Safety Interlock Switch

Features & Benefits

®

Description

The Series AZ15/16 is designed for use with movable

machine guards/access gates which must be closed for

operator safety. Their positive-opening NC contacts provide a

significantly higher level of safety than conventional springdriven switches whose contacts can weld or stick shut. And

their tamper-resistant design prevents bypassing with simple

tools, bent wires or other readily available means. Their IP67

rating makes them ideal for interlocking safety guards in

hostile environments.

• Highly tamper-resistant actuating mechanism … difficult

to defeat with simple tools, tape, bent wires, etc. Reduces

liability exposure.

• Non-removable actuating head … heightens tamperresistance.

• Four optional key entry locations … provide installation

flexibility.

• Individually-coded actuator key option (15,000 codes)

… provides extra security in high-risk applications. See

AZ16zi.

• “Positive-Break” NC contacts … assure circuit

interruption upon actuator key removal.

• High key-retention force (7 pounds) … eliminates

inadvertent opening of guard due to shock/vibration.

• Watertight design … meets IP67 washdown requirements.

• High-strength, stainless-steel actuator key … tolerates

mechanical abuse without damage.

• Rugged, corrosion-resistant housing … tolerates the

most hostile environments.

• Wide selection of accessories … to meet diverse

application requirements.

• Padlockable key … for added security during equipment

maintenance.

• Meets rigid safety agency standards … BG, UL and

CSA.

• Explosion-proof model and M12x1 quick-connect (“ST”)

available (Please consult factory).

Optional Safety

Controller.

See Page 328.

Operation

The AZ15/16 electromechanical safety interlock switch

consists of a rugged switch mechanism and a geometricallyunique actuating key. The key is mounted to the movable

guard. Upon opening of the guard the NC contact(s) are

forced to open through a direct (non-resilient) mechanical

linkage with the actuating key. These positive-break NC

contacts assure circuit interruption (and machine stoppage)

upon removal of the actuator key. (The NO contact closes

upon key removal.)

When the guard is closed, the actuating key forces the NC

contacts to close and the NO contacts to re-open.

Typical Applications

The AZ15/16 is intended for use as a safety interlock switch

on movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Typical

applications are the interlocking of protective gratings, access

doors/gates, hinged covers, access panels and other movable

guards.

22

®

is a trademark of SCHMERSAL

AZ15/16 AVAILABLE MODELS AND ACCESSORIES

AVAILABLE MODELS

ACCESSORIES

(Includes 1⁄2" NPT Plastic Adapter**

Actuator Key Sold Separately)

for AZ15/16 Keyed-Interlock Switches

Part Number

Contacts (with

actuator key inserted)

Part Number

AZ15-zvk (key spring returned)

1 NC

AZ15-zvrk (key maintained upon insertion)*

1 NC

AZ16-zvk (key spring returned)

1 NO & 1 NC

AZ16-zvrk (key maintained upon insertion)*

1 NO & 1 NC

AZ16-02zvk (key spring returned)

2 NC

AZ16-02zvrk (key maintained upon insertion)* 2 NC

AZ15/16-BI-2024

Gasketed key caps

AZ15/16-CAP

Key entry closure caps

(for unused entry slots)

M20-CG

Cord grip (cable gland)

M20-1⁄2"P

Plastic 1/2" NPT adapter

M20-1⁄2"M

Metal 1/2" NPT adapter

AZ15/16-BI-1747

AZ15/16-B3-1747

Door holding magnet kit

(7 pound holding force)

(for use with AZ16…zvr-2254

models)

PL-M20-24V

24VAC/DC pilot light kit

PL-M20-120V

120VAC/DC pilot light kit

Add suffix -1637 to basic

part number when ordering

Gold contacts

(for AZ15/16zvr)

AZ15/16-BI-2053

(for use with AZ16...zvrk)

Ball latch kit

(Adjustable holding force up to

22 pounds)

#6-3⁄8SPH (Package of 6)

#6-3⁄8 Spanner Pan Head

Tamper-resistant sheet metal

screws (for actuator key mounting

or switch contact cover)

#10-32×1⁄2" OWOH

(Package of 6)

#10-32 One-Way Oval Head

Tamper-resistant machine screws

SZ16/335

Actuator Key Lockout Device

(Accepts up to 6 padlocks)

AZ15/16-AP

Alignment Pins (Set of 2)

MS AZ 15/16-P

(See illustration Page 29)

Adjustable mounting kit for

parallel mounting

MS AZ 15/16-R/P

(See illustration Page 29)

Adjustable mounting kit for

parallel and perpendicular

mounting

Suffix “-ST”

Optional M12x1 quick-connect

(2 contact models only)

AZ15/16-B2-1747

AZ16-12zvk (key spring returned)

1 NO & 2 NC

AZ16-12zvrk (key maintained upon insertion)* 1 NO & 2 NC

AZ16-03zvk (key spring returned)

3 NC

AZ16-03zvrk (key maintained upon insertion)* 3 NC

*Feature 7 pound key retention force. For lighter key retention force

(1-2 pounds) add suffix "2254".

**To order unit with cordgrip instead of 1⁄2" NPT adapter, add suffix

"CG" to part number...eg. AZ15-zvk-CG.

Short-radius actuator keys available. See below.

ACTUATOR KEYS

Part Number

Description

AZ15/16-B1

Standard Key (5.9" minimum closing radius)

AZ15/16-B2

Small radius actuating key (1.8" minimum

closing radius)

AZ15/16-B3

Small radius actuating key (1.3" minimum

closing radius)

AZ15/16-B6

Flexible-movement actuating key

AZ15/16-B1-2177

Funnel entry adapter with elongated

straight actuating key

AZ15/16-B6-2177

Funnel entry adapter with elongated

flexible-movement actuating key

AZ15/16-B1-KRH

Key Removal Hand-Grip Assembly with Key

Retention Chain (for use with AZ15...zvrk

and AZ16...zvrk)

Description

1

MS mounting kits require the use of the -B6 key

AZ15/16-2053 with ball catch

Holding force up to 22 pounds

AZ15/16-1747 with holding magnet

Holding force 7 pounds

Actuator Key Removal Handle

AZ15/16-B1-KRH

Lockout Device SZ16/335

(padlock not included)

23

AZ15/16 TECHNICAL DATA

MECHANICAL SPECIFICATIONS

Housing

Actuator Key

Degree of Protection

Travel for Positive-Break

Key Ejection Force

Key Retention Force

Closing Force

Operating Temperature

Mechanical Life

Conformity to Standards

Minimum Closing Radius

Glass-fibre reinforced, selfextinguishing thermoplastic

Stainless steel (defeat-resistant

design)

IP67

8 mm (0.315 inches)

"-zv" models: 3N ( 0.7 pounds)

"-zvr-2254 models: 5N (1.2 pounds)

"-zvr" models: 30N (7 pounds)

Approx. 15N (3.4 pounds)

–22°F to +175°F

> 1 million operations

IEC 947-5-1

EN 60947-5-1

DIN VDE 0660-200

BG-GS-ET-15

UL & CSA (A600, P300)

TUV

1.3" (with B3 actuator key)

1.8" (with B2 actuator key)

5.9" (with B1 actuator key)

ELECTRICAL SPECIFICATIONS

Contacts

Contact Configuration

Contact Gap

Contact Rating

Switching Action

Short Circuit Protection

Rated Isolation Voltage

Rated Impulse Withstand

Voltage

Type Terminals*

Fine silver

Double-pole, double-break with

electrically separated contact

bridges

2×2mm (minimum)

4A/230VAC (A600)

2.5A/230VAC (with M12x1 quickconnect)

Slow-action, positive-break

NC contacts

Fuse 6A (time-delay)

500VAC

6kV

Screw terminals with self-lifting

clamps for up to 13 AWG flexible

stranded wire (2.5mm2)

* Units available with M12x1 quick-connect.

(Please consult factory).

SWITCHING DIAGRAMS & CONTACT SCHEMATICS

AZ16z

DIMENSIONS

13

21

14

22

“Make before

break”

0

2,3 5,2

13-14

21-22

5,5

8

5,5

8

AZ16-02z

11

21

12

22

2,3

0

11-12

21-22

5,5

8

AZ16-12z

13

21

31

14

22

32

0

2,3 5,2

13-14

21-22

31-32

5,5

8

5,5

8

AZ16-03z

11

12

21

22

31

32

0

2,3

11-12

21-22

31-32

5,5

AZ15/16-2053 Ball Latch Kit

24

8

AZ15/16-2024 Gasketed Key Caps

AZ15/16 ACTUATOR KEY SPECIFICATIONS

AZ15/16-B1 Actuator Key

Minimum

actuating radius

with actuator B1/B1-1747

AZ15/16-B1 Actuator Key

with AZ15/16-1747

Holding Magnet Kit

1

1

5

ø5,5

.22

56

2.24

16

.64

2

0.08

34,3

1.37

11

.43

40

1.58

5

.2

AZ15/16-B1-2177 Actuator Key

Minimum

actuating radius

with actuator

B1/B1-1747

23,3

0.93

27

1.08

4

Actuator B1 is standard for AZ15/16; it allows a

minimum actuating radius of 150 mm. Please note

that the center of rotation must be in the same

plane as the upper edge of the safety switch.

AZ15/16-B2 Actuator Key

Ordering example:

Switch, holding magnet and

actuator: AZ16-zv/B1-1747

AZ15/16-B2 Actuator Key

with AZ15/16-1747

Holding Magnet Kit

mm

inch

Minimum

actuating

radius with

actuator

B2/B2-1747

Actuator B2 is particularly suitable for small

actuating radii over the wide edge of the

actuator (R=45 to 150mm). The basic setting

(angle 15°) provides a minimum radius of

45mm=1.8 in. For larger radii, the angle has

to be adjusted correspondingly by turning the

set screw counter-clockwise.

AZ15/16-B3 Actuator Key

AZ15/16-B3 Actuator Key

with AZ15/16-1747

Holding Magnet Kit

Minimum actuating

radius with actuator

B3/B3-1747

Actuator B3 is particularly suitable

for small actuating radii over the narrow edge of the actuator (R=32 to

150mm). The basic setting (angle

10°) provides a minimum radius of

32mm=1.3in. For larger radii, the

angle has to be adjusted correspondingly by turning the set screw

clockwise.

25

AZ15/16 ACTUATOR KEY SPECIFICATIONS

AZ15/16-B1-2177 Funnel Entry Adapter

(with straight actuating key)

AZ15/16-B6 Flex Actuator Key

10

.4

16

.64

16

.64

2

0.08

a

56

2.24

b

ø 5,5

.22

40

1.6

7

0.28

ø5,5

.22

16

0.63

34,3

1.37

11

.43

11

.43

40

1.58

5

.2

56

2.2

75°

27,3

1.09

79°

23,3

0.93

27

1.08

27

1.08

52

208

6

.24

31,4

1.26

14

.56

8

.32

16

64

10,9

.44

26

28

1.12

1

Safer

by

Design

27

SERIES AZ16zi

Individually-Coded Movable

Machine Guard Safety Interlock Switch

Features & Benefits

®

• Highly tamper-resistant actuating mechanism … difficult

to defeat with simple tools, tape, bent wires, etc. Reduces

liability exposure.

• Individually-coded actuator key (15,000 codes) …

provides extra security in high-risk applications.

• Non-removable actuating head … heightens tamperresistance.

• Four optional key entry locations … provide installation

flexibility.

• “Positive-Break” NC contacts … assure circuit

interruption upon actuator key removal.

• Watertight design … meets IP67 washdown requirements.

• High-strength, stainless-steel actuator key … tolerates

mechanical abuse without damage.

• Rugged, corrosion-resistant housing … tolerates the

most hostile environments.

• Tamper-resistant key mounting screws … deter

bypassing.

• Wide selection of accessories … to meet diverse

application requirements.

• Padlockable key … for added security during equipment

maintenance.

• Meets rigid safety agency standards … BG, UL and

CSA.

Description

The Series AZ16zi are designed for use with movable

machine guards which must be closed for operator safety.

Their tamper-resistant design, and positive-opening NC

contacts, provide a significantly higher level of safety than

conventional spring-driven switches whose contacts can

weld/stick shut. Their IP67 rating makes them ideal for

interlocking safety guards in hostile environments.

Operation

The AZ16zi is a two-piece, electromechanical safety interlock

switch. It consists of a rugged switch mechanism and an

individually-coded, geometrically-unique actuating key. The

key must be directly hard-mounted to the movable guard.

Upon opening of the guard, the normally-closed (NC)

contact(s) are forced to open through a direct (non-resilient)

mechanical linkage with the actuating key. The positive-break

NC contacts assure circuit interruption (and machine

stoppage) upon removal of the actuator key. (The NO

contacts close upon key removal.)

When the guard is closed, the actuating key forces the NC

contacts to re-close, and any NO contacts to re-open. The

tamper-resistant design prevents bypassing with simple tools,

bent wires or other readily available means.

Typical Applications

The AZ16zi is intended for use as a safety interlock on

movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Typical

applications are the interlocking of protective gratings, hinged

covers, access panels and other movable guards.

Patented geometrically-unique tumbler

configuration

®

28

is a trademark of SCHMERSAL

AZ16zi AVAILABLE MODELS AND ACCESSORIES

AVAILABLE MODELS

AVAILABLE ACCESSORIES

(Includes Individually-Coded Actuator Key and

1

⁄2" NPT Plastic Adapter)

Part Number

AZ16-12zi-B1

Description

Contacts (with

actuator key inserted)

Standard unit

AZ16-03zi-B1

AZ16-12zi-B1-1747

AZ16-03zi-B1-1747

AZ16-12zi-B1-2024

AZ16-03zi-B1-2024

AZ16-12zi-B1-2053

AZ16-03zi-B1-2053

1 NO & 2 NC

3 NC

Standard unit with

built-in key actuator

magnet latch

Standard unit with

built-in slot rubber

seals on key actuator

Standard unit with

built-in ball-latched

key actuator

1 NO & 2 NC

3 NC

1 NO & 2 NC

3 NC

3 NC

Description

Cord grip (cable gland)

Spare Plastic 1⁄2" NPT adapter

(One supplied with each unit)

M20-1⁄2"M

AZ15/16-CAP

(3 per kit)

#6-3/8 SPH

(package of 6)

Metal 1⁄2" NPT adapter (optional)

Key entry closure caps

(for unused entry slots)

#6-3/8 Spanner Pan Head

Tamper-Resistant Sheet Metal Screws

(For use on AZ16zi housing terminal cover)

#10-32 One-Way Oval Head

Tamper-Resistant Machine Screws

(For use in mounting actuator key)

#10-32 × 1⁄2" OWOH

(package of 6)

1 NO & 2 NC

MS AZ 15/16 ADJUSTABLE MOUNTING KIT

(Eases installation and facilitates

adjustments due to guard misalignment)

Part Number

M20-CG

M20-1⁄2"P

AZ-SZ

1

AZ16zi Lockout Device

(accepts up to 6 padlocks)

PL-M20-24V

24VAC/DC LED Pilot Light Kit

PL-M20-120V

110VAC/DC Pilot Light Kit

MS AZ 15/16-P

Adjustable mounting kit for parallel mounting

MS AZ 15/16-R/P

Adjustable mounting kit for parallel or

perpendicular mounting

Suffix “-2177”

Funnel entry adapter (Must be ordered with

base switch for factory assembly…see

page 30)

TYPICAL INDIVIDUALLY-CODED KEYS

EXAMPLE OF INDIVIDUALLY-CODED KEYS

15,000 codes provide extra security

in high-risk applications

MS AZ 15/16-R/P

(for parallel or

perpendicular mounting)

w!

Ne

MS AZ 15/16-P

(for parallel mounting)

29

AZ16zi TECHNICAL DATA

Housing

Actuator Key

Degree of Protection

Travel for Positive-Break

Key Ejection Force

Insertion Force

Operating Temperature

Mechanical Life

Conformity to Standards

Key Withdrawal Speed

Minimum Closing Radius

Glass-fibre reinforced, selfextinguishing plastic

Stainless steel

IP67

0.315 inches (8 mm)

3 N (0.7 pounds)

Approx. 15N (3.3 pounds)

–22°F to +175°F

1 million operations

UL & CSA, BG

A600, P300

2 meters/second (maximum)

9.8" (250mm)

Contacts

Contact Configuration

Contact Gap

Switching Action

Contact Rating

Rated Insulation Voltage

Thermal Current Rating

Current Rating

SWITCHING DIAGRAMS & CONTACT SCHEMATICS

Rated Impulse

Withstand Voltage

Short Circuit Protection

Type Terminals*

AZ16-12zi

13

21

31

0

14

22

32

5,5

13-14

21-22

31-32

5,6

8

5,5

8

Fine silver

Double-pole, double-break with

electrically-separated contact

bridges

2 × 2 mm

Slow-action, positive-break

NC contacts

A600

500VAC

10A (300VAC)

6A @ 120VAC

4A @ 230VAC

2.5V/230VAC (with M12x1 quickconnect)

6kV

Fuse 6A (slow-blow)

Screw terminals with self-lifting

clamps for up to 2.5 mm2

(AWG13) wire

*Optional plug-in M12x1 quick-connect available. Please consult

factory.

AZ16-03zi

11

12

21

22

31

32

0

11-12

21-22

31-32

5,5

“-2177” Funnel Entry Adapter

8

(Order as part of base switch…

e.g. AZ16-02z1-B1-2177)

5

.2

10

.4

DIMENSIONS

40,7

1.63

11

.43

5,5

.22

mm

inch

23

.9

40

1.58

56

2.24

52

208

6

.24

31,4

1.26

14

.56

8

.32

16

64

10,9

.44

30

28

1.12

AZ16zi INDIVIDUALLY-CODED ACTUATOR KEY SPECIFICATIONS

1

Applications: harsh environments

(coarse dirt, chips, flour…)

For holding light to medium-weight guards closed

31

SERIES AZ 200

Pulse-Echo Based

Non-Contact Safety Interlock Switch

Features & Benefits

• Tamper resistant … frequency-matched switch and

actuator required for operation.

• Non-contact sensing … for long term reliability.

• Dual purpose handle … modern, ergonomic design—no

additional door handles are needed.

• Integral LED diagnostics … indicates operating states

• Integral self-monitoring and door detection sensors …

satisfy requirements of Safety Control Category 4.

*See Note Below.

• One-hand emergency release … hazardous area can be

left quickly and safely.

• Switch and actuator do not protrude into door

opening … no risk of injury or damage from a protruding

actuator.

• Dual PNP 250 mA safety outputs … for application versatility.

w!

e

N

AVAILABLE AZ 200 MODELS

(Actuator ordered separately below)

Model Number

Description

The AZ 200 pulse-echo based non-contact safety interlock is

designed for use with movable machine guards/access gates

which must be closed for operator safety.

The AZ 200 consists of an interlock switch and actuator unit

with door handle and optional emergency exit handle. The

actuator is always inserted into its housing, protecting the

actuator and the operator against damage and injury. Utilizing

pulse-echo sensor technology, the actuator and interlock can

have an offset of ±5 mm and the actuator still engages the

interlock. A sensor stimulates a coil in the actuator, which in

turns sends a signal back to the sensor. The pulse-echo

technology provides diagnostic information and detects and

indicates any misalignment at an early stage. Two different

actuator designs accommodate both sliding or hinged guards.

Description

AZ200SK-1P2P

2-PNP safety outputs, without door

detection sensors, one diagnostic output

AZ200SK-T1P2P

2-PNP safety outputs, with door

detection sensors, one diagnostic output

AZ200SK-3P2P

2-PNP safety outputs, without door

detection sensors, three diagnostic outputs

AZ200SK-T3P2P

2-PNP safety outputs, with door

detection sensors, three diagnostic outputs

Sensors available with M23 quick disconnect—Replace SK with ST in

catalog number.

Part number: SZ200

Description: Lockout tag, up to 5 padlocks

The AZ 200 interlock is a dual channel design with two shortcircuit proof, safe PNP outputs, each of which can switch up

to 250 mA. It features a choice of one or three electronic

diagnostic outputs. These diagnostic outputs signal errors

before the safety outputs are switched off, thus enabling a

controlled shutdown of the machine.

With continuous internal function tests, the monitoring of

the safety outputs and the use of door detection sensors,

AZ 200 safety interlocks with one diagnostic output can be

wired in series without detriment to the control category.

Series wired AZ 200s continue to fulfill the requirements of

Control Category 4 according to EN 954-1 with door detection

sensors (without the need of a second switch).

Typical Applications

The AZ 200 is intended for use as a safety interlock switch

on movable machine guards which, when open, expose the

operator/maintenance personnel to machine hazards. Typical

applications are the interlocking of protective gratings, access

panels and other movable guards. The AZ 200 is suitable for

both sliding guards and hinged guards.

32

Safety Control Module Requirements

Dual-channel safety inputs, suitable for PNP semiconductor

outputs. The internal function tests of the sensor cause the

outputs to periodically switch off for a millisecond. This

must be tolerated by the control module. The following

SCHMERSAL safety control modules are recommended

for this application: SRB 301 LCB, SRB 324 ST

*Note: A safety control module may be required for reset

function and/or feedback monitoring functions, as

well as increased output current requirements.

SERIES AZ 200 AVAILABLE KEYS AND DIMENSIONS

AZ 200-B1 ACTUATOR FOR SLIDING DOORS

AZ/AZM 200-B1-

AZ 200-B30 ACTUATOR FOR HINGED DOORS

AZ/AZM 200-B30-

A

G1

Leave blank (without emergency

exit handle)

P0 (with emergency exit handle)

Leave blank (without

door detection sensor)

T (with door detection sensor)

Leave blank (without

door detection sensor)

T (with door detection sensor)

L (Door hinge on left side)

L (Door hinge on left side)

R (Door hinge on right side)

R (Door hinge on right side)

Ordering example: To order an AZ 200 actuator handle assembly for a left

hand door, with door detection sensor and emergency

exit handle, order p/n AZ/AZM200-B1-LTP0

Leave blank (without

emergency exit handle)

P1 (with emergency

exit handle)

Ordering example: To order an AZ 200 actuator handle assembly for a left

hand door, with door detection sensor and emergency

exit handle, order p/n AZ/AZM200-B30-LTAG1P1

DIMENSIONS OF AZ 200 & AZ/AZM 200-B1 HANDLE

AZ/AZM 200-B1

for sliding doors

33

SERIES AZ 200 TECHNICAL DATA

MECHANICAL SPECIFICATIONS

Housing

Degree of Protection

Unlocked Holding Force

Operating Temperature

Storage Temperature

Response Time

Vibration Resistance

Shock Resistance

Mechanical Life

Mounting

Conformity to Standards

ELECTRICAL SPECIFICATIONS

Fiberglass reinforced thermoplastic

IP67

30N (7 pounds)

–25°C to +60°C

–25°C to +85°C

≤ 60ms

10-55Hz, amplitude 1mm

30g/11ms

1 million operations

40-45mm profiles

CE

BG

EN 60947-5-1 UL/CSA Pending

EN 954-1

IEC 61508

Mode of Operation

Rated Operating Voltage

Rated Operating Current

No Load Current

Residual Current

Rated Impulse

Withstand Voltage

Rated Insulation Voltage

Safety Outputs

Safety Output

Operating Current

Safety Output

Operating Voltage

Signaling Output

Signaling Output

Operating Current

Signaling Output

Operating Voltage

Type Terminals

Inductive

24 VDC -15%/+10%

0.6A

0.1A

≤ 0.5mA

0.8kV

32 VDC

(2) PNP, short-circuit proof

0.25A per output

Max. 4V below rated

operating voltage

PNP, short-circuit proof

Max. 0.05A

Max. 4V below rated

operating voltage

Screw Terminals for up to 15

AWG flexible stranded wire

(1.5 mm2)

DIMENSIONS OF AZ 200 & AZ/AZM 200-B30 HANDLE

A

Door hinge on

left-hand side

Door hinge on

right-hand side

Legend

A = Front and rear manual release

B = Cable entry M20 x 1,5

C = Emergency exit P1

D = Door handle G1

AZ/AZM 200-B30

for hinged doors

B

34

C

C

D

D

SERIES AZ 200 DIAGNOSTICS

Function table of visual diagnostic LED, electronic diagnostic output and safety outputs

Diagnostic Outputs

LED

Safety

Outputs

State AZ 200

AZ200...-3P2P

AZ200...-1P2P

OUT

OUT2

OUT3

OUT

Green

Door open

0V

0V

0V

0V

0V

Green

Door closed

0V

0V

0V

24 V

0V

Yellow & Green

Door closed and actuator inserted

24 V

24 V

0V

24 V

24 V

Blinking red (1–9 impulses)

Error: see blinking codes

24 V

24 V

24 V

24 V

0V

Diagnostic LED error codes

The blinking sequence of the red

LED of the AZ 200 identifies the

active error. The following errors

are indicated:

Blinking Codes (red)

Indication (red)

Meaning

1 blinking impulse

Error output Y1

2 blinking impulses

Error output Y2

3 blinking impulses

Cross-wire

4 blinking impulses

Temperature too high

5 blinking impulses

Target error

6 blinking impulses

Error target combination

7 blinking impulses

Error AD values

8 blinking impulses

Error transmission voltage

9 blinking impulses

Channel error

Continuous red

Error

Meaning

Autonomous switch-off after

Cause

1 blinking impulse

Error output Y1

30 min.

Error in output test or voltage at output “Y1”, although

the output is switched off

2 blinking impulses

Error output Y2

30 min.

Error in output test or voltage at output “Y2”, although

the output is switched off

3 blinking impulses

Cross-wire

30 min.

Cross-wire between the output cables or error at

both outputs

4 blinking impulses

Temperature too high

30 min.

Temperature measurement indicates too high an

inner temperature

5 blinking impulses

Target error

0 min.

The difference between the code (frequency) of the

detected target and the set value is too large, false target

6 blinking impulses

Error target combination

0 min.

An invalid combination of targets was detected at

the 4 coils of the AZ200 T. (Current setting: latching

bolt detected & door target not detected => latch

breakage or tampering attempt)

7 blinking impulses

Error AD values

30 min.

Internal hardware error

8 blinking impulses

Error transmission voltage

0 min.

Supply voltage too low or defective internal voltage

control

9 blinking impulses

Channel error

0 min.

Data comparison between the channels leads to

differences in the signal evaluation because of an

internal hardware error

35

SERIES AZ 200 WIRING EXAMPLES

WIRING EXAMPLE: SINGLE DEVICE WIRING

WIRING COMPARTMENT

Meaning

Terminal

Supply Voltage

24 V

Supply Voltage

24 V

Safety Input 1

X1

Safety Input 2

X2

Ground

GND

Ground

GND

Safety Output 1

Y1

Safety Output 2

Y2

Diagnostic Output

OUT

Note: In case of single device wiring, the

bridge between the “24 V” terminal and

the “X1” and “X2” terminals must be

established; for series wiring, this bridge

must only be established in the first

device of the series.

WIRING EXAMPLE: SERIES WIRING OF 3 AZ 200

Only interlocks with one

diagnostic output can be

wired in series.

36

COMPATIBLE AZ 200 SAFETY CONTROLLER – SRB 301 LCB

ELECTRICAL SPECIFICATIONS

Operating Voltage

Power Consumption

Fuse (Input Power)

Fuse (Safety Outputs)

Switching Capacity

(Safety Outputs)

Switching Capacity

(Auxilliary Contacts)

Application Category

Pick-up Delay

Drop-out Delay