General range of flameproof electrical motors

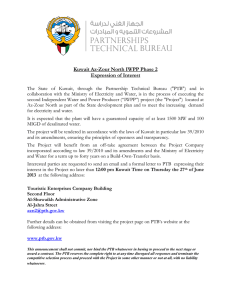

advertisement