FlexTubularHeat 3c.qxp

advertisement

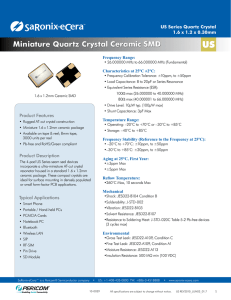

Z.R.E. ... Infinite solutions ... Infrared heaters MODEL Z.91 (INFRARED) MODEL Z.92 (HEATLAMP) MODEL Z.93 (QUARTZ) Z.R.E. Ceramic infrared elements Technical features Model Z.91 infrared General features Ceramic infrared heating elements are efficient, robust heaters which provide long wave infrared radiation. Ceramic elements operate in the temperature of 300°C to 700°C (572°F - 1292°F) producing infrared wavelengths in the 2 - 10 micron range. Most plastics and many other materials absorb infrared best in this range, which makes the ceramic heater the most efficient infrared radiant emitter on the market. A range of aluminised steel reflectors are also available to ensure that most of the radiation generated is reflected forward on to the target area. Applications Ceramic infrared elements are used in a diverse range of industrial processes such as: Heating l Thermoforming l Heat treatment on fabric l Sealing Feeding leads l Metal sheet folding Drying l Paint/ glue curing l Printing Mounting turret l Lacquering and other surface treatments for wood l Glazing of ceramics Special ceramic Oven for l Dust painting l Teflon coating l Coachwork repairs (paint) l Printing Resistive winding Ceramic elements are also very effectively in infrared outdoor heaters and infrared saunas Advantages in using infrared ceramic heaters l Fast heat transmission l Radiation constant over time l Uniform heating l Durability l long lasting surface – anti corrosion-anti-spray Thermocouple l Easy to install For further information please contact our technical dep. We reserve the right to change technical details. Element with built in K thermocouple 2 Z.R.E. Ceramic infrared elements Technical features Technical features l Power from 2.5W/cm2 up to 15W/cm2 l Max working T° 700°C l Infrared emission rate: 96% l Heating wire: NiCr 80/20 l High purity ceramic insulation with high mechanical strength, resistant to thermal stress and high dielectric strength. l power leads made of Ni ceramic beads insulated – high temperature resistant l Standard Mounting turret suitable for slot 15x41mm Assembling Included with ceramic heaters as standard ZRE supply wave spring and clip. The scheme shows how to fix an FTE element on a reflecting sheet. Wave spring and clip Slot 15x41mm Reflecting sheet Infrared element 3 Z.R.E. Ceramic infrared elements Heat up / cool down graphs Ceramic heat up curves Based on FTE tests of average surface temperature with an infared thermometer ser at an emissivity of 0.9 ( with the element mounted in an aluminised steel reflector l These temperatures also apply to the FFE and SFSE l For THE and HFE divide the wattage by two l For QTE and QFE divide the wattage by four Cermic cooling down curves Based on FTE tests of average surface temperature with an infared thermometer ser at an emissivity of 0.9 ( with the element mounted in an aluminised steel reflector RAS) l These temperatures also apply to the FFE and SFSE l For THE and HFE divide the wattage by two l For QTE and QFE divide the wattage by four 4 Z.R.E. Standard ceramic elements Standard ceramic elements Technical features general features l Heating wire made of FeCrAl alloy l Standard feeding voltage 230V ( other voltage upon request) l Useful Wavelength range: form 2 up to 10 microns l Average operating life 5000/1000h l UL approved l Recommended radiation distance from heater: 100 mm to 200 mm l Supplied with 100mm ceramic beaded power leads 60 FTE – full Through element 31 245 Dimensions Average Weight [ mm ] [g] 245 x 60 x 31 206 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z91C2450150FTE Z91C2450150FTE/T 255 250 Z91C2450250FTE Z91C2450250FTE/T 354 300 Z91C2450300FTE Z91C2450300FTE/T 400 400 Z91C2450400FTE Z91C2450400FTE/T 452 500 Z91C2450500FTE Z91C2450500FTE/T 486 650 Z91C2450650FTE Z91C2450650FTE/T 553 750 Z91C2450750FTE Z91C2450750FTE/T 602 1000 Z91C2451000FTE Z91C2451000FTE/T 685 5 Z.R.E. Standard ceramic elements FFE – full flat element 24 60 245 Dimensions Average Weight [ mm ] [g] 245 x 60 x 24 206 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z91P2450150 Z91P2450150T 255 250 Z91P2450250 Z91P2450250T 354 300 Z91P2450300 Z91P2450300T 400 400 Z91P2450400 Z91P2450400T 452 500 Z91P2450500 Z91P2450500T 486 650 Z91P2450650 Z91P2450650T 553 750 Z91P2450750 Z91P2450750T 602 1000 Z91P2451000 Z91P2451000T 685 60 HTE – half trough element 31 122 Dimensions Average Weight [mm] [g] 122 x 60 x 31 6 116 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91C122125HTE Z91C122125HTE/T 354 150 Z91C122150HTE Z91C122150HTE/T 400 200 Z91C122200HTE Z91C122200HTE/T 452 250 Z91C122250HTE Z91C122250HTE/T 486 325 Z91C122325HTE Z91C122325HTE/T 553 500 Z91C122500HTE Z91C122500HTE/T 685 Z.R.E. Standard ceramic elements 60 HFE – half flat element 122 Dimensions Average Weight [mm] [g] 122 x 60 x 31 113 24 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91P122125 Z91P122125T 354 150 Z91P122150 Z91P122150T 400 200 Z91P122200 Z91P122200T 452 250 Z91P122250 Z91P122250T 486 325 Z91P122325 Z91P122325T 553 500 Z91P122500 Z91P122500T 685 122 SFSE - square flat solid element 122 Dimensions [mm] 122 x 122 x 24 Average Weight [g] 231 24 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z91PQ1220150 Z91PQ1220150T 255 250 Z91PQ1220250 Z91PQ1220250T 354 300 Z91PQ1220300 Z91PQ1220300T 400 350 Z91PQ1220350 Z91PQ1220350T 452 400 Z91PQ1220400 Z91PQ1220400T 452 500 Z91PQ1220500 Z91PQ1220500T 486 650 Z91PQ1220650 Z91PQ1220650T 602 750 Z91PQ1220750 Z91PQ1220750T 602 7 Z.R.E. Standard ceramic elements 60 QTE - quarter through element 60 Dimensions Average Weight [mm] [g] 60 x 60 x 31 78 32 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91PQ60125 Z91PQ60125T 354 250 Z91PQ60250 Z91PQ60125T 685 60 QFE - quarter flat element 60 Dimensions Average Weight [mm] [g] 60 x 60 x 31 8 107 32 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91PQ60125 Z91PQ60125T 354 250 Z91PQ60250 Z91PQ60125T 685 Z.R.E. Standard ceramic elements 110 LFTE - Large full through element 250 Dimensions Average Weight [mm] [g] 245 x 110 x 37 369 37 Watt Part number Part number with thermocouple Mean surface temperature °C 1000 Z91C2451000LFTE Z91C2451000LFTT 511 1500 Z91C2451500LFTE Z91C2451500LFTT 596 110 LFFE - Large full flat element 250 24 Dimensions [mm] 245 x 95 x 24 Average Weight [g] 342 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z91PR245150 Z91PR245150T 204 350 Z91PR245350 Z91PR245350T 338 750 Z91PR245650 Z91PR245650T 501 1400 Z91PR2451400 Z91PR2451400T 667 9 Z.R.E. Standard ceramic elements QCE – quarter curved element 10 Dimensions [mm] Average Weight [g] 60 x 55 x 40 75 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z91C060150QCE Z91C060150QCE/T 440 250 Z91C060250QCE Z91C060250QCE/T 592 Z.R.E. Standard ceramic elements Ceramic Hollow elements Technical features The Hollow element offers the following advantages over conventional ceramic emitters: l Heat up time reduced by over 40% l Energy savings of over 15% in some applications l Lightweight construction with low thermal mass The Hollow element is available in a range of Power ratings and voltages l The universal ceramic mounting allows it to be easily interchanged with a conventional emitter in an existing installation l All Hollow emmitters are fitted with high density thermal insulation in the hollow cavity. Technical features l Heating wire made of FeCrAl alloy l Standard feeding voltage 230V ( other voltage upon request) l Useful Wavelength range: form 2 up to 10 microns l Average operating life 5000/1000h l Recommended radiation distance from heater: 100 mm to 200 mm l Supplied with 100mm ceramic beaded power leads FFEH – Full flat element Hollow 245 60 36 Dimensions Average Weight [mm] [g] 245 x 60 x 36 222 Watt Part number Part number with thermocouple Mean surface temperature °C 250 Z91P245250FFEH Z91P245250FFEHT 383 300 Z91P245300FFEH Z91P245300FFEHT 400 400 Z91P245400FFEH Z91P245400FFEHT 488 500 Z91P245500FFEH Z91P245500FFEHT 535 600 Z91P245600FFEH Z91P245600FFEHT 563 800 Z91P245800FFEH Z91P245800FFEHT 670 11 Z.R.E. Standard ceramic elements 60 HFEH –Half flat element Hollow 122 Dimensions [mm] 122 x 60 x 36 Average Weight [g] 106 36 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91P122125HFEH Z91P122125HFEHT 383 200 Z91P122200HFEH Z91P122200HFEHT 488 250 Z91P122250HFEH Z91P122250HFEHT 535 300 Z91P122300HFEH Z91P122300HFEHT 563 400 Z91P122400HFEH Z91P122400HFEHT 670 60 QFEH –quarter flat element Hollow 60 Dimensions Average Weight [mm] [g] 60 x 60 x 36 12 75 36 Watt Part number Part number with thermocouple Mean surface temperature °C 125 Z91P060125QFEH Z91P060125QFEHT 535 200 Z91P060200QFEH Z91P060200QFEH 670 Z.R.E. Standard ceramic elements 122 SFEH –Square flat element Hollow 122 Dimensions [mm] 122 x 122 x 36 Average Weight [g] 242 36 Watt Part number Part number with thermocouple Mean surface temperature °C 250 Z91P122250SFEH Z91P122250SFEHT 383 300 Z91P122300SFEH Z91P122300SFEHT 400 400 Z91P122400SFEH Z91P122400SFEHT 488 500 Z91P122500SFEH Z91P122500SFEHT 535 600 Z91P122600SFEH Z91P122600SFEHT 563 800 Z91P122800SFEH Z91P122800SFEHT 670 13 Z.R.E. Infrared ceramic bulbs Technical features ESE Edison Screw Ceramic Bulbs The Ceramic Infrared Bulb is primarily used in the area of animal / pet healthcare. Applications l Pet healthcare e.g. nestling, swine etc. l Therapeutic use e.g. arthritis and rheumatism treatment l Anti moisture systems Advantages in using ESE series in farming l Uniform and constant heating l natural night sleep thanks to absence of light emissions l easy to install , they do not need any maintenance l easy to clean We recommend to use bulb heaters together with the suitable reflectors in order to get the highest efficiency and to protect bulb holder and the connection against overheating. For this purpose we normally suggest to use ceramic bulb holder able to resist to high temperatures ESEXL Technical features l Iron-chrome aluminium resistance wire 140 140 l Heater Voltage: 230~240 V standard except for the 250 W ESER bulb l 240 V as standard (other voltages available on request) l Useful wavelength range: 2-10 microns l Average Operating Life-Up to 20,000 hrs depending on conditions ESER l Recommended radiation distance from heater is 100 mm to 200 mm 95 140 l E27 tap on bulb cap Power [ W ] Technical features ESEB ESES ESEB ESES ESER ESER ESEXL 60 60 100 100 150 250 500 Mean surface temperature [ °C ] 300 300 426 426 441 560 516 2 Maximum power density kW/m 13,5 7,3 22,5 12 15 25 30 Average Weight [ g ] 112 113 115 112 165 170 253 Dimensions [ mm ] 14 80 x 110 65 x 140 65 x 140 80 x 110 95 x 140 95 x 140 140 x 140 Z.R.E. Metal panel Technical features Metal holder and reflectors for infrared ceramic heaters general features The load bearing structure it is composed by a robust Ushaped section bar made of zinc coated steel which carry the reflectors in which the infrared elements is mounted. The U-shaped bar has some holes in order to permit the wiring. It has also one slot 18x9mm on both sides in order to enable the anchorage to the machinery l PFTE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 1 up to 8 FTE elements l PSFSE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 2 up to 16 SFSE elements l PFFE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 1 up to 8 FFE elements l PHFE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 2 up to 16 HFE elements For further information please contact our technical dep. We reserve the right to change technical details. Per ordinare Model Z.91 Application: ............................................................................... + Part number : ........................................................................ + Panel length: ......................................................................... + Infrared elements: ................................................................. + Built in TC elements: ............................................................. + Connection type (strap or cables): ....................................... + Internal fastening/esternal fastening: ................................... 15 Z.R.E. Metal panel Technical features 8 7 4 4 9 9 6 8 5 3 5 1)Infrared element 2)stainless steel (AISI 430) reflector 3)Wave spring and clip 4)square screw and nut 5)spacer 6)zinc coated U-shaped channel 7)2poles ceramic connector 8)screw + nut for ceramic connector 9)external slots for fixing to the lead bearing structure of the machinery 2 41 4 15 4 Standard dimensions of the slots for the ceramic elements fastening 1 Internal fastening / external fastening Is possible to have two different U- shaped channel or the panel fastening: External fastening: The U-channel is as long as the reflector. The fastening is possible thanks to the lateral screws. Internal fastening: The U-channel length is 80mm longer ( 40mm each side) than the reflector and it has 2 slot at both extremities to enable the fastening to the machinery 16 Z.R.E. Panel scheme Metal panel Fastening slot 18 x 9 L= (250 / 2000) 20 20 40 Type P.F.T.E - P.H.T.E. F.T.E H.T.E 50 100 2 30 52 50 L= (250 / 2000) 72 62 Fastening slot 18 x 9 Type P.F.F.E - P.H.F.E. F.F.E - H.F.E 42 65 Connections We normally use two standard way of connections : Strap connection: The infrared elements are connected in parallel with 2 stainless steel strap Cable connection: The panel is supplied with the ceramic connectors. Customer has to provide for wiring and connections . special connection box upon request. 17 Z.R.E. Quartz infrared element Technical features Model Z.93 Quartz infrared element general features Use Quartz infrared heating Elements provide medium wave infrared radiation. They are favoured in industrial applications where rapid heater response is necessary, including systems with long heater off cycles. Quartz infrared heating elements are particularly effective in systems where rapid heater response and/or zone controlled heating is required. They have a broad emission spectrum and cover various absorption ranges. Pillared quartz elements have the same mounting fixture as ceramic elements allowing replacement without difficulty. This is ideal for design alternation involving the use of materials with different absorption characteristics. Advantages is using quartz infrared elements l Rapid response l Quinck heating up l quick cooling down l High radiation efficiency l Uniform heating l Easy to install Technical features l Iron-chrome aluminium resistance wire l Heater Voltage: 230 Volts standard (other voltages available on request) l Useful wavelength range: 1.5 - 8 microns l Recommended radiation distance from heater is 100 mm to 200 mm l 18 Supplied with 100mm ceramic beaded power leads Z.R.E. Infrered quartz elements 110 22.5 FQE full quartz element 187 62 40 247 Dimensions [mm] 247 x 62.5 x 22 Average Weight [g] 327 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z93Q2470150FQE Z93Q2470150FQE/T 343 250 Z93Q2470250FQE Z93Q2470250FQE/T 438 400 Z93Q2470400FQE Z93Q2470400FQE/T 542 500 Z93Q2470500FQE Z93Q2470500FQE/T 593 650 Z93Q2470650FQE Z93Q2470650FQE/T 664 750 Z93Q2470750FQE Z93Q2470750FQE/T 690 1000 Z93Q2471000FQE Z93Q2471000FQE/T 772 22.5 HQE Half quartz element 63.5 123.5 Dimensions [mm] 124 x 62.5 x 22 Average Weight [g] 210 Watt Part number Part number with thermocouple Mean surface temperature °C 150 Z93Q124150HQE Z93Q124150HQE/T 470 250 Z93Q1242500HQE Z93Q124250HQE/T 593 400 Z93Q124400HQE Z93Q124400HQE/T 720 500 Z93Q124500HQE Z93Q124500HQE/T 772 19 Z.R.E. Infrared quartz elements PFQE pillared full quartz element Dimensions [mm] Average Weight [g] 247 x 62,5 x 22 387 Part number with thermocouple Mean surface temperature °C Watt Part number 150 Z93Q2480150PFQE 343 250 Z93Q2480250PFQE 438 400 Z93Q2480400PFQE 542 500 Z93Q2480500PFQE 593 650 Z93Q2480650PFQE 664 750 Z93Q2480750PFQE 690 1000 Z93Q2481000PFQE 772 29 QQE quarter quartz element 32 110 22.5 Dimensions Average Weight [mm] [g] 62,5 x 62,5 x 22 20 136 40 62.5 62.5 Part number with thermocouple Mean surface temperature °C Watt Part number 150 Z93Q063150QQE 635 250 Z93Q063250QQE 772 Z.R.E. Infrared quartz elements 22.5 SQE square quartz element 123.5 63.5 123.5 Dimensions [mm] 124 x 124 x 22 Average Weight [g] 386 Part number with thermocouple Mean surface temperature °C Watt Part number 150 Z93Q1240150SQE 343 250 Z93Q1240250SQE 438 400 Z93Q1240400SQE 542 500 Z93Q1240500SQE 593 650 Z93Q1240650SQE 664 750 Z93Q1240750SQE 690 1000 Z93Q1241000SQE 772 21 Z.R.E. Metal panel Technical features Metal panel for quartz infrared element general features The load bearing structure it is composed by a robust Ushaped section bar made of anticorodal (special Aluminium alloy) which carry the quartz elements by the threaded pins The U-shaped bar has some holes in order to permit the wiring. It has also one slot 18x9mm on both sides in order to enable the anchorage to the machinery l PHSQ panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 2 up to 16 HSQ elements l PFSQ panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 1 up to 8 FSQ elements l PSQE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 2 up to 16 SQE elements l PLQE panel standard dimension are: 250-500-750-1000-1250-1500-1750 -2000mm suitable for mounting from 1 up to 8 LQE elements For further information please contact our technical dep. We reserve the right to change technical details. 22 Z.R.E. Metal panel HOW TO MOUNT A QUARTZ LEMENT ON A PANEL 4 1) infrared elements 2) U-shaped 3) Two poles ceramic connector 4) Screws and nuts for connector 5) Screws and nuts for heater fastening 3 5 5 2 4 5 5 1 L= (250 / 2000) 60 62 Fastening slot 18 x 9 F.Q.E. H.Q.E. 20 42 65 23 Z.R.E. Quartz tungsten elements Technical features Quartz halogen/tungsten elements general features Ceramicx Ireland produces extremely penetrative infrared heaters (infrared emitters) using two types of tungsten filaments: the porcupine or star type filament for fast medium wave emitters, and the supported filament for short wave halogen emitters. The emitters heat up and cool down within seconds making them particularly suitable for systems requiring short cycle times. Fast Medium Wave Quartz Tungsten Heaters Technical features general features The tungsten filament used in these heaters is the porcupine or star type coil, which can be operated at temperatures up to 1500°C (2732°F), with peak wavelength emissions of approximately 1.6 microns. It reaches top temperatures within seconds. As well as having excellent structural rigidity, this coil is designed to minimize light output and maximize IR emission thereby increasing IR radiant efficiency. As well as having excellent structural rigidity, this coil is designed to minimize light output and maximize IR emission thereby increasing IR radiant efficiency. 24 Type Watt Max T° on the coil [ °C ] Total Length [ mm ] Heated length [ mm ] QTS 750 1450 224 170 QTM 750 1210 277 225 QTM 1000 1450 277 225 QTL 1000 1270 473 415 QTL 1750 1470 473 415 QTL 2000 1500 473 415 Z.R.E. Quartz tungsten elements Short Wave Quartz Halogen Heaters Technical features general features These heaters are filled with halogen gas to allow the supported tungsten filament to reach temperatures as high as 2600°C (4712°F). With peak wavelength emissions of approximately 1 micron they are extremely penetrative and allow rapid on/off cycles. Standard Products: R7s termination and 10 mm diameter glass. Type Watt Voltage [V] Max T° on the coil [ °C ] Total Length [ mm ] Heated length [ mm ] QHS 1000 240 2410 224 170 QHS 1000 240 2520 224 170 QHM 1000 240 2410 277 235 QHL 2000 240 2250 473 425 QHL 2000 480 2390 473 425 25 Z.R.E. Quartz tungsten elements FastIR Infrared Heating Systems Technical features general features Model FastIR 305 The FAST IR infrared heat system was developed by Ceramicx. These compact robust systems form an ideal installation for quartz tungsten/halogen glass tube emitters. Optimum efficiency is achieved by highly polished aluminum steel reflection and near mounted axial flow fans, which eliminate rear convection losses and keep the reflectors cool for better directional quality on the infrared output. The external body which manufactured from aluminum can be maintained at “touch safe” temperature. Model FastIR 500 26 Type Configuration Voltage [V] Infrared elements Dimensions [ mm ] FastIR 305 4 tubi: 4 kW 5 tubi: 5 kW 240 1000 W QTM o 1000 W QHM 305 x 305 x 150 FastIR 500 6 tubi: 12 kW 7 tubi: 14 kW 240 2000 W QTL o 2000 W QHL 500 x 500 x 150 Z.R.E. Quartz tungsten elements Accessories for Quartz Tungsten / Halogen Heaters Technical features general features Mounting the quartz tungsten emitters in reflectors of high reflectivity maximizes output and gives a rigid, robust assembly. The reflectors are fitted with the specialized R7 holders allowing safe and easy installation of quartz tungsten heaters with the R7s terminations. Ceramic R7s holders used for mounting of heaters with the R7s termination: l Voltage rating: 250 V a.c. l Current Rating: 8 A l Max. Temperature: 350° C l Leads: 190 mm long PTFE insulated (max. 250°C). l Fixing Screw: M4 l Please note some off-standard connectors are available on request. Special features l Polished aluminised steel (gold coated on request). l Temperature rating (max) of 500°C (932°F). l Thickness: 0.75mm 27 Z.R.E. Accessories for infrared heating Accessories for infrared heating Ceramic Terminal Blocks Wave Spring and Clip E27 Ceramic Bulb Holder Buzz Bars V-Clips Ceramic Bulb Reflector 28 High temperature ceramic terminal blocks. They are used with buzz bars to produce power distribution systems. Used in the mounting and installation of all Ceramic elements and the PFQE element. Included with these heaters as standard. One piece spring/clip also available High temperature porcelain holder used in operation of ceramic IR bulbs. Buzz Bars (Dimensions: 8 mm x 2 mm) can be used with the ceramic terminal block to produce a flexible and maintenance free power distribution system Can be used to connect power leads to buzz bar distribution systems in combination with a fixing screw (supplied) Highly polished reflector for use with ceramic IR bulbs. R7s Holders The Ceramic R7s holder is used for mounting of heaters with the R7s termination. Max temperature: 350°C (662°F) High temperature leads Up to 350°C Z.R.E. Accessories Technical features VLC20 measuring with static relays general features special instruments with 2 separate programmable control systems, phase angle and fast zero crossing with phase angle. Static relay and thermal fuse built in suitable for resistive load mono 230V 4KW as infrared heaters short and medium wave phase angle: soft start 200ms and auto soft start for temporary brown out l l fast zero crossing with pre heating : soft start with phase angle with maintaining for 5 sec then with switch to fast zero crossing with 400ms as cycle time NOTE: Soft start and fast zero crossing enable the operator to reduce the in – rush extracurrent during the start up and the cycle which may reduce the life spam of many components as short wave infrared elements. Furthermore they avoid any damage of the protection thermal fuse. How to set VLC20 To set VLC20 with phase angle or fast zero crossing please follow instructions below: Push DOWN button since the display value is 0 Keeping push DOWN push also UP button since the display shows a line, then F ( phase angle) then release or push DOWN again to P (zero crossing) Pushing DOWN is possible to switch from F to P To confirm push UP VLC20 restart automaticallywhen function are saved on E2prom Technical data l Feeding tension 230V AC/DC 2VA l Static relay 20A 230V AC 50hz l Internal thermal fuse 25AmpFF l General mechanical switch l Metal case with fairlead Control l Range 0-100% steps. l Set up saving on E2prom l Thermal fuse break warning ( on the display) Connection and internal therminal block L2 R TRAS.1 N 4KW 230V 50Hz Dimension 170 U Fairlead Ø 12mm M1 HEAT DISSIPATOR F1 FUSE. 25FF 6,3 x 32 150 NEUTRAL L1 CARICO LINE S1 VLC20 70 29 10040 San Gillio - Torino (Italy) - Via Druento, 48/2 Marcatura secondo direttiva 2006/95/CE del 11/12/2006 © Copyright Z.R.E. 20\0 - Rev 1.0 - All right reservedi Tel. +390119841848 8 linee R.A. - Fax +390119848099 e-mail: info@zre.it www.zre.it