RECOMMENDATIONS There are two most critical parts for this project. ... indentation which determine the hardness of the ceramic at that...

advertisement

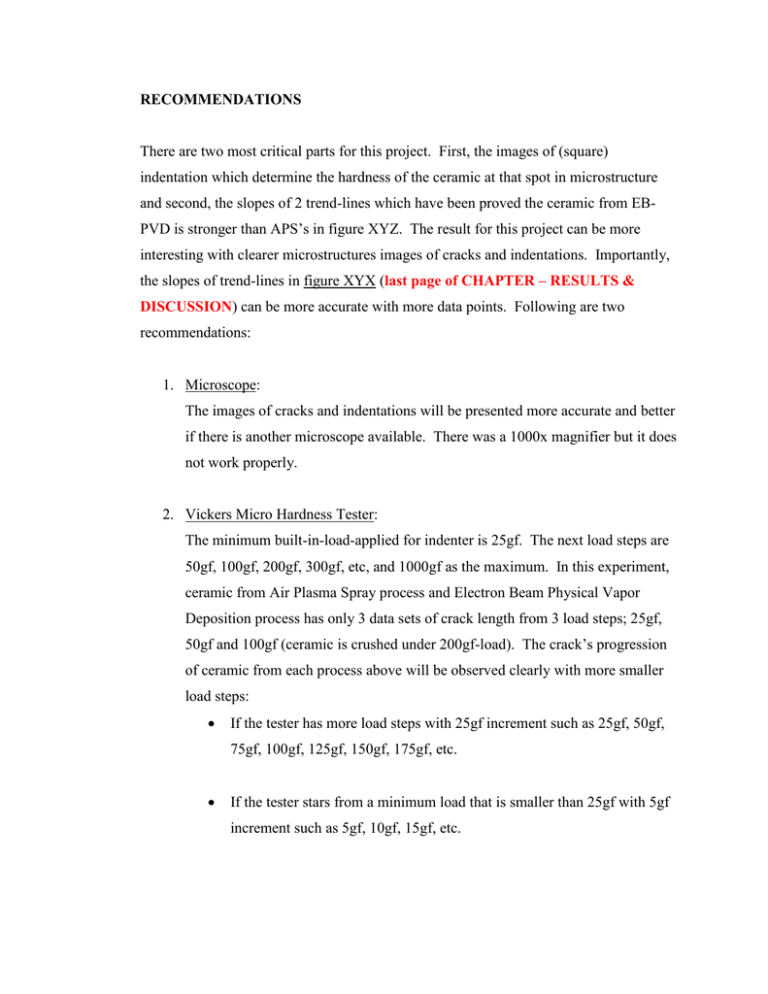

RECOMMENDATIONS There are two most critical parts for this project. First, the images of (square) indentation which determine the hardness of the ceramic at that spot in microstructure and second, the slopes of 2 trend-lines which have been proved the ceramic from EBPVD is stronger than APS’s in figure XYZ. The result for this project can be more interesting with clearer microstructures images of cracks and indentations. Importantly, the slopes of trend-lines in figure XYX (last page of CHAPTER – RESULTS & DISCUSSION) can be more accurate with more data points. Following are two recommendations: 1. Microscope: The images of cracks and indentations will be presented more accurate and better if there is another microscope available. There was a 1000x magnifier but it does not work properly. 2. Vickers Micro Hardness Tester: The minimum built-in-load-applied for indenter is 25gf. The next load steps are 50gf, 100gf, 200gf, 300gf, etc, and 1000gf as the maximum. In this experiment, ceramic from Air Plasma Spray process and Electron Beam Physical Vapor Deposition process has only 3 data sets of crack length from 3 load steps; 25gf, 50gf and 100gf (ceramic is crushed under 200gf-load). The crack’s progression of ceramic from each process above will be observed clearly with more smaller load steps: If the tester has more load steps with 25gf increment such as 25gf, 50gf, 75gf, 100gf, 125gf, 150gf, 175gf, etc. If the tester stars from a minimum load that is smaller than 25gf with 5gf increment such as 5gf, 10gf, 15gf, etc.

![Additive manufacturing of ceramic components [ PDF 0.69 MB ]](http://s2.studylib.net/store/data/018643837_1-58a67504533c09dae7066bbc1a8a8941-300x300.png)