What makes Positronic`s new PosiBand® contact interface a

advertisement

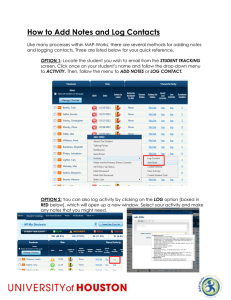

1 Positronic Industries w h i t e p a p e r What makes Positronic’s new PosiBand ® contact interface a significant improvement? T he PosiBand ® contact system has many ­a dvantages over the legacy split tine design. POSITRONIC INDUSTRIES, INC. 423 N Campbell Avenue PO Box 8247 Springfield, MO 65801 Toll Free (800) 641-4054 Telephone (417) 866-2322 Fax (417) 866-4115 info@connectpositronic.com is more robust than the split tine contact, which can be pried open 7 PinosiBand harsh ­environments, resulting in reduced normal force and degradation of electrical performance. osiBand has greater surface area at the male and female contact interface, 7 P­resulting in more consistent electrical performance. has lower average insertion forces, resulting in greater ease in mating, 7 P­eosiBand specially in larger high density connectors. The average lower insertion force is ­accomplished while meeting or exceeding performance requirements. PosiBand’s contact body does not require annealing of the crimp ­barrels, 7 Tashedoes the split tine design. This eliminates concern of unintentionally heat-treating the mating end of the contact, which can cause electrical failure. POSITRONIC INDUSTRIES, S.A.S. Zone Industrielle d’Engachies 46 Route d’Engachies France 32020 Auch Cedex Telephone 33 5 62 63 44 91 Fax 33 5 62 63 51 17 contact@connectpositronic.com POSITRONIC ASIA PTE LTD. 3014A Ubi Road 1 #07-01 Singapore 408703 Telephone (65) 6842 1419 Fax (65) 6842 1421 singapore@connectpositronic.com osiBand is qualified under SAE AS39029 and MIL-DTL-24308 specifications. 7 PPosiBand is also ­­qualified under GSFC S-311-P4/08 Rev C and GSFC S-311-P4/10 Rev C to the higher 40 gram contact separation test requirement. 7 See page 4 for PosiBand’s electrical characteristics. H igh reliability connectors utilize female closed entry contacts that provide an unbroken ring of solid material at the face of the contact. The closed entry feature is crucial in preventing damage to female contacts used in harsh ­environments, repeated mating cycles, blind mate applications and applications requiring highest reliability. New MDX Series connector f­eaturing PosiBand contacts A common closed entry design utilized by connector manufacturers is a split tine and sleeve concept. The main part of the contact has split tines to provide normal force on male contacts when connectors are mated. A sleeve is placed over the main part of the contact to provide a closed entry. continued on next page www.conne c t p o s i t r o n i c . c o m Catalog CBR-0001 Rev. A1 2 Positronic Industries The sleeve surrounding the split tines offers greater contact reliability when compared to a similar contact without the closed entry feature. The sleeve serves to limit the ­distance the contact tines can open. If female contact tines open too far, they may not return to their original position. This may cause diminished normal forces and can result in ­intermittent or open electrical circuits. w h i t e p a p e r Female contact tines can open too far if an oversized pin is inserted into the contact. The most common cause for damage can occur if a male contact is inserted into a female contact at an angle. Rocking the connectors back and forth during mating and unmating can pry the female contacts open. Utilizing a sleeve to provide a closed entry feature does allow split tine contacts greater r­ eliability. This design has been used for decades because it provided a degree of reliability at an affordable price. However, split tine contacts are still susceptible to being pried open if care is not taken when cable connectors are mated and ­unmated to other cable or board mount connectors. Disassembled closed entry split tine contact The split tine design has other i­ nherent weaknesses. One weakness is the need to anneal the crimp barrel. The material used to manufacture split tine female contacts must have Assembled closed entry split tine contact elasticity to allow the tines to open when receiving the male contact and then to return to their original ­position after the male contact is ­disengaged. Unfortunately, elasticity is not a characteristic that is desirable for the crimp barrel. When crimping a wire onto a contact, the material must be ductile to allow a permanent set after the ­crimping operation. Split tine contacts are manufactured using a material with elastic properties. The crimp barrel is then annealed to soften the material so a proper crimp can be achieved. If the ­annealing process is not carefully controlled, the mating portion of the contact may ­unintentionally be annealed. This will result in diminished normal forces and potential e­ lectrical failures. Other weaknesses of split tine contacts revolve around the fact that the tines must be ­depressed to provide normal force. The depressed tines slope inward and form a “point” at the mating end of the contact. If the forming operation is not carefully executed, proper ­normal force will not be achieved. Also, since the tines slope toward a point, there is a reduced area of contact between the male and female contact interface. The interface consists of a small ring at the tip of the female contact. Electrical contact depends solely on this small area between the male and female interface. continued on next page www.conne c t p o s i t r o n i c . c o m POSITRONIC INDUSTRIES, INC. 423 N Campbell Avenue PO Box 8247 Springfield, MO 65801 Toll Free (800) 641-4054 Telephone (417) 866-2322 Fax (417) 866-4115 info@connectpositronic.com POSITRONIC INDUSTRIES, S.A.S. Zone Industrielle d’Engachies 46 Route d’Engachies France 32020 Auch Cedex Telephone 33 5 62 63 44 91 Fax 33 5 62 63 51 17 contact@connectpositronic.com POSITRONIC ASIA PTE LTD. 3014A Ubi Road 1 #07-01 Singapore 408703 Telephone (65) 6842 1419 Fax (65) 6842 1421 singapore@connectpositronic.com 3 Positronic Industries w h i t e p a p e r Positronic’s new PosiBand technology takes a unique new approach for contacts, ­eliminating many of the weaknesses of the split tine design. POSITRONIC INDUSTRIES, INC. PosiBand contacts utilize a twopiece contact design. Each piece serves a separate function. The main body of the contact provides the ­mechanical platform for the contact system. This includes a true closed entry contact opening. The PosiBand spring clip provides normal force on the male contact. 423 N Campbell Avenue PO Box 8247 Springfield, MO 65801 Toll Free (800) 641-4054 Telephone (417) 866-2322 Fax (417) 866-4115 info@connectpositronic.com POSITRONIC INDUSTRIES, S.A.S. Zone Industrielle d’Engachies 46 Route d’Engachies France 32020 Auch Cedex Telephone 33 5 62 63 44 91 Fax 33 5 62 63 51 17 contact@connectpositronic.com 3014A Ubi Road 1 #07-01 Singapore 408703 Telephone (65) 6842 1419 Fax (65) 6842 1421 singapore@connectpositronic.com Assembled size 22 and size 16 PosiBand contacts The PosiBand system does not have a split tine female contact that can be pried open during the mating process. Instead, it uses the PosiBand spring clip, which is very robust and less susceptible to damage. The PosiBand system is much more rugged than traditional female contact designs. Another important feature of the PosiBand system is the use of brass to manufacture the base contact. Brass has excellent properties for crimping wire onto contacts, eliminating the need for annealing, thus avoiding the potential for intermittent or open ­electrical circuits due to ­improper heat treating. The base contact can be made of brass because the PosiBand spring clip provides contact normal force. The spring clip is made of spring ­tempered beryllium copper. PosiBand Cross Section chamfer unbroken ring spring clip electrical paths POSITRONIC ASIA PTE LTD. Disassembled size 16 PosiBand contact The PosiBand system also increases the ­interface area between male and female contacts when compared to the sloped design of split tine contacts. The greater contact area provides more reliable electrical integrity. On a micro level, there are a greater number of electrical paths through the contact interface. The greater contact area provides better resistance to discontinuity during vibration. The greater contact area may also ­minimize the effects to electrical ­performance due to corrosion over time. Greater contact area provided by the PosiBand system does not increase insertion forces; in fact, the PosiBand design provides a more ­consistent insertion force value, which results in a lower average insertion force when c­ ompared to the split tine design. PosiBand parent technology has been utilized in connectors, including MIL-DTL-28748 military connectors, for decades. The PosiBand is qualified under SAE AS39029 and MIL-DTL-24308 specifications. PosiBand is also qualified under GSFC S-311-P4. Specific PosiBand technology has been used by Positronic for many years and is now being imported into a variety of products. continued on next page w w w . c o n n e c t p o s i t r onic.com 4 Positronic Industries w h i t e p a p e r Positronic is now offering the ­PosiBand system in standard density and high density D-subminiature ­connectors, combination D-subminiature connectors, as well as subminiature rectangular ­connectors. Other Positronic products will utilize this advanced contact system in the near future. Printed circuit board compliant Press-in Subminiature Rectangular Connector Lastly, although other alternate contact interface designs in the marketplace carry a heavy premium in cost, this is not the case with the PosiBand. Products using the PosiBand system will be priced the same as products using the previous design. Please contact your local Positronic representative for more information about this ­r evolutionary design. To find a Positronic representative near you, visit www.connectpositronic.com. Electrical Characteristics POSITRONIC INDUSTRIES, INC. 423 N Campbell Avenue PO Box 8247 Springfield, MO 65801 Toll Free (800) 641-4054 Telephone (417) 866-2322 Fax (417) 866-4115 info@connectpositronic.com TEMPERATURE RISE CURVES Test conducted in accordance with UL1977. Size 20 PosiBand Contacts Size 22 PosiBand Contacts Initial Contact Resistance: 0.005 ohms, maximum. 14 CONTACTS LOADED IN POSITIONS 1-6 10 8 6 4 2 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 CONTACTS LOADED IN POSITIONS 1-2 RATED CURRENT (AMPS) TEMPERATURE RISE (ºC) 14 10 8 CONTACTS LOADED IN POSITIONS 1 - 62 6 4 2 0 10 20 30 40 50 60 70 80 90 100 110 120 130 TEMPERATURE RISE (ºC) CONTACTS LOADED IN POSITIONS 1 - 104 18 16 CONTACTS LOADED IN POSITIONS 1-6 14 12 Zone Industrielle d’Engachies 46 Route d’Engachies France 32020 Auch Cedex Telephone 33 5 62 63 44 91 Fax 33 5 62 63 51 17 contact@connectpositronic.com 10 8 CONTACTS LOADED IN POSITIONS 1-2 6 4 2 CONTACTS LOADED IN POSITIONS 1 - 26 12 0 RATED CURRENT (AMPS) 20 12 0 0.004 ohms, maximum. urve developed using Standard Density D-subminia­ C ture connectors loaded with size 20 crimp contacts ­terminated to size 20 AWG wire. 0 0 10 20 30 40 50 60 70 80 90 POSITRONIC ASIA PTE LTD. 100 110 120 130 TEMPERATURE RISE (ºC) RATED CURRENT (AMPS) RATED CURRENT (AMPS) urve developed using High Density D-subminiature conC nectors loaded with size 22 crimp contacts ­terminated to size 22 AWG wire. Initial Contact Resistance: POSITRONIC INDUSTRIES, S.A.S. 14 CONTACTS LOADED IN POSITIONS 1 - 15 12 10 8 CONTACTS LOADED IN POSITIONS 1 - 25 6 4 2 0 0 10 20 30 40 50 60 70 80 90 100 110 120 130 TEMPERATURE RISE (ºC) www.conne c t p o s i t r o n i c . c o m CONTACTS LOADED IN POSITIONS 1 - 50 3014A Ubi Road 1 #07-01 Singapore 408703 Telephone (65) 6842 1419 Fax (65) 6842 1421 singapore@connectpositronic.com