Study of Electroless Ni-P Plating on Stainless Steel

advertisement

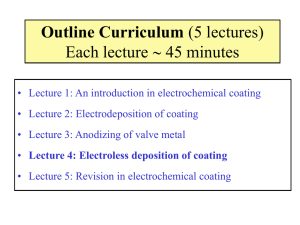

The Online Journal on Mathematics and Statistics (OJMS) Vol. (1) – No. (1) Study of Electroless Ni-P Plating on Stainless Steel I. E. Ayoub Hot Laboratory Center, Atomic Energy Authority, P. O. 13759, Cairo, Egypt. Abstract- Electroless Ni-P plating treatment was applied to stainless steel as the substrate for improving its corrosion resistance and micro-hardness. In this research a layer of Ni-P was deposited on stainless steel by using sodium hypophosphite as reducing agent. In order to determine the properties of the deposited layers, corrosion resistance of the Ni-P coatings was evaluated by potentiodynamic polarization through immersing in 3 % NaCl solution. A microhardness tester was used for microhardness measurement, XRD for microstructure analysis, and a scanning electron microscope equipped with EDAX for determining morphology and analyzing the deposits. The results showed that corrosion resistance and hardness of the stainless steel were improved after electroless plating. Keywordselectroless, plating, microstructure, Ni-P, stainless steel. corrosion, I. INTRODUCTION Normally, stainless steel is resistant to surface attack in mildly corrosive environments. When corrosion does occur, pits forms on the surface or within details of the component. What can be done to prevent this? Electroless nickel plating is the process of applying film on stainless steel to offers superior protection from corrosion and oxidation. Electroless nickel plating also provides moderate abrasion resistance, high wear and hardness resistance [1-4]. Electroless nickel plating produces uniformly plating specific areas which has correct tolerance specification and do not require any machining rework after plating [5,6]. Electroless deposition technique of Ni-P [7-9] alloy coatings has been a well- known commercial process that has found numerous applications in many fields due to excellent properties of coatings, such as high corrosion resistance, high wear-resistant, good lubricity, high hardness and acceptable ductility [10,11]. Low-phosphorous deposits (1 to 3 % P) are crystalline and exhibit good wear resistance, but relatively poor corrosion resistance in a chloride environment. Medium-phosphorus deposits (5 to 8 % P) have a smaller crystalline size and tend to be semi-amorphous, whereas high- phosphorus deposits (more than 10 percent P) exist mainly as a metallic glass. Medium- phosphorus deposits usually have properties lying between the low and high - phosphorus deposits, but the solution offer enhanced deposition rates. High - phosphorus deposits typically exhibit the best corrosion properties, but suffer from slow rates of deposition [12]. Moreover, in order to improve further the properties (mechanical and chemicals) Ref er en ce Num b e r: W10-0028 of EN coatings, numerous EN composite coatings [13] are investigated. II. EXPERIMENTAL DETAILS Coating on stainless steel is very difficult because the problem in activation of that surface. The pre-treat mental processes play a very important role in getting a good protective coating on stainless steel. Successful deposition depends on the removal of thin, passivating surface oxides layer on the stainless steel. This was accomplished by an initial cleaning [14]. Samples of stainless steel were used as the substrate material for deposition of electroless Ni-P. First the surface of the samples were mechanically cleaned from corrosion products and then degreased with a detergent solution were then rinsed in distilled water, and then etching in 10 ml HNO3, 20 ml HCL and 30 ml H2O at room temperature for 2 min. After these operations, they were rinsed in distilled water. The samples were activated in 0.6 g/l PdCl2 +5 ml HCL at room temperature for 10 min. After these operations, they were rinsed in distilled water in ultrasonic cleaning for 1 min and finally the samples dealing with 50 g/l NaH2PO2 for 10 min and then wash with distilled water and then introduced in electroless plating Ni-P bath. The chemical composition of electroless Ni-P coating bath is given in Table 1. A scanning electron microscope (SEM, JEOL Model JSM5400) was employed for the observations of the Ni-P alloy coating and an EDAX attachment was used for qualitative elemental chemical analysis and crystallographic structure of the sample was studied by the X-ray difractometer (XRD). The electroless Ni-P plating was heat-treatment film from 100 to 500 °C in an electric convection. The specimens were maintained for 1 hr at the setting temperature and allowed to be coaled. The corrosion resistance of the deposited was measured by using computerized auto lab system PG state 30 (potentiostatgalvanostat) electrochemical tests, in electrolyte used was 3 % sodium chloride. The working electrode was electroless nickel Ni-P deposited on stainless steel with 3 cm2 surface area. The auxiliary electrode was a platinum electrode and a saturated calomel electrode (SCE) used as a reference electrode and the scan rate 1mV/s. III. RESULTS AND DISCUSSION 3.1 Surface morphology and elemental analysis The properties of electroless Ni-P deposits are attributed to their microstructure characteristics. The details of structure of EN deposits are not well understood but as plated EN films 13 The Online Journal on Mathematics and Statistics (OJMS) has been reported to be either crystalline, amorphous or a coexistence of both. Studying the microstructure of the deposits helps us to understand the mechanism of deposition and evaluate the properties of EN deposits. The electroless Ni-P coatings were practically identical, with an average phosphorus content of 8.57 % determined by using EDX analysis as shown in Table 2 and thickness 13 μm for 1hr. The scanning electron micrograph of electroless Ni-P coating is shown in fig.1. It seems that the surface of the as deposited samples was uniformly and continuously covered by precipitates the electroless Ni–P deposition, and there were no obvious flaws or apertures on the coating surface. 3.2 X-ray diffraction analysis Figure 2 shows the X-ray diffraction (XRD) patterns of electroless Ni-P coatings of as plated. The as plated have one abroad peak of Ni at 2Ө = 44.5255 and exhibited more diffused peaks revealing that the plate contains mixture of microcrystalline and amorphous phases du to the plate have medium phosphorous and the phosphorus was dissolved in the nickel matrix [15]and exhibited a [1 1 1] preferred orientation. After annealing at 400 °C for 1h, as shown in fig. 3 the X- ray diffraction, indicate high crystalline structure of free nickel at 2Ө = 43.6453 with preferred orientation of [1 1 1] and d- spacing 2.07217 (A°), good crystalline structure of Ni3P and Ni12P5 which have low crystalline. 3.3 Corrosion resistance test NaCl is one of the most common corrosion medium for the electrochemical tests. It can significantly accelerate the pitting corrosion of Ni-P coatings in the artificial solution. The Cl easily replace oxygen in water molecules to prefer initially adsorb on the Ni-P coatings surface and form soluble NiCl2 (Ni +2 + 2Cl2 ←→ NiCl2) [14]. Electroless Ni–P coating could exhibit some voids. Chloride ions can penetrate through these voids causing pitting corrosion. Therefore the Ni–P coating should be expected much more compact and flawless [16]. Figure 3,4 shows the potentiodynamic polarization curves for electroless Ni-P coating of as plated and heat-treated at 400°C in 3% NaCl solution respectively. The electrochemical corrosion data could be obtained based on the potentiodynamic polarization curves, which are showed in Table 1. For the heat-treatment sample the corrosion potential Ecorr shifts positively 28 mV than that of the as plated – 409 mV. And the corrosion current density Icorr after plating is much lower than that of the substrate. These results explain that the heat-treated samples have better corrosion resistance and protection characterization than the as plated. 3-4 Effect of heat-treatment on hardness resistance The effect of heat treatment over the temperature range of 100 to 500°C for 1 hour on the microhardness of the coating is shown in fig. 6. It seems that heat treatment at temperature range from 100 to 200°C improve the adhesion of the deposits on the substrate only, and a few changes on their Ref er en ce Num b e r: W10-0028 Vol. (1) – No. (1) hardness but heat treatment at temperature above 200°C enhanced the microhardness of the coating up to 400°C, as a result of hard compounds of Ni3P and Ni12P5 phase formation in deposit [17] then microhardness decrease with increasing heat treatment temperature up to 500°C. Table 1. Chemical composition and deposition condition for Ni-P coatings. Composition NiSo4-6H2O Na3C6H5O7 NaOOCCH3 - 3H2O NaH2PO2-H2O` pH Temp Condition 35 g/l 15 g/l 5 g/l 20 g/l 4-5 80-90 °C Table 2. Chemical composition of electroless Ni-P deposits. Bath Ni-P Composition Ni P Wt% 91.25 8.57 Atomic% 86.8 13.2 Table 3 Corrosion characteristics of the electroless Ni-P alloys in 3 % NaCl. Results I corrosion Rp ( Polarization resistance ) E corr. Corrosion rate Sample area Condition 7.069E-6 A/cm2 2.07E+4 Ohm -0.381 V 8.919E-2 mm/year 3 cm2 Figure (1). Scanning electron micrographs of the electroless Ni-P as plated 14 The Online Journal on Mathematics and Statistics (OJMS) Vol. (1) – No. (1) 800 700 Figure (2) X-ray diffraction pattern of Ni-P coating As plated Microhardness HV 600 500 400 300 200 100 0 0 100 200 300 400 500 600 o Temperature ( C) Figure (6). Microhardness of electroless Ni-P coating vs. heat-treated temperature. IV. CONCLUSION Figure (3) X-ray diffraction pattern of electroless Ni-P in heat-treated (400°). Figure (4). Polarization curve obtained from electroless Ni-P coating as plated. 1- Ni-P coating can be successfully plated on the surface of stainless steel. The coating was compact, uniform and showed mixture microstructure of amorphous and microcrystalline with phosphorus contents of 8.57 wt.%. 2- The corrosion resistance of Ni-P on stainless is greatly improved by heat-treatment which were tested by the immersion experiment and the potentiodynamic polarization experiment in 3 % NaCl solution. 3- The microhardness of the coating was increasing with increased the heat treatment temperature for a constant time (1hr), maximum hardness was achieved at 400°C. Increase in microhardness after heat treatment is related to formation of hard compound Ni3P and Ni12P5. REFERENCES [1] [2] [3] Figure (5) Polarization curve obtained from electroless Ni-P coating heat-treated at 400C° Ref er en ce Num b e r: W10-0028 [4] Y. Wu, J. Gav, B. Shen, L. Liu, W. Huand, W. Ding, Process and Properties of Electroless Ni-P-PTFE Composite Coatings, Plating and Surface Finishing, August 2005, pp. 33-42. Y.T. Wu, L. Lei, B. Shen, and W.B. Hu, Investigation in Electroless Ni-P– Graphite-SiC Composite Coating, Surface and Coatings Technology , 2006, Vol. 201, 441- 445. B. Bozzini and M. Boniardi, Fracture Toughness of Supported Ni-P Films Prepared by Autocatalytic Chemical Deposition, Z. Metallkd. 88, 493-497, 1997. S. Dulal, Tae. Kim, H. Rhee, J. Sung and C. Kim, 15 The Online Journal on Mathematics and Statistics (OJMS) [5] [6] [7] [8] [9] [10] Development of an Alkaline-Metal-Free Bath for Electroless Deposition of Co-W-P Capping Layers for Copper Interconnection, Journal of Alloys and Compound 467, 370-375, 2009. J. Rohan, B. Ahern and et al., Electroless Thin Film Co-Ni-Fe-B Alloys for Integrated Magnetices on Si, Electrochimica Acta 54,1851-1856, 2009. H. Kang .J. Bae and et al., Control of Interfacial Layers Formed in Sn-3.5Ag -0.7 Cu/Electroless Ni-P Solder Joints, Scripta Materialia 60, 257-260, 2009. R. Sharma, R. Agrwala and V. Agarwala, Development of Electroless (NiP)/BaNi0.4Ti0.4Fe11.2O19 Nanocomposite Powder Enhanced Microwave Absorption, Journal of Alloys and Compounds, 467, 357-365, 2009. L. Hou, C. Yong, L. Sha, Z. Feng and D. Gan, Corrosion and Wear Properties of Electroless Ni-P Plating Layer on AZ91D Magnesium Alloy, Trans. Nonferrous Met. Soc. Chenia18, 819-824, 2008. R. Elansezhian, B. Ramamovsthy and P. Nair, Effect of Surfactants on the Mechanical Properties of Electroless (Ni-P) Coating, Surface Coating Technology 203, 709-712, 2008. C. Gu, J. lian, G. li, l. Niu, and Z. Jiang, Electroless Ni- P Plating on AZ91D Magnesium Alloy from A Sulfate Solution, J. of Alloys and Compounds 39, P 104-109, 2005. Ref er en ce Num b e r: W10-0028 Vol. (1) – No. (1) [11] [12] [13] [14] [15] [16] [17] C. J. lin and J. L He, Cavitations Erosion Behavior of Electroless Nickel- Plating on AISI1045 Steel, Wear 259, pp. 154-159, 2005 N. Martyak, S. Wettere, L. Harrison, M. Mcneil, R. Heu and A. Neiderer, Structure of Electroless Nickel Coatings, Plating and Surface Finishing June 60-64, 1993. X. Huang, Y. Wu and L. Qian, The Tribological Behavior of Electroless Ni-P-SiC (Nanometer Particles) Composite Coatings, Plating and Surface Finishing July 46-48, 2004. P. Lam, K. Kumar, G. Wnek and T. Przybycien, Electroless Gold Plating 316 Beal's, Journal of Electrochemical Society, Volume 146, Issue, 7 PP 2571-2521, July, 1999. L. Yang, J. Li, Y. Zheng, W. Jiang, M. Zhang, Electroless Ni-P Plating with Molybdate Pretreatment on Mg-8Li Alloys, Journal of Alloys and Compounds Vol. 467, P. 562-566, 2009. Y. Song, D. Y. Shan and E. Han, Corrosion Behaviors of Electroless Plating Ni-P Coatings Deposited on Magnesium Alloy in Artificial Sweat Solution, Electrochimica Acta 53 2009-2015, 2007. F. Wu, S. Tien, J. Duh and J. Wang, Surface Characteristics of Electroless and Sputtered Ni-P-W Alloy Coatings, Surface and Coating Technology, 166, 2003, pp. 60-66. 16