Recycling Postconsumer Nylon Carpet

advertisement

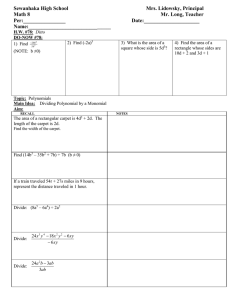

A P P L I C A T IO N S A N D I M P L E M E N T A T I0NS Recycling Postconsumer Nylon Carpet A Case Study of the Economics and Engineering Issues Associated with Recycling Postconsumer Goods Lester Lave, Noellette Conway-Schempf,James Harvey, Deanna Hart, Timothy Bee, and Christopher MacCracken Graduate School of Zndustid Administration Cmnegie M e l h University Pittsburgh, PA, USA I KeY-Jvords carpet recycling landfill cover materials properties nylon recycling recycled carpet plastic (RCP) recycling economics Address correspondence to: Lester Lave Graduate School of Industrial Administration Camegie Mellon University Schenley Park Pittsburgh, PA 15213, USA lester.lave@andrew.cmu.edu 0Copyright 1998 by the Massachusetts Institute of Technology and Yale University Summary Each year 3 4 billion pounds of nylon carpet are discarded into landfills in the United States.As a case study we examine the technical and economic feasibility of recyclinga portion of this source of discarded plastic.The carpet could be ( I ) shredded for use as daily cover at landfills or as a strengthening component of concrete, (2) sheared or chemically processed for reuse as recycled nylon or as pure nylon feedstock,or (3) made into a new type of plastic.We estimate the costs of a recycling facility t o handle 450,000 Ib of discarded nylon carpet each month in Pittsburgh, Pennsylvania.Wefound that with current technology, regulations, and markets,only the recycling of carpet from commercial settings using shearing or chemical processing is economical and only under very narrow circumstances.We learned four lessons from this study, First,collection costs are high and can dominate the economics of recycling. Second, given time and incentives, collection costs can be reduced.Third, trying to recycle products not designed to be recycled leads t o many problems. Carpet could be redesigned t o make recycling easier by making the carpet out of a single material and using an adhesive that can be removed easily. Fourth, recycling processes should be designed to produce an existing material if at all possible, because new materials present marketing problems. Volume 2, Number 1 I journal of lndustriol Ecology I I7 I A P P L ICAT I 0NS A N D I M P L E ME NTATl 0 NS Introduction The high levels of waste generation in the United States have prompted consumers and industry to reconsider the fate of products when consumers no longer desire them. Concerns over the availability of easily accessible landfill space, the threat of stricter regulations regarding disposal of material, and the potential for profitable reuse of discarded products and materials have prompted a closer look at the potential for recycling materials currently considered useless. Changes in European regulations, such as the EcoCycle product take-back law in Germany, which requires manufacturers of diverse durable products to take back their products once the end of life is reached (Bremer-Davis 1996), have prompted manufacturers to consider the effect of product take-back regulation on their operations. In our judgment, states such as California, Massachusetts, and New York will enact product take-back regulations for some goods in the next decade. Postconsumer carpet is potentially attractive for recycling: it is available in large quantities, is easily separated from other postconsumer wastes, and has potentially high value. Americans discard about 3-4 billion lb of carpet each year (Gardner 1995). At present, almost all of this carpet is hauled away and disposed in landfills, at a cost of roughly $100 million per year. Used carpeting accounts for about 1% by weight (2% by volume) of municipal solid waste in the United States (Minnesota OER 1995). Rather than thinking of used carpet as waste that requires disposal, the carpet and plastics industries are searching for ways to transform it into a valuable raw material. In this article we focus on recycling postconsumer carpet with nylon face fiber (carpet is referred to by the type of face fiber). We discuss the costs and barriers to establishing and operating a nylon carpet recycling facility under the prevailing economic and marketing conditions in a large U.S. city (Pittsburgh, Pennsylvania). We investigate the costs of collecting nylon carpet and then reusing it in three forms: (1) shredded for use as daily cover at landfills or as a strengthening component of concrete, ( 2 ) sheared or chemically processed for reuse as re- I I8 journal of Industrial Ecology cycled nylon or as pure nylon feedstock, or (3) made into a new type of plastic. A number of lessons emerge from the study, not only about recycling postconsumer carpet but about recycling postconsumer goods more generally. Background Characteristics of Postconsumer Carpet in the United States Typical carpeting is constructed of multiple layers. The face fiber of residential carpet makes up about 45%-50% of the weight ofcarpet (35% for commercial carpet). The other components, by weight, are primary and secondary backing (lo%), adhesive (6%-lo%), and calcium carbonate or other fillers (30%-40%) (Schut 1993; Williams 1994; Leaversuch 1993; Minnesota OER 1995).' Each of these layers is composed of different materials. Generally, the backing is polypropylene, and the adhesive is latex. The only material with much recycle potential at the moment is the face fiber. The quantity of carpet that is discarded will reflect the sales of new carpet 3 to 20 years ago. Table 1 summarizes two estimates for 1994 face-fiber market share (Costello 1995; Williams 1994). We assume nylon 6,6 is 45% and nylon 6 is 30% of discarded carpet. Of carpet sold in the United States, approximately 70% is for replacement of old carpet. About one-third of carpet sold in the United States is used in commercial applications such as offices, retail stores, or other commercial places; the other two-thirds is used in residences (Costello 1995). In general, commercial installations (such as hotels or office buildings) Table I Two estimates of 1994 face-fiber market share Material AUiedSignaf Monsanto 36% 44.2% 29% 14.5% 10.5% 1.1% ~ Nylon 6,6 Nylon 6 Polypropylene Polyester Wool and acrylic 26% 26% 11% 1% Source: Costello (1995), Williams (1994). A P P L I C AT1 0 N S A N D IMP L E M E N TAT1 0 N S contain more carpet than a single residential installation. T h e principal tasks required to recycle postconsumer carpet are: collection, sorting, handling, and storage of the carpet; transformation of the carpet materials into a valuable material; and then, marketing the recycled material. Collecting Postconsumer Carpet The first task in recycling is collecting the postconsumer carpet. Buildings with large quantities of discarded carpet, such as large commercial offices, are preferable targets for several reasons. First, the larger quantities of carpet available reduce the per-unit hauling costs. Second, either the owner knows the type of face fiber or the large quantity justifies testing prior to removal. Knowing the type of face fiber means that the recycler, that is, the business collecting the carpet and doing the first level of processing, can arrange to acquire only the desired carpet types. Third, the carpet owner must pay about $50 per ton for hauling and disposal of the carpet. T h e current tipping fee in Pittsburgh is about $30 per ton or $O.O15/lb. Thus the owner should be willing to pay the recycler up to $0.025/lb to collect the carpet, or would deliver it to the recycler and pay $0.015/lb in lieu of a tipping fee. Because it has more face fiber than commercial carpet, residential carpet is attractive to recyclers. Recycling it, however, presents major problems. Compared with commercial installations, the quantity is lower and the face fiber is not known. Distinguishing different face fiber types, particularly nylon 6 versus nylon 6,6, is difficult by visual inspection. Thus the recycler is likely to get all types of face fibers, not just the desired nylon. Equipment is available that can distinguish fiber types, but the equipment is ex$600 for a n infrared unit pensive-about (Costello 1996)-and because there is no current need to identify the face fiber, this equipment is not likely to be in the hands of carpet installers. This means that a recycler accepting all discarded residential carpet, but recycling only nylon-faced carpet, would have to pay to 1 dispose of the 25% of the recovered carpet that does not have nylon face fiber. In many cities, such as Pittsburgh, the municipal solid waste (MSW) service will collect small quantities of discarded carpet free of charge from residences. The recycler would have to pick up the carpet from the landfill, residence, or carpet store. In cities where residential carpet is collected with trash, most of the residential discard carpet would be sent to landfills. Recovering the carpet at the landfill is dirty, difficult, and dangerous (and usually requires a permit from the organization operating the landfill). If the recycler wanted to collect carpet directly from the residence, the carpet installers could notify the recycler about the place and time when the discarded carpet would be removed during the installation of new carpet. This individual pickup would be the most expensive collection option. We estimated that a truck would make a round trip of 10-50 miles (16-80 kilometers) taking one to two hours to pickup and unload 50 square yards (200 lb) of carpet. A t $0.50 per mile for the truck and $10 per hour for the driver, the cost is $15 to $45 or $0.075$0.225/1b. We assume collection costs of $O.lO/ Ib for individual residential pickup. Installers often take the discarded carpet to a large waste receptacle, known in the United States as a “dumpster,” at a carpet store or warehouse. At present, recovery from the dumpster is unpleasant, because the carpet is mixed with other trash and is often wet, because large dumpsters are not covered. Although recovery by such a strategy is possible, it is unpleasant for the workers and not highly desirable. We estimate the cost of removing discarded carpet from the dumpster and then hauling it to the recycler to be about $O.lO/lb. The collection costs can be reduced by scheduling pickups at adjacent locations, using special containers at carpet stores, or by charging residences. The recycler might arrange for the store to place the discarded carpet in a dry location separated from trash; this solution would be ideal, but space was scarce at the stores we inspected. The stores we inspected did not view pickup of discarded carpet by a recycler to be very attractive. A typical trash collection contract has a fee that rises much less than proportionally with the Lave, Conwoy-Schempf,Harvey, Hart, Bee, and MacCracken, Recycling Nylon Carpet I19 1 AP P L ICAT10 NS A N D I M P LE M E NTAT I0NS size of the dumpster. Thus stores would not save much by switching to a smaller size dumpster.2 Recycling regulations or prodding from manufacturers should get most stores to find a place to store the carpet for pickup. In summary, commercial nylon carpet might be delivered to the recycler with a payment to the recycler of $0.015/lb compared to residential nylon carpet that would have to be picked up at a cost of at least $0.10/lb. We assume that only nylon carpet would be accepted from commerical installations while, for residential carpet, the recycler would incur the cost of disposing of undesirable (nonnylon) carpet. Transforming and Processing Discarded Nylon Carpet We have investigated three different ways to reuse discarded carpet: shredding carpet into small pieces, recycling the face fiber into a high-value plastic, and recycling the entire carpet into a lowvalue plastic. A carpet recycler would choose among these three alternatives on the basis of the net profit expected from each. We now estimate the cost and revenue from each approach. 1. Shredded Carpet Uses Shredded carpet fiber can be used as filler in concrete applications or landfill cover applications (Herlihy 1994). For both uses, the value of carpet fiber is low, hardly greater than zero. In a modern landfill, the compacted trash must be covered by dirt or some other material every day to minimize odor, litter, and pests. Because carpet fiber saves landfill space, it is preferred to dirt as a daily cover (U.S. EPA 1992). The demand for carpet fiber in this application is virtually unlimited. Thus the price of disposing of undesired carpet or carpet backing should be no greater than the cost of shredding the carpet and transporting it to a landfill. The Cost of Shredding Carpet Once carpet has been collected, the cost of shredding for an operation of this size is estimated I20 lourno1 of Industrial Ecology to be no more than $0.045/lb, including unloading, handling, and shredding (Costello 1996). Alternatively, the cost of hauling and disposal in a landfill is about $0.025/lb. Thus, with a hauling cost of $O.Ol/lb, the landfill operator would have to pay at least $0.03/lb for the recycler to find shredding superig to landfilling. We could find no indication that landfill operators would be willing to pay this much for this material. 2. Recycling as Nylon or Conversion to a Nylon Feedstock Pure nylon is a valuable material selling for $1-$3/lb. Currently, there are two viable technologies for high-value recycling of nylon recovered from carpets. AlliedSignal and BASF have developed processes for transforming nylon 6 in carpet back into caprolactam, the feedstock for nylon 6 (Herlihy 1994). At an AlliedSignal demonstration plant, the resulting feedstock is so pure that it can be remade into carpet, rather than processed for less-demanding, lower-value uses. Some of the materials, such as calcium carbonate and adhesive, must be disposed of at a standard landfill at a cost of about $0.025/lb. Nylon 6,6 carpet, which has the largest market share, is difficult to transform back to original feedstocks because of the combined nature of the component substances (monomers). The most attractive use for nylon 6,6 is as mechanically reground nylon feedstock, which is less pure than virgin nylon 6,6. Pellets of pure reground nylon, using scrap fiber from the manufacture of new carpet, currently sell for about $0.40/lb (Costello 1996). Pellets made from used carpet are contaminated with dirt and other plastics and sell for much less. The Costs of Separating the Face Fiber from the Carpet Given the current technology and economics, only the face fiber of carpet is attractive for high-value recycling. Thus the face fiber must be separated from the backing and other material. The undesired part of the carpet would need to be landfilled at a cost of $0.025/lb. AlliedSignal buys bundled nylon 6 carpet for a pilot recycling plant that uses a chemical process to separate the face fibers from the backing. They have purchased bundled nylon 6 carpet for $0.05- APPLICATIONS A N D IMPLEMENTATIONS $O.IO/lb FOB3from the recycler. AlliedSignal currently pays less than $O.lO/lb, but we will assume they offer this amount for the rest of the analysis. Collecting nylon 6 carpet to sell to AlliedSignal is marginally attractive at best. It costs the recycler almost $0.10/lb for the warehouse, equipment, and labor to bundle the carpet. Thus a lower price from AlliedSignal, having to pay collection costs, or having to dispose of nonnylon 6 carpet would drive the recycler into bankruptcy. This business would be attractive now for commercial carpet where only nylon 6 carpet was delivered to the recycler with a payment of $0.0151 Ib, or where regulations were changed so that the recycler received a payment when residential carpet was delivered. Rather than selling bundled carpet to AlliedSignal, the recycler could separate the face fiber and then sell the pelletized nylon. The simplest way to separate the face fiber is by shearing it from the backing. We estimate this would cost about $0.03/lb. Shearing, however, recovers only 30%-70% of the face fiber, depending on the type of carpet, whereas AlliedSignal recovers most of the nylon 6 through its chemical process (the exact amount is proprietary information). 1 The sheared material would then be pelletized at a cost of $0.09/lb (Costello 1996). To assess the potential for carpet shearing and recycling, we first do the analysis for residential carpet, assuming that all carpet is delivered to the recycler at a price of $0.10/lb (see table 2). If 1,333 Ib of discarded carpet arrived at the recycler, the collection cost would be $133, and handling costs would amount to $26.66 (at a cost of $0.02/lb). Of the 1,333 Ib of carpet, 1,000 Ib would be nylon carpet. Thus the shearing cost would be $30. The 1,000lb of nylon carpet would contain 450 Ib of face fiber, but assuming a generic shearing efficiency of 50%, only half of the nylon, 225 Ib, would result from the shearing. This 225 lb of sheared nylon would be pelletized at $0.09/lb, or $20.25. In addition, the cost of disposingof the 333 Ib of carpet without nylon face fiber and the 775 lb of carpet left after the nylon face fiber was sheared would cost $0.025/lb for a total of $27.70. The 225 Ib of nylon pellets would sell for $90. Thus the total cost of collection, handling, processing, and disposal would exceed the value of the pellets; this is true even if collection costs were zero. In fact, just to break even, the recycler would need to Table 2 Estimated costs and revenues associated with recycling residential carpet into nylon pellets Description Discarded carpet: collection handling Carpet without nylon face fibers: dispose Carpet with nylon face fibers: shear Backing, residual face fiber: dispose Nylon face fiber: pelletize Total operating costs Nylon pellets: sell Total revenue Unit cost Total cost 333 lb $O.lO/lb $0.02/lb $133.30 $26.66 333 lb $0.025/lb $8.32 000 Ib $0.03/lb $30.00 775 lb $0.025/lb $19.38 225 Ib $0.09/lb $20.25 $237.9 1 2251b $0.40/1b Gross margin (revenue minus variable cost) Margin excluding collection costs Material quantity $90.00 $90.00 -$147.91 (-$O.ll/lb) - $14.61 (- $0.011/lb) Assumptions: 75% of carpet is nylon carpet, 45%of residential carpet by weight is face fibez and shearing efficiency is 50%. lave, Conway-SchempL Harvey, Hart, Bee, and MacCracken, Recycling Nylon Carpet I 2I I A P P L ICAT I0NS A N D IMPLE M E NTAT10 N S Table 3 Estimated costs and revenues associated with recycling residential and commercial carpet into nylon 6 feedstock and nylon 6.6 Dellets Commercial Residential Unit Description Discarded carpet: collect residential carpet Collected carpet: handling Carpet without nylon face fibers: dispose Carpet with nylon 6,6 face fibers: shear Backing, residual face fiber: dispose Nylon face fiber: pelletize Total operating costs Discarded carpet: drop-off commercial carpet Nylon pellets: sell Nylon 6 carpet: sell to AlliedSignal Total revenue cost Material quantity Total Material cost quantity 1,333 0 $133.30 $O.lO/lb 1,333 $0 1.000 $26.66 $0.02/lb $20.00 0 333 $8.32 $0.025/lb $0 600 600 $18.00 $0.03/lb 465 $18.00 495 $11.62 $0.025/lb 135 $12.38 105 $12.15 $210.05 $0.09/lb 0 $0.015/lb $9.45 $59.83 1,000 $15.00 $0 135 105 $54.00 $0.40/lb $42.00 400 400 $40.00 $94.00 $O.IO/lb Gross margin - $116.05 (- $0.087/lb) Margin excluding collection costs $17.25 ($0.013/lb) Total cost $40.00 $97.00 $37.17 ($0.037)/lb $22.17 ($0.022)/lb Assumptions: 75% of carpet is nylon carpet, nylon 6,6 accounts for 45% of the carpet market, or 60% of the nylon carpet market; nylon 6 accounts for 30%of the carpet market or 40%of the nylon carpet market; 45%of residential carpet is face fiber, 30%of commercial carpet is face fiber, and shearing efficiency is 50%. *Recall that residential carpet is 45%face fiber, while commercial carpet is 30%face fiber by weight. charge at least $0.01 I/lb as carpet was delivered to the warehouse. For comparison, in table 3 for both a residential and commercial scenario, we consider a combination of shipping nylon 6 carpet to AlliedSignal and shearing nylon 6,6 carpet. In the residential case, 1,333 lb of carpet collected by the recycler would contain 333 lb of carpet without nylon face fiber (to be disposed of). Of the 1,000 lb of nylon carpet, 400 lb would be nylon 6 carpet. At $0.10/1b, the recycling company would receive $40.00. The other 600 lb of nylon 6,6 carpet (containing 270 lb of nylon 6,6) could be sheered to obtain 135 lb of pure nylon 6,6. The remaining 465 lb of sheered carpet must be I22 journal of Industrial Ecology disposed of. As shown in table 3, unless collection costs drop below $0.013/lb, the costs again exceed the revenues. This analysis shows that for residential carpet, shearing is less attractive than shipping bundled carpet to AlliedSignal at $O.lO/lb. Only if collection costs drop below $0.013/lb does the gross profit margin reach zero. Given that we estimate the collection costs for residential carpet to be $0.10/1b, recycling residential carpet is not an attractive business. In the case of commercial carpet, the recycler need take only the carpet desired-however, face fiber accounts for only about 35% of commercial carpeting. If only nylon carpet were recycled, using the same sce- A P P L I C A T I O N S A N D IMPLEMENTATIONS nario as in table 3, accepting only commercial nylon carpet and charging a drop-off fee of $0.015/lb would result in a gross margin of $37.17, or about $O.O37/lb. Note, however, that if installers insisted on being paid to drop off the carpet, a payment of as little as $0.022/lb would push the recycler into the red. It appears that the most profitable arrangement would be to accept only nylon 6 carpet. In the best-case scenario, if the installers paid $0.015/lb when dropping off the carpet and handling was $0.02/lb as assumed previously, the gross margin would be $0.095/lb when the carpet was sent to AlliedSignal. As a solution to carpet landfilling,however, this is not particularly effective: recycling only the face fiber of nylon 6 carpet would reduce the amount of carpet ending up in landfill by less than about 14% (30% of carpet is nylon 6; face fiber is about 45% of the carpet). 3. Converting Whole Carpet to a New Plastic Monsanto (1994) has patented a process for transforming entire nylon 6,6 carpeting into a recycled carpet plastic (RCP). The entire carpet is shredded and processed to remove most of the dirt. The remaining material is melted and mixed in two stages. During the second stage, a chemical compatabilizer helps meld the face fiber, backing, adhesive, and calcium carbonate into a new material, RCP. Transforming Nylon 6,6 Carpet to RCP We examined the size of a facility, equipment, and personnel needs for a carpet-recycling facility based in Pittsburgh that would use the Monsanto process to convert entire pieces of nylon 6,6 carpet into RCP. The facility is assumed to process 450,000 lb of discarded carpet per month, of which 200,000 lb would be nylon 6,6 carpet. We assumed a single collection facility in the same building as the processor. The process of producing RCP has the nylon 6,6 carpet being shredded, cleaned, and fed into a series of machines that remove most of the dirt and inorganic filler (and some of the face fiber). The carpet is then transferred to an extruder where it is melted and mixed with the compatabilizerand 1 Table 4 Best-case scenario for recyclingof nylon 6,6 to RCP in Pittsburgh (monthly costs) Component Disposal costs Rental Carpet collection Labor Depreciation Compatabilizer Total Cost per munth $8,053 $5,000 $0 $46,987 $13,784 $21,440 $106,264 . . Revenue from the sale of Nylon 6 = $13,500. Cost per pound of pellets produced = $0.53. converted into pellets. We assume carpet without nylon face fiber is sent to the landfill and that nylon 6 carpet is sold to AlliedSignal. As shown in table 4, assuming zero collection costs and an income from selling nylon 6 carpet to AlliedSignal, the cost of producing RCP pellets was found to be $0.53 per pound of pellets. With collection costs of $O.lO/lb, the monthly costs would increase by $45,000, or $0.78/lb. Based on the price of virgin nylon at $1-$2/lb, this recycling offers the most potential. However, because the pellets contain some impurities with the nylon 6,6, a premium price, as explained below, is not expected for the material. Marketing the Material: Uses for Postconsumer Carpet Plastic The market outlook for plastics in general is excellent, with increased usage of plastic materials in many areas. Recycled plastics are more difficult to market, however, unless their quality and characteristics are equal to virgin equivalents. In general, virgin plastics appear to sell at about twice the price of recycled equivalents (Hart 1995), with virgin nylon materials selling for about $1-$2.30/lb and recycled material, shredded plastic from product scraps, currently selling for about $0.40/lb (Costello 1996). To discover uses for RCP, we first need to know its characteristics and price. Perhaps the two most relevant properties of the material are its Young’s Modulus, E, and density, rho, because they indicate stiffness and low weight. Figure 1 shows RCP in comparison with other materials. Love, Conway-Schempfi Harvey, Hart, Bee, and MacCrocken. Recycling Nylon Carpet I23 1 A P P L I C AT1 0 N S A N D I M P L E M E N TAT I 0 N S 10 1.o 0.1 0.3 1.o 3.0 10 Density (Mg/m^3) Figure I Materials comparison of RCP Source: Adapted from Ashby ( I 992). The properties of the RCP overlap those of its main constituent compounds, namely, nylon and polypropylene. But given the amount of fill material and dirt mixed into the plastic, the strength and density are slightly higher. Table 5 shows the physical properties of RCP in terms of tensile strength, tensile modulus, elongation, and impact strength. For comparison, we have calculated the properties of six other plastics, including nylon 6,6. The table shows that RCP does not have any unique characteristics that would make it desirable, other than the fact that it is a recycled material. A simpler characterization of RCP is revealing. Even with the addition of the compatabilizer, RCP is not a uniform material. Parts of the various materials can still be identified. Given that the components of the RCP will vary from batch to batch depending on the exact composition of the carpet processed, the range of values for each property is much wider than that of "pure" plastics. This greater variability and uncertainty of the RCP properties makes it a less desirable choice for products with specific and exacting physical requirements. In addition, because RCP is a mix of face fibers of different color and of other materials, its color is typically olive green. It could be dyed black, but other colors would be difficult to achieve. In addition to color limitations, RCP has other undesirable characteristics. Because it contains a high percentage of inorganic material, its melt and flow rates are likely to be slow, increasing processing (mold) time. In addition, as a high-melt, crystalizable polymer, the nylon 6,6 in the composite would require higher processing temperatures, further decreasing the melt flow rate and increasing cooldown time in the mold. Thus RCP will probably have higher energy costs and take longer for molding than an easily processed material such as polystyrene. Perhaps the most important shortcoming is that RCP is brittle, as a result of the high proportion of inorganic material in the plastic. Thus RCP is not a desirable material for applications where the plastic would have to stand up to impacts. RCP appears to be roughly comparable to polystyrene, although it would have a higher melting temperature and would take longer to mold and would use more energy. Because it is not a known, tested material, RCP is less desirable than polystyrene. We conclude that RCP would have to be considerably less expensive than polystyrene, unless there are regulations or strong preferences for recycled materials. Virgin polystyrene currently Table 5 Physical properties of RCP compared with those of several typical polymers Polymer RCP PS N66 ABS PP HDPE PET Tensile strength 1O"3 psi Tensile modulus 1O"5 psi Elongation % I m p a t strength (notched) ft-lb/in 5.6-5.9 5-12 9-12 3.5-6.2 4.3-5.5 3.1-5.5 8.5-10.5 3.64.3 4 4 1.8-4.2 2-3.5 1.6-2.3 0.6-1.8 4.6 3 1-1.5 60-300 5-60 200-700 2-1000 50-300 0.48-0.60 0.25-0.40 1-2 3-8 0.5-2 0.5-2 0.25-0.35 = Recycled Carpet Plastic; PS = Polystyrene; N66 =Nylon 6,6; ABS = Acrylonitrile-Butadiene-Styrene Co-polymer; PP = polypropylene; HDPE = High Density Polyethylene. Data adapted from Williams (1994), and McCrum e t al. (1992). Notes: RCP I24 Journal of Industrial Ecology APPLICATIONS A N D IMPLEMENTATIONS sells for about $0.30/lb. At the estimated cost of $0.53/lb for RCP pellets when collection costs are zero, this option is not acceptable. Because it was the option with the most potential for profitability for the recycler, we gave considerable effort to evaluating the market for RCP. Finding a use for a new material requires considerable work and ingenuity. The users must be convinced that the new material is attractive and will stand up to the proposed use. Because RCP is not a currently marketed plastic, we sought to discover markets where it might compete, such as serving as a replacement for wood in outdoor applications. This market is already occupied by low-quality mixed recycled plastics. Plastic wood has the advantage of not being attractive to termites or fungus. To protect natural wood in outdoor applications, it is filled with or coated with a variety of pesticides that are toxic to people. For example, telephone poles face disposal problems because of the impregnated pesticides (Lebow 1993). The plastic would also have the advantage of being an engineered product, allowing for new designs. A plastic telephone pole could be a hollow cylinder that was much lighter than, but just as strong as, a wooden pole, making installation easier. The pole could be designed to absorb much of the energy of a vehicle collision and thus lower highway deaths. Preventing deaths would come at a price, however: these poles would be put out of service by vehicle collisions, leading to more disruptions in electricity and telephone service and greater replacement costs.' A telephone pole made of a new material would have to be tested in a wide variety of conditions to demonstrate that the pole could continue to perform for decades in a wide range of temperatures and weather conditions. Producing a known material saves the recycler from having to prove the properties of the new material. Factors that Could Increase the Attmctiveness ofRecycling Nylon Carpet A variety of actions would change the attractiveness of recycling nylon carpet. Market actions would include increases in the price of petroleum, increases in landfill prices, and consumer desires for recycled material. Government 1 actions would include banning discarded carpets from landfills, forcing manufacturers to take back and recycle their carpets, refusing to collect discarded carpet with MSW,or forcing stores selling replacement carpet to deliver the discarded carpet to a recycler. Petroleum prices would have to rise sharply before it would induce recycling on the basis of raw materials costs. The same is true for landfill prices for avoided disposal costs. DuPont currently offers customers the option to pay $1 per square yard ($0.25/lb) to recycle their nylon carpet. In 1996, three million square yards were recycled in this program. (DuPont 1997). Government laws and regulations can force recycling. At present, none of these factors appears likely to make carpet recycling much more attractive. Lessons Learned Our project allowed us to discover a few painful truths about recycling (see also Carpet and Rug Institute 1995). The first is that collection costs are important. In each scenario investigated, collection costs led to a net profit loss. To make recycling economically attractive, the recycler cannot pay for delivery of discarded carpet. The second insight is that, given time and incentives for adjustment, collection costs could be reduced. Installers who currently take loads of carpet to landfills could take them to strategically placed carpet collection points. If the carpet is labeled, the recycler could accept only the desirable carpet. Given that the landfill has a tipping fee, the recycler could charge up to the tipping fee. Thus, with adjustment, collection costs would become negative, and most of the expense of disposing of unwanted materials would disappear. The third lesson is that trying to recycle products that were not designed for recycling poses many problems. For carpet, identification of the face fiber and separation of the different components are obstacles. An obvious, low-cost change would be to note the face fiber on the underside of the carpet to facilitate sorting. Other changes that become progressively more expensive would be to (1) make the backing of carpet from the same material as the face fiber, (2) choose the adhesive, so that it could be easily removed during recycling, and (3)eliminate Love, Conwoy-Schernpf; Harvey, Hart, Bee, ond MocCrocken, Recycling Nylon Carpet I25 1 APPLICATIONS A N D IMPLEMENTATIONS the calcium carbonate, leaving a single material that could be much more easily recycled. If all of these changes were made, the recycler could get only the desired carpets, and almost the entire carpet could be pelletized for recycling. Recycling would be a n attractive business under these conditions, even at a collection cost of $O.lO/lb. The final insight is that the recycling process should produce a n existing material, if a t all possible, given that new materials face major marketing problems. In the case of RCP, the material has value as a commercial material, but the inconsistency in properties makes it less desirable. Acknowledgments This study was funded by a grant from Monsanto Corporation and the Green Design Consortium a t Carnegie Mellon University. Deanna Hart c.ontributed engineering analysis from her M.S.thesis in the Department of Civil and Environmental Engineering under the supervision of Professors Francis McMichael and Chris Hendrickson. Business analyses were carried out in a n MBA project course by Timothy Bee, James Harvey, and Christopher MacCracken. The course was supervised by Professors Lester Lave and Noellette Conway-Schempf. Notes ' 1. One square yard of carpet weighs approximately 4 Ib; one square meter approximately 2 kilograms. 2. The cost of weekly pickup in Pittsburgh varies with container size: 4 cubic yards: $80/week = $20/cubic yard, 8 cubic yards: $120/week = $151 cubic yard, 20 cubic yards: $280/week = $14/cubic yard (Phillips 1997). 3. Free on board (FOB) is a designation used in shipping to indicate that a quoted price does not include the cost of shipping (i.e., the purchaser pays the cost of transport). 4. Telephone companies are unlikely to welcome the controversy, and likely lawsuits, that would ensue from being able to use a pole that prevented some highway deaths at the cost of more frequent disruptions and replacement. References Ashby, M. E 1992. Materials selectionin mechanical design. Oxford: Pergamon Press. 126 journal of Industrial Ecology Bremer-Davis, 1. 1996. Product stewardship and the coming age of takeback. Arlington, MA: Cutter Information Corporation. Carpet and Rug Institute. 1995. Covering the future: Environmental stewardshipof the carpet and rug industry. Dalton, GA: Carpet and Rug Institute. Costello, M. 1995. Post-consumer recycling, n6 carpet fiber recycling. AlliedSignal. Carpet Fibers Division. Overhead presentation at Carnegie Mellon University. Costello, M. 1996. Personal communication. AlliedSignal. Carpet Fibers Division. DuPont. 1997. DuPont flooring systems dealers say no to used carpets in landfills. Press release. 29 January. Gardner, H. C. 1995. Carpet recycling technology. InremationaI Fibers journal lO(4): 36-49. Hart, D. 1995. Identification and specification of recycled materials for use in new products: A case study of post-consumer carpets. Master's thesis, Department of Civil and Environmental Engineering, Carnegie Mellon University. Herlihy, J. 1994. Carpet recycle update. Dalton, GA: Carpet and Rug Institute. Leaversuch, R. D. 1993. Process reclaims polymer content of fibers in discarded carpets. Modem Plastics 70(4): 4142. Lebow, S. 1993. Leaching of wood preservative components and their mobility in he environment. General technical report FPL-GTR-93 Madison, W1: U.S. Department of Agriculture, Forest Service, Forest Product Laboratory. McCrum, N. G., C. P. Buckley, and C. B. Bucknall. 1992. Principles of polymer engineering. Oxford: Oxford Science Publications. OER (Minnesota Office of Environmental Resources). 1995. Barriers to recycling corrugated paper products and carpeting. Draft report. Monsanto Company. 1994. Thermoplastic composition and method for producing thermoplastic composition by melt blending carpet. US. patent #5,294,384. 15 March. Phillips, A. 1997. Personal communication. Anthony Phillips Hauling Company. Schut, J. H. 1993. A recycling first: Carpets! Plastics Technology (April): 22-24. U.S.EPA (U.S.Environmental Protection Agency). 1992. The use of alternative materials for daily cover municipal solid waste landfills. NTIS PB92227197. Washington, DC: U S . Government Printing Office. Williams, S. R. 1994. Carpet Recycle Program. Overhead presentation. Gonzales, FL.