AN4549

Application note

Single-channel boost LED driver using the ALED6001 with graphic

user interface for quick evaluation

Introduction

The ALED6001 is an automotive-grade LED driver that combines a boost controller and

high-side current sensing circuitry optimized for driving a string of high brightness LEDs.

The device is compatible with multiple topologies such as boost, SEPIC and floating load

buck-boost. PWM dimming of the LED brightness is achieved via an external MOSFET in

series with the LED string, directly driven by a dedicated pin. Another pin allows analog

control of the LED current (10:1 analog dimming) and can also be used to limit the

temperature of the LED string (thermal feedback) by means of an NTC thermistor.

High-side current sensing in combination with a P-channel MOSFET provides effective

protection in cases where the positive terminal of the LED string shorts to ground. The high

precision current sensing circuitry allows a LED current regulation reference within +/-4%

accuracy over the whole temperature range and production spread.

A fault output (open drain) informs the host system of device over-temperature, output overvoltage (disconnected LED string) or LED overcurrent fault conditions.

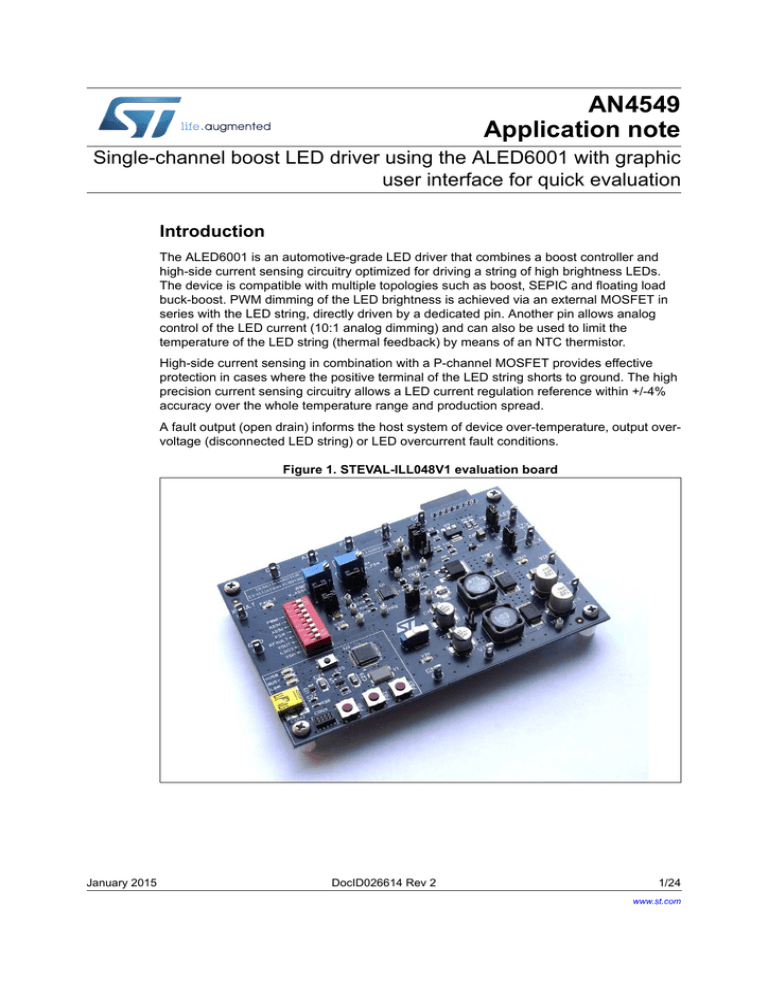

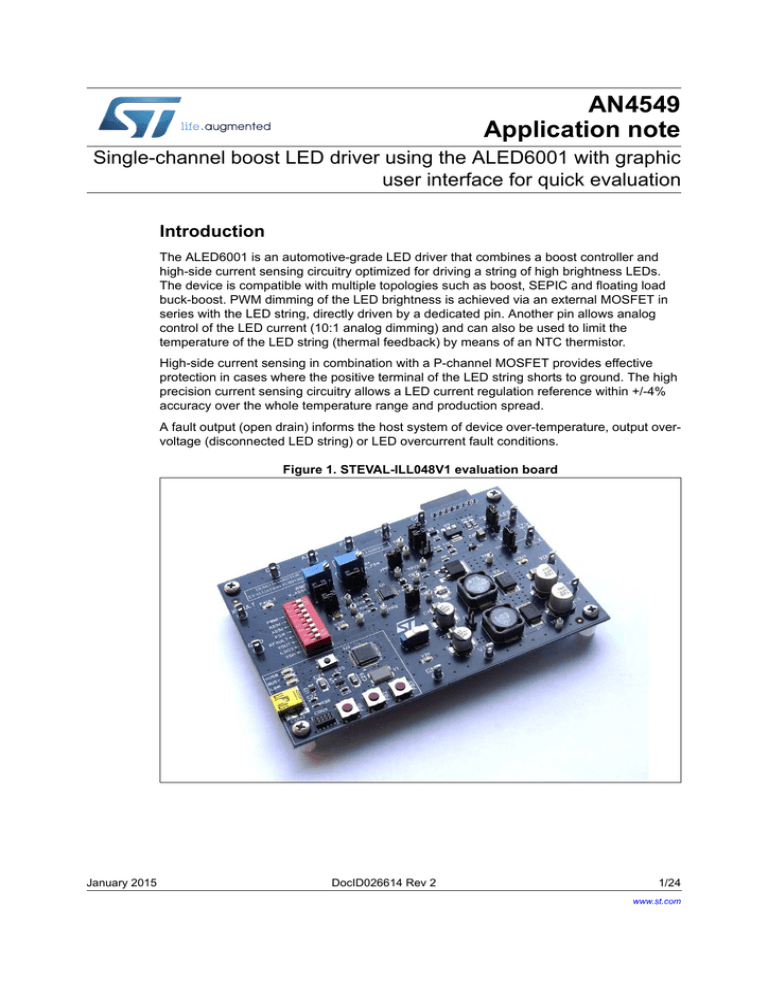

Figure 1. STEVAL-ILL048V1 evaluation board

January 2015

DocID026614 Rev 2

1/24

www.st.com

Contents

AN4549

Contents

1

STEVAL-ILL048V1 evaluation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1

Board connectors and test-points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2

Recommended equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4

Getting started with STEVAL-ILL048V1 board . . . . . . . . . . . . . . . . . . . . 8

4.1

Quick startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Appendix A STEVAL-ILL048V1 board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix B OSLON_DTRL_R board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5

2/24

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DocID026614 Rev 2

AN4549

1

STEVAL-ILL048V1 evaluation board

STEVAL-ILL048V1 evaluation board

The STEVAL-ILL048V1 evaluation board is based on the ALED6001 in boost configuration

and is designed to drive a string of high-brightness LEDs in series, starting from a single

supply rail.

The board integrates a micro controller section that allows the user to quickly evaluate all

the ALED6001 functions through a graphic user interface (GUI) running on a PC.

Table 1 summarizes the main features of the STEVAL-ILL048V1 board.

Table 1. STEVAL-ILL048V1 board specifications summary

Parameter

Conditions

Value

Minimum input voltage

6V

Maximum input voltage

24 V

Output voltage

24 V÷40 V

Output OVP threshold

48 V

Boost section switching

frequency

FSW high (LDO3)

630 kHz

FSW pin to R14 trimmer

100 kHz-1 MHz

Minimum dimming on-time

100Hz<FDIM<20kHz

10 µs

Output (LED) current

Output current accuracy

(respect to nominal value)

350 mA

ADIM to LDO3

±4% max (<±2% typ.)

This document is intended as a reference guide to start working with the ALED6001 LED

driver only using the STEVAL-ILL048V1 board, a DC power supply and a PC.

1.1

Board connectors and test-points

The STEVAL-ILL048V1 board has a set of connectors and test points that facilitate

interfacing it with the measurement equipment. The following tables summarize the function

of each terminal and test-point on the board.

DocID026614 Rev 2

3/24

24

STEVAL-ILL048V1 evaluation board

AN4549

Table 2. STEVAL-ILL048V1 board terminals description

Connector

Description

VIN

Input voltage, positive terminal

GND

Reference ground

LED_A

Positive terminal of the LED string (anode)

LED_K

Negative terminal of the LED string (cathode)

VOUT

Boost regulator output voltage

ADIM

Analog dimming control

PWMI

Enable/PWM dimming control

FSW

Boost converter synchronization input

XFAULT

Fault signal, active low

Table 3. STEVAL-ILL048V1 board test-points description

Connector

4/24

Description

TP1

VIN pin

TP2

VDR pin

TP3

LDO3 pin

TP4

GATE pin

TP5

Switching node

TP6

R6 sensing resistor, hot terminal

TP7

CSNS pin

TP8

Boost converter output voltage

TP9

OVFB pin

TP10

VFBP pin

TP11

VFBN pin

TP12

COMP pin

TP13

PWMO pin

DocID026614 Rev 2

AN4549

2

Recommended equipment

Recommended equipment

The on-board MCU section controls all the functions of the ALED6001 by applying the

required signals and reading back certain voltages.

Rapid evaluation of the ALED6001 can be performed with just a DC power supply and a PC

with USB connectivity; more detailed performance analyses require conventional lab

equipment (digital multi-meters, oscilloscope, etc.).

DocID026614 Rev 2

5/24

24

Configuration

3

AN4549

Configuration

The STEVAL-ILL048V1 board allows the user to select different options by acting on a set of

jumpers and switches (see Table 4 and Table 5).

Table 4. STEVAL-ILL048V1 jumpers’ description

6/24

Jumper

Function

Default position

JP1

The input filter consists of C1, C2, L1, C2 and C3

and it has been added to reduce EMI emission.

In the default setting, JP1 is closed and L1 is

shorted so that its DC resistance does not affect

the overall efficiency.

Closed

JP2

The JP2 jumper is used to measure the real

current consumption of the ALED6001. Once

JP1 is removed, a current meter can be

connected in series with the VIN pin of the

device.

Closed

JP3

The JP3 jumper is used to measure the current

consumption of the external circuitry connected

to the 3.3V LDO of the ALED6001. Once JP3 is

removed, a current meter can be connected in

series with the LDO3 pin of the device.

Closed

JP4

If this jumper is removed, the VFBP pin is

disconnected from the sensing resistor and the

ALED6001 returns a fault condition (XFAULT pin

low)

Closed

JP5

If this jumper is removed, the VFBP pin is

disconnected from the sensing resistor and the

ALED6001 returns a fault condition (XFAULT pin

low)

Closed

JP6

If this jumper is removed, the VFBP pin is

disconnected from the sensing resistor and the

ALED6001 returns a fault condition (XFAULT pin

low)

Closed

JP7

This jumper enables high-side PMOS driving.

When a simple low-side dimming NMOS is used,

this jumper should be open to avoid undesired

power dissipation.

Open

JP8

This jumper connects the FSW pin of the

ALED6001 to LDO3 (630 kHz default switching

frequency, dot position) or to the R14 trimmer

(100 kHz–1 MHz adjustable switching frequency.

Left (dot)

JP9

This jumper connects the ADIM pin of the

ALED6001 to LDO3 (full-scale LED current) or to

the R18 trimmer (adjustable 30 mV–300 mV

feedback reference for analog dimming)

Left (dot)

JP10

“VIN” LED disconnection

Closed

JP11

“VOUT” LED disconnection

Closed

DocID026614 Rev 2

AN4549

Configuration

Table 4. STEVAL-ILL048V1 jumpers’ description (continued)

Jumper

Function

Default position

JP12

“LDO3” LED disconnection

Closed

JP13

“VDR” LED disconnection

Closed

JP14

This jumper powers the MCU from the LDO3 pin

of the ALED6001. The SW1 switch must be in

the “ON” position to ensure the MCU is powered

when the input voltage is applied.

Open

JP15

If this jumper is closed, the R43-C39 snubber is

connected in parallel to the Q3 low-side switch in

order to damp undesired oscillations that may

occur in long wiring between the board and the

LED string (parasitic inductance)

Open

Table 5. STEVAL-ILL048V1 switches’ description

Jumper

Function

Default position

SW1

If this switch is in the default position (left, dot),

the PWMI pin of the ALED6001 is left floating,

i.e. tied to ground by the internal pull-down

resistor. If moved to the right position, the PWMI

pin is pulled-up by the input rail and the device

turns-on.

Left (dot)

SW2

This jumper is used to assign the LED_A

connector according to the selected dimming

MOSFET (low-side or high-side). If the low-side

dimming MOSFET is used, this jumper must be

in the upper position (dot).

Upper (dot)

SW3

This jumper is used to assign the LED_A

connector according to the selected dimming

MOSFET (low-side or high-side). If the low-side

dimming MOSFET is used, this jumper must be

in the upper position (dot).

Upper (dot)

SW4

This switch array is used to connect the

ALED6001 to the on-board MCU, allowing the

latter to control the device. If external signals

have to be applied to specific pins of the

ALED6001, the related switch must be opened to

avoid conflict with the MCU.

Right (all ON)

DocID026614 Rev 2

7/24

24

Getting started with STEVAL-ILL048V1 board

4

AN4549

Getting started with STEVAL-ILL048V1 board

Figure 2 shows how to connect the STEVAL-ILL048V1 board to the DC power supply and

the LED string. Alternatively, an OSLON_DTRL_x board (see Appendix B) can be directly

connected to CON1 on the STEVAL-ILL048V1 board.

Figure 2. Basic setup for quick evaluation

4.1

Quick startup

The following step-by-step sequences provide a guideline to quickly connect the STEVALILL048V1 board to the PC and evaluate the ALED6001 performance.

1.

Working in an ESD-protected environment is highly recommended. Check all wrist

straps and mat earth connections before handling the STEVAL-ILL048V1 board.

2.

Check all the jumpers are set according to Figure 3. Note that JP9 is removed to give

the MCU full control of the ADIM pin.

Figure 3. Jumpers and switches default settings

8/24

DocID026614 Rev 2

AN4549

Getting started with STEVAL-ILL048V1 board

3.

Connect a 12 V±10% (3 A current capability) power supply to the STEVAL-ILL048V1

board (VIN and GND terminals).

4.

Connect a suitable LED string (8-12 high-brightness White LEDs capable of handling at

least 350 mA) between LED-A & LED-K terminals. If the OSLON_DTRL_x board is

used, connect it to CON1 of the STEVAL-ILL048V1 board.

5.

Connect the STEVAL-ILL048V1 board to the PC via a USB cable. The yellow “LINK”

LED should light after a while. You may need to install the STM32 Virtual COM Port

Driver on the PC beforehand.

6.

Launch the STEVAL-ILL048V1 Control Tool and click on “Autodetect” for the tool to

locate the evaluation board port. Manual assignment of the COM port is also possible

via the “Select COM” button.

Figure 4. Control tool window: link status

DocID026614 Rev 2

9/24

24

Getting started with STEVAL-ILL048V1 board

7.

AN4549

Turn on the power supply. The LED string should turn on at 3% PWM dimming. Check

the voltage of the LDOs (LDO3 and VDR pins) and the output voltage of the boost

converter.

Figure 5. Control tool window: XFAULT pin and voltages monitor

8.

In the “digital dimming” section, change the frequency and duty-cycle of the PWM

signal applied to the PWMI pin of the device. If the duty-cycle is set to zero, the device

shuts-down.

Figure 6. Control tool window: PWM dimming management

10/24

DocID026614 Rev 2

AN4549

Getting started with STEVAL-ILL048V1 board

9.

In the analog dimming section, change the DC level at the ADIM pin of the device. The

real value is read back by the on-board MCU.

Figure 7. Control Tool window: analog dimming management

10. Digital and analog dimming controls can operate at the same time. A “Start demo”

button for each dimming mode runs the respective demo.

Figure 8. Control tool window: demo-mode management

DocID026614 Rev 2

11/24

24

Getting started with STEVAL-ILL048V1 board

AN4549

11. The switching frequency of the boost converter can be changed during runtime by

applying a synchronization signal at the FSW pin of the device. Preset values can be

selected through the dedicated section of the control tool.

Figure 9. Control tool window: external synchronization selection

12. The XFAULT pin of the device is monitored in real-time. To simulate a fault condition,

remove any of SW2, SW3, JP4, JP5 or JP6: the XFAULT pin goes low and the +5V

LDO is disabled.

Figure 10. Control tool window: faulty condition detected

12/24

DocID026614 Rev 2

AN4549

Getting started with STEVAL-ILL048V1 board

13. Normal operation can resume once the fault condition is cleared and the device is reset

by toggling the PWMI pin (digital dimming to zero for more than 10ms and then high

again).

Figure 11. Control tool window: device turned-off at zero PWM dimming

DocID026614 Rev 2

13/24

24

1

CON1

J12

CON1

J9

CON1

J8

CON1

J7

CON1

J2

CON1

1

1

1

1

C1

47u

0

VCC_INT

SIL2

JP1

10u

D9 R-LED

XFAULT

C2

10u

L1

R22 680R

R21 47k

SIL2

JP3

0

0

3

C11

1u

L DO

VCC_INT

C4

10u

TP3

T POINT R

C3

47u

47u

GATE

TP4

T POINT R

L2

D1 STPS3L60

ND

PWMI

FSW

XFAULT

LDO3

SGND

COMP

ADIM

OVFB

G

TP8

T POINT R

TP6

T POINT R

3R3

R5

T POINT R

0

R6

0R1

1

2

3

4

5

6

7

8

CSNS

PWMI

FSW

XFAULT

LDO3

SGND

COMP

ADIM

OVFB

U1

PGND

1k8

R7

Q1

STD12NF06L

LX

TP5

100p

C13

COMP

VFBP

VFBN

VIN

VDR

GATE

PGND

PWMO

CSNS

ALED6001

T POINT R

TP7

D2 STPS3L60

TPAD

17

SIL2

JP6

0

C12

4n7

R12

47k

TP12

T POINT R

16

15

14

13

12

11

10

9

R2

5k6

R1

220k

TPAD

VFBP

VFBN

VIN

VDR

GATE

PGND

PWMO

CSNS

OVFB

0

C10

1u

TP2

T POINT R

T POINT R

TP9

C7

4u7

SW1

SIL3

+VIN

0

D4

0

PWMI

C8

4u7

PWMO

TP13

+VIN

BZT52C4V7

2

R19

47k

T POINT R

C9

470n

SIL2

JP2

C6

100u

TP1

T POINT R

C5

100u

5R6

R8

0

R20

100k

R11

10k

R10

1k

1

R9

2k2

JUMPER 2

PW

CON1

J10

VFBN

T POINT R

TP11

JP7

M

I

C14

10n

VFBP

T POINT R

TP10

SIL2

JP4

FXD_LED+

PWM_LED-

PWM_LED+

STN3PF06

Q3

R16

16k

Q2

IRLML0060TRPBF

D3

MMSZ5245B

SIL2

JP5

R3

1R5

1

3

1

R18

50k

R17

68k

VCC_INT

3

+VIN

0

0

1u

C15

2 LED_K

SW3

SIL3

2 LED_A

SW2

SIL3

R4

2R0

VOUT

3

1

3

1

DocID026614 Rev 2

1

14/24

0

CON1

J4

CON1

J3

2

NTC-

NTC+

G

ND

L ED_ K

ADIM

CON1

J6

CON1

J5

JP9

SIL3

1

1

C39

2n2

R43

47R

JP15

JUMPER 2

1

1

1

ADI M

CON1

J11

100n

C17

LED_K

LED_A

VDR

VCC_INT

VOUT

+VIN

VI N

UT

3

L4

L3

BEAD

0

C16

N.M.

VCC_INT

NTC+

NTC-

R26 1k

R25 390R

R24 15k

R23 5k6

R27

1k

0

BEAD

D8 R-LED

VDR

D7 R-LED

L DO

D6 B-LED

VO

D5 Y -LED

1

0

R15

47k

R14

500k

JP8

SIL3

2

R13

470R

FSW

1

2

3

4

5

6

7

8

JUMPER 2

JP13

JUMPER 2

JP12

JUMPER 2

JP11

JUMPER 2

JP10

CON8

CON1

0

1

FSW

CON1

J13

Appendix A

3

J1

STEVAL-ILL048V1 board

AN4549

STEVAL-ILL048V1 board

Figure 12. STEVAL-ILL048V1 board schematic (LED driver section)

GSPG2901150945SG

6

7

SLD

100n

C34

22p

100n

C22

8MHz

10k

R36

C29

C33

22p

Y1

8

9

VOUT_uC

LDO3_uC

ADIM_uC

1

2

3

4

5

6

7

8

9

10

11

12

C32

FD-

FD+

VDR_uC

PWMI_uC

XFAULT_uC

VDD

JTRST

PBUTT1

PBUTT2

PBUTT3

3

1

U3

5

VDD

VSS

2

CON2

1

2

3

4

5

USBDP

USBDN

6

4

VDD

VBAT

PC13

PC14

PC15

OSCI

OSCO

NRST

VSSA

VDDA

PA0

PA1

PA2

100n

LINK_LED

BUSY _LED

USBUF02W6

UD-

UD+

200mA

48

47

46

45

44

43

42

41

40

39

38

37

STM32F103C6T6

VDD3

VSS3

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PA15

PA14

C30

VDD2

VSS2

PA13

PA12

PA11

PA10

PA9

PA8

PB15

PB14

PB13

PB12

36

35

34

33

32

31

30

29

28

27

26

25

100n

U2

JTRST

JTDO

JTDI

JTCK

PWM2_uC

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB10

PB11

VSS1

VDD1

DocID026614 Rev 2

13

14

15

16

17

18

19

20

21

22

23

24

VDD

100n

JTMS

USBDP

USBDN

C31

BEAD

FSW_uC

VDD

C23

100n

L5

1

2

D10

B-LED

R37

1k

C24

4u7

VUSB

C25

100n

5

1

SD

VIN

U4

BY P

VOUT

LK11233

GND

2

F1

4

JTRST

PBUTT3

PBUTT2

PBUTT1

3

C37

C36

C35

C26

100n

P2

1

3

P3

1

3

C38

100n

RESET

1

R42 100R

PB4

2

100n

1

3

R41 100R

PB3

2

4

100n

PB2

2

4

100n

P1

R40 100R

PB1

2

4

C27

100n

VDD

C28

4u7

SIL2

JP14

VCC_INT

VDD

1k

R39

1

D12

1

D11

JTRST

JTDI

JTMS

JTCK

JTDO

1k

R38

2

CON3

2

BUSY _LED

2

4

6

8

10

VDD

LINK_LED

C_JTAG_M

1

3

5

7

9

Y -LED

R-LED

PWM2_uC

47k

R29

0

C18

1u

ADIM_uC

C19

1u

VOUT_uC

R28

10k

0

R31

15k

R30

220k

C20

1u

LDO3_uC

FSW_uC

XFAULT_uC

PWMI_uC

0

R33

100k

R32

22k

C21

1u

VDR_uC

0

R35

100k

R34

100k

SW DIP-8

SW4

FSW

XFAULT

VOUT

LDO3

VDR

PWMI

ADIM

AN4549

STEVAL-ILL048V1 board

Figure 13. STEVAL-ILL048V1 board schematic (MCU section)

15/24

24

STEVAL-ILL048V1 board

AN4549

Table 6. BOM

Qty Component

Description

Package

Part-Number

SIL8

613-008-143-121

MFR

Value

1

CON1

8 pin female header

1

CON2

Mini USB connector

6510-0516121

1

CON3

5x2 female connector

6233-10235321

2

C1,C3

Aluminum, 50V

D8

EEEFK1H470XP

Panasonic

47u

2

C5,C6

Aluminum, 50V

F

EEEFP1H101AP

Panasonic

100u

4

C2,C4,C7,

C8

MLCC, 50V, X7R, 10%

1210

GCM32ER71H475KA40

Murata

4.7u

1

C9

MLCC, 50V, X7R, 10%

0805

GCM21BR71H474KA40

470n

7

C10,C11,

C15

C18,C19,

C20, C21

MLCC, 25V, X7R, 5%

GCM188R71E105KA64

1u

1

C39

MLCC, 50V, X7R, 10%

GCM188R71H222KA37

2n2

1

C12

MLCC, 50V, X7R, 10%

GCM188R71H103JA37

10n

1

C13

MLCC, 50V, C0G, 5%

GCM1885C1H101JA16

100p

1

C14

MLCC, 50V, X7R, 10%

GCM188R71H103KA37

10n

0603

Wurth

Elektronik

C16

N.M.

14

C17,C22,

C23,C25,

C26,C27

C29,C30,

C31,C32,

C35,C36

C37,C38

MLCC, 50V, X7R, 10%

2

C24,C28

MLCC, 10V, X7R, 10%

2

C33,C34

2

1

GCM188R71H104KA57

100n

1206

GCM31CR71A106KA64

10u

MLCC, 50V, C0G, 5%

0603

GCM1885C1H220JA16

22p

D1,D2

Schottky, 60V, 3A

SMB

STPS3L60SY

ST

D3

Zener 15V 400mW

MMSZ5245B

Zetex

SOD123

1

D4

Zener 4.7V1 400mW

BZT52C4V7S

Zetex

2

D6,D10

Blue LED

KP-2012PBC-A

Kingbright

4

D7,D8,D9

D11

Red LED

2

D5,D12

Yellow LED

1

F1

Fuse

16/24

0805

KP-2012SRC-PRV

KP-2012SYC

1206

0466.200NR

DocID026614 Rev 2

Littelfuse

200mA

AN4549

STEVAL-ILL048V1 board

Table 6. BOM (continued)

Qty Component

Description

Package

13

J1,J2,J3,

J4,J5

J6,J7,J8,J9,

J10,J11,J12,

J13

Faston terminal

hole

1.2mm

11

JP1,JP2,

JP3,JP4,

JP5,JP6

JP7,JP10,

JP11,JP12,

JP13

jumper

SIL2

2

JP8,JP9

jumper selector

SIL3

JP14,JP15

jumper

tin-drop

L1

custom

custom

1

Part-Number

MFR

MSS1260T-103

Value

10u

Coilcraft

1

L2

custom

custom

MSS1260T-473

47u

3

L3,L4,L5

Ferrite bead, 600Ω, 0.6A

0805

BLM21AG601SN1

Murata

3

PB1,PB2,

PB3

430453031836

Pushbutton

Wurth

Elektronik

1

PB4

1

Q1

NMOS 60V 12A

DPAK

STD12NF06L

ST

1

Q2

NMOS 60V 2.5A

SOT23

IRLML0060TRPBF

IR

1

Q3

PMOS 60V 2.5A

SO8

STN3PF06

ST

2

R1,R30

Resistor, 1%, 0.125W

0603

2

R2,R23

1

R3

0R

434123025816

220k

5k6

ERJ8BQF1R5V

1

R4

Sensing resistor

1%, 0.5W

1

R5

Resistor, 1%, 0.125W

0603

1

R6

Sensing resistor

1020

1206

1R5

Panasonic

ERJ8BQF2R0V

2R0

3R3

ERJB2CFR10V

DocID026614 Rev 2

Panasonic

R100

17/24

24

STEVAL-ILL048V1 board

AN4549

Table 6. BOM (continued)

Qty Component

Description

Package

Part-Number

MFR

Value

1

R7

1k8

1

R8

5R6

1

R9

6

R10,R26

R27,R37

R38,R39

1

R11

1

R12

1

R16

2k2

0603

1k

Resistor, 1%, 0.125W

0805

10k

39k

16k

0603

2

R28,R36

10k

1

R13

470R

1

R14

500k

Through-hole trimmer

SIL3

1

R18

50k

1

R17

68k

4

R20,R33

R34,R35

100k

4

R15,R19

R21,R29

47k

1

R22

680R

0603

Resistor, 1%, 0.125W

2

R24,R31

1

R25

390R

1

R32

22k

3

R40,R41,R4

2

100R

1

R43

1

SW1

switch selector

SIL3

2

SW2,SW3

jumper selector

SIL3

1

SW4

DIP switch

13

TP1,TP2,

TP3,TP4,

TP5, TP6

TP7,TP8,

TP9,TP10,

TP11,TP12,

TP13

Test point (white)

18/24

15k

0805

47R

MMP1010D

Knitter

DIL8

DBS3108

Knitter

hole 1mm

200-202

RS

DocID026614 Rev 2

AN4549

STEVAL-ILL048V1 board

Table 6. BOM (continued)

Qty Component

Description

Package

Part-Number

MFR

Value

1

U1

LED driver

TSSOP 16

ALED6001

ALED6001

1

U2

Microcontroller

LQFP-48

STM32F103C6T6

STM32F103

C6T6

ST

1

U3

USB protector

SOTT-123

USBUF02W6

USBUF02W6

1

U4

3V3 Linear regulator

SOT-23

LK112M33TR

LK11233

1

Y1

Crystal resonator

FQ7050B

FQ7050B-8.000

FOX

8MHz

Figure 14. Top side components placement

Figure 15. Bottom side components placement

DocID026614 Rev 2

19/24

24

OSLON_DTRL_R board

Appendix B

AN4549

OSLON_DTRL_R board

Figure 16. OSLON_DTRL_L and STEVAL-ILL048V1 assembly

The OSLON_DTRL_R board is a simple LED string involving 12 High-Brightness, OSRAM

Opto white LEDs (OSLON series) and a few other components. It can be easily coupled to

the STEVAL-ILL048V1 evaluation board via the 8-pin strip connector (CON1).

A negative temperature coefficient (NTC) thermistor is thermally coupled to the LED string in

order to provide a feedback signal to the LED driver. As visible in the schematic of the

STEVAL-ILL048V1 board (see Appendix A), the ADIM pin of the ALED6001 is connected to

this signal and used for limiting the operating temperature of the LEDs through a closed

loop. Optionally, if a LED current lower than the default 350 mA is desired, a fixed value

resistor can be selected through the JP1 jumper (Figure 17).

20/24

DocID026614 Rev 2

AN4549

OSLON_DTRL_R board

Figure 17. OSLON_DTRL_R board schematic

TP1

T POINT R

TP2

T POINT R

D1

LED

F1

0.75A

TP3

T POINT R

TP4

T POINT R

TP5

T POINT R

TP6

T POINT R

D2

D3

D4

D5

D6

LED

LED

LED

LED

LED

TP7

T POINT R

CON1

1

2

3

4

5

6

7

8

D12

D11

D10

D9

D8

D7

CON8

LED

SHIELD

ESD

LED

T POINT R

TP12

TP13

T POINT R

0

RT1

LED

T POINT R

TP11

LED

T POINT R

TP10

LED

T POINT R

TP9

LED

T POINT R

TP8

R1

t

47k

N.M.

JUMPER 3

3

2

1

JP1

Table 7. OSLON_DTRL_R component list

Qty

Component Description

Package

Part-Number

MFR

1206SFF075F/63-2

Littlefuse

NCP18WB473J03RB

Murata

LUW H9QP

OSRAM

Opto

1

F1

fuse

1206

1

R1

resistor

0603

1

RT1

47k NTC

0603

1

CON1

Strip

connector

SIL8 SMD

12

D1…D12

White LEDs

custom

Figure 18. OSLON_DTRL_R board layout and components placement (top)

DocID026614 Rev 2

21/24

24

OSLON_DTRL_R board

AN4549

Figure 19. OSLON_DTRL_R board layout and components placement (bottom)

22/24

DocID026614 Rev 2

AN4549

5

Revision history

Revision history

Table 8. Document revision history

Date

Revision

Changes

11-Dec-2014

1

Initial release.

29-Jan-2015

2

Updated Figure 12 on page 14.

DocID026614 Rev 2

23/24

24

AN4549

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and

improvements to ST products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on

ST products before placing orders. ST products are sold pursuant to ST’s terms and conditions of sale in place at the time of order

acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or

the design of Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2015 STMicroelectronics – All rights reserved

24/24

DocID026614 Rev 2