RD-576 - Automotive Ignition Application Evaluation Board

advertisement

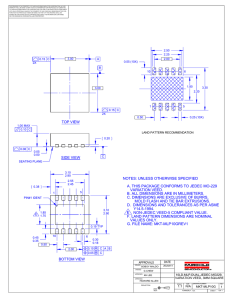

Fairchild Reference Design RD-576 Automotive Ignition Application Evaluation Board Ignition Application reference design for device evaluation in test bench Featured Fairchild Products: FAN1100_F085 FGD3040G2_F085 Fairchild’s Automotive Conventional Vehicles Group Direct questions or comments about this evaluation board to: “Worldwide Direct Support” Fairchild Semiconductor.com © 2016 Fairchild Semiconductor Corporation RD-576 • Rev. 1.0 Table of Contents 1. Introduction ............................................................................................................................... 3 1.1. 1.2. Devices description .......................................................................................................... 4 Devices features ............................................................................................................... 4 2. Evaluation Board Specifications ............................................................................................... 5 3. Photographs............................................................................................................................... 6 4. Printed Circuit Board ................................................................................................................ 7 5. Schematic .................................................................................................................................. 9 6. Bill of Materials ...................................................................................................................... 10 7. External devices assumptions ................................................................................................. 11 8. Production and use of the Evaluation Board........................................................................... 12 8.1. 8.2. 8.3. 8.4. Production of the PCB.................................................................................................... 12 Suggested application circuit ......................................................................................... 12 Connection and supply of the evaluation board ............................................................. 13 Cautions and other considerations ................................................................................. 13 9. Test Equipment ....................................................................................................................... 14 10. Performance of the Evaluation Board ..................................................................................... 15 10.1. 10.2. 10.3. Dwell and Current Limit............................................................................................. 15 Clamp.......................................................................................................................... 16 Max-dwell function and Soft Shutdown (SSD) .......................................................... 17 11. Conclusions ............................................................................................................................. 18 12. Related Resources ................................................................................................................... 19 © 2016 Fairchild Semiconductor Corporation 2 RD-576 • Rev. 1.0 This reference design supports the application evaluation board called Automotive Ignition Application Evaluation Board. It should be used in conjunction with the device datasheets, Fairchild’s application notes, and technical support team. It is highly recommended to have on hand our application note AN-8208: Introduction to Automotive Ignition Systems. Please consider that the present document and the evaluation board itself are meant to be a reference design to support the customer during the first stages of design. The board has been evaluated just under certain conditions and assumptions that differ to an automotive final application. Please visit Fairchild’s websites www.fairchildsemi.com and the Automotive Ignition webpage for further product information. 1. Introduction This document describes a proposed solution for an ignition Inductive Discharge Ignition (IDI) System using our EcoSPARKTM Ignition IGBTs and the Ignition Driver IC FAN1100_F085. The battery voltage range is from 6 V to 28 V (typical and recommended 12-14 V) and the input drive signal is up to 6 V (recommended 5 V). The board is not fully automotive qualified and it has been designed for evaluation purposes only. One coil two spark Ignition Coil + Automotive Ignition Evaluation Board Battery IGBT Driver V1 Ignition IGBT Vcc Z1 V2 + Spark plug R1 ECU Z2 R2 Figure 1. Block diagram ignition application. IDI system This document contains general description of the Evaluation Board and the featured devices, the application specifications and boundary assumptions, schematic, bill of materials and the typical operating characteristics. © 2016 Fairchild Semiconductor Corporation 3 RD-576 • Rev. 1.0 1.1. Devices description EcoSPARK® Ignition IGBTs are optimized to control the load current through the ignition coil and feature an integrated clamp structure that limits the maximum voltage on the primary side. In this evaluation board, the Ignition IGBT FGD3040G2_F085 is used as an example. Our driver ICs are designed to directly drive the ignition IGBT and control the current and spark event of the coil. The FAN1100_F085 is designed to directly drive an ignition IGBT and control the current and spark event of the coil. The coil current is controlled via the input pin. When the input is driven high, the output of the FAN1100_F085 is enabled to turn on the IGBT and start charging the coil. The FAN1100_F085 will sink a current into the input pin based on programmed current on the RA line. An input spike filter suppresses input signals of less than 13 µsec in duration. A Max Dwell timer is included in the FAN1100_F085 which will turn off the IGBT if the input stays active for longer than the programmed time. This time interval can be modified through an external capacitor on the CSSD pin. When the Max Dwell timer is exceeded, the FAN1100_F085 will enter a Soft-ShutDown mode (SSD) slowly dropping the collector current by lowering the gate drive to the IGBT thereby discharging the coil such as to inhibit a spark event. Once the soft shutdown operation has started, any transitions on the input signal are ignored until after completion of the soft shut down function. The FAN1100_F085 will also limit the collector current of the IGBT to Ic(lim) during charging. This again is done through the sense resistor in the emitter leg of the Ignition IGBT developing a signal input to the Vsense pin of the FAN1100_F085. 1.2. Devices features SCIS Energy = 300 mJ at TJ = 25°C for the FGD3040G2_F085 Logic Level Gate Drive at the IGBT gate Automotive qualified and RoHS Compliant Signal Line Input Buffer and Input spike filter Programmable maximum dwell time Programmable Input Pull down current Control IGBT current limiting through Vsense pin Soft Shutdown following Max Dwell Time out © 2016 Fairchild Semiconductor Corporation 4 RD-576 • Rev. 1.0 2. Evaluation Board Specifications All data for this table was measured at an ambient temperature of 25°C. Table 1. Summary of features and performance Description Input Voltage Symbol Value VIN, min, VIN, nom, VIN,max Comments Refer to FAN1100_F085 datasheet Input Frequency freqIN,max 200 Hz Collector Current ICtyp 12 A Current limit Ilim Based on selection of Rsense Max-Dwell TMAX Based on selection of Cssd SSD Slew Rate Islew 1.5 A/ms Typical slew rate TFANxxx < 150°C TIGBT < 175°C At full load (all at open frame, room temperature / still air) Temperature Application © 2016 Fairchild Semiconductor Corporation Typical 5-60 Hz Typical collector current Ignition system 5 RD-576 • Rev. 1.0 3. Photographs Figure 2. © 2016 Fairchild Semiconductor Corporation Evaluation board. (Photograph top view) 6 RD-576 • Rev. 1.0 4. Printed Circuit Board Figure 3. Top view PCB layout including TOP and BOT layers (not real size) Figure 4. © 2016 Fairchild Semiconductor Corporation Top view PCB layout. TOP layer (not real size) 7 RD-576 • Rev. 1.0 Figure 5. © 2016 Fairchild Semiconductor Corporation Top view PCB layout. BOT layer (not real size) 8 RD-576 • Rev. 1.0 5. Schematic Figure 6. © 2016 Fairchild Semiconductor Corporation Evaluation Board Schematic 9 RD-576 • Rev. 1.0 6. Bill of Materials Table 2. Bill of materials Reference Qty Part Number Value Description Manufacturer Cbat1 1 SMD - 0805 0.47 µF Supply filter - Rbat 1 SMD - 1210 300 Ω Supply filter - Cbat2 1 SMD - 0805 0.1 µF Supply filter - Cinc 2 SMD - 0805 No populate - Rin 1 SMD - 1210 No populate - Cin/Cind 1 SMD - 0805 10 nF Input signal filter - RA 1 SMD - 0805 15 kΩ Input Current Reference Resistor - RB 1 SMD - 1210 51 Ω Input Buffer Resistor - CIGF 1 - No populate - Jumpers 6 Cssd 1 SMD - 0805 FAN1100 1 Ignition IGBT 1 Rsense 1 TP 11 Connector 1 Soft shutdown - FAN1100_F085 IGBT Driver IC Fairchild FGD3040G2_F085 Ignition IGBT Fairchild Current sense - © 2016 Fairchild Semiconductor Corporation 10 nF 20 mΩ Test point - 10 RD-576 • Rev. 1.0 7. External devices assumptions Table 3. Reference Qty Ignition Coil 1 Spark Plug 1 External BOM Description The coil primary winding inductance is approximately 3.6 mH The resistance of primary winding is approximately 0.6 ohm The capacitance is approximately 25 pF Figure 7. Test circuit setup scheme Figure 8. © 2016 Fairchild Semiconductor Corporation Test circuit setup 11 RD-576 • Rev. 1.0 8. Production and use of the Evaluation Board 8.1. Production of the PCB These are the PCB characteristics of the evaluation board we have built: 3.8 by 2.5 Inch, 2 Layer Board Solder Mask on Top and Bottom Silkscreen on Top Laminate: FR-4 with a Dielectric Constant between 4.2 to 5 Copper Thickness: ~0.0017 inches 8.2. Suggested application circuit One coil two spark Ignition Coil Battery or Battery Simulator Demo Board - + Cbat1 Pin 1 Collector V1 - Pin 2 Vbat Rbat V2 + Ignition IGBT Cbat2 Signal current measurement Pin 3 INPUT/INH Primary current measurement Z1 Spark plug RB R1 Vce measurement Cin ECU or Signal Generator Vin measurement Pin 4 INL IGBT Driver Figure 9. © 2016 Fairchild Semiconductor Corporation Z2 R2 Cssd RA Pin 6 Gnd Application circuit setup 12 RD-576 • Rev. 1.0 8.3. Connection and supply of the evaluation board For a safe installation of the test setup, we recommend to follow the next steps: Connect the primary return wire form the Ignition Coil to “Pin 1 Collector” of the Ignition Driver Evaluation Board. Connect the positive terminal of the battery or battery simulator to “Pin 2 Vbat”. Connect the positive terminal of a signal generator to “Pin 3 INPUT/INH”. Connect the negative terminal of a signal generator to “Pin 4 INL”. Connect the negative terminal of the battery or battery simulator to “”. Connect the primary power of the ignition coil to the positive terminal of the battery or battery simulator. Connect the coil to the sparkplug. Connect the ground of the sparkplug to the ground of the negative terminal of the battery or battery simulator. Insert the FAN1100_F085 into the socket and firmly close the socket. Configure the signal generator parameters, such as voltage levels, duty ratio and frequency, as specified in Section 2. 8.4. Cautions and other considerations We assume that you have a decent and safe lab to work in. Please consider that we work here with high voltages and currents and an improper or unsafe use could be lethal. Prepare, check and calibrate the equipment and review that cables, connectors and scopes are in good state. Clean the desk and safety shields. Test circuit breakers and emergency circuits. Fuse suggested to be placed on the battery line for protection and safety. The wire connecting the collector of the IGBT and the primary return of the coil is recommended to have greater than 800 V insulation. The spark plug should be grounded, otherwise undesired arcing over may occur. Recommend to power down the board before replacing any components. © 2016 Fairchild Semiconductor Corporation 13 RD-576 • Rev. 1.0 9. Test Equipment Table 4. Test Equipment Battery Simulator Pulse Generator: DG4162 by RIGOL Oscilloscope: 610Zi by LeCroy Test Equipment Current Probe: AP015 by LeCroy High Voltage Probe: PPE4KV by LeCroy Voltage Probe: PP005A by LeCroy Pearson coil for low current measurement © 2016 Fairchild Semiconductor Corporation 14 RD-576 • Rev. 1.0 10. Performance of the Evaluation Board Please study carefully the application note, AN-8208, to understand all the details of the ignition system behavior shown below. 10.1. Dwell and Current Limit After a certain dwell time, an increase in the dwell time will not affect the peak primary current, as the device gets into current limit. Figure 10. Dwell time and current limit © 2016 Fairchild Semiconductor Corporation 15 RD-576 • Rev. 1.0 10.2. Clamp To initiate the sparking event, the device turns off the current rapidly. The energy in leakage inductance causes the voltage to rise to the voltage clamp of the IGBT. Figure 11. Clamping period after dwell time © 2016 Fairchild Semiconductor Corporation 16 RD-576 • Rev. 1.0 10.3. Max-dwell function and Soft Shutdown (SSD) Adjust the pulse width for a time longer than max dwell time associated with the selected CSSD capacitor. Once the device enters SSD after the max dwell time, any change in the signal will not be noticed on the output until the current is fully discharged. CSSD Vs Time can be found in the FAN1100_F085 datasheet. Figure 12. Max dwell and soft shutdown © 2016 Fairchild Semiconductor Corporation 17 RD-576 • Rev. 1.0 11. Conclusions In RD-576, the evaluation board for an ignition application has been presented. Schematics and layout have been shown and some relevant test results have been shared. The test setup has been suggested and some safety advices have been given. This information must be sufficient for an experienced electronic system designer to set the evaluation running. With help of the devices datasheets and the application note AN-8208, a designer can even fine tune the circuitry according to his needs and that could be a very good initial point for the design of the final application. Please consider that the present document and the evaluation board itself are meant to be a reference design to support the customer during the first stages of design. The board has been evaluated just under certain conditions and assumptions that differ to an automotive final application. © 2016 Fairchild Semiconductor Corporation 18 RD-576 • Rev. 1.0 12. Related Resources AN-8208 Introduction to Automotive Ignition Systems FAN1100_F085 Product Page FGD3040G2_F085 Product Page Automotive Ignition Webpage Authors: Jose Padilla – Product Marketing Manager Qingquan Tang – Applications Engineer Mitchell Henry – Applications Engineer Reference Design Disclaimer Fairchild Semiconductor Corporation (“Fairchild”) provides these reference design services as a benefit to our customers. Fairchild has made a good faith attempt to build for the specifications provided or needed by the customer. Fairchild provides this product “as is” and without “recourse” and MAKES NO WARRANTY, EXPRESSED, IMPLIED OR OTHERWISE, INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Customer agrees to do its own testing of any Fairchild reference designs in order to ensure design meets the customer needs. Neither Fairchild nor Customer shall be liable for incidental or consequential damages, including but not limited to, the cost of labor, requalifications, rework charges, delay, lost profits, or loss of goodwill arising out of the sale, installation or use of any Fairchild product. Subject to the limitations herein, Fairchild will defend any suit or proceeding brought against Customer if it is based on a claim that any product furnished hereunder constitutes an infringement of any intellectual property rights. Fairchild must be notified promptly in writing and given full and complete authority, information and assistance (at Fairchild’s expense) for defense of the suit. Fairchild will pay damages and costs therein awarded against Customer but shall not be responsible for any compromise made without its consent. In no event shall Fairchild’s liability for all damages and costs (including the costs of the defense by Fairchild) exceed the contractual value of the products or services that are the subject of the lawsuit. In providing such defense, or in the event that such product is held to constitute infringement and the use of the product is enjoined, Fairchild, in its discretion, shall procure the right to continue using such product, or modify it so that it becomes noninfringing, or remove it and grant Customer a credit for the depreciated value thereof. Fairchild’s indemnity does not extend to claims of infringement arising from Fairchild’s compliance with Customer’s design, specifications and/or instructions, or the use of any product in combination with other products or in connection with a manufacturing or other process. The foregoing remedy is exclusive and constitutes Fairchild’s sole obligation for any claim of intellectual property infringement and Fairchild makes no warranty that products sold hereunder will not infringe any intellectual property rights. All solutions, designs, schematics, drawings, boards or other information provided by Fairchild to Customer are confidential and provided for Customer’s own use. Customer may not share any Fairchild materials with other semiconductor suppliers. © 2016 Fairchild Semiconductor Corporation 19 RD-576 • Rev. 1.0