1 1 - psg-online.de

advertisement

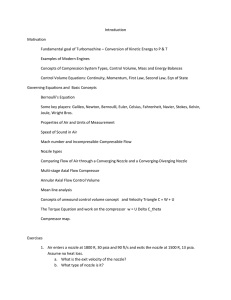

Thermoject® Nozzles - Premium Big Shot-Series 2076 HK/OH - Valve gate DNZ + DNZL Low heater price and quick availability With this generously dimensioned melt channel geometry and the innovative heating technology the processing of nearly all plastic types and a large application spectrum from 400 g up to 3,000 g is possible (relating to low viscosity materials). By sheathing the nozzle flange with a heat conduction, the number of heaters could be reduced. Using similar heaters in standard lengths lowers the price and increases the availability. HK = protective tube shortend 1 Low-stress injection molding reduces the reject loss For nearly all plastic types and shot weights from 400 g up to 3,000 g 2 The exact heater positioning and the adjustment of the heat capacity to the stepless nozzle length ensure a homogeneous temperature profile OH = without protective tube Technical Data: •Electrical connection: 230 Volt •Thermocouple: FeCu-Ni (type J) •Max. injection pressure: 1800 bar Materials: 1 •Nozzle body, nozzle head, valve pin: tempered steel •Wear resistant treatment for pos. 2 on request 2 Stock list: 1 Nozzle body 1.1 Heat conduction tube 2 Nozzle head DNZ 3 Valve pin (not part of delivery) 4 Support disc (not for OH) 5 Protective tube (not for OH) 6 Absorption ring (not for OH) 7 Locking ring (not for OH) 8 Location ring (not for OH) 9-11 Heater with integrated thermocouple and wedge lock (leads 3m/5m) 12 Operating Unit (not part of delivery) Section "X" Needle valve Type DNZ and DNZL Important Notice: The tool must be grounded! If the nozzle is operated outside the tool, the nozzle must be grounded. We reserve the right to make technical changes PSG Plastic Service GmbH • P.O. Box 42 01 62 • 68280 Mannheim • Germany Phone +49 621 7162-0 • Fax +49 621 7162-162 • www.psg-online.de • info@psg-online.de 05/11 Nozzle dimensions Big Shot 2076 HK/OH - DNZ/DNZL: 4 3 SW/head 6 8 7 9 1 2 SW/nozzle 5 1 AO=A-expansion 10 1 2 4 5 6 7 8 9 M SW / nozzle SW / head Heater Art.-No., Pos.9 Heater Art.-No., Pos.10 Heater Art.-No., Pos.11 54 M 42x1.5 50 41 332927 332927 - 70 54 M 42x1.5 50 41 332928 332927 - 22 61 54 M 42x1.5 50 41 332928 332927 - 293805-320 22 70 54 M 42x1.5 50 41 332928 332928 - 2076 OH A>240≤320 293804-320 22 61 54 M 42x1.5 50 41 332928 332928 - 2076 HK A>320≤450 293805-450 22 70 54 M 42x1.5 50 41 332928 332928 332928 2076 OH A>320≤450 293804-450 22 61 54 M 42x1.5 50 41 332928 332928 332928 2076 HK A>450≤600 293805-600 22 70 54 M 42x1.5 50 41 332928 332928 332928 2076 OH A>450≤600 293804-600 22 61 54 M 42x1.5 50 41 332928 332928 332928 2076 HK A>600≤800 293805-800 22 70 54 M 42x1.5 50 41 332928 332928 332928 2076 OH A>600≤800 293804-800 22 61 54 M 42x1.5 50 41 332928 332928 332928 Order description nozzle 2076, Pos.1-11 (without Pos.2 and 3) Article no. Ød1 (standard) 2076 OH A≥110≤150 293804-150 22 61 2076 HK A>150≤240 293805-240 22 2076 OH A>150≤240 293804-240 2076 HK A>240≤320 3 ØD1 ØD2 •The number of control circuits per nozzle depends on the nozzle length. Marking consecutively by starting at the gate (max. 3). Use 4 control circuits per nozzle for heat sensitive plastics, see PSG's specification •The number of control circuits per nozzle can be determined from the "Heating" section on the above table. •By specifying the mold measurement A, with details of the molding material, the nozzle dimension A0 will be made, allowing for expansion. * Dimensions see datasheet "Operating units". 1 2076 Ø d1 10 2076 b Ø 20 70 Ø 22 70 Manifold height b depends on melt channel Ød1. Nozzle head dimensions Big Shot 2076 HK/OH - DNZ/DNZL: cyl. Cone DNZL 0.3 needle overlap 1 3 2 Nozzle head, Pos. 2: Order description nozzle head 2076 Article no. DNZ 2072/76 294011 DNZL 2072/76 294011-* 1 2 3 L variable ØDg6 SW ØOH7 standard - 30 41 Ø 6.0 20/50 30 41 Ø 6.0 Note: ØO=4.5 OX available for extra costs. * Article no. for dimension L elongated: L = 0≤20 / Art.-No. nozzle head - 020 L > 20≤50 / Art.-No. nozzle head - 050 L > 50≤100 / Art.-No. nozzle head - 100 ** Cone angle in parentheses (10°) is available for extra cost Dimensions and installation dimensions, Duct for wiring: Duct for wiring Article no. BxH Cross section (mm2) Type 1 165670 35x41 1254 Type 2 165672 37x11 264 Type 3 165674 30x31 784 Type 4 165676 24x31/41 856 Type 6 165680 17x29 405 Type 7 165682 35x60 1881 revolving Example: DNZL 2072/76, L=30mm, Art.-no. 294011-050 Duct for wiring Manifold BxH = depending on the size of the system. (Clarify with PSG!) Duct for wiring Installation dimensions Big Shot 2076 HK/OH - DNZ/DNZL: 6 7 8 9 5 3 4 1 2 1 2 3 4 5 6 7 8 9 A L B T Ø DH7 Ø P3 Ø P2 Ø P1 ØP 2076 HK 150 ≤ 240 max. 100 variabel 80 12.5 30 43 60 76 115 2076 HK >240 - 800 max. 100 variabel 110 12.5 30 43 60 76 115 2076 OH 110 ≤ 150 max. 100 variabel 80 12.5 30 43 60 70 115 2076 OH >150 - 800 max. 100 variabel 110 12.5 30 43 60 70 115 Series Minimum nozzle length A1 depending on manifold's inside dimensions (x/y): While heating up the screwed-in nozzle an extra bending moment is built up on the nozzle axis because of the manifold's linear expansion. The bending moment depends on the inside dimension of the nozzle (direct flow way from the center per example sprue bush to inside dimension). Further more the bending moment depends on the ∆T (melt temperature - tool temperature) Assumed ∆T = 250°C. Minimum A1 = inside dimension (x/y) (valid A1 > 150-820) 2 Notice: If A1= 130≤150 (please contact PSG) Measurement details: General tolerances DIN ISO 2768 mK. Contact height with elongation nozzle head Big Shot 2076 - DNZL: Contact height [mm] DNZL nozzle head - contact height Elongation L [mm] These are guide values, depending on cooling and injection process. (Upgrading is possible) PP, PE(1), PMMA, ABS, PS, PD, PC/ABS, ASA, SAN, TPE .. PP+GF, PA6, PA12, PC, POM, PPO,TPU ------- PA6+GF,PBT, PC/PBT, SMA, SMA+GF, PES, PES+GF, PSU, PSU+GF, PEI, PEI+GF (all (2)) --- --- PA6.6 (3), PA6.6+GF (3) Contour Exemption (1) For PE, without elongation L, heightening contact up to 8mm for Big Shot 2076 (2) Min. elongation L=10mm (3) Min. elongation L=15mm Contact height "K" adjustment by customer by following the contour. (If the chamfer >30° then please contact PSG). A = Nozzle length L = Elongation K = Contact height Install and construction note: •Cooling must be provided close to the gate, with circulating water. On the moving side of the mold a fountain type cooling, opposite to the gate should be used. •The front face of the nozzle head must be completely in the melt. Where the gate is on a sub runner, a thin disc should be molded immediately in front of the nozzle head. •Reduce the contact surface to the tool in the area of the nozzle head if you use elongated nozzle heads. Please see diagram "Contact height for elongated nozzle heads DNZL." Connecting Leads: Connecting leads of the nozzles are heat resistant max. up to 200°C and may not have direct contact to the beam of the manifold. Spare parts Big Shot 2076 HK/OH - DNZ/DNZL: Series Heater band with wedge lock* and integrated thermocouple, Pos. 9-11 Article no. 2076 RPI Ø45x35 / 275 W / AS: 3000 332927 2076 RPI Ø45x35 / 275 W / AS: 5000 332927-1 2076 RPI Ø45x65 / 500 W / AS: 3000 332928 2076 RPI Ø45x65 / 500 W / AS: 5000 332928-1 (*) Equipment see nozzle dimensions. AS=connection lenght Order example: Nozzle (pos. 1-11, without pos. 2 and 3) 2076 OH 360 293804-450 PP Series Execution Mold dimension A Article no. Please state plastic type or tool and processing temperature Nozzle head (pos. 2): DNZL 2072/76 Ø O=6.0 L=50 Art.-No. 294011-050 Gate type Series Gate diameter Please state elongation L only for DNZL Article no. •The hot runner nozzle is supplied complete with nozzle head fitted! •Please be sure to observe the numbering of the control circuits before shortening the cables!