Concrete Anchor Design: IBC & ACI 318 Guide

advertisement

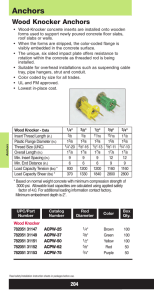

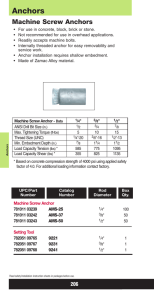

Concrete Anchor Design for the International Building Code (800) 999-5099 | www.strongtie.com Purpose The intent of this technical bulletin is to clarify code language and outline the correct path for the design of concrete anchors under the International Building Code (IBC). The reader will be able to clearly distinguish between “code anchors” and anchors that are considered “alternative materials,” as well as understand the logical sequence of code language for designing each type. The distinction between “cracked” concrete and “uncracked” concrete anchor design will be made. This technical bulletin will lend clarity to the qualification of post-installed anchors for use in concrete. Excerpts from the IBC and its Referenced Standards will be provided to facilitate the description of the design requirements. Background More than a decade after the introduction of the American Concrete Institute’s ACI 318, Appendix D design methodology for anchor design in 2002, many design professionals either do not fully understand or are unaware of the code requirements for the design of concrete anchors. Several factors contribute to the challenges associated with understanding the code mandates: 1. The incorrect notion that ACI 318, Appendix D is exclusively for anchors designed for “cracked concrete,” leading to regionally varying degrees of enforcement and implementation of the design requirements 2. Multiple Reference Standards for the design and qualification of different anchor types 3. The evolving scope of Reference Standards, which have reclassified some anchors as “Code Anchors” that were previously considered “Alternative Materials” 4. Confusing language in IBC sections that address concrete anchorage 5. Complexity of the anchor design methodology itself 6. Varying levels of special inspections enforcement It is nevertheless incumbent upon the licensed design professional to design anchors in accordance with the minimum provisions of the code in order to protect public safety, reduce liability risk and fulfill professional responsibilities. The International Building Code, beginning with the 2000 edition, describes the design methodology of concrete anchors by virtue of the language within the IBC itself, or through language in the Referenced Standard (ACI 318). In this technical bulletin, specific reference to the 2012 IBC and ACI 318-11 will be made, since this is currently the most widely adopted edition of the IBC. 2 | Concrete Anchor Design for the International Building Code © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 “Code Anchors” and “Alternative Materials” Anchors can be divided into two major categories: 1) “Code Anchors”, which are those that are specifically addressed in the IBC or its Referenced Standards, and 2) “Alternative Materials”, the design and qualification of which are not addressed in the IBC or its Referenced Standards. The following “Code Anchors” recognized by the 2012 IBC: •• Headed studs •• Headed bolts •• Hooked (J- or L-) bolts •• Expansion anchors (such as Simpson Strong-Tie® Strong-Bolt® 2) Headed Studs Headed Bolts Hooked (J- or L-) Bolts •• Undercut anchors (such as Simpson Strong-Tie® Torq-Cut™) •• Adhesive anchors (such as Simpson Strong-Tie® SET-XP ®, AT-XP ®, and ET-HP ®) Strong-Bolt® 2 Torq-Cut™ AT-XP® SET-XP® ET-HP® Anchor types not listed above are considered “Alternative Materials.” The following are anchors qualified as such: •• Screw anchors (such as Simpson Strong-Tie® Titen HD®) Alternative materials also apply to anchor types specifically excluded from ACI 318-11 calculation and analysis requirements. •• Specialty inserts (such as Simpson Strong-Tie® Blue Banger Hanger®) •• Through-bolts •• Multiple anchors connected to a single steel plate at the embedded end •• Grouted anchors Titen HD® PDPA GDP Blue Banger Hanger® •• Powder- or gas-actuated fasteners (such as Simpson Strong-Tie® PDPA) Heli-Tie™ Helical Wall Tie Grouted Anchors © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Through-Bolts Multiple Anchors Connected to a Single Steel Plate at the Embedded End Concrete Anchor Design for the International Building Code | 3 Designing “Code Anchors” The starting point for the design of all anchors is Section 1908 of the 2012 IBC. SECTION 1908 Anchorage To Concrete — Allowable Stress Design 1908.1 Scope. The provisions of this section shall govern the allowable stress design of headed bolts and headed stud anchors cast in normal-weight concrete for purposes of transmitting structural loads from one connected element to the other. These provisions do not apply to anchors installed in hardened concrete or where load combinations include earthquake loads or effects. The bearing area of headed anchors shall not be less than one and one-half times the shank area. Where strength design is used, or where load combinations include earthquake loads or effects, the design strength of anchors shall be determined in accordance with Section 1909. Bolts shall conform to ASTM A 307 or an approved equivalent. International Code Council (ICC) authorized reprint from 2012 IBC, “International Building Code” Section 1908.1 states that only cast-in-place headed bolts and headed studs are permitted to be designed using “Allowable Stress Design,” provided that they are not used to resist earthquake loads or effects. For these anchors, Section 1908.2 references Table 1908.2 for the determination of the allowable service load. Section 1908.1 makes explicit reference to post-installed anchors (anchors installed into hardened concrete), stating that the provisions of “Allowable Stress Design” is not permitted. For the design professional, this means that determining anchor performance by means of “Allowable Load Tables” based on previous test criteria that used a safety factor of 4.0 to determine allowable loads, as in the example below, is not permitted under the IBC. 4 | Concrete Anchor Design for the International Building Code © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Section 1909 of the 2012 IBC, “Anchorage to Concrete – Strength Design” makes explicit reference to Appendix D of ACI 318 as the required design standard for the anchors listed in this section. SECTION 1909 Anchorage To Concrete — Strength Design 1908.1 Scope. The provisions of this section shall govern the strength design of anchors installed in concrete for purposes of transmitting structural loads from one connected element to the other. Headed bolts, headed studs and hooked (J- or L-) bolts cast in concrete and expansion anchors and undercut anchors installed in hardened concrete shall be designed in accordance with Appendix D of ACI 318 as modified by Sections 1905.1.9 and 1905.1.10, provided they are within the scope of Appendix D. The strength design of anchors that are not within the scope of Appendix D of ACI 318, and as amended in Sections 1905.1.9 and 1905.1.10, shall be in accordance with an approved procedure. International Code Council (ICC) authorized reprint from 2012 IBC, “International Building Code” Cast-in-place headed bolts and headed studs used to resist earthquake loads or effects must be designed using “Strength Design” in accordance with ACI 318 Appendix D. Additionally, Section 1909 does not make reference to adhesive anchors, despite their status as “code anchors.” ACI 318-11 was the first edition to include adhesive anchors in its scope; however, the 2012 IBC was approved prior to the approval of ACI 318-11. This resulted in the omission of adhesive anchors from the language in Section 1909 of the 2012 IBC. Section 1901.3 of the 2015 IBC, entitled “Anchoring to Concrete” includes language for adhesive anchors and their applicability to the ACI 318-14 design and qualification requirements. The omission of adhesive anchors from Section 1909 of the 2012 IBC, however, does not exclude them from the design and qualification requirements of ACI 318-11 by virtue of their inclusion in ACI 318-11 Section D.2.2. The design professional must then reference Section D.2 of ACI 318-11, Appendix D to confirm that the anchors being designed fall within its scope. D.2 — Scope D.2.1 — This appendix provides design requirements for anchors in concrete used to transmit structural loads by means of tension, shear, or a combination of tension and shear between: (a) connected structural elements; or (b) safety-related attachments and structural elements. Safety levels specified are intended for in-service conditions, rather than for short-term handling and construction conditions. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” Note that anchors used for temporary construction means, such as tilt wall panel bracing, are not addressed in the IBC. As a result, they are not required to be designed in accordance with the provisions of ACI 318, Appendix D. Section D.2.2 lists anchor types that fall within its scope, and those that are excluded (considered “Alternative Materials”). D.2.2 — This appendix applies to cast-in anchors and to post-installed expansion (torquecontrolled and displacement-controlled), undercut, and adhesive anchors. Adhesive anchors shall be installed in concrete having a minimum age of 21 days at time of anchor installation. Specialty inserts, through-bolts, multiple anchors connected to a single steel plate at the embedded end of the anchors, grouted anchors, and direct anchors such as powder or pneumatic actuated nails or bolts are not included in the provisions of Appendix D. Reinforcement used as part of the embedment shall be designed in accordance with other parts of this Code. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Concrete Anchor Design for the International Building Code | 5 Code Anchors are required to meet the ACI 318-11 Section D.2.3 qualification requirements described below. D.2.3 — Design provisions are included for the following types of anchors: (a) Headed studs and headed bolts having a geometry that has been demonstrated to result in a pullout strength in uncracked concrete equal to or exceeding 1.4Np, where Np is given in Eq. (D-14); (b) Hooked bolts having a geometry that has been demonstrated to result in a pullout strength without the benefit of friction in uncracked concrete equal to or exceeding 1.4Np, where Np is given in Eq. (D-15); (c) Post-installed expansion and undercut anchors that meet the assessment criteria of ACI 355.2; and (d) Adhesive anchors that meet the assessment criteria of ACI 355.4. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” ACI 355.2 (qualification standard for expansion and undercut anchors) and ACI 355.4 (qualification standard for adhesive anchors) are referenced here as the qualification criteria for specific types of postinstalled anchors. For the design professional it can be difficult to determine, without fully investigating these Referenced Standards, whether a specific proprietary anchor has been tested and is qualified for use in concrete. A simpler means by which to identify whether a proprietary anchor has been qualified to the Referenced Standard is a current Research Report (e.g., Evaluation or Code Report) which provides third-party review and verification that the product has been tested to and meets the qualification standard. There are two primary Research Report providers: IAPMO UES (International Association of Plumbing & Mechanical Officials Uniform Evaluation Service) and ICC-ES (International Code Council Evaluation Service). These agencies are ANSI ISO 17065 accredited. They review independent laboratory test data, witnessed or conducted by an accredited third party, for a product and verify its conformance to publicly developed and majority-approved qualification criteria (or acceptance criteria) established for a given anchor type. Research Reports are an invaluable tool to the design professional and building official as evidence of conformance with the IBC. There are two acceptance criteria that apply to post-installed “Code Anchors”: •• ICC-ES AC193 – Acceptance Criteria for Post-Installed Mechanical Anchors in Concrete Elements •• ICC-ES AC308 – Acceptance Criteria for Post-Installed Adhesive Anchors in Concrete Elements These acceptance criteria reference ACI 355.2 and ACI 355.4, respectively, as the foundation for the test program by which the anchor is evaluated, and establish minimum performance standards for qualification. A Research Report is issued for an anchor that meets these minimum standards. Designing “Alternative Materials” Concrete anchor types whose designs are not addressed in the IBC or its Referenced Standards, or are specifically excluded from the scope of the Referenced Standard (ACI 318-11), may be recognized as Alternative Materials. Section 1909 of the 2012 IBC requires that “The strength design of anchors that are not within the scope of Appendix D of ACI 318, shall be in accordance with an approved procedure.” Section D.2.2 of ACI 318-11 lists some concrete anchor types that are considered “Alternative Materials” and specifically excludes these anchors from its scope. The list of “Alternative Material” anchors provided in this section is not, however, a comprehensive list. Section 104.11 of the 2012 IBC describes how the design professional must approach the design of Alternative Materials. 6 | Concrete Anchor Design for the International Building Code © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Section 104.11 [A] 104.11 Alternative materials, design and methods of construction and equipment. The provisions of this code are not intended to prevent the installation of any materials or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved. An alternative material, design or method of construction shall be approved where the building official finds that the proposed design is satisfactory and complies with the intent of the provisions of this code, and that the material, method or work offered is, for the purpose intended, not less than the equivalent of that prescribed in this code in quality, strength, effectiveness, fire resistance, durability and safety. Where the alternative material, design or method of construction is not approved, the building official shall respond in writing, stating the reasons why the alternative was not approved. [A] 104.11.1 Research reports. Supporting data, where necessary to assist in the approval of materials or assemblies not specifically provided for in this code, shall consist of valid research reports from approved sources. [A] 104.11.2 Tests. Wherever there is insufficient evidence of compliance with the provisions of this code, or evidence that a material or method does not conform to the requirements of this code, or in order to substantiate claims for alternative materials or methods, the building official shall have the authority to require tests as evidence of compliance to be made at no expense to the jurisdiction. Test methods shall be as specified in this code or by other recognized test standards. In the absence of recognized and accepted test methods, the building official shall approve the testing procedures. Tests shall be performed by an approved agency. Reports of such tests shall be retained by the building official for the period required for retention of public records. International Code Council (ICC) authorized reprint from 2012 IBC, “International Building Code” Section 104.11 provides the design professional with two options for the substantiation of the acceptable performance of an Alternative Material: a. Research Reports. As described in the previous section (Design of Code Anchors), Research Reports are referenced as the primary source for the design and qualification of Alternative Materials. Research Reports for anchors are published by IAPMO UES or ICC-ES, both ANSI ISO 17065 accredited agencies. Publicly developed, majority-approved acceptance criteria are used to establish the test program and minimum performance requirements for an anchor type. Some Alternative Material anchor types have established acceptance criteria to which a product can be evaluated: •• Screw Anchors in Concrete (such as Simpson Strong-Tie® Titen HD®): ICC-ES AC193 •• Headed Cast-in Specialty Inserts (such as Simpson Strong-Tie® Blue Banger Hanger ®): ICC-ES AC446 •• Powder- or Gas-Actuated Fasteners (such as Simpson Strong-Tie® PDPA and GDP): ICC-ES AC70 If Research Reports are used to substantiate an anchor’s performance, the design professional is bound by the design methodology and product limitations described in the Research Report. b.Tests. If a Research Report is not available, and no acceptance criteria exists for a given anchor type, IBC Section 104.11 permits the use of tests performed in accordance with “recognized and accepted test methods” by an “approved agency” to substantiate performance. One example of an anchor type for which no acceptance criteria exists is: •• Helical Wall Ties (such as Simpson Strong-Tie® Heli-Tie™) © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Concrete Anchor Design for the International Building Code | 7 Cracked Concrete Determination One of the many design considerations that the design professional must determine when designing either “Code Anchors” or anchors qualified as “Alternative Materials” is whether to consider the state of the concrete “cracked” or “uncracked.” The concrete state can significantly influence the anchor’s capacity. Neither the IBC nor ACI 318, Appendix D explicitly defines which applications should be categorized as “cracked” or “uncracked” concrete. The design professional must determine by analysis whether cracking will occur in the region of the concrete member where the anchors are installed. Absent an analysis to determine whether cracking will occur, the design professional may conservatively assume that the concrete state is “cracked.” With that said, there are two circumstances that require the design professional to design for “cracked” concrete: a) Anchors in structures assigned to Seismic Design Categories C, D, E, or F (per 2012 IBC, Chapter 16) are required to be designed for “cracked” concrete unless the design professional can demonstrate that cracking does not occur at the anchor locations. The prequalification requirements of ACI 355.2 for mechanical anchors and ACI 355.4 for adhesive anchors include a test program that evaluates the performance of anchors in cracked concrete. Only anchors that have been tested and have passed the cracked concrete test program qualify for use in “cracked” concrete. The Research Report for a post-installed anchor (mechanical or adhesive) will clearly indicate whether it qualifies for use in “cracked concrete.” b) Anchors located in a region of the concrete element where analysis indicates cracking at service level loading must be designed for “cracked” concrete (e.g. f r ≥ 7.5λ√f'c , ACI 318-11 eq. 9-10). The design professional must consider additional factors that have the potential to result in concrete cracking in the region of anchorage. These factors include restrained shrinkage, temperature changes, soil pressure, and differential settlement. If no cracking is assumed in the region of the anchorage, the design professional should be able to justify that assumption. Design Calculations The design methodology in ACI 318 Appendix D is cumbersome. Calculations can be performed by hand using the design equations in Appendix D, inserting the substantiated data from an anchor manufacturer’s data tables or Research Reports to design with post-installed anchors. Designing with cast-in-place “Code Anchors” does not require additional data beyond what is included in ACI 318, Appendix D since these are “standard” anchors with standard design characteristics. Performing hand calculations can be time-consuming, and for most design professionals is impractical due to the complexity of the design equations associated with multiple failure modes required to be considered. Design software, such as Simpson Strong-Tie® Anchor Designer™ Software for ACI 318, ETAG and CSA provides a fast, reliable method of calculating anchor performance for both cast-in-place and post-installed anchors. This software designs both “Code Anchors” and “Alternative Materials” for which an acceptance criteria exists. 8 | Concrete Anchor Design for the International Building Code © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Simpson Strong-Tie® Anchor Designer™ Software for ACI 318, ETAG and CSA is free and can be downloaded here: strongtie.com/anchordesigner. Specification of Concrete Anchors The 2012 IBC and its Referenced Standard, ACI 318-11, is the first to mandate that contract documents specifically address installation, inspections and design parameters of concrete anchorage. For this reason, the specification of anchors in drawing details alone is impractical. To fully and effectively address these code mandates, concrete anchorage is more practically specified in both drawing detail(s) and the General Structural Notes or specifications of the contract documents. The drawing detail(s) would typically call out the anchor type, material specification, diameter, and embedment depth. The General Structural Notes or specifications would include the name of the qualified anchor(s) and address the installation, inspections and design parameter requirements of ACI 318-11. The following sections of ACI 318-11 discuss the contract document requirements for concrete anchorage: D.9.1 – Anchors shall be installed by qualified personnel in accordance with the contract documents. The contract documents shall require installation of post-installed anchors in accordance with the Manufacturer’s Printed Installation Instructions (MPII). Installation of adhesive anchors shall be performed by personnel trained to install adhesive anchors. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Concrete Anchor Design for the International Building Code | 9 The commentary in ACI 318-11, RD.9.1 discusses the sensitivity of anchor performance to proper installation. It emphasizes the importance of qualified installers for all anchors, and compliance with the Manufacturer’s Printed Installation Instructions (MPII) for post-installed anchors. Training is required for adhesive anchor installers per ACI 318-11 D.9.1. Simpson Strong-Tie Co. Inc. provides free installer training by experienced Technical Sales Representatives for our adhesive, mechanical and specialty anchors. Contact us at 1-800-999-5099. Special inspection and proof loading are addressed in ACI 318-11 D.9.2 and D.9.2.1. D.9.2 – Installation of anchors shall be inspected in accordance with 1.3 and the general building code. Adhesive anchors shall be subject to the following additional requirements: D.9.2.1 – For adhesive anchors, the contract documents shall specify proof loading where required in accordance with ACI 355.4. The contract documents shall also specify all parameters associated with the characteristic bond stress used for the design according to D.5.5 including minimum age of concrete; concrete temperature range; moisture condition of concrete at the time of installation; type of lightweight concrete, if applicable; and requirements for hole drilling and preparation. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” Per the section above, anchor installation requires inspection per Section D.9.2. In addition, the design parameters for adhesive anchors are required to be specified in the contract documents. An explanation of the design parameters listed in ACI 318-11 D.9.2.1 is provided below: 1. Proof loading where required in accordance with ACI 355.4. Proof loading is only required for adhesive anchors loaded in tension in which the inspection level chosen for the adhesive anchor design is “Continuous” (Ref. ACI 355.4 Section 10.4.6). Selecting “Continuous Inspection” can result in a higher “Anchor Category,” which in turn results in a higher strength reduction factor, φ. Reference Section 13.3.4 of ACI 355.4 for the minimum requirements of the proof loading program, where required. The Design Professional is responsible for determining the quantity, the duration of the applied load, and the proof load to which the anchors will be tested. These parameters will be specific to the anchor design conditions. 2. Minimum age of concrete at time of anchor installation. Per ACI 318 D.2.2, adhesive anchors must be installed in concrete having a minimum age of 21 days at time of anchor installation. Simpson Strong-Tie® has performed in-house testing of SET-XP®, AT-XP®, and ET-HP® adhesive anchors installed in 7-day- and 14-day-old concrete. The results of testing are published in an engineering letter (L-A-ADHGRNCON15.pdf), which can be viewed and downloaded at www.strongtie.com. 3. Concrete temperature range. This is the in-service temperature of the concrete into which the adhesive anchor is installed. Temperature Ranges are categorized as 1, 2 or 3. Some manufacturers use A, B, or C as the category designations. Each Temperature Range category has a maximum short-term concrete temperature and a maximum long-term concrete temperature. Short-term concrete temperatures are those that occur over short intervals (diurnal cycling). Long-term concrete temperatures are constant temperatures over a significant time period. 4. Moisture condition of concrete at time of installation. Moisture conditions, as designated by ACI 355.4, are “dry” or “water-saturated.” Moisture condition impacts the characteristic bond stress of an adhesive. 5. Type of lightweight concrete, if applicable. 6. Requirements for hole drilling and preparation. These requirements are specific to the adhesive, and are described in the Manufacturer’s Printed Installation Instructions (MPII). Reference to the MPII in the contract documents is sufficient. 10 | Concrete Anchor Design for the International Building Code © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Adhesive anchors installed in a horizontal or upwardly inclined orientation that resist sustained tension loads require a “certified” installer. D.9.2.2 – Installation of adhesive anchors horizontally or upwardly inclined to support sustained tension loads shall be performed by personnel certified by an applicable certification program. Certification shall include written and performance tests in accordance with ACI/CRSI Adhesive Anchor Installer Certification program, or equivalent. D.9.2.3 – The acceptability of certification other than the ACI/CRSI Adhesive Anchor Installer Certification shall be the responsibility of the licensed design professional. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” A certification program has been established by ACI/CRSI. Installers can obtain certification by successful completion of this program. Contact your local ACI or CRSI chapter for more information. Other means of certification are permitted, and are the responsibility of the licensed design professional. The installation of adhesive anchors in a horizontal or upwardly inclined orientation presents unique challenges to the installer. Simply put, the effects of gravity for these applications make it difficult to prevent air bubbles and voids, which can limit full adhesive coverage of the insert (threaded rod or reinforcing bar). Due to the increased installation difficulty of these anchors, they are required to be continuously inspected by a certified special inspector. D.9.2.4 – Adhesive anchors installed in horizontal or upwardly inclined orientations to resist sustained tension loads shall be continuously inspected during installation by an inspector specifically approved for that purpose by the building official. The special inspector shall furnish a report to the licensed design professional and building official that the work covered by the report has been performed and that the materials used and the installation procedures used conform with the approved contract documents and the manufacturer’s printed installation instructions. American Concrete Institute authorized reprint from ACI 318-11, “Building Code Requirements for Structural Concrete and Commentary” Suggested General Structural Notes or specifications for post-installed anchors can be viewed and downloaded at http://www.strongtie.com/products/anchorsystems/technicalinfo/ suggested-specs.html, or contact a Simpson Strong-Tie® representative for help with your post-installed General Structural Notes or specifications. © 2015 SIMPSON STRONG-TIE COMPANY INC. T-A-CADG15 Concrete Anchor Design for the International Building Code | 11 Simpson Strong-Tie Suggested General Note for Anchor Products Post-Installed Anchors into Concrete, Masonry and Steel and Cast-in-Place Anchors into Concrete The below products are the design basis for this project. Substitution requests for products other than those listed below may be submitted by the contractor to the Engineer-of-Record (EOR) for review. Substitutions will only be considered for products having a code Report recognizing the product for the appropriate application and project building code. Substitution requests shall include calculations that demonstrate the substituted product is capable of achieving the equivalent performance values of the design basis product. Contractor shall contact manufacturer’s representative (800-999-5099) for product installation training and a letter shall be submitted to the EOR indicating training has taken place. Refer to the building code and/or evaluation report for special inspections and proof load requirements. 1. For anchoring into cracked and uncracked concrete a)Mechanical anchors shall have been tested in accordance with ACI 355.2 and/or ICC-ES AC193 for cracked concrete and seismic applications. Pre-approved products include: i. Simpson Strong-Tie® Strong-Bolt® 2 (ICC-ES ESR-3037) ii. Simpson Strong-Tie® Titen HD® (ICC-ES ESR-2713) iii. Simpson Strong-Tie® Torq-Cut® (ICC-ES ESR-2705) iv. Simpson Strong-Tie® Titen HD® Rod Hanger (ICC-ES ESR-2713) v. Simpson Strong-Tie® Blue Banger Hanger® (ICC-ES ESR-3707, except roof deck insert) b)Adhesive anchors shall have been tested in accordance with ACI 355.4 and/or ICC-ES AC308 for cracked concrete and seismic applications. Adhesive anchors shall be installed by a certified adhesive anchor installer where designated on the contract documents. Pre-approved products include: i. Simpson Strong-Tie® AT-XP® (IAPMO-UES ER-263) ii. Simpson Strong-Tie® SET-XP® (ICC-ES ESR-2508) III. Simpson Strong-Tie® ET-HP® (ICC-ES ESR-3372) *These anchor design provisions also apply to building codes that use the International Building Code as the model code, such as the Florida Building Code and the North Carolina Building Code. This flier is effective until December 31, 2017, and reflects information available as of November 1, 2015. This information is updated periodically and should not be relied upon after December 31, 2017; contact Simpson Strong-Tie for current information and limited warranty or see www.strongtie.com. © 2015 Simpson Strong-Tie Company Inc. • P.O. Box 10789, Pleasanton, CA 94588 T-A-CADG15 11/15 exp. 12/17 800-999-5099 www.strongtie.com