Flow Control Valves Contents

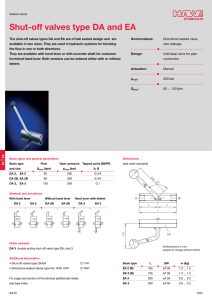

advertisement