HERE - Forum Energy Technologies

advertisement

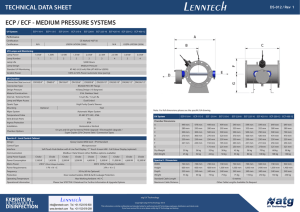

C H O K E / / VA LV E C O N T R O L / / 2 0 1 2 Choke/Control Valves EXPERIENCE, DEDICATION AND VISION Introducing Forum Energy Technologies – a global provider of manufactured technologies and applied products and services. We may be a new name to you but our equipment and employees have a long history of solving our customers’ challenges. FET brings together some of the most well-known brands in our industry with an extensive range of mission critical products and services. We are building a world class company to bring innovative solutions to our worldwide customers. With offices in the key oilfield distribution centers of the globe, Forum is well-positioned to supply our clients with the equipment and related services that improve safety and performance and lower operating costs. Forum’s products and services range from the underwater reservoir to the refinery, from the sea floor to the above ground transportation line. We pride ourselves on giving you a comprehensive offering of solutions to maximize your operations and improve your bottom line. Our customers are our partners and we work with them to solve their ever-changing challenges. Choke/Control Valves FORUM provides a broad range of chokes/control valves, to meet most applications from basic manual operated to fully automated systems. As the industry continues to increase technology demands, operators select FORUM to obtain best-in-class service, performance and value. We are ISO-9001 certified, thus assuring design and manufacturing of the highest quality products available in the market. Model BAP // Page 2 - 6 Model BTE // Page 2 - 7 Model BEAP // Page 8 - 9 • 2” and 3” Sizes • A487 Carbon Steel or 316 Stainless Steel Bodies • NPT, Butt Weld and Flanged End Connections • Tungsten Carbide or Ceramic Discs • • • • • • • • 1”, 2”, 3” and 4” Sizes A487 Carbon Steel or 316 Stainless Steel Bodies NPT, Butt Weld and Flanged End Connections Tungsten Carbide or Ceramic Discs 2” Size A487 Alloy Steel or Carbon Steel NPT Tungsten Carbide or Ceramic Discs FORUM Inline Choke // Page 10 - 12 BLF Inline Choke // Page 13 - 14 • • • • • • • • 1” and 2” Sizes A487 Carbon Steel, Aluminum Bronze or 316 Stainless Steel NPT, Union End and Flanged End Tungsten Carbide or Ceramic Discs 1” Size 316 Stainless Steel NPT Connection Ceramic Discs // 01 Choke/Control Valves Model BAP // BTE // Choke // Control Valve Forum Energy Technologies have designed trim assemblies to interchange between our Inline Model BTE and Angle Pattern BAP. The top entry design enables easy conversion from manual to automated. FEATURES AND BENEFITS OF MODEL BAP CHOKE/CONTROL VALVES • • • • • • • • • • • • • • • • Quarter-turn disc/turning fork valve Easily actuated Discs available in Ceramic for standard service and Tungsten Carbide for extreme erosive service Bodies available in corrosion-resistant, high strength Cast Steel or 316 Stainless Steel Top entry enables replacement of internal parts while in the well flow line Available with Tungsten Carbide wear sleeves & discs for high-pressure drops Several orifice sizes available Manual adapter cap locking mechanism Unique two adjustable pressure drops Inhibits freeze-up for natural gas service with staged pressure drops breaking up ice crystals Kam-Lok wear sleeve/turning fork to install or remove complete trim in one operation Impinging 180 degree flow characteristics Removable handle Cost effective Lubricated and built rugged for extened service life HSN Sealing components available as an option for sour gas service CONNECTIONS • • • Butt Weld FNPT Threaded Flanged End - Raised Face (RF) and Ring Type Joint (RTJ) ANSI Class 600, 900, 1,500, 2,500 and API 3,000 5,000 and 10,000 STANDARD TRIM • • • • • • 02 // ASTM A487 High Strength Cast Steel Body AISI 4130 Steel Bonnet 90 Durometer Peroxide Cured Nitrile Seals Ceramic Disc 99.5% Al2O3 17-4 PH Turning Fork 316 Stainless Steel Wear Sleeve APPLICATIONS • • • • • • • • • • • • • • Wellhead control valve/choke Wellhead choke to help reduce hydrates Pump bypass control Remote control (actuated) of wellhead flow lines Water and CO2 injection wellhead control valve Gas storage wellhead Gas lift injection control valve Gas plant flow control valve Back pressure valve on bottom hole pump Remote control valve on directional drilling Pump start-up Sales gas line Gas blowdown line Automated line heater choke Choke/Control Valves BTE/BAP Specifications Item 1 Item 2 BALL [1] HANDLE [1] Item 5 Item 7 HEX HEAD CAP SCREW [1] LOCK SCREW [1] Item 6 Item 4 SPLIT LOCK WASHER [1] INDICATOR PIN [2] Item 3 Item 8 ADAPTER CAP MANUAL [1] O-RING [1] Item 11 Item 12 HEX SOCKET HEAD CAP SCREW [6] ASSEMBLY PIN [2] Item 10 Item 15 BONNET* [1] O-RING [1] Item 13 Item 9 GREASE FITTINGS [1] BACK UP RING [1] Item 16 Item 8 THRUST WASHER [1] O-RING [1] Item 17 TURNING FORK [1] Item 20 Item 21 ORIFICE DISK* [2] O-RING [2] Item 14 Item 22 DOWEL PIN [1] WEAR SLEEVE ASSY W/ TUNGSTEN CARBIDE INSERT [1] Item 18 Item 23 MACHINE SCREW [2] O-RING [1] Item 19 INDICATOR BAND* [1] Item 26 BODY* [1] Item 27 BODY SLEEVE [1] Item 24 BLEEDER PLUG [1] Item 25 Item 28 RETAINER NUT [1] O-RING [1] Item Description 1 Handle Ball Stop 2 Handle 3 Manual Adapter Cap 4 Indicator Pin for Adapter Cap 5 Hex Socket Head Cap Screw for Adapter Cap 6 Split Lock Washer 7 Handle Lock Screw 8 Seal for Turning Fork Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 9 Back up Ring for Lower Turning Fork Seal 10 Bonnet* 11 Hex Socket Head Cap Screw for Bonnet 12 Indicator Pin for Bonnet/Body 13 Grease Fitting 14 Dowel Pins 15 Seal for Bonnet Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 16 Thrust Bearing 17 Turning Fork** Standard Increased Flow For 72/64” Pie Disk 18 Hex Head Slotted Self Tapping Screw 19 Indicator Band 1/8” 3/16” 1/4” 3/8” 44.5/64 Pie 1/2” 9/16” 54/64” Pie 61/64” Pie 72/64” Pie 20 Disk See page 5 for options 21 Disk Seal Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 22 Wear Sleeve Assembly Standard With Carbide Insert For 72/64” Pie Disk 23 Wear Sleeve Seal Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 24 Pressure Relief Plug 25 Seal for Pressure Relief Plug Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 26 Body See page 5 for options 27 Body Sleeve Threaded End (optional) Flanged End Weld End 28 Retainer for Body Sleeve Standard (optional) Weld End 1 inch 2 inch 3 inch 051969500 051961200 051962820 051963200 WWG1180S0 WWK118000 WWG50B1H0 WWB206P41 WWB206V40 WWB206HN2 WWB206KR1 WWB206AFL WWD206T10 051962730 WWG11H18N 051963200 WWW00C000 WWLA060HH WWB224P41 WWB224V40 WWB224HN2 WWB224KR1 WWB224AFL 051969120 051968224 N/A N/A WWGG0618F 051970601 051970606 051970602 051970603 051970604 N/A N/A N/A N/A N/A 051969500 051961200 051960300 051961000 WWG11B100 WWK11B000 WWG11B2SS WWB210P41 WWB210V40 WWB210HN2 WWB210KR1 WWB210AFL WWD210T10 052120830 WWG11M1HN 051961000 WWW00C000 WWLA060HH WWB227P41 WWB227V40 WWB227HN2 WWB227KR1 WWB227AFL 051969430 051961524 052119435 052118635 WWGG0618F 051961601 051961609 051961602 051961603 N/A 051961604 051961607 051961605 051961606 051961613 051969500 051961200 051960300 051961000 WWG11B100 WWK11B000 WWG11B2SS WWB210P41 WWB210V40 WWB210HN2 WWB210KR1 WWB210AFL WWD210T11 052120830 WWG11M1HN 051961000 WWW00C000 WWLA060HH WWB227P41 WWB227V40 WWB227HN2 WWB227KR1 WWB227AFL 051969430 051961524 052119435 052118635 WWGG0618F 051961601 051961609 051961602 051961603 N/A 051961604 051961607 051961605 051961606 051961613 WWB126P41 WWB126V40 WWB126HN2 WWB126KR1 WWB126AFL 051968134 N/A N/A WWB223P41 WWB223V40 WWB223HN2 WWB223KR1 WWB223AFL N/A N/A N/A N/A N/A N/A WWB132P41 WWB132V40 WWB132HN2 WWB132KR1 WWB132AFL 051961434 052070434 052118534 WWB226P41 WWB226V40 WWB226HN2 WWB226KR1 WWB226AFL 051988780 WWB014P41 WWB014V40 WWB014HN2 WWB014KR1 WWB014AFL WWB132P41 WWB132V40 WWB132HN2 WWB132KR1 WWB132AFL 051961434 052070434 052118534 WWB226P41 WWB226V40 WWB226HN2 WWB226KR1 WWB226AFL 051988780 WWB014P41 WWB014V40 WWB014HN2 WWB014KR1 WWB014AFL N/A N/A N/A N/A N/A 051975100 051976400 051975100 N/A N/A 051975100 051976400 051975100 052131320 052137620 *A487 High Strength Carbon Steel bodies listed. 1”, 2”, & 3” Size BTE Bodies and Bonnets are also available in 316 Stainless. Nickel Plating is also available upon request. Special Connections and Dimensions can be requested per customer needs upon request. **Standard Material for Turning Fork is Stainless Steel, but Nitronic 50 is also available. BAP // 03 Choke/Control Valves Specifications BTE 4” Item Item 3 Item 4 INDICATOR PINS [2] Item 5 ADAPTER CAP MANUAL [1] Item 6 SPLIT LOCK WASHER [1] HEX HEAD CAP SCREW [1] Item 8 Item 1 O-RING [1] BALL [1] Item 19 INDICATOR BAND* [1] Item 2 Item 18 HANDLE [1] MACHINE SCREW [2] Item 10 Item 11 BONNET* [1] HEX SOCKET HEAD CAP SCREW [6] Item 13 GREASE FITTINGS [1] Item 22 Item 23 DOWEL PINS [4] Item 9 HEX HEAD CAP SCREW [1] Item 15 O-RING [1] BACK UP RING [1] Item 16 THRUST WASHER [1] Item 21 O-RING [2] Item 8 O-RING [1] Item 17 TURNING FORK [1] Item 20 ORIFICE DISK* [2] Item 27 BLEEDER PLUG [1] Item 28 Item 25 O-RING [1] Item 24 O-RING [1] CAGE ASSEMBLY [1] Item 12 ASSEMBLY PINS [2] **Standard Material for Turning Fork is Stainless Steel, but Nitronic 50 is also available. Item 29 BODY SLEEVE [1] Item 26 BODY* [1] Item 30 RETAINER FOR BODY SLEEVE [1] 04 // Description 1 Handle Ball Stop 2 Handle 3 Manual Adapter Cap 4 Indicator Pin for Adapter Cap 5 Hex Socket Head Cap Screw for Adapter Cap 6 Split Lock Washer 7 Handle Lock Screw (not shown) 8 Seal for Turning Fork Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 9 Back up Ring for Lower Turning Fork Seal 10 Bonnet* 11 Hex Socket Head Cap Screw for Bonnet 12 Indicator Pin for Bonnet/Body 13 Grease Fitting 14 Dowel Pins (not shown) 15 Seal for Bonnet Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 16 Thrust Bearing 17 Turning Fork** Standard 18 Hex Head Slotted Self Tapping Screw 19 Indicator Band 48/64” 64/64” (1.00) 96/64” 112/64” 126/64” Pie 20 Disk See page 5 for options 21 Disk Seal Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 22 Hex Socket Head Cap Screws for Cage 23 Dowel Pins for Bonnet 24 Cage Assembly 25 Cage Seal Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 26 Body See page 5 for options 27 Pressure Relief Plug 28 Seal for Pressure Relief Plug Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 29 Body Sleeve Threaded End Flanged End Weld End 3” FNPT 30 Retainer for Body Sleeve Standard 3” FNPT 4 inch 051969500 005196120 052181020 051961000 WWG11B100 WWK11B000 WWG11B3HS WWB218P41 WWB218V40 WWB218HN2 WWB218KR1 WWB218AFL WWD124T10 052180630 WWG11S2HM 051961000 WWW00C000 WWLA060HH WWB242P41 WWB242V40 WWB242HN2 WWB242KR1 WWB242AFL 052181100 052168580 WWGG0618F 052172202 052172204 052172206 052172208 052172209 WWB153P41 WWB153V40 WWB153HN2 WWB153KR1 WWB153AFL WWG5180HS WWLA080HH 052178400 WWB240P41 WWB240V40 WWB240HN2 WWB240KR1 WWB241AFL 051988780 WWB014P41 WWB014V40 WWB014HN2 WWB014KR1 WWB014AFL 052180700 052180700 052180700 052171500 052180800 052171620 Choke/Control Valves BTE Options BTE/BAP Item Description 1 inch 2 inch 3 inch 4 inch 20 Ceramic Disk Tungsten Carbide Disk 26 BTE Body* 1/8” 3/16” 1/4” 3/8” 44.5/64 Pie 1/2” 9/16” 54/64” Pie 61/64” Pie 72/64” Pie 1/8” 3/16” 1/4” 3/8” 44.5/64 Pie 1/2” 9/16” 54/64” Pie 61/64” Pie 72/64” Pie 48/64” 64/64” (1.00) 96/64” 112/64” 126/64” Pie FNPT (5000 psi) 3” FNPT Union End BW 1.88 ID BW SCH XXS 600 RF 600 RTJ 900 RF 900 RTJ 1500 RF 1500 RTJ 2500 RF 2500 RTJ 5000 RTJ 2 1/16 - 10K RTJ 600 RF WN 600 RTJ WN 900 RF WN 900 RTJ WN 1500 RF WN 1500 RTJ WN 2500 RF WN 2500 RTJ WN 051963522 051963523 051963524 051963526 051970820 N/A N/A N/A N/A N/A 051963542 051963543 051963544 051963546 051970840 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 051962620 N/A 052198520 N/A N/A N/A N/A 051964020 051972020 051964020 051972020 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 051962122 051962123 051962124 051962126 N/A 051962128 051962129 051962020 051961320 051983620 051962142 051962143 051962144 051962146 N/A 051962148 051962149 051962040 051961340 051983640 N/A N/A N/A N/A N/A 051975320 N/A N/A 052096620 N/A 052098720 052090420 051977320 051976520 051977320 051976520 052144320 052133220 051976520 052077520 N/A N/A N/A N/A N/A N/A 052096900 052127300 051962122 051962123 051962124 051962126 N/A 051962128 051962129 051962020 051961320 051983620 051962142 051962143 051962144 051962146 N/A 051962148 051962149 051962040 051961340 051983640 N/A N/A N/A N/A N/A N/A N/A N/A N/A 051984420 N/A N/A 052203920 052207520 052118020 052118120 N/A 052187120 052179920 N/A 052178820 052179720 052180525 N/A N/A N/A N/A 051994725 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 052172142 052172144 052172146 052172148 052178540 N/A 052171420 N/A N/A 052168410 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 052196525 052195925 052196025 052206920 052196225 052176125 N/A 052196325 *A487 High Strength Carbon Steel bodies listed. 1”, 2”, & 3” Size BTE Bodies and Bonnets are also available in 316 Stainless. Nickel Plating is also available upon request. Special Connections and Dimensions can be requested per customer needs upon request. BAP Options Item Description 2 inch 3 inch 20 Ceramic Disk 1/8” 3/16” 1/4” 3/8” 1/2” 9/16” 54/64” Pie 61/64” Pie 72/64” Pie 051962122 051962123 051962124 051962126 051962128 051962129 051962020 051961320 051983620 051962122 051962123 051962124 051962126 051962128 051962129 051962020 051961320 051983620 1/8” 3/16” 1/4” 3/8” 1/2” 9/16” 54/64” Pie 61/64” Pie 72/64” Pie 051962142 051962143 051962144 051962146 051962148 051962149 051962040 051961340 051983640 051962142 051962143 051962144 051962146 051962148 051962149 051962040 051961340 051983640 FNPT (5000 psi) BW SCH XXS 600 RF 600 RTJ 900 RF 900 RTJ 1500 RF 1500 RTJ 1500 RTJ WN 2500 RF WN 2500 RTJ WN 2 1/16 - 5K RTJ 3 1/8 - 5K RTJ WN 2 1/16 - 10K RTJ 2 9/16 - 10K RTJ WN 052076725 052097725 052128815 052204325 052143625 052069825 052143625 052069825 N/A 052189125 052223025 052069825 N/A 052081020 N/A N/A 052088120 052182725 N/A N/A N/A N/A N/A 052088325 N/A 052173520 N/A 052088325 N/A 052209820 Tungsten 26 Carbide Disk BAP Body* *A487 High Strength Carbon Steel bodies listed. 2” Size BAP Bodies are also available in 316 Stainless, as are Bonnets. BAP Bodies are available with Nickel Plating upon request. Special Connections and Dimensions like those required in ANSI B16.10 can be requested per customer needs upon request. // 05 Choke/Control Valves Model BAP Dimensions and Requirements BAP Dimensions and Requirements F D A C B Patent Numbers 5217046 and 5365978 A Dimensions Size 2” A B C D FNPT BW SCH XXS ASME/ANSI B16.5 600 RF 600 RTJ 900 RF / 1500 RF 900 RTJ / 1500 RTJ 2500 RF WN API 6A 2 1/16 - 5K RTJ 2 1/16 - 10K RTJ ASME/ANSI B16.10 900 RTJ/1500 RTJ 12 12 15 15 15 15 16 15 15 14 4.00 4.00 6.88 6.88 6.88 6.88 8.00 6.88 7.14 7.31 5.00 5.00 8.00 8.00 8.00 8.00 9.00 2.05 2.05 8.00 8.26 7.31 2.05 2.05 Size 3” BW SCH XXS ASME/ANSI B16.5 600 RF 1500 RTJ WN 2500 RTJ WN API 6A 3 1/8 - 5K RTJ WN 2 9/16 - 10K RTJ WN ASME/ANSI B16.10 1500 RTJ WN 12 15 17 19 17 16 16 4.00 6.90 9.37 11.19 9.37 9.04 9.31 5.00 8.00 10.37 12.00 2.05 10.37 9.04 9.31 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05 2.05 Flange Requirements D B C Patent Numbers 5217046 and 5365978 06 // Size 2” Flange Diameter Bolt Size Bolt Quantity Bolt Circle Ring Type FNPT BW SCH XXS ASME/ANSI B16.5 600 RF 600 RTJ 900 RF / 1500 RF 900 RTJ / 1500 RTJ 2500 RF WN API 6A 2 1/16 - 5K RTJ 2 1/16 - 10K RTJ ASME/ANSI B16.10 900 RTJ/1500 RTJ N/A N/A N/A N/A N/A N/A N/A N/A 5.00 5.00 6.50 6.50 6.75 N/A R-23 N/A R-24 N/A 8.50 7.88 8.50 7/8 3/4 7/8 N/A N/A 8 8 8 8 8 8 8 8 6.50 6.25 R-24 BX-152 6.50 R-24 Size 3” BW SCH XXS ASME/ANSI B16.5 600 RF 1500 RTJ WN 2500 RTJ WN API 6A 3 1/8 - 5K RTJ WN 2 9/16 - 10K RTJ WN ASME/ANSI B16.10 1500 RTJ WN N/A N/A N/A N/A 6.63 8.00 9.00 N/A R-35 R-32 8.00 7.25 R-35 BX-153 8.00 R-35 6.50 6.50 8.50 8.50 9.25 5/8 5/8 7/8 7/8 1 8.25 10.50 12.00 3/4 1-1/8 1-1/4 10.50 9.12 10.50 1-1/8 7/8 1-1/8 N/A 8 8 8 8 8 8 Choke/Control Valves Model BTE Dimensions and Requirements A End to End Dimensions (A) Connection/Size 1 inch 2 inch 3 inch 4 inch FNPT (3705 psi) FNPT (5000 psi) 3” FNPT Union End BW 1.88 ID BW SCH XXS BW SCH 120 600 RF 600 RTJ 900 RF 900 RTJ 1500 RF 1500 RTJ 2500 RF 2500 RTJ 5000 RTJ 2 1/16 - 10K RTJ 600 RF WN 600 RTJ WN 900 RF WN 900 RTJ WN 1500 RF WN 1500 RTJ WN 2500 RF WN 2500 RTJ WN 9.50 9.50 N/A 9.00 N/A N/A N/A N/A N/A 12.50 12.50 12.50 12.50 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 9.38 9.38 N/A N/A 7.89 N/A N/A 14.50 14.50 14.50 14.63 14.50 14.63 18.63 18.75 14.63 14.63 N/A N/A N/A N/A N/A N/A 17.38 18.00 N/A N/A N/A N/A N/A 8.75 N/A N/A N/A 17.75 18.63 18.50 18.63 N/A 23.00 18.63 N/A 15.88 16.00 17.25 N/A N/A N/A N/A 23.01 N/A N/A 16.63 N/A N/A 16.63 16.63 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 25.50 25.62 26.50 26.37 27.26 27.38 N/A 32.88 Models BTE and BAP Class 600, 900, 1500, 2500, and 5000 API Torque Requirements 1 in. w/ Ceramic or Tungsten Trim 2 in. & 3 in. w/ Ceramic or Tungsten Trim 4 in. w/ Tungsten Trim 1,000 psi Differential Pressure = 11 ft.-lbf. or 130 in.-lbf. 1,000 psi Differential Pressure = 34 ft.-lbf. or 408 in.-lbf. 1,000 psi Differential Pressure = 106 ft.-lbf. or 1,275 in.-lbf. 2,000 psi Differential Pressure = 19 ft.-lbf. or 223 in.-lbf. 2,000 psi Differential Pressure = 50 ft.-lbf. or 604 in.-lbf. 2,000 psi Differential Pressure = 165 ft.-lbf. or 1,975 in.-lbf. 3,000 psi Differential Pressure = 26 ft.-lbf. or 315 in.-lbf. 3,000 psi Differential Pressure = 67 ft.-lbf. or 799 in.-lbf. 3,000 psi Differential Pressure = 223 ft.-lbf. or 2,674 in.-lbf. 4,000 psi Differential Pressure = 34 ft.-lbf. or 408 in.-lbf. 4,000 psi Differential Pressure = 83 ft.-lbf. or 994 in.-lbf. 4,000 psi Differential Pressure = 281 ft.-lbf. or 3,374 in.-lbf. 5,000 psi Differential Pressure = 42 ft.-lbf. or 501 in.-lbf. 5,000 psi Differential Pressure = 99 ft.-lbf. or 1,189 in.-lbf. 5,000 psi Differential Pressure = 340 ft.-lbf. or 4,074 in.-lbf. // 07 Choke/Control Valves Forum Economical Angle Pattern Choke (BEAP) This economical angle pattern control valve was designed for longevity, performance, and versatility. The BEAP is an ANSI Class 1500 with a working pressure of 3,705 psi and a test pressure of 5,558 psi. The BEAP features are 1/4-turn open/close travel with a self-impinging flow path, directing the erosive kinetic energy away from the valve walls. All bonnets are drilled and tapped to incorporate an actuator bracket at the time of order, or at a later date. For the operator’s safety, a pressure relief port with plug is standard equipment to ensure a depressurized valve for dismantling purposes. A greasing zerk allows o-rings to be properly lubricated without disassembly. The manual adapter cap contains a locking mechanism to set turning fork position. The versatile bean sizes for this choke, range from 11/64ths to 61/64ths, offered in ceramic disks for standard service and tungsten carbide disks for erosive service. A tungsten carbide lined discharge port is available as an option. The A487 4D alloy steel body construction is nearly twice the yield strength of standard A216 WCB carbon steel fittings. Trim components of 17-4PH martensitic stainless steel are superior to typical 316 stainless steel items in wear and tensile strength. FEATURES AND BENEFITS OF MODEL BTE CHOKE/CONTROL VALVES • • • • • • • • 08 // 2” NPT class 1500 connections CV’s range from 0.7 to 22.6 Low alloy steel construction Drilled and tapped bonnet for actuation Actuation kits available Tungsten carbide trim available for maximum life in an extreme erosive service Gas blowdown line Automated line heater choke Specifications Working Pressure 3705 psi Test Pressure 5558 psi Temperature Range -20 oF to 275 oF Maximum Operating Torque 42 ft-lbs Weight 14 lbs Choke/Control Valves Forum Economical Angle Pattern Choke (BEAP) Item 6 O-RING [1] Item 11 HEX HD SLOTTED SELF TAP [2] Item 17 INDICATOR DISK [1] Item 8 RETAINER [1] Item 12 GREASE ZERK [1] Item 10 BONNET [1] Item 7 BACK-UP RING [1] Item 14 THRUST WASHER [1] Item 9 O-RING [1] Item 15 TURNING FORK [1] Item 13 Item 22 O-RING [1] BODY [1] Item 21 PLUG [1] Item 19 O-RING [2] Item 18 Item 16 DISK [2] DOWEL PINS [4] Specifications Item Description 1 Manual Adapter Cap 2 Indicator Pin for Adapter Cap 3 Hex Socket Head Cap Screw for Adapter Cap 4 Split Lock Washer 5 Hex Socket Head Set Screw (Cup Point) 6 Seal for Turning Fork Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 7 Back up Ring for Lower Turning Fork Seal 8 Retainer 9 Seal for Retainer Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 10 Bonnet 11 Hex Head Slotted Self Tapping Screw 12 Grease Fitting 13 Seal for Bonnet Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 14 Thrust Bearing 15 Turning Fork 16 Dowel Pins 17 Indicator Disk 1/8” 1/4” 3/8” 1/2” 9/16” 54/64” Pie 61/64” Pie 18 Ceramic Disk 1/8” 1/4” 3/8” 1/2” 9/16” 54/64” Pie 61/64” Pie Tungsten Carbide Disk 1/8” 1/4” 3/8” 1/2” 9/16” 54/64” Pie 61/64” Pie 19 Disk Seal Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 20 Wear Sleeve Options MNPT (Class 1500) MNPT with Insert FNPT (Class 1500) 21 Pressure Relief Plug 22 Body See chart below for acuation options available. 2 inch 052156220 052156400 WWG11B100 WWK11B000 WWG50B1H0 WWB113P41 WWB113V40 WWB113HN2 WWB113KR1 WWB113AFL WWD210T10 052156120 WWB210P41 WWB210V40 WWB210HN2 WWB210KR1 WWB210AFL 052156020 WWGG0618F WVA116340 WWB124P41 WWB124V40 WWB124HN2 WWB124KR1 WWB124AFL 051969430 052155980 WWLA060HH 052156301 052156302 052156303 052156304 052156305 052156306 052156307 051962122 051962124 051962126 051962128 051962129 051962020 051961320 051962142 051962144 051962146 051962148 051962149 051962040 051961340 WWB132P41 WWB132V40 WWB132HN2 WWB132KR1 WWB132AFL 052155820 052168320 052174920 WWS120DSS 052155720 BEAP Actuator Components Item 20 WEAR SLEEVE [2] Actuator ASAHI Model A92 Centura and VALVCON 600 Power Flex PF Actuator Bracket 052167700 052167700 052171820 Actuator Coupling 052167820 052168920 052168620 Hex Head Cap Screw for Bonnet WWG31B0MA WWG31B0MA WWG31B0MA Hex Head Cap Screw for Actuator WWGJ0816B WWGJ0816B WWG41B0MA M8-1.25 x 16 M8-1.25 x 16 5/16-24UNF x .63 // 09 Choke/Control Valves Forum Inline Choke The Forum Inline Choke, formerly the Delta Inline Choke, is designed specifically for controlling gas and liquid flowline rates. Water and CO2 systems are designed to control the rate of fluid injection. The stellite sleeve absorbs the cavitation and pitting action of the fluid as it takes the pressure drop. The sleeve design allows the thickest material around the disc holes and is funnel-shaped to direct the flow back into the center of the piping. SIZES 1 in. and 2 in. CONNECTIONS • • • • • • Threaded ANSI 600 and 900/1500 Flanged Grooved Union x Socket Weld Union x Union Socket Weld x Socket Weld ACTUATION Available upon request. STANDARD TRIM Body: Disc: Body Seals: Rotator Seals: Disc Pins: ASTM A216 WCB Steel or ASTM B148 Aluminum Bronze Grade 955 D Alloy or CF8M 316 Stainless Steel or CF3M 316 L Stainless Steel Ceramic Al2O3 for applications to 400 psi Tungsten Carbide for applications above 600 psi Type 1, Grade 1 PTFE Fluorocarbon 90 Durometer A Peroxide Cured Nitrile O-Ring with Type 1, Grade 1 PTFE Fluorocarbon Back-Up Ring Monel Wearsleeve: Stellite 6B APPLICATIONS Wellhead control valve/choke Wellhead choke to help reduce hydrates PRESSURE RATING FNPT ANSI 600 ANSI 900/1500 10 // 3,705 psi Working Pressure 1,480 psi Working Pressure 3,705 psi Working Pressure 5,575 psi Test Pressure 2,225 psi Test Pressure 5,575 psi Test Pressure Choke/Control Valves Forum Inline Choke (DELTA) Specifications Item Item 7 DOWEL DISK PINS [4] Item 11 DISC* [2] Item 7 Item 12 DOWEL DISK PINS [4] O-RING [1] Item 3 CAP SCREWS [6] Item 16 HUB ASSEMBLY* [1] Item 2 HANDLE [1] Item 15 BODY* [1] Item 1 SNAP RING [1] Item 4 GREASE FITTING [1] Item 10 INDICATOR BAND [1] Item 13 Item 9 O-RING [1] MACHINE SCREWS [2] Item 5 O-RING [2] Item 8 ROTATOR [1] Description 1 Snap Ring 2 Handle 3 Hex Head Cap Screw for Hub/Body 4 Grease Fitting 5 Seal for Rotator Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 6 Back up Ring for Rotator Seal 7 Dowel Pins 8 Rotator** Aluminum Bronze 316 Stainless Steel 9 Hex Head Slotted Self Tapping Screw 10 Indicator Band 1/8” 1/4” 3/8” 1/2” 5/8” 11 Ceramic Disk 1/8” 1/4” 3/8” 1/2” 5/8” Tungsten Carbide Disk 1/8” 1/4” 3/8” 1/2” 5/8” 12 Disk Seal 13 Seal for Hub/Body 14 Wear Sleeve (not shown) Optional Stellite Tungsten Carbide 15 Body* Threaded Union End XX = Socket Weld 20 for Steel Grade WCB Grooved End ‘ES’ Sch 80 60 for Aluminum Bronze 600 RF 80 for 316 Stainless Steel 600 RTJ 900/1500 RF 900/1500 RTJ 16 Hub* Threaded Union End XX = Socket Weld 20 for Steel Grade WCB Grooved End ‘ES’ Sch 80 60 for Aluminum Bronze 600 RF 80 for 316 Stainless Steel 600 RTJ 900/1500 RF 900/1500 RTJ 17 Union Adapter+ (not shown) Threaded Socket Weld 18 Nut for Union+ (not shown) 1 inch 2 inch WWC510075 051938500 WWG31H1HN WWW00C000 WWB223P41 WWB223V40 WWB223HN2 WWB223KR1 WWB223AFL WWD223T1A WWLA060HH 051938660 051938680 WWGG0618F 051938402 051938404 051938406 051938408 051938409 051938322 051938324 051938326 051938328 051938329 051938342 051938344 051938346 051938348 051938349 WWB224T10 WWB227T10 W51938201 W51938240 0519371XX 0519372XX 0519870XX N/A N/A N/A N/A N/A 0519379XX 0519380XX 0519876XX N/A N/A N/A N/A N/A 051939909 051957909 051940000 WWC510075 051938500 WWG31H1HN WWW00C000 WWB223P41 WWB223V40 WWB223HN2 WWB223KR1 WWB223AFL WWD223T1A WWLA060HH 051938660 051938680 WWGG0618F 051938402 051938404 051938406 051938408 051938409 051938322 051938324 051938326 051938328 051938329 051938342 051938344 051938346 051938348 051938349 WWB224T10 WWB227T10 W51938201 W51938240 0519373XX 0520784XX 0520871XX 0519840XX 0519374XX 0519460XX 0519375XX 0519458XX 0519381XX 0520785XX 0520872XX 0519839XX 0519376XX 0519461XX 0519377XX 0519459XX 051940508 052079409 051940600 *Bodies and Hubs are available in 316 Stainless, Aluminum Bronze, and Grade WCB Steel. Nickel Plating is also available upon request. **Standard Material for Rotator is Stainless Steel. +These are only included for bodies and hubs that are Union Ended Item 6 BACK-UP RING [2] // 11 Choke/Control Valves Forum Inline Choke Dimensions B Inline Choke Assembly Dimensions Union End / Threaded Dimension (in.) Description B 1 in. Inline Choke 6-9/16 in. 2 in. Inline Choke 6-9/16 in. A Inline Choke Assembly Flanged End B B A A Inline Choke Assembly Threaded End, Socket Weld Inline Choke Assembly Union End End to End Dimensions (A) 1” Threaded 8.93 2” Threaded 10.05 1” Union End (w/ Adapters) 10.21 2” Union End (w/ Adapters) 11.55 1” Socket Weld 8.93 2” Socket Weld 10.05 2” Grooved ‘ES’ Schedule 80 10.05 2” - 600 RF 10.44 2” - 600 RTJ 10.56 2” - 900/1500 RF 10.44 2” - 900/1500 RTJ 10.56 12 // Choke/Control Valves Forum Model BLF Low Flow Inline Choke For Economical Control of Wellhead Injection Rates With SPD’s new, improved Model BLF Low Flow Inline Choke, your enhanced oil recovery project can also benefit from enhanced economy. That’s because the new BLF is designed to handle the low flow and low pressure drops that characterize CO2 and water injection operations. Simple, Inline flow characteristics make the BLF Inline Choke unsurpassed for reducing and/or controlling flow rates on gas and liquid lines near the wellheads. Stainless steel bar stock construction makes the BLF less susceptible to porosity leaks. FEATURES AND BENEFITS • • • Connection: 1 in. FNPT Maximum working pressure: 3,705 psi (ANSI Class 1500) Maximum recommended pressure differential: 500 psi • Dimensional Length: 7.38 in. AVAILABLE IN THE FOLLOWING CHOKE SIZES: Orifice Size Holes Equivalent Flow Area (in2) Equivalent 64 th Estimated Cv 1/8 in. 0.0246 11.3 0.7 1/4 in. 0.0982 22.6 3.33 3/8 in. 0.2208 33.9 6.0 6.56 Ø2.00 Ø3.70 7.38 // 13 Choke/Control Valves Forum BLF Product Specifications Item 3 CAP SCREWS [6] Item Description 1 Handle 2 Snap Ring 3 Hex Socket Head Cap Screw for Hub/Body 4 Grease Fitting 5 Seal for Rotator and Disk Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 6 Back up Ring for Rotator Seal 7 Dowel Pins 8 Rotator** 9 Hex Head Slotted Self Tapping Screw 10 Indicator Band 1/8” 1/4” 3/8” 11 Ceramic Disk 1/8” 1/4” 3/8” Tungsten Carbide Disk 1/8” 1/4” 3/8” 12 Seal for Body/Hub Connection Buna-N Fluoroelastomer HSN Perfluoroelastomer Aflas® 13 Body* Threaded FNPT 14 Hub* Threaded FNPT Item 14 HUB F/1” BLF [1] Item 5 O-RING [3] Item 7 DOWEL DISK PINS [4] Item 11 DISC* [2] Item 12 O-RING [1] Item 8 **Standard Material for Rotator is Stainless Steel, but is also available in 1018/1020 Carbon Steel. *Body and Hub are available in 1018/1020 Carbon Steel. ROTATOR [1] Item 5 O-RING [3] Item 6 BACK-UP RING [2] Item 7 Item 5 O-RING [3] DOWEL PIN [5] Item 13 BLF CHOKE BODY [1] Item 2 SNAP RING [1] Item 1 HANDLE [1] Item 9 SELF TAP SCREWS [2] 14 // Item 10 INDICATOR BAND [1] 1 inch 052089800 WWC510075 WWG11H1H6 WWW00C000 WWB220P41 WWB220V40 WWB220HN2 WWB220KR1 WWB220AFL WWD220T1A WWLA060HH 052089380 WWGG0618F 052089500 052089600 052089700 051963522 052089424 052089426 051963542 051963544 051963546 WWB224P41 WWB224V40 WWB224HN2 WWB224KR1 WWB224AFL 052089180 052089280 Nomograph for Gas Estimator for Flow Rate Connect two points then read third point UPSTREAM PRESSURE (PSI) 4000 3000 NATURAL GAS IN MCF/DAY 100000 80000 600000 40000 2000 20000 900 700 SINGLE ORIFICE CHOKE 1500 1000 800 600 450 400 300 200 150 8000 4000 2000 1000 600 400 10000 6000 3000 1500 800 500 300 200 100 60 150 80 50 BEAN SIZE IN 64 THS 200 175 160 150 140 130 120 110 100 90 80 75 70 65 60 55 50 45 40 35 30 25 23 21 19 17 15 13 11 40 70 100 80 60 30 8 50 20 10 9 8 7 6 10 5 5 4 40 24 22 20 18 16 14 12 2” CHOKE RANGE SEE CHART Choke/Control Valves 4 2 30 3 1 20 2 10 BTE/BAP/BEAP CHOKES HOLE SIZE (2) - 1/8” (2) - 3/16” (2) - 1/4” (2) - 3/8” (2) - 1/2” (2) - 61/64” (2) - 72/64” ROUND ROUND ROUND ROUND ROUND PIE PIE BTE/BAP/BEAP CHOKES FLOW RATED Cv Standard/Increased (Flow Coefficient) 0.70 1.74 2.60 8.40 12.7/17.3 IF 14.7/22.65 IF 28.04 CHOKE RANGE HOLE SIZE (2) - 1/8” (2) - 3/16” (2) - 1/4” (2) - 3/8” (2) - 1/2” (2) - 61/64” (2) - 72/64” EQUIVALENT BEAN SIZE 0.177 - 11.3/64” 0.265 - 17/64” 0.354 - 22.7/64” 0.530 - 34/64” 0.707 - 45.2/64” 0.953 - 61/64” 1.125 - 72/64” *Contact Engineering for Inline Choke Cv Values. // 15 Choke/Control Valves Nomograph for Water BEAN SIZE IN 64THS Estimator for Flow Rate Connect two points then read third point 200 175 WATER FLOW IN BBL/DAY 2000 1000 800 600 500 400 300 200 100 80 60 50 40 30 20000 10000 6000 50000 17200 15000 9400 8000 5500 4000 3000 2000 1500 800 500 300 100 60 1000 12200 7700 3900 2450 1740 1230 870 615 600 400 435 200 122 80 60 40 27 220 310 157 45 80 70 60 50 40 35 30 25 23 21 19 17 15 13 11 24 22 20 18 16 14 12 10 9 8 7 6 86 30 20 75 65 55 27500 30000 3000 100 2" CHOKE RANGE SEE CHART 40000 160 140 120 90 100000 70000 SINGLE ORIFICE CHOKE ACROSS CHOKE (PSI) 10000 8000 6000 5000 4000 3000 DOUBLE ORIFICE CHOKE PRESSURE DROP (∆P) 150 130 110 42 20 5 10 8 6 5 4 3 4 3 20 BTE/BAP/BEAP CHOKES HOLE SIZE (2) - 1/8” (2) - 3/16” (2) - 1/4” (2) - 3/8” (2) - 1/2” (2) - 61/64” (2) - 72/64” ROUND ROUND ROUND ROUND ROUND PIE PIE BTE/BAP/BEAP CHOKES FLOW RATED Cv Standard/Increased (Flow Coefficient) 0.70 1.74 2.60 8.40 12.7/17.3 IF 14.7/22.65 IF 28.04 *Contact Engineering for Inline Choke Cv Values. 16 // CHOKE RANGE HOLE SIZE (2) - 1/8” (2) - 3/16” (2) - 1/4” (2) - 3/8” (2) - 1/2” (2) - 61/64” (2) - 72/64” EQUIVALENT BEAN SIZE 0.177 - 11.3/64” 0.265 - 17/64” 0.354 - 22.7/64” 0.530 - 34/64” 0.707 - 45.2/64” 0.953 - 61/64” 1.125 - 72/64” Choke/Control Valves Drilling Sales Headquarters 8807 W. Sam Houston Pkwy N Houston, TX 77040 USA 713.351.7900 Regional Offices Unit 7, Murcar Industrial Estate Denmore Road, Bridge of Don Aberdeen AB23 8JW UK 44.1224.707800 Oilfields Supply Center, Building B-45 Jebel Ali Free Zone Dubai UAE 9714.8835266 506- 23a Avenue Nisku, Alberta T9A 8G2 Canada 780.955.1797 26 Soon Lee Rd Singapore 628 086 Singapore 65.6465.4850 Our goal is to become the leading provider of mission critical oilfield products and related services in terms of customer satisfaction, safety and financial performance. Our experienced management team and employees are dedicated to solving our customers’ problems. We invest in long term relationships and cooperate on product development with our clients, we consider them our partners. OUR CORE VALUES Integrity – In everything we do, in every interaction, both internally and externally, we strive to operate with the upmost integrity and mutual respect. Long-term view – We are building our company for the long-term, a company that we can be proud of. Open communication – We believe partnerships with our customers and co-workers must be based on trust, professionalism and transparency. Customer focused – Our products enhance our customer’s performance and we listen to their needs and work with them to solve their challenges. Good place to work – We are committed to creating a workplace that fosters innovation, teamwork and pride. Every team member is integral to our success and is treated equally and fairly. No one gets hurt – The safety of our employees and customers is our first priority coupled with a healthy respect for the environment. 920 Memorial City Way, Suite 800 Houston, TX 77024 281.949.2500 281.949.2554 [f] www.f-e-t.com 11/21