Amendment

advertisement

Industrial Cord

Cord & Cordset

e

Super Vu- Iron" Type G and Type G-GC Round

gooe (UL), 2000 Volt Portable Power Cable

Product Construction:

Conductor:

• 8 AWG thr0tJ9h 500 kcrrd ruBy anne~

stm:>ded

bare copper

Insulation:

• Premium-grade.

cotoo-cooeo 9O"C EPOM

• Color code: See cnart l>eIcr..,

• Insuls'.ed grounds and ground checks

Jacket:

• S~(

Vu-Troo- 900c. bfad<

- Teffipel1lttEe mrge: -4ll"C 10 .•!!O'c

3 CONDUCTOR

Jacket Marking:

TYPE G-GC (4/0 AND SMAllER)

CAROL SUPER VU-TIlOt.'" S!Z£ (mtn') TYPE

G-GC PORTABLE POW-t:R CABLE (Ul) 2000 V

DRY

WET 7S'C SUN RES P-7K-1230~9MSHA-CSA TYPE G--GC (-40"C) 2 KV FTS

MADE 1111

USA (TR\J-MARK SEQUENTIAl

fOOTAGE)

o TYPE G-GC {LAAGER

THAN .vO] (SIZf) TYPE G-GC CAROl SUPER VU-TROt-"

9O"C DRY ANO WATER RESISTANT 7S"C 2000

V SUN RES (Ut} P-7K-123C49MSHA LR271G1

MADE IN USA (TRU-MARK SEQUENTIAl

FOOTAGE)

-TYPEGCAROL SUPER VU-TRDN- SIZE {mm-l TYPE G

PORTABLE POWER CABLE (UL)60012000 V

DRY 9O"C WET 75"C SUN RES P-7l(-'23~9

MHSA - CSA TYPE G (--4O"C) 2 KV FTS MAOE

IN USA (TRU-MARK SEOUENTIAl

FOOTAGE)

o

CATALOG

HUMBSl

NO. AM>

OR

c:n

kanU

snwm

ItICIt:S

mm

olnduS:rial and light- to medium-duty

applca!ions

3

8

133

0.160

4.06

10

2#10

0.060

1.52 0.965 24.51

6S

3

6

259

0.198

5.03

10

2#10

0.060

1.52 1.020 25.91

87

170

82643

3

-1

259

0.245

6.22

10

2#8

0.060

1.52 1.125 28.58

114

1005

82663

3

2

259

0.297

7.54

10

2#7

0.1)60 2.03 1.315 33.40

152

14BO

82373

3

1

259

0.353

B.97

8

U6

0.080 2.03 1.445 36.10

177

1815

82383

3

110

259

0.385

9.78

8

2#5

0.080 2.03 1.570 39.88

205

2205

82393

3

210

259

0.442 11.23

8

2#4

0.080 2.03 1.660 42.16

237

2545

82403

3

310

259

0.480 12.19

a

2#3

0.080 2.03 1.810 45.97

274

3230

• Sunlight-reslsta.'I!

• TAU· Mar!(- seqoomial

footage m¥.<lng

Industry Approvals:

• UL Type G. G·GC

·CSA

• MSHA Ap;:rO\~

• RoHS Compliant

Packaging:

• Lengths cut to ordEr

!Of ."",.,cion

n ,,-:::or ~ pt'C9etly ".::Iec! Ofld

~'C1rnin:1ted.

.

•~

COLOR

CODE CHART

KO.Of

CONDUCTORS

3

4

COlOR

Black, Wtllle, Red

-

Black, White, Red. Orange

600

82413

3

410

259

0.555 14.10

8

2#2

0.080 2.03 1.920 48.77

316

3675

82423C'"

3

250

627

0.615 15.62

8

2~2

0.095 2.41 2.390 60.71

352

6060

82~

3

350

855

0.725

8

21:1/0

0.095 2.41 2.680 68.07

433

7400

2#210

0.095 2.41 3.030

536

10100

82473Cl1" 3

500

1235

18.42

0.880 22.35

8

CATAlOG

HUMBat

82314

NO.

AW&

~.

OR

.;

GRmI HOMUW.IHS..

CONn. l'lUCKN£SS

CONO.O.o_

NGIMNAlOJ).

AWG

kcmII ~~

8

76.96

- TYPE G - 600/2000 VOLT

4 CONDUCTOR

NOMItW.

• Excellen! impact and abrasion resista:1C9

WIlhstar(js exposure to oil adds. all<a!ies. heat.

mois1ure and most chemicals

• Suitable for ~01l1n

wa:¥'

• Indent-printed for easy i~lCa1ioo

• Rope lay simnding fof maximum fl& life

• Cable core bound lor superior IIeJcib;Ioty and

lOUghneas

" Non-wicking ruober filk!cs (G--GCI

• CEnadian COlor code available t.1>OflI'1>qUes1

AI'PIIOX.

CU!IR. NETWT.

82313

Features:

o

NOMttAtlHS.

IIIIfdIHAL

ntfCKItESS

OD.

COtfl).

AWGSIZE IN&HES mm IHCHES mm

82623

mining

• Heavy-duty service as po\V~1'supply ~

• Mobile and ~

eloctrical eq:i;:lmem

o 3- and <I·conductor-use

00 three·phase AC

systems wher!> grounding is required

WEN

MOO.,

A:~

COHO.OD.

CONI)..

so-c

Applications:

- TYPE G-GC - 2000 VOLT

Y£U..OW

GROOID

Wl*lIW.

mROX.

CUIU!EMT

AIlfS(tI

~r'

INCI!ES

mm

S(Z£

INtHES

mm

lHCII£S

mm

133

0.160

4.06

4#12

0.060

1.52

1.045

26.54

259

0.198

5.03

4#12

0.060

1.52

1.125

28.58

70

880

259

0.245

6.22

MttO

o.oso

1.52

1.225

31.12

91

1160

52

M'III

690

82624

4

6

82644-

4

4

82664

4

2

259 0.297

7.54

4#9

0.080 2.03 1.435 36.45

122

1720

82374"

4

1

259

0.353

8.97

4#8

0.080

2.03

1.595 40.51

142

2200

82384

4

110

259

0.385

9.78

4#7

0.080

2.03

1.730

43.94

164

2705

3190

I

82394

4

210

259

0.442

1123

4#6

0_000 2.03

1.855

47.12

190

82404

4

3JO

259

00480

12.19

4l!5

0.080

2.03 2.040

51_82

219

4005

82414

4

410

259

0.555

14.10

4#4

0.080

2.03

54.48

253

4560

"~bo«d

on!lO"C ~

•• UL ldcd,.,-,;l clU4 ~

• ~kP-""'C~q.-1i:y~~

"Acttcl~".=ror.<)<.

3d

33'C ~

~pe:

2.145

T:J!:io lOO.5W!2lofthe t~

Eloc:ri:cl Codo" •

NEMA 4 Watertight

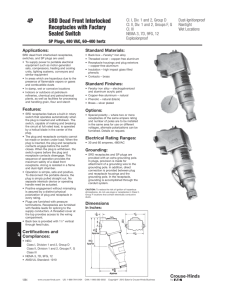

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

1P

Industrial Heavy Duty

Non-hazardous Areas

Certifications

Compliances:

Applications:

Arktite circuit breaking plugs and

receptacles are used:

• To supply power to portable electrically

operated devices such as motorgenerator sets, compressors, heating

and cooling units, welders, conveyors,

lighting systems and similar equipment

Where temporary power is needed, such

as at trailers, building units, heavy

machinery and similar equipment

and

• UL Standards: 1682,514; 1010 (APJ and

NPJ plugs only)

• CSA Standard: C22.2 No. 182.1

SPLIT

PIN CONTACT

OESIGN

Split-pin contacts:

• Made of high grade naval brass

to ensure

• 3601» of

• Wherever electrical loads must be

quickly disconnected from power source

• In a typical installation, where a large

machine utilizes a number of electrical

motor drives and for ease of adjustment,

removal, maintenance and replacement,

each motor is connected by portable

cord and Arktite receptacles rather than

permanently wired

long life

contact batweGn the pin

and sleeve to reduce

and eliminate arcing

• Self-wiping

to prevent

heat rise

at every insertion

contamination

• In areas where dust, dirt, moisture and

corrosion are a problem

• Indoors and outdoors in non-hazardous

areas of chemical plants, process

industry facilities, meat packing plants,

manufacturing plants and similar

industrial locations

Features:

• Circuit breaking: plugs through 100

ampere rating may be disconnected

under load; 150-400 ampere units are

for service disconnect use only.

• Receptacles accept only plugs of the

same amperage rating, style and

number of poles, making it impossible

to mismate, and provides for positive

polarization.

• Extra wide electrical spacing allows for

maximum safety.

• Insulator materials are the result of

intensive testing. Selection has been

made based on highest dielectric

strength, maximum mechanical and

impact resistance, lowest moisture

absorption and highest arc tracking

resistance.

• A variety of installations is possible due

to the availability of several types of

back boxes.

• Designed to withstand rough usage and

the effects of adverse environments.

• Reversible interiors, 30, 60 and 100

ampere (except 30 and 60 ampere,

5-pole) Arktite plug and receptacle

interiors are interchangeable using a

screwdriver. This makes it possible to

feed a normally de-energized receptacle

from an energized plug with usual Arktite

safety; no energized contacts are

exposed.

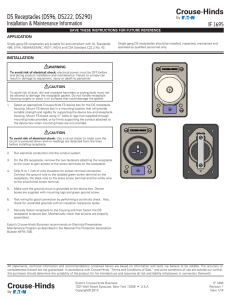

• The additional features below are

called out in the illustration on this

page

The ground contact is bonded to the

receptacle housing (Style 2)

o

@

e

receptacle to prevent mispolarization

Easy access terminals make

wiring simple

Grounding contacts that make-first and

break-last in the unlikely event of

keyway failure

8The gasketing

when the plug is being

removed is instantly snuffed in the deep

confined insulated arcing chamber

A detent spring forms a parallel

grounding path through the metallic plug

sleeve and receptacle housing and is

the first contact to make and the

last to break

o

o An arc formed

o

o The plug sleeve is keyed to the

o

system provides

unsurpassed watertight integrity

(NEMA4)

All aluminum Uni-Shell" construction

provides superior strength in abusive

environments

The Tri-Lock" cable grip has three

clamps which provide even gripping and

superior cord clamping

~ The unique Sure-Seal" cable gland

provides a complete environmental seal

around the cable (NEMA 4)

~ Wrenching surfaces make Arktite plugs

quick and easy to assemble

tI"

1230

www.crouse-hinds.com

us:

'·866-764-5454

CAN: 1-800-265·0502

Copyright"

2010 Cooper Crouse-Hinds

COOPER Crouse-Hinds

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

1P

NEMA 4 Watertight

Industrial Heavy Duty

Non-hazardous Areas

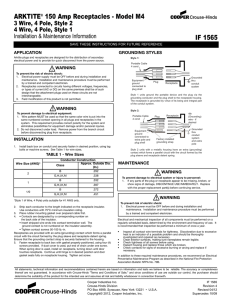

Grounding: Style 1

VS.

Style 2

Cooper Crouse-Hinds Arktite devices utilize two methods, or styles, for completing the grounding circuit in plugs and receptacles.

NEC reference 250.138 (A) & (8).

Style 1 - Metallic

Style 2 - Metallic

Style 2 - Non-metallic

A Style 1 plug is one in which the

grounding conductor in the flexible cable is

bonded to the plug sleeve by a pressure

connector. A Style 1 receptacle is one

which is grounded by virtue of the fact that

it is an integral part of a grounded conduit

system. On insertion. the plug sleeve

makes contact with detent springs of the

grounded receptacle housing before line

and load poles engage, and on withdrawal,

remains in contact until after line and load

poles disengage. Therefore, exposed metal

parts of the portable equipment or plug are

suitably grounded.

A Style 2 metallic housing plug is one in

which the grounding conductor in the

flexible cable is bonded to the extra

(grounding) pole and metal plug sleeve by

a pressure connector. A Style 2 metallic

housing receptacle is one in which the

extra (grounding) pole is electrically

connected to the equipment grounding

conductor and the metal receptacle

housing which itself is grounded by virtue

of the fact that it is an integral part of a

grounded conduit system. In Style 2, nonmetallic housing plugs and receptacles, the

extra pole is used for grounding since the

housings are non-conductive.

In a Style 2 receptacle, the grounding

connection is made before line and load

poles engage, and is broken after the line

load poles disengage. Furthermore, upon

insertion, the plug sleeve of metal shelled

units makes contact with detent springs of

the grounded receptacle housing before

line and load poles engage. and on

withdrawal, remains in contact until after

line and load poles disengage. Therefore,

exposed metal parts of the portable

equipment or plug are suitably grounded.

T----'

,

,

-!.

Made of

non-metallic

Krydon

material

Metal

shelled

type

Style 1

Ground conductor

attaches to shell.

-'"

COOPER Crouse-Hinds

Style 2

Ground conductor

attaches to contact,

which is bonded to

shell.

www.crouse-hinds.com

us: '-866-764-5454

CAN: 101300-265-0502

Copyright"

2010 Cooper Crouse-Hinds

1231

1P

NEMA 4 Watertight

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

Industrial Heavy Duty Non-hazardous Areas

Standard Materials:

• Metallic receptacle housings, plug and

cord connector bodies - high impact

strength copper-free aluminum

• Non-metallic receptacles, plugs and

cord connectors - Krydont> fiberglassreinforced polyester material

~'--,\

L....

I

Arktite receptacles have a cast raised

rib located inside the receptacle sleeve.

The location of the rib is in a specific

relationship to the receptacle insulator

that houses the contacts.

• Back boxes: 20, 30, 60, 100,150 and

200 ampere - cast aluminum; 400

ampere - Feraloye iron alloy

• Insulation (metallic products): (2-, 3-,

and 4-pole) 30, 60, 100,200,400

ampere - fiberglass-reinforced

polyester; 20, 30 ampere (5-pole) melamine

• Contacts: pressure, solder, binding

screw - brass; crimp/solder 20, 30. 60,

100 ampere - leaded red brass;

crimp/solder 150, 200,400 amperetelurium copper

Standard Finishes:

• Feraloy - electrogalvanized and

aluminum acrylic paint

• Aluminum - natural

• Krydon fiberglass-reinforced polyester

material - gray

• Fiberglass-reinforced polyester

insulation - (red)

Accessories:

• Melamine - natural (brown)

• Brass - natural

• Leaded red brass - electro-tin-plate

• Accessories include a variety of angle adapters. panel adapters and back boxes for Arktite

receptacles. See pages 1250-1253.

• Included throughout 1 P are wire mesh cable grips and protective caps for Arktite plugs.

The mating plug has a cast groove

located on the outside of the plug

sleeve. This groove lines up with the

raised rib.

'-------------

Options:

The following special options are available

from factory by adding the suffix to the

Cat. #:

Description

Suffix

• Reversed contacts. Receptacle

assembled with plug interior

(exposed contacts). plug

assembled with receptacle

interior (recessed contacts). For

applications where plug is

energized to feed normally

de-energized receptacle. Available

on 30 through 400 ampere units ... S22

• Special polarity. For use where

two or more receptacles of the

same ampere rating, style and

number of poles are to be

installed in the same area for use

on different voltages and/or

frequencies. Prevents insertion of

a plug in a receptacle with

different electrical rating.

Available on 20 through 400 ampere

units as follows:

• Receptacle interior rotated 22'1'to right and plug changed to

match (see photo to right)

S4

• Cerro-free" epoxy powder finish

for added corrosion resistance

S752

§150A, 200A and 400A rated units are for service disconnect

1232

www.crouse-hmds.com

APQ/NPQ

Arktite Motor Plug

APJ/NPJ Arktite Plug

Transformer

Switch

Generator

APR/NPR

AR/NR Arktite

Arktite Connector

Receptacle

Typical Installation

use only.

US: '·866-764-5454

CAN: 1-800-265-0502

Copyright·

2010 Cooper Crouse-Hinds

,

COOPER

Crouse-Hinds

NEMA 4 Watertight

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

1P

Industrial Heavy Duty Non-hazardous Areas

Arktite Horsepower

Ratings

Maximum Horsepower for Plug and

Receptacle Combinations by Input

Voltage*

Locked-Rotor Interrupting

Motor Horsepowert

Ampere Rating

Plug and Receptacle

240

Volts

480

Volts

600

Volts

Single-phase Electrical System

30

2

60

5

100

10

200

15

3

10

20

40

7.5

25

10

20

Three-phase Electrical System

30

3

60

10

100

15

200

30

5

20

30

60

10

40

40

25

120

Volts

Following values are typical horsepower ratings based on NEC

Article 430 tables.

HP Ratings are based on the largest conductor size for each

plug and receptacle combination per the Wire Size table below.

Motor Horsepower";

10

50

25

15

Ampere Rating

Plug and Receptacle

240

Volts

480

Volts

600

Volts

30

60

100

150

200

15

20

30

40

60

30

40

60

75

125

40

50

75

100

150

Wire Sizes:

The table below lists the diameter of the wire recess in Arktite plug

and receptacle contacts so that maximum size of bare conductor

can be figured. Range of wire sizes shown in table is intended only

as a guide. Depending on type of wire used (building wire, flexible or

extra flexible cable) and its construction (number and size of

strands), bare copper diameters vary widely.

Diameter of Wire Recess in Plug and Receptacle Contacts

Ampere

Rating

Contact

Type

Diameter

of Recess

Wire Size:!:

Building

Extra Flex

20

30 (2, 3, & 4-pole)

30 (2. 3, & 4-pole)

30 (S-pole)

60 (2, 3, 4 & 5-pole)

60 (3 & 4-pole)

100 (2, 3 & 4-pole)

100 (3 & 4-pole)

150 (4-pole)

200 (3 & 4-pole)

200 (Std. 3 & 4-pole)

200 (Lg. 3 & 4-pole)

400 (Std. 3 & 4-pole)

400 (Lg. 3 & 4-pole)

Binding Screw

Pressure

Crimp/Solder

Solder

Pressure

Crimp/Solder

Pressure

Crimp/Solder

Pressure

Pressure

Crimp/Solder

Crimp/Solder

Crimp/Solder

Crimp/Solder

N/A

.281

.180

.188

.312

.277

.390

.390

.390

.687

.560

.750

.840

1.25

#14-#12

#10-#6

#10-#8~

#12-#6

#6-#4

#6-#4"

#4-#1

#2-#1"

#2-2/0

2/0-4/0

#1-4/0

4/0-250MCM

250-500MCM

500-1000MCM

#14-#12

#10-#8

#10-#8

#12-#8

#8-#4

#8-#4

#4-#2

#2-#2

#2-1/0

21D-3/0

#1-3/0

3/D-250MCM

2S0-400MCM

40D-750MCM

§150A. 200A and 400A rated units are for service disconnect use only.

t Horsepower ratings are based on Cooper Crouse-Hinds testing in which locked-rotor currents were interrupted by withdrawing the plug from the receptacle.

recommended. however. that such use be limited to emergency conditions only; and that a horsepower rated switch be used for motor disconnect:

It is hfghly

. Thisguide is for reference only. Consult your local electrical codes

beiore installation.

Cooper Crouse-Hinds does not recommend our plug and receptacle be used for disconnect

"Smaller sizes may be used with well reducers - information aVailable upon request.

~Do not use wire size smaller than minimum size recommended.

If!

,

COOPER Crouse-Hinds

www.crouse-hinds.com

under load.

us: 1-866-764-5454

CAN: 1-800-265-0502

Copyright·

2010 Cooper Crouse-Hinds

1233

1P

Weatherproof

Arktite® Heavy Duty Receptacle

Assemblies

400 A, 600 VAC/250 VDC,50-400 hertz

Features:

Wire Mesh Grips:

• Grounding contact wire terminators will accommodate ground wire

of same size as phase wire

• Spring band contact design provides multiple points of electrical

contact. Improves electrical reliability and significantly reduces

effort required for insertion and withdrawal

Applications:

• Crimp/solder type contacts are standard

• Large wire wells are available for "extra flexible' wire

• Larger wire well size connectors will interchange with connectors

of other wire well size of same amperage and contact

configuration

• Self-closing spring doors on receptacles and cord connectors

provide environmental sealing

• Threaded nuts provide positive plug retention

• Two piece plug and cord connector design provide easy

installation

• For disconnect use only - not for current interrupting

1. For listing of additional back boxes, see page 1251. Illustration

shows 3 blank plates and 1 hub plate.

2. S22 suffix for reverse interiors is available from factory only. Field

conversion cannot be done.

3. Replacement interiors for standard units vs. S22 units vary in

length. Specify the unit type when ordering parts.

Wire mesh grips are used:

• To provide secure cable termination

• To extend cable life

• With 20, 200 and 400 ampere plugs

Features:

• Eliminate sharp radius of cable bend at the point where cable

enters plug, thereby reducing cable failure

• Absorb longitudinal stresses placed on the point of termination

caused by pulling the cable

• Gripping action increases in direct proportion to amount of tension

applied to cable

Standard Material and Finishes:

• Stainless steel wire braid - Natural

Ordering Information:

Plug Cable Range

Grip Range

Nominal Grip

Length-Inches

Grip Cat. #

1.375 to 1.875

1.375 to 1.625

1.625 to 1.875

8

11

K163

K188

1.875 to 2.500

1.875 to 2.000

2.000 to 2.250

10

11'/.

K200

K225

Dimensions

In Inches:

-.-------r

I

19

I

.1

AP Plugs

r -----201~--

APR Connectors

AR Receptacles

AREX Assemblies

Description

a

With blank hub plate

With hub plate max.

No. Poles

c

d

3

4

5'/,.

4'/,.

5"1'6 4"1,.

till

COOPER

Crouse-Hinds

www.crouse-hinds.com

us:

1-866-764-5454

CAN: 1-800-265-0502

Copyright"

2010 Cooper Crouse-Hinds

1245

1P

Arktite® Heavy Duty Receptacle

Weatherproof

Assemblies

400 A, 600 VAC/250 VDC, 56-400 hertz

Ordering Information:

Receptacle

Assembly

With AJ Back Boxes and Angle Adapters:!:

Spring Door

Hub

Cover Cat. #

Description

Size (In.)

Mating Plug

Receptacle

Receptacle Housings

Spring Door

Cat. #

Mating Connector

only

Cable

Dia.

Plug Cat. II

Connector

Cat. /I

Style 1 - Wire Well Takes .84" Maximum Conductor Size

3-wile,

3-pole

2'f..

4-wire.

4-pole

2'12

3

3

AREX40317

AREX40318

AR4031

1375 to 1875

1 875 to 2.500

AP40357

AP40356

APR40317

APR40318

AREX40417

AREX40418

AR4041

1.375 to 1.875

1.875 to 2.500

AP40457

AP40458

APR40417

APR40418

2.500 to 3.000

3.000 to 3 800

AP40351 0

AP403512

APR403110

APR403112

2.500 to 3.000

3.000 to 3.800

AP40451 0

AP404512

APR404110

APR404112

Style 1 - Wire Well Takes 1.25" Maximum Conductor Size

3-wlre.

3-pole

3

3'/:

4

AREX403128

AREX403129

AREX4031210

AR40312

4-wire,

4-pole

4

5

AREX4041210

AREX4041212

AR40412

Style 2 - Wire Well Takes .84" Maximum Conductor Size

2-wlre,

3-pole

2

2'/.

3

AREX40326

AREX40327

AREX40328

AR4032

1.375 to 1.875

1875 to 2 500

AP40367

AP40368

APR40327

APR40328

3-wire,

4-po/e

2'/,

3

AREX40427

AREX40428

AR4042

1.375 to 1.875

1.875 to 2.500

AP40467

AP40468

APR40427

APR40428

Style 2 - Wire Well Takes 1.25" Maximum Conductor Size

2-wlre.

3-pole

3

3'/,

4

AREX403228

AREX403229

AREX4032210

AR40322

2.500 to 3 000

3.000 to 3.500

AP403610

AP403612

APR403210

APR403212

3-wire,

4-pole

4

5

AREX4042210

AREX4042212

AR40422

2.500 to 3.000

3.000 to 3.500

AP404610

AP404612

APR404210

APR404212

;Hub

1246

prates and blank plates may be Interchanged to permit conduit feed from bottom or sides.

WWW.crouse-hinds.com

us: 1-866-764-5454

CAN: 1-800·265-0502

Copyright"

2010 Cooper Crouse-Hinds

--

COOPER Crouse-Hinds

PRODUCT DATA SHEET

Controlled

Documenl-

Engineering

Drive

1530 Shields Drive

Waukegan,

Il 60085

Toll-Free (800) 323-9355

Fax: (847) 689-1192

Royal® Type G-GC Conductors

Construction

Parameters:

CONDUCTOR:

8 AWG - 500 MCM slTanded

INSULATION:

COLOR CODE:

EPDM

Conductors:

Grounds:

Ground

JACKET:

COLOR:

INDENT LEGEND:

Black.

White.

oar. copper

Red

Green

Check:

Yellow

CPE

Black

(Other

colors

available

upon

request)

CCI ROYAL XX AWG rxxx mm') XlC TYPE G-GC PORTABLE POWER CABLE E172226 (Ul)

2oo0V 90C DRY 90C WET SUN RES-I56016

CSA TYPE G·GC 20DOV-40C FTI FT5 P,n7-l<All0D09-MSHA

PHYSICAl PROPERTIES:

TEMPERATURE RANGE: ""O'C to 90'C

WATER RESISTANT:

Yes

ELECTRICAl PROPERTIES:

VOLTAGE RATING:

2000V"""

Max

Industry Approvals:

e UL Subject 1650

o NEC Ar1lc1e400

o CSA C222 No. 96

o Passes

CSA. FT1, FTS Horizontal

Flame

Tests

oMSHA

o EPA 40 CFR. Part 261, Subpart C. heavy metals per Table I, TCLP melhod

Part

Number

830130

e

No

Condo

3

830332

6

4

3

3

133129

259f.lO

259128

830334

2

3

259/26

0.050

1.52

1.52

1.52

1.52

830335

1

3

259125

0.080

2.03

'/0

259124

Gauge

AWG MeM

830331

fnsutation Wall. Nom

Stranding

Inches

0.060

0.060

0.060

mm

210

34212'

0.080

0.080

830338

3/0

3

3

3

2.03

830337

418124

0.080

2.03

830339

4I\l

3

532/24

830340

250

627fl4

2.03

2.41

830341

350

500

3

3

0.080

0.095

88&2'

0,095

2.41

3

t29512~

0.095

2.41

8Jtt~6

830~

Nct.:AR'dImMsIo<lt"IooefgbTs_

·~bJlsNaItHECT

This producl. complies

2.03

••~SlIb}I!dIvInfl<nlty~sM'ld~"c."""""tO~M""Nd.

on ,Nom.

Grt:en

Ground

2#10

2#10

Yellow

Ground Check

#10

Inches

mm

0.940

23.88

sa7

.to

0..976

Z4.79

aa

Sto

#10

1.108

28.14

1,300

33.02

#6

1.450

36.83

71.

993

1395

1680

H7

2#6

2#5

204

2#3

2#2

2'2

••

••

••

••

2#1/0

2#210

Net Weight

LbJ1<ft. kg/km

2075

2500

In

205

237

27.

316

352

433

53.

874

1063

1478

39.78

2081

3095

1.680

42.67

1.834

46.56

1,948

49.48

2492

2997

~92

IUl

2.180

55.37

.c;.297

3709

4459

5345

6395

IUl

2.s97

65£16

••

6188

9209

2.940

74.68

8236

12256

1.566

Am

NEC

65

87

114

152

s·

CEC

65

Nom DCR

OJ1M'

0.65

lIT

0.42

II.

0.26

152

177

205

0.13

237

274

316

352

.33

536

0.17

0.11

0.08

0.07

0.05

0.04

0.03

0.02

••&Io4O(l.:scaJ~CE.(;T.bH1'ZAltwfI>rHct;ll7'MtCMFYf"flc~

WlIh Europe~

Oll'ectNe2011165/EU

(RoHS-2)

The customer vnll accept all factory lengths and -1-/. 10 percent of tolal order requested.

The informa"'Jon pres:ented here is. 10 !he best of OUTknowledge. true and accurate. Since condtlons of use are beyond Coleman Cable's control all product data presented is for

purposes only and does not ereale a binding obliga'6on Of liability on Coleman Gable or confer any rigtrts on any customer. The sale of products(s} is condiicned upon

of a purchase order subject to Coleman cf1':cla:imsailliabiity in connection with the use of inform~

contained heron or otherwise.

inforrr.aOOnal

acceptance

Th~ !>p(!Cif'~tion G pl'OpriGtary intellecluai pl"oporty of Cofeman Cable. Arty information contained herein shall not DBdisclosed IQ any party without written consent 01 Coleman

Cable.

SpecifICation Issue Date: December 3, 2013

1-800-323·9355

1-847-689-1192

(Phone)

(Fax)

Designed By: PEM

©2013

eel

NEMA 4 Watertight

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

1P

Indusbial Heavy Duty

Non-hazardous Areas

Applications:

Arktite circuit breaking plugs and

receptacles are used:

• To supply power to portable electrically

operated devices such as motorgenerator sets, compressors, heating

and cooling units, welders, conveyors,

lighting systems and similar equipment

• Where temporary power is needed, such

as at trailers, building units, heavy

machinery and similar equipment

Certifications

Compliances:

and

• UL Standards: 1682, 514; 1010 (APJ and

NPJ plugs only)

• CSA Standard: C22.2 No. 182.1

SPLIT PIN CONTACT DESIGN

SpHt-pin contacts:

• Made of hiSh grade naval brass

to ensure long life

• 360° of contact between the pin

• Wherever electrical loads must be

quickly disconnected from power source

• In a typical installation. where a large

machine utilizes a number of electrical

motor drives and for ease of adjustment,

removal, maintenance and replacement,

each motor is connected by portable

cord and Arktite receptacles rather than

permanently wired

and sleeve

to reduce

heat rise

and ellmirrate arcing

• Self-wiping at every insertion

to prevent

I

contamination

• In areas where dust, dirt, moisture and

corrosion are a problem

• Indoors and outdoors in non-hazardous

areas of chemical plants. process

industry facilities. meat packing plants,

manufacturing plants and similar

industrial locations

Features:

• Circuit breaking: plugs through 100

ampere rating may be disconnected

under load; 150-400 ampere units are

for service disconnect use only.

• Receptacles accept only plugs of the

same amperage rating. style and

number of poles, making it impossible

to mismate, and provides for positive

polarization.

• Extra wide electrical spacing allows for

maximum safety.

• Insulator materials are the result of

intensive testing. Selection has been

made based on highest dielectric

strength, maximum mechanical and

impact resistance, lowest moisture

absorption and highest arc tracking

resistance.

• A variety of installations is possible due

to the availability of several types of

back boxes.

• Designed to withstand rough usage and

the effects of adverse environments.

• Reversible interiors, 30, 60 and 100

ampere (except 30 and 60 ampere,

s-pore) Arktite plug and receptacle

interiors are interchangeable using a

screwdriver. This makes it possible to

feed a normally de-energized receptacle

from an energized plug with usual Arktite

safety; no energized contacts are

exposed.

1230

www.crcuse-hmds.corn

• The additional features below are

called out in the illustration on this

page

The ground contact is bonded to the

receptacle housing (Style 2)

o

t) The

@ Easy access terminals make

e

o

o

us: 1-866·764·5454

wiring simple

Grounding contacts that make-first and

break-last in the unlikely event of

keyway failure

An arc formed when the plug is being

removed is instantly snuffed in the deep

confined insulated arcing chamber

A detent spring forms a parallel

grounding path through the metallic plug

sleeve and receptacle housing and is

the first contact to make and the

last to break

CAN: 1-800-265-0502

Copyright"

~ The plug sleeve is keyed to the

receptacle to prevent mispolarization

gasketing system provides

unsurpassed watertight integrity

(NEMA4)

All aluminum Uni-Shell'" construction

provides superior strength in abusive

environments

The Tri-Lock" cable grip has three

clamps which provide even gripping and

superior cord clamping

(Ii) The unique Sure-Seal" cable gland

provides a complete environmental seal

around the cable (NEMA 4)

(D Wrenching surfaces make Arktite plugs

quick and easy to assemble

o

o

2010 Cooper Crouse-Hinds

--

COOPER Crouse-Hinds

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

NEMA 4 Watertight

1P

Industrial Heavy Duty

Non-hazardous Areas

Grounding: Style 1

VS.

Style 2

Cooper Crouse-Hinds Arktite devices utilize two methods, or styles, for completing the grounding circuit in plugs and receptacles.

NEC reference 250.138 (A) & (B).

Style 1 - Metallic

Style 2 - Metallic

Style 2 - Non-metallic

A Style 1 plug is one in which the

grounding conductor in the flexible cable is

bonded to the plug sleeve by a pressure

connector. A Style 1 receptacle is one

which is grounded by virtue of the fact that

it is an integral part of a grounded conduit

system. On insertion, the plug sleeve

makes contact with detent springs of the

grounded receptacle housing before line

and load poles engage, and on withdrawal,

remains in contact until after line and load

poles disengage. Therefore, exposed metal

parts of the portable equipment or plug are

suitably grounded.

A Style 2 metallic housing plug is one in

which the grounding conductor in the

flexible cable is bonded to the extra

(grounding) pole and metal plug sleeve by

a pressure connector. A Style 2 metallic

housing receptacle is one in which the

extra (grounding) pole is electrically

connected to the equipment grounding

conductor and the metal receptacle

housing which itself is grounded by virtue

of the fact that it is an integral part of a

grounded conduit system. In Style 2, nonmetallic housing plugs and receptacles, the

extra pole is used for grounding since the

housings are non-conductive.

In a Style 2 receptacle, the grounding

connection is made before line and load

poles engage, and is broken after the line

load poles disengage. Furthermore, upon

insertion, the plug sleeve of metal shelled

units makes contact with detent springs of

the grounded receptacle housing before

line and load poles engage, and on

withdrawal, remains in contact until after

line and load poles disengage. Therefore,

exposed metal parts of the portable

equipment or plug are suitably grounded.

,

,

-:.

1----"'\

n

Made of

non-metallic

Krydon

material

,

.

•~

Metal

shelled

type

Style 2

Ground conductor

attaches to contact,

which is bonded to

shell.

Style 1

Ground conductor

attaches to shell.

"""

COOPER Crouse-Hinds

www.crouse-hinds.com

us: 1-866-764-5454

CAN: 1-80()"265-O502

CopyrightO

2010 Cooper Crouse-Hinds

1231

1P

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

NEMA 4 Watertight

Industrial Heavy Duty Non-hazardous Areas

Standard Materials:

• Metallic receptacle housings, plug and

cord connector bodies - high impact

strength copper-free aluminum

Arktite receptacles have a cast raised

rib located inside the receptacle sleeve.

The location of the rib is in a specific

relationship to the receptacle insulator

that houses the contacts.

• Non-metallic receptacles, plugs and

cord connectors - Krydon~ fiberglassreinforced polyester material

• Back boxes: 20, 3D, 60, 100, 150 and

200 ampere - cast aluminum; 400

ampere - Fernloy" iron alloy

• Insulation (metallic products): (2-, 3-,

and 4-pole) 30, 60, 100, 200, 400

ampere - fiberglass-reinforced

polyester; 20, 30 ampere (5-pole) melamine

• Contacts: pressure, solder, binding

screw - brass; crimp/solder 20, 30, 60,

100 ampere - leaded red brass;

crimp/solder 150, 200, 400 ampere telurium copper

Standard Finishes:

• Feraloy - electrogalvanized and

aluminum acrylic paint

• Aluminum - natural

• Krydon fiberglass-reinforced polyester

material - gray

• Fiberglass-reinforced polyester

insulation - (red)

Accessories:

• Melamine - natural (brown)

• Brass - natural

• Leaded red brass - electro-tin-plate

• Accessories include a variety of angle adapters, panel adapters and back boxes for Arktite

receptacles. See pages 1250-1253.

• Included throughout 1P are wire mesh cable grips and protective caps for Arktite plugs.

The mating plug has a cast groove

located on the outside of the plug

sleeve. This groove lines up with the

raised rib.

'-------------

Options:

The following special options are available

from factory by adding the suffix to the

CaL #:

Description

Suffix

• Reversed contacts. Receptacle

assembled with plug interior

(exposed contacts), plug

assembled with receptacle

interior (recessed contacts). For

applications where plug is

energized to feed normally

de-energized receptacle. Available

on 30 through 400 ampere units ... 522

• Special polarity. For use where

two or more receptacles of the

same ampere rating, style and

number of poles are to be

installed in the same area for use

on different voltages andlor

frequencies. Prevents insertion of

a plug in a receptacle with

different electrical rating.

Available on 20 through 400 ampere

units as follows:

• Receptacle interior rotated 22%0

to right and plug changed to

match (see photo to right)

S4

• Cerro-free" epoxy powder finish

for added corrosion resistance

S752

§15OA, 200A and 400A rated units are for service disconnect

1232

www.crouse-hinds.com

APQ/NPQ

Arktite Motor Plug

APJ/NPJ Arktlte Plug

Transfonme..r---'l:::---1

Switch

APRINPR

Arktite Connector

ARINR Arktite

Receptacle

Typical Installation

use only.

us; 1·866-764-5454

~

CAN; 1-8<>0-265-0502

Copyright"

2010 Cooper Crouse-Hinds

COOPER Crouse-Hinds

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

1P

NEMA 4 Watertight

Industrial Heavy Duty Non-hazardous Areas

Maximum Horsepower for Plug and

Receptacle Combinations by Input

Voltage*

Arktite Horsepower Ratings

Locked-Rotor Interrupting

Motor Horsepcwerr

Ampere Rating

Plug and Receptacle

Single-phase

30

60

100

200

Electrical

Three-phase

30

60

100

200

Electrical

240

Volts

480

Volts

600

Volts

2

3

5

10

15

10

20

40

7.S

25

10

20

3

10

15

30

5

20

30

60

120

Volts

System

Motor Horsepowel*

System

10

40

40

25

Following values are typical horsepower ratings based on NEC

Article 430 tables.

HP Ratings are based on the largest conductor size for each

plug and receptacle combination per the Wire Size table below.

10

50

25

15

Ampere Rating

Plug and Receptacle

240

Volts

480

Volts

600

Volts

30

60

100

150

200

15

20

30

40

60

30

40

60

75

125

40

50

75

100

150

Wire Sizes:

The table below lists the diameter of the wire recess in Arktite plug

and receptacle contacts 50 that maximum size of bare conductor

can be figured. Range of wire sizes shown in table is Intended only

as a guide. Depending on type of wire used (building wire, flexible or

extra flexible cable) and its construction (number and size of

strands), bare copper diameters vary widely.

Diameter of Wire Recess in Plug and Receptacle Contacts

Ampere

Rating

Contact

Type

Diameter

of Recess

Wire Size;

Building

Extra Flex

20

30 (2. 3, & 4-pole)

30 (2, 3, & 4-pole)

30 (S-pole)

60 (2, 3, 4 & 5-pole)

60 (3 & 4-pole)

100 (2, 3 & 4-pole)

100 (3 & 4-pole)

150 (4-pole)

200 {3 & 4-pole}

200 (Std. 3 & 4-pole)

200 (Lg. 3 & 4-pole)

400 (Std. 3 & 4-pole)

400 (Lg. 3 & 4-pole)

Binding Screw

Pressure

Crimp/Solder

Solder

Pressure

Crimp/Solder

Pressure

Crimp/Solder

Pressure

Pressure

Crimp/Solder

Crimp/Solder

Crimp/Solder

Crimp/Solder

N/A

.281

#14--#12

#10-#6

#10--#8""

#12-#6

#6--#4

#6--#4"

#4-#1

#2--#1"

#2-210

2/0-4/0

#1-4/0

4/0-250MCM

250-500MCM

500-1000MCM

#14-#12

#10-#8

#10--#8

#12-#8

#8--#4

#8--#4

#4-#2

#2-#2

#2-1/0

2/0-3/0

#1-3/0

3/0-250MCM

250-400MCM

400-750MCM

.180

.188

.312

.277

.390

.390

.390

.687

.560

.750

.840

1.25

§150A. 200A and 400A rated units are for service disconnect use only.

testing tn which locked-rotor currents were interrupted by withdrawing the plug from the receptacle. It is

recommended. however. that such use be limited to emergency conditions only; and that a horsepower rated switch be used for motor disconnect .

• This guide is for reference only. Consult your local electrical codes before installation.

th Cooper Crouse-Hinds does not recommend our plug and receptacle be used for disconnect under load.

"Smaller sizes may be used with well reducers - information ava~able upon request.

;00 not use wire size smaller than minimum size recommended.

t Horsepower ratings are based on Cooper Crouse-Hinds

"'"

COOPER

Crouse-Hinds

www.crouse-hinds.com

us: 1-866-764-5454

CAN:

1-900-265-0502

highly

Copyright" 2010 Cooper Crouse-Hinds

1233

Arktite® Heavy Duty Circuit

1P

NEMA 3R

Breaking Receptacle Assemblies

200 A, 600 VAC/250 VDC, 50t - 400 hertz

Ordering Information - Mechanical Lug Termination:

Receptacle

Assembly

Receptacle

Receptacle Assembly with AJ Back Boxes and

Angle Adapters

Hub

Description

Size (In.) Cat. #

Receptacle

Cat. #

2

2'/,

AREAL20416

AREAL20417

Style 2 - Wire Well Takes 0.687" Maximum

ARL2041

Conductor

Lug

Housings only

Cable

Dia.

Style 1 - Wire Well Takes 0.687" Maximum Conductor Size

1'/,

AREAL20315

3-Wlre,

AREAL20316

2

ARL2031

3-pole

AREAL20317

2'/'

4-wire,

4-pole

wI Mechanical

Mating Plug

Mating Connector

Plug Cat. #

Connector

0875 to 1375

1.375 to 1.875

1 875 to 2.500

APL20355

APL20357

APL20358

APRL20315

APRL20317

APRL20318

0.875

1.375

1.875

2.500

1.375

1.875

2.500

3.000

APL20455

APL20457

APL20458

APL20451

APRL20415

APRL20417

APRL20418

APRL204113

to

to

to

to

Cat. #

Size

z-wire,

3-pole

1'/2

2

2'/,

AREAL20325

AREAL20326

AREAL20327

o 875 to

ARL2032

1.375

1.375 to 1.875

1.875 to 2.500

APL20365

APL20367

APL20368

APRL20325

APRl20327

APRl20328

3-wire,

4-pole

1'/,

2

2'12

AREAL20425

AREAL20426

AREAL20427

ARL2042

0.875 to 1.375

1.375 to 1.875

1.875 to 2.500

APL20465

APL20467

APL20468

APRL20425

APRL20427

APRL20428

Plug Cat. #

Connector

0.875 to 1.375

1.375 to 1 875

1 875 to 2.50U

AP20355

AP20357

AP20358

APR20315

APR20317

APR20318

0.675 to 1.375

1.375 to 1.875

1.875 to 2.500

AP20455

AP20457

AP20458

APR20415

APR20417

APR20418

1.375 to 1.875

1 875 to 2.500

AP203511

AP203512

APR203111

APR203112

1.375 to 1.875

1.875 to 2.500

AP204511

AP204512

APR204111

APR204112

2.500 to 3.000

AP204513

APR204113

0875 to 1375

1 375 to 1.875

1.675 to Z .500

AP20365

AP20367

AP20368

APR20325

APR20327

APR20328

0.875 to 1.375

1.375 to 1.875

1.875 to 2.500

AP20465

AP20467

AP20468

APR20425

APR20427

APR20428

0.875 to 1 375

1.375 to 1 875

1 875 to 2.500

AP203610

AP203611

AP203612

APR203210

APR203211

APR203212

1.375 to 1.875

1.875 to 2.500

AP204611

AP204612

APR204211

APR204212

Ordering Information - Crimp/Solder Termination:

Receptable Assembly with AJ Back Boxes and

Angle Adapters

Hub

Description

Size (In.) Cat. #

Receptacle

Cat. #

Housings only

Cable

Dia.

Style 1 - Wire Well Takes 0.56" Maximum Conductor Size

1'1,

AREA20315

s-wue,

AREA20316

2

AR2031

3-pole

AREA20317

2'12

4-wire.

4-pole

2

2'/2

AREA20416

AREA20417

AR2041

Style 1 - Wire Well Takes 0.75" Maximum Conductor Size

1'I,

AREA203125

2

AREA203126

AR20312

2'j,

AREA203127

3-wlre,

3-pole

4-wire,

4-pole

2

2'/z

AREA204126

AREAZ04127

AR20412

Style 2 - Wire Well Takes 0.56" Maximum Conductor Size

1'/.

AREA20325

2-wne,

AREA20326

2

AR2032

a-cote

AREA20327

2'/,

3-wire,

4-pole

1%

2

2'/2

AREA20425

AREA20426

AREA20427

AR2042

Style 2 - Wire Well Takes 0.75" Maximum Conductor Size

1'10

AREA203225

AREA203226

2

AR20322

AREA203227

2'/2

2-wlre,

3-pole

3-wire,

4-pole

1%

2

2'f,

AREA204225

AREA204226

AREAZ04227

tFor use on system less than 60 hertz the receptacles.

"'"

COOPER

Crouse-Hinds

AR20422

plugs and connectors

www.crouse-hinds.com

are for disconnect

Cat. #

use only.

us: 1-866-764·5454

CAN: 1-800·265·0502

Copyright"

2010 Cooper Crouse-Hinds

1243

Weatherproof

Arktite® Heavy Duty Circuit

Breaking Receptacle Assemblies

1P

200 A, 600 VAC/250 VDC, 50t - 400 hertz

200A Replacement

Receptacle

Interior

.56 wire well

Cat. #

Config.

Parts

Plug Interior

Brass Retaining Shoe

.75 wire well

Cat. #

.56 wire well

Cat. #

.75 wire well

Cat. #

.56 wire well

Cat. #

.75 wire well

Cat. #

200A Standard and S4

2W3P

3W3P

3W4P

ATP401

ATP402

ATP433

ATP434

0490335

0490335

ATP397

ATP403

ATP398

ATP404

ATP429

ATP435

ATP430

ATP436

0490327

0490337

0490337

4W4P

ATP399

ATP400

ATP431

ATP432

0490331

0490332

0490328

200A ST22 and 54 S22

2W3P

ATP417

ATP418

ATP449

ATP450

0490335

0490335

3W3P

ATP414

ATP445

3W4P

ATP413

ATP419

ATP420

ATP451

ATP446

ATP452

0490327

0490337

0490337

4W4P

ATP415

ATP416

ATP447

ATP448

0490331

0490332

0490328

Cord Grip Assembly

Plug Clamp Nut

Cord Diameter Range

.875 -1.375

1.375 - 1.875

1.875 - 2.500

Replacement

,-------,

AP2 KIT1 M80

AP2 KIT2 M80

AP2 KIT3 M80

2W3P

3W3P

AP:0401965

AR:0401502-2

2W3P

3W4P

AP:0401964

AR:0401502-1

Pin & Sleeve Contacts:

Receptacle

Cat. #

Cat. #

Type

Plug

Cat. #

Cat. #

200A Standard & S4

.56 wire well

.75 wire well

.56 wire well

.75 wire well

Phase Contact

Ground Contact

0490339

0490343

0490340

0490344

0490319

0490323

0490320

0490324

200A 522 & S4 S22

Phase Contact

.56 wire well

0490351

.75 wire well

0490352

.56 wire well

0490355T

.75 wire well

0490356

Ground Contact

0490347

0490348

0490359

0490360

200A Mechanical

Phase Contact

Rec Spring Door

Lug

Ground Contact

.687 wire well

0403668

.687 wire we"

0403678

0403687

0403677

tFor use on system less than 60 hertz the receptacles,

plugs and connectors

are for disconnect

use only.

tfII'

1244

www.crcuse-hinds.com

us: 1-866·764-5454

CAN: 1-800-265-0502

Copyright"

2010 Cooper Crouse-Hinds

COOPER

Crouse-Hinds

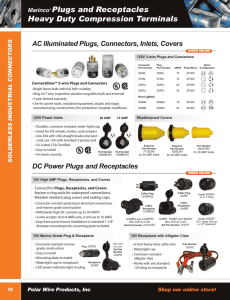

Rubber Cord Products

Mining

Carolprene® Jacketed Type SOOW, Non-UL

90°C 600 Volt Portable Cord

Product Construction:

Conductors:

• 8 through 2 AWG fuUy annealed

bare copper per ASTM £3..174

stranded

Insulation:

• Premium-grade.

color-coded

• Colot code: See chart

9O"C

EPDM

OOICIIJ

Jacket:

• Carolprene-. black

• Temperature

range: -4O"C to

TYPE SOOW, NON-UL - 600 VOLT

+9O"C

Jacket Marking:

• CAROL (SIZE) 1YPE SOOW 9O"C

P-7K-123033 MSHAMADE IN USA

No.'II-Ul

2

8

65/26

0.050

127

0.660

16.76

40

283

250'

3

8

65/26

0.050

1.27

0.695

17.65

40

340

250'

4

8

65/26

0.050

127

0.760

19.30

35

491

250'

8

65/26

0.050

1.27

0.840

21.34

28

550

250'

6

101126

0.050

127

0.790

20.07

55

531

250'

6

101/26

0.050

1.27

0.865

21.97

45

660

250'

6

101126

0.050

127

0.945

24.00

36

759

250'

2

4

119/25

0.050

1.27

0.860

21.84

70

580

250'

3

4

119/25

0.050

127

0.915

23.24

70

745

250'

01811·

01812

01821

982G7

5

• Excellent resistance to oil and moisture

• Good tensile strength, elongation and aging

charactaristlcs

01825

3

01824

4

• High flexlbaity

• Excellent atxasion

98270

5

. • Sun!lght-reslstant

01823"

Industry Approvals:

01822

01821

98463

4

4

119/25

0.050

127

1.000

25.40

60

5

4

119/25

0.050

1.27

1.095

27.81

48

01819

3

2

1331.0211

0.055

1.40

1.085

27.56

01818

98187

4

2

1331.0211

0.055

1.40

1.170

29.72

5

2

1331.0211

0.055

1.40

1.390

35.31

64

Applications!

• Portable tools and equipment

• Temporary and portable POWQf

• Molees and associated machlnety

Features:

resistance

• MSHA Approved

• RoHS Coo-.pIiant

Packaging:

• 250' (762 m). 500' (152.4 m).

1000' (304.8 m)

• Other put-ups available on special order

• NOtHtod< ilem; rrin:rntm~.ity

~

t Gc1:u> C<lOduct.,..forgrounc!ng od-J. ~io:::

""Win9 waigh! r=y V31Y.

COLOR CODe CHART

fOActu;:/

WO-OF

COII:IOClOttS

COLOR

2

Black. White

3

Black. White. Green

4

Black, Wi'.ite. Red. Green

5

Black. White. Red. Orange. Green

~uired.

_

<In NEe bb/.c .:oo..~

918

250'

1030

250'

95

10n

250'

80

1344

250'

1702

250'

NEMA 4 Watertight

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

1P

Industrial Heavy Duty

Non-hazardous Areas

Applications:

Arktite circuit breaking plugs and

receptacles are used:

• To supply power to portable electrically

operated devices such as motorgenerator sets, compressors, heating

and cooling units, welders, conveyors,

lighting systems and similar equipment

Where temporary power is needed, such

as at trailers, building units, heavy

machinery and similar equipment

• Wherever electrical loads must be

quickly disconnected from power source

• In a typical installation, where a large

machine utilizes a number of electrical

motor drives and for ease of adjustment,

removal, maintenance and replacement,

each motor is connected by portable

cord and Arktite receptacles rather than

permanently wired

• In areas where dust, dirt, moisture and

corrosion are a problem

• Indoors and outdoors in non-hazardous

areas of chemical plants, process

industry facilities, meat packing plants,

manufacturing plants and similar

industrial locations

Certifications

Compliances:

and

• UL Standards: 1682, 514; 1010 (APJ and

NPJ plugs only)

• CSA Standard: C22.2 No. 182.1

SPLIT

PIN CONTACT

OESIGN

Split-pin contacts:

• Made of high grade naval brass

to ensure long life

• 360" of contact

between the pin

and sleeve to reduce beet rise

and eliminate arcing

• Self-wiping at every insertion

to prevent contamination

Features:

• Circuit breaking: plugs through 100

ampere rating may be disconnected

under load; 150-400 ampere units are

for service disconnect use only.

• Receptacles accept only plugs of the

same amperage rating, style and

number of poles, making it impossible

to mismate, and provides for positive

polarization.

• Extra wide electrical spacing allows for

maximum safety.

• Insulator materials are the result of

intensive testing. Selection has been

made based on highest dielectric

strength, maximum mechanical and

impact resistance, lowest moisture

absorption and highest arc tracking

resistance.

• A variety of installations is possible due

to the availability of several types of

back boxes.

• Designed to withstand rough usage and

the effects of adverse environments.

• Reversible interiors, 3D, 60 and 100

ampere (except 30 and 60 ampere,

5-pole) Arktite plug and receptacle

interiors are interchangeable using a

screwdriver. This makes it possible to

feed a normally de-energized receptacle

from an energized plug with usual Arktite

safety; no energized contacts are

exposed.

1230

www.crouse-hinos.com

• The additional features below are

called out in the illustration

page

o The ground contact

@

€)

e

o

us; '-866-764-5454

on this

is bonded to the

receptacle housing (Style 2)

Easy access terminals make

wiring simple

Grounding contacts that make-first and

break-last in the unlikely event of

keyway failure

An arc formed when the plug is being

removed is instantly snuffed in the deep

confined insulated arcing chamber

A detent spring forms a parallel

grounding path through the metallic plug

sleeve and receptacle housing and is

the first contact to make and the

last to break

CAN: 1-800-265-0502

Copyright"

o The

plug sleeve is keyed to the

receptacle to prevent mispolarization

6 The

gasketing system provides

unsurpassed watertight integrity

(NEMA4)

9 All aluminum

o

Uni-Shell" construction

provides superior strength in abusive

environments

The Tri-Lock" cable grip has three

clamps which provide even gripping and

superior cord clamping

@ The unique Sure-Seal" cable gland

provides a complete environmental seal

around the cable (NEMA 4)

(D Wrenching surfaces make Arktite plugs

quick and easy to assemble

2010 Cooper Crouse-Hinds

""

COOPER Crouse-Hinds

Arktite® Heavy Duty Circuit

Breaking Plugs and Receptacles

NEMA 4 Watertight

1P

Industrial Heavy Duty

Non-hazardous Areas

Grounding: Style 1

VS.

Style 2

Cooper Crouse-Hinds Arktite devices utilize two methods, or styles, for completing the grounding circuit in plugs and receptacles.

NEC reference 250.138 (A) & (8).

Style 1 - Metallic

Style 2 - Metallic

Style 2 - Non-metallic

A Style 1 plug is one in which the

grounding conductor in the flexible cable is

bonded to the plug sleeve by a pressure

connector. A Style 1 receptacle is one

which is grounded by virtue of the fact that

it is an integral part of a grounded conduit

system. On insertion, the plug sleeve

makes contact with detent springs of the

grounded receptacle housing before line

and load poles engage, and on withdrawal,

remains in contact until after line and load

poles disengage. Therefore, exposed metal

parts of the portable equipment or plug are

suitably grounded.

A Style 2 metallic housing plug is one in

which the grounding conductor in the

flexible cable is bonded to the extra

(grounding) pole and metal plug sleeve by

a pressure connector. A Style 2 metallic

housing receptacle is one in which the

extra (grounding) pole is electrically

connected to the equipment grounding

conductor and the metal receptacle

housing which itself is grounded by virtue

of the fact that it is an integral part of a

grounded conduit system. In Style 2, nonmetallic housing plugs and receptacles, the

extra pole is used for grounding since the

housings are non-conductive.

In a Style 2 receptacle, the grounding

connection is made before line and load

poles engage, and is broken after the line

load poles disengage. Furthermore, upon

insertion, the plug sleeve of metal shelled

units makes contact with detent springs of

the grounded receptacle housing before

line and load poles engage, and on

withdrawal, remains in contact until after

line and load poles disengage. Therefore,

exposed metal parts of the portable

equipment or plug are suitably grounded.

Made of

non-metallic

Krydon

material

Metal

shelled'

type

Style 1

Ground conductor

attaches to shell,

",-

COOPER

Crouse-Hinds

Style 2

Ground conductor

attaches to contact,

which is bonded to

shell.

www.crouse-hind5.com

us: 1-866-764-5454

CAN:

1-800·265-0502

Copyright·

2010 Cooper Crouse-Hinds

1231

lP

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

NEMA 4 Watertight

Industrial Heavy Duty Non-hazardous Areas

Standard Materials:

~

• Metallic receptacle housings, plug and

cord connector bodies - high impact

strength copper-free aluminum

",: ~

I

-=r._

.

I.

Arktite receptacles have a cast raised

rib located inside the receptacle sleeve.

The location of the rib is in a specific

relationship to the receptacle insulator

that houses the contacts.

I

• Non-metallic receptacles, plugs and

cord connectors - Krydon'" fiberglassreinforced polyester material

I

• Back boxes: 20, 30, 60, 100, 150 and

200 ampere - cast aluminum; 400

ampere - Fersloy" iron alloy

• Insulation (metallic products): (2-, 3-,

and 4-pole) 30, 60, 100,200,400

ampere - fiberglass-reinforced

polyester; 20. 30 ampere (5-pole) melamine

• Contacts: pressure, solder. binding

screw - brass; crimp/solder 20, 30, 60,

100 ampere - leaded red brass;

crimp/solder 150, 200. 400 amperetelurium copper

Standard

Finishes:

• Feraloy - electrogalvanized and

aluminum acrylic paint

The mating plug has a cast groove

located on the outside of the plug

sleeve. This groove lines up with the

raised rib.

'-------------

• Aluminum - natural

• Krydon fiberglass-reinforced polyester

material - gray

• Fiberglass-reinforced polyester

insulation - (red)

• Melamine - natural (brown)

• Brass - natural

• Leaded red brass - electro-tin-plate

Accessories:

• Accessories include a variety of angle adapters, panel adapters and back boxes for Arktite

receptacles. See pages 1250-1253.

• Included throughout 1P are wire mesh cable grips and protective caps for Arktite plugs.

Options:

The following special options are available

from factory by adding the suffix to the

Cat. #:

Description

Suffix

• Reversed contacts. Receptacle

assembled with plug interior

(exposed contacts), plug

assembled with receptacle

interior (recessed contacts). For

applications where plug is

energized to feed normally

de-energized receptacle. Available

on 30 through 400 ampere units ... S22

• Special polarity. For use where

two or more receptacles

APQ/NPQ

Arktite Motor Plug

1232

Generator

Switch

APR/NPR

Arktite Connector

of the

www.crouse·hinds.com

Plug

Transforme..t----\:':-1

ARfNR Arktite

Receptacle

Typical Installation

same ampere rating, style and

number of poles are to be

installed in the same area for use

on different voltages and/or

frequencies. Prevents insertion of

a plug in a receptacle with

different electrical rating.

Available on 20 through 400 ampere

units as follows:

• Receptacle interior rotated 22'1'to right and plug changed to

match (see photo to right)

S4

• Cerro-free" epoxy powder finish

for added corrosion resistance

5752

§1S0A, 200A and 400A rated units are for service disconnect

APJ/NPJ Arktite

,,-

use only.

us: 1-866-764-5454

CAN: 1-800-265-0502

Copyright·

2010 Cooper Crouse-Hinds

COOPER Crouse-Hinds

Arktite® Heavy Duty Circuit

Breaking§ Plugs and Receptacles

NEMA 4 Watertight

1P

Industrial Heavy Duty Non-hazardous Areas

Arktite Horsepower

Locked-Rotor

Ratings

Maximum Horsepower for Plug and

Receptacle Combinations by Input

Voltage*

Interrupting

Motor Horsepowert

Ampere Rating

Plug and Receptacle

120

Volts

240

Volts

480

Volts

600

Volts

Single-phase Electrical System

30

2

60

5

100

10

200

15

3

10

20

40

7~

25

10

20

Three-phase Electrical System

30

3

60

10

100

15

200

30

5

20

30

60

10

40

40

25

Following values are typical horsepower ratings based on NEC

Article 430 tables.

HP Ratings are based on the largest conductor size for each

plug and receptacle combination per the Wire Size table below.

Motor Horsepower>!<

10

50

25

15

Ampere Rating

Plug and Receptacle

240

Volts

480

Volts

600

Volts

30

60

100

150

200

15

20

30

40

60

30

40

60

75

125

40

50

75

100

150

Wire Sizes:

The table below lists the diameter of the wire recess in Arktite plug

and receptacle contacts so that maximum size of bare conductor

can be figured. Range of wire sizes shown in table is intended only

as a guide. Depending on type of wire used (building wire, flexible or

extra flexible cable) and its construction (number and size of

strands), bare copper diameters vary widely.

Diameter of Wire Recess in Plug and Receptacle Contacts

Ampere

Rating

Contact

Type

20

30 (2, 3, & 4-pole)

30 (2, 3, & 4-pole)

30 (5-pole)

60 (2, 3, 4 & 5-pole)

60 (3 & 4-pole)

100 (2, 3 & 4-pole)

100 (3 & 4-pole)

150 (4-pole)

200 (3 & 4-pole)

200 (Std. 3 & 4-pole)

200 (Lg. 3 & 4-pole)

400 (Std. 3 & 4-pole)

400 (Lg. 3 & 4-pole)

Binding Screw

Pressure

Crimp/Solder

Solder

Pressure

Crimp/Solder

Pressure

Crimp/Solder

Pressure

Pressure

Crimp/Solder

Crimp/Solder

Crimp/Solder

Crimp/Solder

Wire Size:!:

Diameter

of Recess

NlA

.281

.180

.188

.312

.277

.390

.390

.390

.687

.560

.750

.840

1.25

Building

Extra Flex

#14-#12

#10-#6

#10-#8"

#12-#6

#6-#4

#6-#4"

#4-#1

#2-#1"

#2-2/0

2/0-4/0

#1-410

4/0-250MCM

250-S00MCM

500-1000MCM

#14-#12

#10-#8

#10-#8

#12-#8

#8-#4

#8-#4

#4-#2

#2-#2

#2-1/0

2/0-3/0

#1-3/0

3/0-250MCM

250-400MCM

400-750MCM

§1 SOA, 200A and 400A rated units are for service disconnect use only.

testing in which locked-rotor currents were interrupted by withdrawing the plug from the receptacle.

recommended, however, that such use be limited to emergency conditions only; and that a horsepower rated switch be used for motor disconnect .

t Horsepower ratings are based on Cooper Crouse-Hinds

tt is highly

• This guide is for reference only. ConsuH your local electrical codes before installation.

~ Cooper Crouse--Hinds does not recommend our plug and receptacle be used for discomect under load.

"'SmaUer sizes may be used with well reducers - information available upon request.

~Do not use wire size smaller than minimum size recommended.

,

COOPER Crouse-Hinds

www.crouse-llinds.com

us: 1-866-764·5454

CAN: 1-800-265-0502

CopyrighF

2010 Cooper Crouse-Hinds

1233

NEMA 4 Watertight

Arktite® Heavy Duty Circuit Breaking

Receptacle Assemblies and Housings

1P

100 A, 600 VAC/250 VDC, 50t - 400 hertz

150 A, 600 VAC/250 VDC, 50t - 400 hertz

.'

Receptacle Assembly

Hub

Size (In.)

Description

Spring Door

Cat. #

Receptacle

Mating

Plug

Mating

Connector

Receptacle Housings Only

Spring Door

Threaded Cap

Cat. #

Only Cat. #

Cable

Dia.

Cat. #

Cat. #

100A - Style 1

2-wlre, }

2-pole

1'I.

1'1.

AREA10214

AREA10215

AR1021

AR1027

0.875 to 1.70

APJ10277

APR10257

3-wire, }

3-pole

1'I,

1'/2

AREA10314

AREA10315

AR1031

AR1037

0.875 to 1.70

APJ10377

APR10357

AREA10415

AREA10416

AR1041

AR1047

0.875 to 170

APJ 10477

APR10457

4-wlre, }

4-pole

100 A - Style 2

2-wire, }

3-pole

1'I,

1'/2

AREA10324

AREA10325

AR1032

AR1038

0.875 to 1.70

APJ10387

APR10367

3-wire, }

4-pole

1't.

2

AREA10425

AREA10426

AR1042

AR1048

0875 to 1 70

APJ10487

APR10467

AR1542

AR1548

0.875 to 1.70

APJ15487

150 A - Style 2 *

3-wire, }

4-pole

Dimensions (In Inches):

-•

I:

ARE Assembly

AR Receptacle - Spring Door

No. Poles

No. Poles

Housing

c

20r3

4

2or3

4

open

open

with cap

with cap

3'/"

37116

3"/16

3'/.

No. Poles

b

c

3

3%

3'/"

4

3'h

3

f

10~_·1__

b

---l

APJ Plug

No. Poles

b

2 or 3

3

4

4

6'/,. 3'/.

6% 4'/.

c

f

b

P 1

7

/,.

AR Receptacle - Open and With Cap

APR Connector

t For use on systems less than 60 hertz the receptacles,

• FOf

1240

plugs and connectors are for disconnect use only .

150A • Consult factory for additional options and conf'9uratians.

Consult factory for certifICations information.

www.crouse-hinds.corn

US: 1·866·764·5454

CAN: 1·BO!J..265-0S02

Copyright"

2010 Cooper Crouse-Hinds

""

COOPER Crouse-Hinds

NEMA 4 Watertight

Arktite® Heavy Duty Circuit Breaking

Receptacle Assemblies and Housings

1P

100 A, 600 VAC/250 VDC, 50t - 400 hertz

150 A, 600 VAC/250 VDC, 50t - 400 hertz

Plug Closure Caps:

Applications:

CPK caps for Arktite plugs are used:

• Where portable equipment is on a

standby basis and plugs are not in use

• To effectively protect insulation and

contacts from excessive moisture. dirt.

dust and corrosion

• With 30, SO, 100, 150 and 200 ampere

plugs with fastening ring and standard

200 ampere plugs for the clamp door

housing

Ordering Information

Config.

Cat. #

I~~

& 3P

CPK62

CPK64

Standard Materials:

• Copper-free aluminum

Standard Finishes:

• Natural

Replacement Parts:

Receptacle Interior

Plug Interior

Spring Door

J

Config.

2W2P

Receptacle Interior

ATP315

Plug Interior

ATP310

Spring Door

Screw Cap

2W3P

3W3P

ATP318

ATP316

ATP313

ATP311

QE53

QE62

3W4P

4W4P

ATP319

ATP314

ATP317

ATP312

QE54

QE64

4W5P

5W5P

N/A

N/A

N/A

N/A

N/A

N/A

Screw Cap

Replacement Pin & Sleeve Contacts:

Description

Available as a kit only.

5 phase contacts & 1 ground contact included.

Recep

Plug

AR100CONKIT

AP100CONKIT

t For use on systems less than 60 hertz the receptacles, plugs and connectors are for disconnect use only_

""

COOPER Crouse-Hinds

www.crouse-hinds.com

us: 1-866-764-5454

CAN: 1-800-265-0502

Copyright"

2010 Cooper Crouse-Hinds

1241