Trinity MeyerLD STEEL POLE DESIGNS

October 2013

MeyerLD STEEL POLE DESIGNS

Trinity MeyerLD

STEEL POLE DESIGNS

Trinity MeyerLD STEEL POLES

Table of Contents

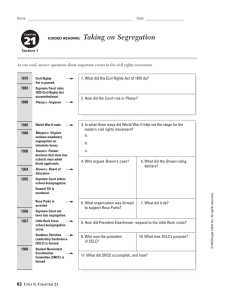

Why Use Steel?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Standard Steel Pole Classification - MeyerLD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard Steel Pole Classification - MeyerLD2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard Steel Pole Classification - MeyerLD3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Standard Steel Pole Classification - MeyerLD4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Standard Steel Pole Classification - MeyerLD5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Steel Pole Classification - MeyerLD6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Steel Pole Classification - MeyerLD7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Standard Steel Pole Classification - MeyerLD8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Standard Steel Pole Classification - MeyerLD9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Standard Steel Pole Classification - MeyerLD10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Standard Steel Pole Classification - MeyerLD11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Standard Steel Pole Classification - MeyerLD12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Plate Thickness - MeyerLD1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Plate Thickness - MeyerLD2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Plate Thickness - MeyerLD3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Plate Thickness - MeyerLD4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Plate Thickness - MeyerLD5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Plate Thickness - MeyerLD6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Plate Thickness - MeyerLD7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Plate Thickness - MeyerLD8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Plate Thickness - MeyerLD9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plate Thickness - MeyerLD10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plate Thickness - MeyerLD11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Plate Thickness - MeyerLD12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Slip Joint Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Standard Davit Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Davit Arm Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LD Bracket Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Standard Davit Arm Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Typical Arm Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Standard Bolt On Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Standard Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standard Galvanized Ladders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Step Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Climbing Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Grounding Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Terms and Conditions of Sale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Catalog #031716

1

Trinity MeyerLD STEEL POLES

Why Use Steel?

Catalog #031716

Steel: The Better Choice

A Trinity Meyer Steel Structures “Light Duty” (LD) transmission pole is a better choice than a wood or concrete pole in most cases. Typically used for voltages from 44kv to 230kv, an LD pole is up to 50% lighter than wood and as much as 80% less weight than a concrete “equivalent”.

More Environmentally Responsible

Surprisingly, steel is the most environmentally responsible of the three materials. Many people think of wood as being 100% recyclable. Wood is renewable, but not 100% recyclable. Wood poles require extensive chemical preservatives to prolong their life. Many groups are concerned about those chemicals leaching into water sources, agricultural and playground dirt, leading many governments to classify wood poles as a hazardous waste which restrict the recycling and landfill choices a pole owner has when the time comes to retire the pole.

And, as the wood pole eventually decays, those chemicals are fully released and the carbon that was bound into the pole’s wood is released back into the environment, giving wood a carbon footprint.

Stronger in All Ways

Stronger than wood, more flexible than concrete, stiffer than composite; steel is unmatched in its universal applicability. Precisely engineered capacities, rather than approximated ones, give you performance you can rely on.

Fewer Poles: Lower Installed Costs; Lower Maintenance Costs: Fewer Headaches

Steel poles support longer spans. Longer spans require fewer poles, less labor, less hardware and less time which result in lower installed costs.

Superior Aesthetics

The predictability and consistency of steel poles’ geometry and straightness provide an advantage in appearance that wood poles cannot offer. The color of a weathering steel pole is very similar to the color of a wood pole, subtly blending into forested backgrounds.

Ease of Handling and Maintenance

The pole handling equipment used to handle wood poles may be used to handle the lighter class-for-class steel pole. Unlike steel poles, wood poles expand and contract over time, requiring periodic maintenance and adjustments to their hardware.

Overall, and for many reasons, steel is simply the better choice.

2

Trinity MeyerLD STEEL POLES

General Notes

Catalog #031716

A. Material - ASTM A871 Modified (Self Weathering) or ASTM A572 modified (galvanized). Fy — 65 ksi

(448 MPa) with a Charpy V-Notch Impact Value of 15 foot-pounds (20.3 joules) at - 20°F/- 29°C (Heat Lot Tested).

B. Pole section properties and moment capacities are calculated in accordance with ASCE/SEI 48-11 and

RUS Bulletin 1724E-214.

1. LD Poles are regular dodecagon (12-Sided Polygon).

2. Pole diameters are measured across the flats.

C. Embedment depths are assumed to be 10% of total pole length +2 ft. (.6m). Actual embedment depths

should be based on existing soil conditions and backfill material.

Example: Pole Length = 80 ft. (24.4m): Assumed embedment depth =10 ft. (3m).

D. For standard steel pole classifications MeyerLD1 -MeyerLD6, standard slip-jointed pole designs are single piece to

total pole length (HT) of 50ft; 2-piece for HT=55ft to HT=90ft, and 3-piece for HT=95ft to HT=120ft. Standard flange

joint pole designs are single piece for HT=50ft, 2-piece for HT=55ft to HT=100ft, and 3-piece for HT=105ft to

HT=120ft. For 55ft and 60ft pole lengths, the top sections are 35ft, for HT=70ft the top section is 45ft. All top sections

within a pole class have the same top diameter, thickness and taper.

E. For standard steel pole classifications MeyerLD7 –MeyerLD12, standard slip-jointed pole designs are single piece

to total pole length (HT) of 50ft; 2-piece for HT=55ft to HT=95ft, and 3-piece for HT=100ft to HT=120ft. Standard

flange joint pole designs are single piece for HT=50ft, 2-piece for HT=55ft to HT=100ft, and 3-piece for

HT=105ft to HT=120ft. For 55ft and 60ft pole lengths, the top sections are 35ft, for HT=70ft the top section is 50ft. All

top sections within a pole class have the same top diameter, thickness and taper.

F. Bearing Plates are welded to the bottom of the poles and extend approximately ¾” (19.05 mm) past the outside

of the tower wall. Bearing plate thicknesses are 3/16” (4.76 mm) for pole diameters = 30” (762 mm), 1/4” (6.35 mm)

for pole diameters > 30” (762 mm) = 45” (1143 mm) and 5/16” (7.94 mm) for pole diameters > 45” (1143 mm). Poles

with a galvanized finish have a sizable opening in the bearing plate to allow for ventilation during galvanizing. Poles

with weathering finishes have bearing plates that are closed. A pole cap is included with each pole.

G. Weld Penetration:

Circumference Weld = 100%

Long Seam Weld = 80%

Long Seam (Female Slip Joint +6”) = 100%

Sealer Plates & Bearing Plates = 3/16 in. (4.8mm) Fillet Weld

H. Pole Grounding is available upon request.

I. Below grade corrosion protection is recommended. Shop applied protective coating and/or

ground sleeves are available upon request.

J. Poles shall be marked with the Trinity Meyer Job number and the LD class and length in feet, e.g. LD2 – 100.

Additional marking is available upon request.

K. Resultant moments were calculated using loading specified in RUS Bulletin 1724E-214.

L. Any correlation of pre-engineered steel pole size to wood pole class is based on Class B construction.

Pre-engineered steel pole sizes shall be selected per section 4.5.4 of ASCE 48-11.

M. The ultimate capacities listed herein are based on the materials’ minimum yield strength. Thus, loads used to calculate

pole moments should include appropriate overload factors.

3

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 8.69 in. (220.7mm)

STANDARD STEEL POLE CLASSIFICATION MeyerLD1

CLASS1; RUS S-02.9

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

13.34/339

13.92/354

14.50/368

14.59/371

15.17/385

15.74/400

16.32/415

16.90/429

17.48/444

18.06/459

18.64/473

19.23/488

19.31/490

19.89/505

20.48/520

21.06/535

21.64/550

Groundline Moment

(ft-kips/kN-m) F-F

93/126

106/144

119/162

132/179

145/197

158/215

171/233

184/250

197/268

210/285

223/303

236/320

248/337

261/355

274/372

287/389

299/406

Estimated Pole

Weight (Black) (lbs./kg)

959/435

1101/499

1248/566

1436/651

1589/721

1765/801

1931/876

2104/954

2283/1036

2466/1119

2657/1205

2931/1329

3130/1420

3332/1511

3543/1607

3757/1704

3979/1805

Top Diameter

= 8.69 in. (220.7mm)

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

STANDARD STEEL POLE CLASSIFICATION MeyerLD2

H-1; RUS S-03.5

Base Dia. at Bearing Plate

(in./mm) F-F

13.99/355

14.64/372

15.31/389

15.47/393

16.14/410

16.80/427

17.46/443

18.12/460

18.79/477

19.44/494

20.11/511

20.77/528

20.93/532

21.60/549

22.25/565

22.92/582

23.58/599

Groundline Moment

(ft-kips/kN-m) F-F

112/152

127/173

143/194

159/215

174/236

190/258

205/279

221/300

236/321

252/342

267/363

283/384

298/405

313/426

329/446

344/467

359/488

Estimated Pole

Weight (Black) (lbs./kg)

990/449

1139/517

1293/586

1494/678

1658/752

1851/840

2029/920

2213/1004

2405/1091

2604/1181

2809/1274

3115/1413

3328/1510

3549/1610

3778/1714

4011/1819

4253/1929

4

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 8.69 in. (220.7mm)

STANDARD STEEL POLE CLASSIFICATION MeyerLD3

H-2; RUS S-04.2

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

14.80/376

15.56/395

16.32/415

16.59/421

17.36/441

18.12/460

18.88/480

19.65/499

20.41/518

21.17/538

21.94/557

22.70/577

22.96/583

23.72/602

24.49/622

25.25/641

26.01/661

Groundline Moment

(ft-kips/kN-m) F-F

132/180

151/205

170/230

188/255

207/280

225/305

244/330

262/355

280/380

299/405

317/430

335/455

354/480

372/504

390/529

408/554

426/579

Estimated Pole

Weight (Black) (lbs./kg)

1027/466

1185/538

1351/613

1566/710

1742/790

1952/885

2145/973

2346/1064

2556/1159

2771/1257

2995/1359

3341/1515

3575/1622

3818/1732

4071/1847

4330/1964

4595/2084

Top Diameter

= 8.69 in. (220.7mm)

STANDARD STEEL POLE CLASSIFICATION MeyerLD4

H-3; RUS S-04.9

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

15.76/400

16.65/423

17.53/445

17.92/455

18.81/478

19.69/500

20.57/522

21.45/545

22.34/567

23.22/590

24.11/612

24.99/635

25.37/644

26.26/667

27.14/689

28.03/712

28.91/734

Groundline Moment

(ft-kips/kN-m) F-F

155/211

177/240

199/270

221/299

242/329

264/358

286/387

307/417

329/446

350/475

372/504

393/534

415/563

436/592

458/621

479/651

501/680

Estimated Pole

Weight (Black) (lbs./kg)

1072/486

1242/563

1421/645

1657/752

1849/839

2079/943

2290/1039

2509/1138

2738/1242

2976/1350

3221/1461

3616/1640

3876/1758

4146/1881

4424/2007

4713/2138

5008/2272

5

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 9.66 in. (245.4mm)

STANDARD STEEL POLE CLASSIFICATION MeyerLD5

H-4; RUS S-05.7

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

17.20/437

18.15/461

19.09/485

19.54/496

20.48/520

21.42/544

22.37/568

23.31/592

24.25/616

25.20/640

26.14/664

27.08/688

27.53/699

28.48/723

29.42/747

30.36/771

31.31/795

Groundline Moment

(ft-kips/kN-m) F-F

180/245

206/279

231/313

256/347

281/382

307/416

332/450

357/484

382/518

407/552

432/586

457/620

482/654

507/688

532/722

557/756

582/790

Estimated Pole

Weight (Black) (lbs./kg)

1180/535

1364/619

1559/707

1827/829

2037/924

2290/1039

2518/1142

2757/1251

3006/1363

3265/1481

3533/1603

3973/1802

4256/1930

4549/2063

4865/2207

5178/2349

5501/2495

Top Diameter

= 9.66 in. (245.4mm)

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

STANDARD STEEL POLE CLASSIFICATION MeyerLD6

H-5; RUS S-06.5

Base Dia. at Bearing Plate

(in./mm) F-F

18.31/465

19.40/493

20.48/520

21.07/535

22.15/563

23.23/590

24.31/617

25.39/645

26.48/673

27.56/700

28.64/727

29.72/755

30.30/770

31.38/797

32.46/824

33.55/852

34.63/880

Groundline Moment

(ft-kips/kN-m) F-F

207/281

236/321

265/360

294/399

323/439

353/478

382/517

410/557

439/596

468/635

497/674

526/714

555/753

584/792

613/831

642/871

671/910

Estimated Pole

Weight (Black) (lbs./kg)

1231/558

1430/649

1640/744

1932/876

2158/979

2435/1104

2685/1218

2945/1336

3216/1459

3498/1587

3793/1720

4321/1960

4633/2101

4957/2248

5997/2720

6454/2927

6927/3142

6

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 9.85 in. (250.2mm)

STANDARD STEEL POLE CLASSIFICATION MeyerLD7

H-6; RUS S-07.4

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

17.08/434

17.98/457

18.88/480

19.16/487

20.07/510

20.97/533

21.88/556

22.78/579

23.68/601

24.58/624

25.49/647

26.39/670

26.67/677

27.58/701

28.48/723

29.38/746

30.28/769

Groundline Moment

(ft-kips/kN-m) F-F

236/321

270/366

303/411

336/455

369/500

402/545

435/590

468/634

501/679

533/723

566/768

599/812

632/857

664/901

697/945

730/990

762/1034

Estimated Pole

Weight (Black) (lbs./kg)

1539/698

1781/808

2035/923

2365/1073

2636/1196

2985/1354

3281/1488

3589/1628

3910/1774

4244/1925

4589/2082

4947/2244

5504/2497

5879/2667

6267/2843

6681/3030

7094/3218

Top Diameter

= 9.85 in. (250.2mm)

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

STANDARD STEEL POLE CLASSIFICATION MeyerLD8

RUS S-08.0

Base Dia. at Bearing Plate

(in./mm) F-F

17.62/448

18.58/472

19.56/497

19.91/506

20.88/530

21.85/555

22.82/580

23.79/604

24.77/629

25.73/654

26.71/678

27.67/703

28.02/712

29.00/737

29.96/761

30.94/786

31.90/810

Groundline Moment

(ft-kips/kN-m) F-F

255/346

291/395

327/443

359/486

398/540

434/588

470/637

505/685

541/733

576/781

612/829

647/877

682/925

718/973

753/1021

789/1069

824/1117

Estimated Pole

Weight (Black) (lbs./kg)

1572/713

1822/826

2085/946

2432/1103

2715/1232

3078/1396

3387/1536

3709/1682

4045/1835

4394/1993

4756/2157

5131/2327

5741/2604

6150/2790

6558/2975

6980/3166

7416/3364

7

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 9.90 in. (251.5mm)

STANDARD STEEL CLASSIFICATION MeyerLD9

RUS S-09.0

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

18.52/470

19.59/498

20.67/525

21.12/536

22.21/564

23.28/591

24.36/619

25.43/646

26.51/673

27.59/701

28.67/728

29.74/755

30.19/767

31.28/795

32.35/822

33.43/849

34.50/876

Groundline Moment

(ft-kips/kN-m) F-F

287/389

327/444

368/499

408/553

448/608

488/662

528/717

568/771

608/825

649/879

688/934

728/988

768/1042

808/1096

848/1150

888/1204

928/1258

Estimated Pole

Weight (Black) (lbs./kg)

1629/739

1892/858

2171/985

2544/1154

2846/1291

3237/1468

3567/1618

3912/1774

4271/1937

4644/2106

5034/2283

5452/2473

6123/2777

6539/2966

6991/3171

7447/3378

7918/3592

Top Diameter

= 10.34 in. (262.6mm)

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

STANDARD STEEL CLASSIFICATION MeyerLD10

RUS S-10.0

Base Dia. at Bearing Plate

(in./mm) F-F

19.51/496

20.66/525

21.81/554

22.33/567

23.48/596

24.62/625

25.77/655

26.92/684

28.07/713

29.21/742

30.36/771

31.51/800

32.03/814

33.18/843

34.33/872

35.48/901

36.62/930

Groundline Moment

(ft-kips/kN-m) F-F

319/433

364/494

409/554

453/615

498/675

543/736

587/797

632/857

677/917

721/978

766/1038

810/1098

854/1159

899/1219

943/1279

988/1339

1032/1399

Estimated Pole

Weight (Black) (lbs./kg)

1713/777

1992/904

2286/1037

2692/1221

3009/1365

3424/1553

3772/1711

4137/1877

4511/2046

4931/2237

5344/2424

5773/2619

6508/2952

6960/3157

7428/3369

7912/3589

8413/3816

8

Catalog #031716

Trinity MeyerLD STEEL POLES

Top Diameter

= 11.50 in. (292.1mm)

STANDARD STEEL CLASSIFICATION MeyerLD11

RUS S-11.0

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

20.57/522

21.70/551

22.84/580

23.36/593

24.50/622

25.63/651

26.77/680

27.90/709

29.04/738

30.17/766

31.31/795

32.44/824

32.95/837

34.09/866

35.22/895

36.36/924

37.49/952

Groundline Moment

(ft-kips/kN-m) F-F

352/477

401/543

450/610

499/677

548/743

597/810

647/877

696/943

745/1010

794/1076

843/1143

892/1209

940/1275

989/1341

1038/1408

1087/1474

1136/1540

Estimated Pole

Weight (Black) (lbs./kg)

1843/836

2136/969

2444/1109

2881/1307

3213/1457

3639/1651

4002/1815

4381/1987

4791/2173

5201/2359

5627/2552

6070/2753

6843/3104

7307/3314

7788/3533

8285/3758

8796/3990

STANDARD STEEL CLASSIFICATION MeyerLD12

RUS S-12.0

Top Diameter

= 11.93 in. (303.0mm)

Total Pole Length

(ft./m)

40/12.19

45/13.72

50/15.24

55/16.76

60/18.29

65/19.81

70/21.34

75/22.86

80/24.38

85/25.91

90/27.43

95/28.96

100/30.48

105/32.00

110/33.53

115/35.05

120/36.58

Base Dia. at Bearing Plate

(in./mm) F-F

21.43/544

22.62/575

23.81/605

24.38/619

25.57/649

26.76/680

27.94/710

29.13/740

30.32/770

31.51/800

32.70/831

33.88/861

34.44/875

35.63/905

36.82/935

38.01/965

39.20/996

Groundline Moment

(ft-kips/kN-m) F-F

384/520

437/593

491/666

544/738

598/811

652/884

705/957

759/1029

813/1102

866/1174

920/1247

973/1319

1026/1392

1080/1464

1133/1536

1186/1609

1241/1682

Estimated Pole

Weight (Black) (lbs./kg)

1920/871

2225/1009

2546/1155

3010/1365

3355/1522

3805/1726

4185/1898

4596/2085

5009/2272

5437/2466

5883/2668

6348/2879

7168/3251

7655/3472

8162/3702

8681/3938

10228/4639

9

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD1

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-01-40

MeyerLD-01-45

MeyerLD-01-50

MeyerLD-01-55

MeyerLD-01-60

MeyerLD-01-65

MeyerLD-01-70

MeyerLD-01-75

MeyerLD-01-80

MeyerLD-01-85

MeyerLD-01-90

MeyerLD-01-95

MeyerLD-01-100

MeyerLD-01-105

MeyerLD-01-110

MeyerLD-01-115

MeyerLD-01-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

PLATE THICKNESS MeyerLD2

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-02-40

MeyerLD-02-45

MeyerLD-02-50

MeyerLD-02-55

MeyerLD-02-60

MeyerLD-02-65

MeyerLD-02-70

MeyerLD-02-75

MeyerLD-02-80

MeyerLD-02-85

MeyerLD-02-90

MeyerLD-02-95

MeyerLD-02-100

MeyerLD-02-105

MeyerLD-02-110

MeyerLD-02-115

MeyerLD-02-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

10

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD3

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-03-40

MeyerLD-03-45

MeyerLD-03-50

MeyerLD-03-55

MeyerLD-03-60

MeyerLD-03-65

MeyerLD-03-70

MeyerLD-03-75

MeyerLD-03-80

MeyerLD-03-85

MeyerLD-03-90

MeyerLD-03-95

MeyerLD-03-100

MeyerLD-03-105

MeyerLD-03-110

MeyerLD-03-115

MeyerLD-03-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

PLATE THICKNESS MeyerLD4

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-04-40

MeyerLD-04-45

MeyerLD-04-50

MeyerLD-04-55

MeyerLD-04-60

MeyerLD-04-65

MeyerLD-04-70

MeyerLD-04-75

MeyerLD-04-80

MeyerLD-04-85

MeyerLD-04-90

MeyerLD-04-95

MeyerLD-04-100

MeyerLD-04-105

MeyerLD-04-110

MeyerLD-04-115

MeyerLD-04-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

11

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD5

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-05-40

MeyerLD-05-45

MeyerLD-05-50

MeyerLD-05-55

MeyerLD-05-60

MeyerLD-05-65

MeyerLD-05-70

MeyerLD-05-75

MeyerLD-05-80

MeyerLD-05-85

MeyerLD-05-90

MeyerLD-05-95

MeyerLD-05-100

MeyerLD-05-105

MeyerLD-05-110

MeyerLD-05-115

MeyerLD-05-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

PLATE THICKNESS MeyerLD6

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-06-40

MeyerLD-06-45

MeyerLD-06-50

MeyerLD-06-55

MeyerLD-06-60

MeyerLD-06-65

MeyerLD-06-70

MeyerLD-06-75

MeyerLD-06-80

MeyerLD-06-85

MeyerLD-06-90

MeyerLD-06-95

MeyerLD-06-100

MeyerLD-06-105

MeyerLD-06-110

MeyerLD-06-115

MeyerLD-06-120

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

0.1875

Bottom

0.1875

0.1875

0.1875

0.250

0.250

0.250

12

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Top

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

Section Thicknesses, mm

Middle Bottom

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

4.763

6.350

6.350

6.350

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD7

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-07-40

MeyerLD-07-45

MeyerLD-07-50

MeyerLD-07-55

MeyerLD-07-60

MeyerLD-07-65

MeyerLD-07-70

MeyerLD-07-75

MeyerLD-07-80

MeyerLD-07-85

MeyerLD-07-90

MeyerLD-07-95

MeyerLD-07-100

MeyerLD-07-105

MeyerLD-07-110

MeyerLD-07-115

MeyerLD-07-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.250

PLATE THICKNESS MeyerLD8

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-08-40

MeyerLD-08-45

MeyerLD-08-50

MeyerLD-08-55

MeyerLD-08-60

MeyerLD-08-65

MeyerLD-08-70

MeyerLD-08-75

MeyerLD-08-80

MeyerLD-08-85

MeyerLD-08-90

MeyerLD-08-95

MeyerLD-08-100

MeyerLD-08-105

MeyerLD-08-110

MeyerLD-08-115

MeyerLD-08-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.250

13

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD9

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-09-40

MeyerLD-09-45

MeyerLD-09-50

MeyerLD-09-55

MeyerLD-09-60

MeyerLD-09-65

MeyerLD-09-70

MeyerLD-09-75

MeyerLD-09-80

MeyerLD-09-85

MeyerLD-09-90

MeyerLD-09-95

MeyerLD-09-100

MeyerLD-09-105

MeyerLD-09-110

MeyerLD-09-115

MeyerLD-09-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.250

PLATE THICKNESS MeyerLD10

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-10-40

MeyerLD-10-45

MeyerLD-10-50

MeyerLD-10-55

MeyerLD-10-60

MeyerLD-10-65

MeyerLD-10-70

MeyerLD-10-75

MeyerLD-10-80

MeyerLD-10-85

MeyerLD-10-90

MeyerLD-10-95

MeyerLD-10-100

MeyerLD-10-105

MeyerLD-10-110

MeyerLD-10-115

MeyerLD-10-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.250

14

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Catalog #031716

Trinity MeyerLD STEEL POLES

PLATE THICKNESS MeyerLD11

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-11-40

MeyerLD-11-45

MeyerLD-11-50

MeyerLD-11-55

MeyerLD-11-60

MeyerLD-11-65

MeyerLD-11-70

MeyerLD-11-75

MeyerLD-11-80

MeyerLD-11-85

MeyerLD-11-90

MeyerLD-11-95

MeyerLD-11-100

MeyerLD-11-105

MeyerLD-11-110

MeyerLD-11-115

MeyerLD-11-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.250

PLATE THICKNESS MeyerLD12

Pole Designation Top

Section Thicknesses, inches

Middle

MeyerLD-12-40

MeyerLD-12-45

MeyerLD-12-50

MeyerLD-12-55

MeyerLD-12-60

MeyerLD-12-65

MeyerLD-12-70

MeyerLD-12-75

MeyerLD-12-80

MeyerLD-12-85

MeyerLD-12-90

MeyerLD-12-95

MeyerLD-12-100

MeyerLD-12-105

MeyerLD-12-110

MeyerLD-12-115

MeyerLD-12-120

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

Bottom

0.250

0.250

0.250

0.250

0.3125

15

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Top

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

Section Thicknesses, mm

Middle Bottom

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

6.350

7.938

Trinity MeyerLD STEEL POLES

SLIP JOINT CONFIGURATION

Catalog #031716

Slip Joint Configuration (LD1 – LD6)

2 PIECE

65 - 90’

3 PIECE

95 - 120’

Slip Joint Configuration (LD7 – LD12)

2 PIECE

65 - 95’

3 PIECE

100 - 120’

1 PIECE

UP TO 50’

2 PIECE

55 - 60’

1 PIECE

UP TO 50’

2 PIECE

55 - 60’

16

Trinity MeyerLD STEEL POLES

STANDARD DAVIT ARMS

Catalog #031716

ARM RISE = 1”/ft (83.3mm/m) of ARM LENGTH

STANDARD DAVIT ARMS - CURVED

AVAILABLE UPON REQUEST ONLY

ARM RISE = 1”/ft (83.3mm/m) of ARM LENGTH

GENERAL NOTES

1. Material - ASTM A871 modified (self-weathering) painted or ASTM A572 modified (galvanized) F

Y

=65 ksi (448 MPa) with a Charpy V-Notch Impact

Value of 15 foot-pounds (20.3 Joules) at -20ºF/-29ºC (Heat Lot Tested).

2. Welds:

Long Seam - 50% Pentr

Bracket to Shaft - .375”/9.5mm Fillet

End Plate to Shaft - .1875”/4.76mm Fillet

3. All bolts - A325 Type III - 92 ksi (634 MPa).

4. All slots - 1.125”/28.6mm x 1.5”/38.1mm.

5. Arm and vang ratings represent hardware capacities only. It is the customer’s responsibility to determine the capacity of pole to resist applied loads.

6. Arms should not be used for permanent deadend or permanent unbalanced conditions.

7. Steel davit arms shall not be left unloaded.

8. Catalog no. and description.

L S A W 40

Bracket - (A) or (C)

End PL - Susp (S) or Dead End (D)

Duty - Light (L), Medium (M), or Heavy (H)

Length Indicator

Finish - Weathering (W),

Painted (P), Galvanized (G)

*Maximum loads shown in chart applied non-simultaneously.

For simultaneous load application:

ML = L x Arm Length

MV = V x Arm Length + (T x W) + Arm Weight x Arm Length

2

SR = ML + MV

Yield Strength

Check SR ≤ Actual Section Modulus

NOTATION:

ML = Longitudinal moment

MV = Vertical moment

L = Longitudinal load

V = Vertical load

T = Transverse load

W = Rise (see tabulation)

Arm Length units

SR = Required section modulus

Actual section modulus listed in tabulation

17

Trinity MeyerLD STEEL POLES

DAVIT ARM DETAILS

1" 25mm HOLE

(GALV. ARMS ONLY

4" 102mm

2" 51mm

R1 1/2" 38mm 1 1/8" 29mm HOLE

END PLATE 'S' - SUSPENSION

10 1/2" 267mm

7 1/2" 191mm

1" 25mm HOLE

(GALV. ARMS ONLY)

(3) 1 1/8" 29mm

HOLES

R1 1/2" 38mm

TYP

END PLATE 'D' - DEADEND

18

Catalog #031716

Trinity MeyerLD STEEL POLES

LD BRACKET DETAILS

Catalog #031716

R5" 127mm

R1 1/2" 38mm

(2 PLCS)

"C" "D"

REF

"B"

"A"

75°0' 1 1/2" 38mm

R5/8" 16mm

TYP

"D"

2 5/8" 67mm

"A" PL

CL ARM CL ARM

"H""

"J"

(2) 1" HOLES

(GALVANIZED ARMS ONLY)

BRACKET 'A'

STANDARD

"H""

"J"

(2) 1" 25mm HOLES

(GALVANIZED ARMS ONLY)

BRACKET 'C'

ALLOWS INDEPENDENT MOUNTING

OF TWO ARMS BACK TO BACK AT

ONE ELEVATION.

PAINTED OR

WEATHERING

GALVANIZED

BRK’T “A” BRK’T “C” BRK’T “A” BRK’T “C”

DUTY “A” “B” “C” “D” “E” “F” “G” “H” “J” “K” “L”

69067 ---------- 69076 ---------- LIGHT 7/16” 72.2” 36.1” 6 7/16” 13 1/2” 6 3/4” 10 1/2” 4 3/8” 8 3/4”

69068 ---------- 69077 ---------- MEDIUM 7/16” 103.5” 51.7” 8 9/16” 19” 9 1/2” 16”

5 3/4” 2 1/8”

6 9/32” 12 9/16” 7 15/16” 3 1/8”

69069 ---------- 69078 ---------- HEAVY 1/2” 103.5” 51.7” 8 11/16” 24”

69073 69082 LIGHT 1/2” -------- -------- 4” 13 1/2”

9 1/2”

6 3/4”

16” 6 11/32” 12 11/16” 7 7/16” 4 1/8”

10 1/2” 7 13/32” 14 13/16” 5 11/16” 2 1/8”

69074

69075

69083 MEDIUM 1/2”

69084 HEAVY 1/2”

-------- --------

--------- --------

5”

6”

19”

24”

9 1/2”

9 1/2”

16” 7 29/32” 15 13/16” 7 15/16” 3 1/8”

16” 8 13/32” 16 13/16” 7 7/16” 4 1/8”

19

Trinity MeyerLD STEEL POLES

STANDARD DAVIT ARMS

Catalog #031716

LIGHT DUTY ARMS

PLATE THICKNESS = .1875"/4.76mm - 65 KSI (448 MPa) SMALL END SQUARE = 3”/76.2mm, LARGE END SQUARE = 4"/101.6mm, SECTION MODULUS = 2.803in

3 /45.94cm

3

CATALOG NO. ARM LENGTH

L_40

L_45

4 ft/1.22m

4.5 ft/1.37m

L_50

L_55

L_60

L_65

5 ft/1.52m

5.5 ft/1.68m

6 ft/1.83m

6.5 ft/1.98m

L_70

L_75

L_80

L_85

L_90

L_95

L_10

7 ft/2.13m

7.5 ft/2.29m

8 ft/2.44m

8.5 ft/2.59m

9 ft/2.74m

9.5 ft/2.90m

10 ft/3.05m

ARM WEIGHT

68 Lbs/31 Kg

72 Lbs/33 Kg

76 Lbs/35 Kg

80 Lbs/37 Kg

84 Lbs/39 Kg

88 Lbs/40 Kg

92 Lbs/42 Kg

96 Lbs/44 Kg

99 Lbs/45 Kg

103 Lbs/47 Kg

107 Lbs/49 Kg

111 Lbs/51 Kg

115 Lbs/53 Kg

ARM RISE

4 in/102mm

4.5 in/114mm

5 in/127mm

5.5 in/140mm

6 in/152mm

6.5 in/165mm

7 in/178mm

7.5 in/191mm

8 in/203mm

8.5 in/216mm

9 in/229mm

9.5 in/241mm

10 in/254mm

*V Lbs/V Kg

3,745/1,698

3,323/1,507

2,986/1,354

2,710/1,229

2,480/1,125

2,285/1,036

2,118/961

1,974/895

1,847/838

1,736/787

1,636/742

1,548/702

1,468/666

*T Lbs/T Kg

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

2,500/1,134

* L Lbs/L Kg

1,250/567

1,111/504

1,000/454

909/412

833/378

769/349

714/324

667/303

625/283

588/267

556/252

526/239

500/227

MEDIUM DUTY ARMS

PLATE THICKNESS = .1875"/4.76mm - 65 KSI (448 MPa) SMALL END SQUARE = 3”/76.2mm, LARGE END SQUARE = 5"/127mm, SECTION MODULUS = 4.783in

3 /78.39cm

3

CATALOG NO. ARM LENGTH

M_40

M_45

4 ft/1.22m

4.5 ft/1.37m

M_50

M_55

M_60

M_65

5 ft/1.52m

5.5 ft/1.68m

6 ft/1.83m

6.5 ft/1.98m

M_70

M_75

M_80

M_85

M_90

M_95

M_10

7 ft/2.13m

7.5 ft/2.29m

8 ft/2.44m

8.5 ft/2.59m

9 ft/2.74m

9.5 ft/2.90m

10 ft/3.05m

ARM WEIGHT

88 Lbs/40 Kg

93 Lbs/42 Kg

97 Lbs/44 Kg

102 Lbs/46 Kg

106 Lbs/48 Kg

111 Lbs/50 Kg

115 Lbs/52 Kg

120 Lbs/54 Kg

124 Lbs/56 Kg

129 Lbs/59 Kg

133 Lbs/61 Kg

138 Lbs/63 Kg

142 Lbs/65 Kg

ARM RISE

4 in/102mm

4.5 in/114mm

5 in/127mm

5.5 in/140mm

6 in/152mm

6.5 in/165mm

7 in/178mm

7.5 in/191mm

8 in/203mm

8.5 in/216mm

9 in/229mm

9.5 in/241mm

10 in/254mm

*V Lbs/V Kg

6,421/2,913

5,702/2,586

5,126/2,325

4,655/2,112

4,262/1,932

3,930/1,783

3,646/1,654

3,399/1,542

3,183/1,444

2,992/1,357

2,823/1,281

2,672/1,212

2,535/1,150

*T Lbs/T Kg

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

* L Lbs/L Kg

1,250/567

1,111/504

1,000/454

909/412

833/378

769/349

714/324

667/303

625/283

588/267

556/252

526/239

500/227

HEAVY DUTY ARMS

PLATE THICKNESS = .1875"/4.76mm - 65 KSI (448 MPa) SMALL END SQUARE = 3.5”/88.9mm, LARGE END SQUARE = 6"/152mm, SECTION MODULUS = 7.267in

3 /119.11cm

3

CATALOG NO. ARM LENGTH

H_40 4 ft/1.22m

H_45

H_50

H_55

H_60

H_65

H_70

H_75

H_80

H_85

H_90

H_95

H_10

4.5 ft/1.37m

5 ft/1.52m

5.5 ft/1.68m

6 ft/1.83m

6.5 ft/1.98m

7 ft/2.13m

7.5 ft/2.29m

8 ft/2.44m

8.5 ft/2.59m

9 ft/2.74m

9.5 ft/2.90m

10 ft/3.05m

ARM WEIGHT

111 Lbs/50 Kg

116 Lbs/53 Kg

122 Lbs/55 Kg

127 Lbs/58 Kg

133 Lbs/60 Kg

138 Lbs/63 Kg

143 Lbs/65 Kg

149 Lbs/68 Kg

155 Lbs/70 Kg

160 Lbs/73 Kg

165 Lbs/75 Kg

172 Lbs/78 Kg

177 Lbs/81 Kg

ARM RISE

4 in/102mm

4.5 in/114mm

5 in/127mm

5.5 in/140mm

6 in/152mm

6.5 in/165mm

7 in/178mm

7.5 in/191mm

8 in/203mm

8.5 in/216mm

9 in/229mm

9.5 in/241mm

10 in/254mm

*V Lbs/V Kg

9,780/4,436

8,687/3,940

7,812/3,544

7,096/3,219

6,560/2,976

5,995/2,719

5,563/2,523

5,188/2,353

4,860/2,205

4,570/2,073

4,313/1,956

4,083/1,852

3,876/1,758

*T Lbs/T Kg

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

4,000/1,814

* L Lbs/L Kg

1,250/567

1,111/504

1,000/454

909/412

833/378

769/349

714/324

667/303

625/283

588/267

556/252

526/239

500/227

20

Trinity MeyerLD STEEL POLES

TYPICAL ARM ASSEMBLIES

Catalog #031716

CURVED RECTANGULAR

WASHER

FLATWASHER

1" [25mm] BOLT WITH NUT

BOLT LENGTH = POLE + 3" [76mm]

ROUNDED UP

1" [25mm] NUT

TYPE A

SINGLE ARM MOUNTING WITH STANDARD BRACKET

"A" SHOWN. FOR DOUBLE ARM MOUNTING,

THE CURVED WASHERS WOULD BE OMITTED.

ARM WITH MOUNTING

BRACKET "A"

1" [25mm] THREADED ROD WITH NUTS

ROD LENGTH = POLE + 10.5" [267mm]

ROUNDED UP

FLATWASHER

1" [25mm] NUT

CURVED RECTANGULAR

WASHER

CURVED RECTANGULAR

WASHER

TYPE C

ARMS MAY BE INDEPENDENTLY MOUNTED.

DOUBLE ARM MOUNTING WITH OPTIONAL

BRACKET "C" SHOWN.

21

Trinity MeyerLD STEEL POLES

STANDARD BOLT ON HARDWARE

4 1/2" 114mm

3" 76mm

R5" 127mm

5" 127mm

CURVED SQUARE WASHER

1 1/2" 38mm

LOAD DIRECTION

R2 1/2" 64mm

3/4" [19mm] BOLT WITH NUT

TORQUE TO 100 FT. LBS. [136 n-m]

BOLT LENGTH = POLE + 2 1/2" [64mm]

ROUNDED UP

VANG ASSEMBLY

10 KIP [4,535 kg] - CATALOG NO. 69054

20 KIP [9,071 kg] - CATALOG NO. 69057

10 OR 20 KIP VANG

4 3/4" 121mm

3" 76mm

(2) 7/8 [22mm]

HOLES

3" 76mm - 69054

4" [102mm] - 69057

5" 127

R5" 127mm

CURVED RECTANGULAR

WASHER

1" [25mm] BOLT WITH NUT

TORQUE TO 150 FT. LBS. [203 n-m]

BOLT LENGTH = POLE +3" [76mm]

ROUNDED UP

R1 3/4" 44mm

1 1/2" 38mm HOLE

45°0'

LOAD DIRECTION

VANG ASSEMBLY 40 KIP [18,144 kg]

GUY OR X-BRACE VANG ASSEMBLY

CATALOG NO. 69060

40 KIP VANG

(2) 1 3/16" [30mm]HOLES

Catalog #031716

22

Trinity MeyerLD STEEL POLES

STANDARD FASTENERS

Catalog #031716

10 KIP/44kN & 20 KIP/89kN VANG ASSEMBLIES

3/4”/19mm Dia. Bolt with 1 Nut

POLE DIAMETER RANGE

(Point to Point Diameters)*

> 8.5”/216mm ≤ 10.5”/267mm

BOLT LENGTH BOLT MARK

13 in/330mm

Weathering Galvanized

65313 69343

> 10.5”/267mm ≤ 12.5”/318mm 15 in/381mm

> 12.5”/318mm ≤ 14.5”/368mm 17 in/432mm

> 14.5”/368mm ≤ 16.5”/419mm 19 in/483mm

> 16.5”/419mm ≤ 18.5”/470mm 21 in/533mm

65315

65317

65319

65321

69345

69347

69349

69351

> 18.5”/470mm ≤ 20.5”/521mm 23 in/584mm

> 20.5”/521 mm ≤ 22.5”/572mm 25 in/635mm

> 22.5”/572mm ≤ 24.5”/622mm 27 in/686mm

> 24.5”/622mm ≤ 26.5”/673mm 29 in/737mm

65323

65325

65327

65329

69353

69355

69357

69359

40 KIP/178kN VANG ASSEMBLIES

1”/25mm Dia. Bolt with 1 Nut

POLE DIAMETER RANGE

(Point to Point Diameters)*

> 8”/203mm ≤ 10”/254mm

> 10”/254mm ≤ 12”/305mm

> 12”/305mm ≤ 14”/356mm

> 14”/356mm ≤ 16”/406mm

> 16”/406mm ≤ 18”/457mm

> 18”/457mm ≤ 20”/508mm

> 20”/508mm ≤ 22”/559mm

> 22”/559mm ≤ 24”/610mm

> 24”/610mm ≤ 26”/660mm

BOLT LENGTH BOLT MARK

13 in/330mm

Weathering Galvanized

65413 78310

15 in/381mm

17 in/432mm

19 in/483mm

21 in/533mm

65415

65417

65419

65421

78311

78312

78313

78314

23 in/584mm

25 in/635mm

27 in/686mm

29 in/737mm

65423

65425

65427

65429

78315

78316

78317

78318

DAVIT ARMS WITH “A” BRACKET

1”/25mm Dia. Bolt with 1 Nut

POLE DIAMETER RANGE

(Point to Point Diameters)*

> 6.5”/165mm ≤ 9.5”/241mm

> 9.5”/241mm ≤ 11.5”/292mm

> 15”/381mm ≤ 17”/432mm

> 17”/432mm ≤ 19”/483mm

> 19”/483mm ≤ 21”/533mm

> 21”/533mm ≤ 23”/584mm

> 23”/584mm ≤ 25”/635mm

BOLT LENGTH BOLT MARK

13 in/330mm

15 in/381mm

> 11.5”/292mm ≤ 13.5”/343mm 17 in/432mm

> 13.5”/343mm ≤ 15”/381mm 19 in/483mm

21 in/533mm

23 in/584mm

25 in/635mm

27 in/686mm

29 in/737mm

Weathering Galvanized

65413

65415

65417

65419

65421

65423

65425

65427

65429

78310

78311

78312

78313

78314

78315

78316

78317

78318

DAVIT ARMS WITH “C” BRACKET

1”/25mm Dia. Rod with 2 Nuts

POLE DIAMETER RANGE

(Point to Point Diameters)*

> 6.5”/165mm ≤ 9.5”/241mm

> 9.5”/241mm ≤ 11.5”/292mm

> 15”/381mm ≤ 17”/432mm

> 17”/432mm ≤ 19”/483mm

BOLT LENGTH BOLT MARK

19 in/483mm

21 in/533mm

> 11.5”/292mm ≤ 13.5”/343mm 23 in/584mm

> 13.5”/343mm ≤ 15”/381mm 25 in/635mm

27 in/686mm

29 in/737mm

> 19”/483mm ≤ 20.5”/521mm 31 in/787mm

> 20.5”/521 mm ≤ 22.5”/572mm 33 in/838mm

> 22.5”/572mm ≤ 24.5”/622mm 35 in/889mm

Weathering Galvanized

66419

66421

66423

66425

66427

66429

66431

66433

66435

78330

78331

78332

78333

78334

78335

78336

78337

78338

Miscellaneous Hardware

3/4”/19mm Dia. Nut

1”/25mm Dia. Nut

1”/25mm Dia. Flat Washer

1”/25mm Dia. Lock Washer

Curved Square Washer

Curved Rectangular Washer

Weathering Galvanized

70677 73441

72940

74269

N/A

69064

69066

73442

74115

74120

N/A

N/A

C L

1/2" [51mm] MIN.

1 1/2" [38mm] MAX.

6"

152mm

R1 3/4"

44mm

1 1/2" 38mm HOLE

3 1/2" [89mm] MIN.

4 1/2" [114mm] MAX.

EQUAL EQUAL

STANDARD THRU VANG

23

Trinity MeyerLD STEEL POLES

STANDARD LADDERS

7 7/8"

200mm

1 1/2"

38mm

Catalog #031716

1 1/2"

38mm

15"

381mm

TYP

15"

381mm

TYP

5"

127mm

3/4" x 7 1/2" [19mm X 188mm]

BUTTON HEAD STEP BOLT

3'-10 1/2"

1181mm

CATALOG NO. 69342 - WEATHERING

CATALOG NO. 50921 - GALVANIZED

3'-10 1/2"

1181mm

4'-6 1/2"

1384mm

7 7/8"

200mm

1 1/2"

38mm

1 1/2"

38mm

15"

381mm

TYP

15"

381mm

TYP

6"

152mm

3/4" x 6 11/16" [19mm X 170mm]

BUTTON HEAD STEP BOLT

3'-10 1/2"

1181mm

CATALOG NO. 69344 - WEATHERING

CATALOG NO. 52540 - GALVANIZED

24

3'-10 1/2"

1181mm

4'-6 1/2"

1384mm

Trinity MeyerLD STEEL POLES

STANDARD STEP BOLTS

6 3/4"

171mm

11/16"

17mm

6 1/16"

154mm

WITH 4" KNURLED

STANDARD STEP BOLT

CATALOG NO. 70860 - WEATHERING

CATALOG NO. 70859 - GALVANIZED

CATALOG NO. 70677 - WEATHERING

CATALOG NO. 74137 - GALVANIZED

7 1/2"

191mm

1 1/2"

38mm

6"

152mm

WITH 4" KNURLED

STANDARD STEP BOLT - 3/4" DIA

CATALOG NO. 79087 - WEATHERING

CATALOG NO. 79097 - GALVANIZED

25

Catalog #031716

Trinity MeyerLD STEEL POLES

CLIMBING ATTACHMENTS

2 1/16"

53mm

3/16"

5mm

29/32"

23mm

1 13/16"

46mm

STANDARD LADDER CLIP

(ALL FINISHES)

CATALOG NO. 76266

1/4"

6mm

2"

51mm

1 1/4"

32mm

1 1/2"

38mm

FOR 3/4" [19mm] STEP BOLT

(ALL FINISHES)

CATALOG NO. 78086

13/16"

21mm

HOLE

26

Catalog #031716

Trinity MeyerLD STEEL POLES

GROUNDING OPTIONS

1 1/2"

38mm

3/4"

19mm

3 1/2"

89mm

7/8"

22mm

1 3/4"

44mm

(2) 1/2" [13mm] - 13 UNC THREADS

TAPPED OVERSIZE

CATALOG NO. 78131

1/2" [13mm] - 13 UNC THREADS

TAPPED OVERSIZE

CATALOG NO. 73515

27

Catalog #031716

Trinity MeyerLD STEEL POLES

TERMS AND CONDITIONS OF SALE

Catalog #031716

TRINITY MEYER UTILITY STRUCTURES, LLC

Terms and Conditions of Sale

The following Terms and Conditions shall govern all transactions between Trinity Meyer Utility Structures, LLC (“TRINITY”) and any buyer or potential buyer (the “Buyer”) placing orders for or otherwise purchasing products (the “Products”) from TRINITY. Notwithstanding any contrary language in

Buyer’s purchase order or any other document purporting to set forth any additional or different terms or conditions governing the purchase and sale of the Products, these Terms and Conditions set forth the full and final expression of the contract of sale of Products by Trinity to the Buyer. No modification of these Terms and Conditions, nor any additional or different term or condition stated in Buyer’s purchase order shall be binding on

TRINITY unless specifically approved in writing in a written agreement signed by an authorized representative of TRINITY. To the extent that the submission of any bid or quotation, or the furnishing of any Products by TRINITY could be considered to operate as an acceptance of any prior terms or conditions published by Buyer, such bid, quotation or furnishing of such Products is expressly made on the condition that Buyer assents to these Terms and Conditions.

1) Delivery, Title, Risk of Loss

All sales are FOB Origin, freight prepaid and added unless otherwise specified by TRINITY. Title to and risk of loss in Products will pass to the Buyer at the

FOB point.

2) Payment Terms

Payment terms for partial and compete shipments are net 30 days from date of invoice. Products are invoiced upon delivery. Buyer agrees to pay a finance charge of one and one-half percent per month (or at the highest rate allowed by law, whichever is less) on all past due balances.

3) Delivery Schedules/Delays

All delivery commitments by TRINITY are good faith estimates based upon current information available from our suppliers at the time the dates for delivery are established. TRINITY shall not be liable for any failure to deliver, or delay in delivery to Buyer to the extent that such failure or delay results from causes beyond TRINITY’s reasonable control including, without any limitation, any act of God, fire, flood, explosion, war, revolution, riot, act of terrorism, boycott, embargo, accident, unavailability of energy or raw materials or the enactment or implementation of any law, regulation, order or decree that is not in effect at the time the order is placed. In the event of any delay in performance due to any such cause, the date of delivery will be extended by a period of time reasonably necessary to overcome the effect of such delay.

4) Taxes

The Buyer shall be fully responsible for the payment of all sales, use, excise, value added and similar taxes applicable to the sale and transportation of the Products. In lieu of paying such taxes to TRINITY, Buyer may furnish TRINITY an exemption certificate or similar documentation acceptable to appropriate taxing authorities.

5) Inspection and Acceptance

Buyer may inspect the Products during business hours at TRINITY’s facility on reasonable notice to TRINITY provided such inspection does not unreasonably interfere with TRINITY’s operations. Unless otherwise agreed in writing, Buyer agrees to accept delivery of all or any portion of the

Products as they are completed and delivered to Purchaser.

6) Compliance with Laws

Buyer and TRINITY agree and covenant that they will each comply with all applicable laws and regulations of the United States and all other jurisdictions regarding the marketing, sale, export and distribution of Products, including, but not limited to, the U.S. export control laws and the U.S.

Foreign Corrupt Practices Act. Buyer covenants that it has not paid, and that it will not pay, offer to pay, agree to pay, or authorize or cause to be paid, directly or indirectly, any money or anything of value to any foreign official (as defined in the U.S. Foreign Corrupt Practices Act) to induce such official to use their influence to obtain an improper business advantage in connection with the purchase, sale, installation or use of any Products.

7) Warranty

TRINITY warrants that Products are being sold to Buyer free and clear of any encumbrances arising through TRINITY. In addition, TRINITY warrants that all Products will conform to mutually agreed specifications for the Products (“Specifications”) and will otherwise be free from defects in workmanship for 18 months from the date of delivery, or 12 months from the date of installation, whichever is earlier. TRINITY agrees to repair or replace any Product that is not in conformance with the foregoing warranties. Buyer’s sole remedy for any breach of this warranty shall be limited to repair or replacement

(at TRINITY’s option) of the warranted Product, provided that TRINITY’s obligations under such warranties shall be waived by Buyer if Buyer fails to (i) provide TRINITY written notice of Buyer’s specific warranty claim and the Product(s) affected, and (ii) provide TRINITY with reasonable opportunity to inspect the Product(s) that are the subject of Buyer’s warranty claim to confirm a warranted defect manifesting during the warranty period. Following

TRINITY’s inspection and confirmation of a warranted defect, TRINITY agrees to perform its warranty obligations within a reasonable period of time, provided Buyer has satisfied its warranty claim obligations in this section during the Warranty Period. Any repair or replacement by Seller shall not extend the Warranty Period.

Other than the warranty of title, the warranties herein do not apply under any circumstances to any type of corrosion irrespective of the cause, or damages or defects due to normal wear and tear, misuse or mishandling or to any Equipment that: (i) is modified or repaired by a party other than

Seller without Seller’s specific prior approval; (ii) is modified or repaired in a manner that is not in accordance with Seller’s erection drawings or prudent industry practice; (iii) is not installed and maintained in a manner consistent with prudent industry practice; (iv) is damaged by any vibration, oscillation or resonance associated with movement of air currents around the Equipment; or (vi) has experienced loads in excess of maximum design loads. Seller specifically disclaims any and all warranties, express or implied, in connection therewith and Purchaser shall have no recourse to Seller therefor. Further, this warranty does not cover and the Purchaser assumes all responsibility and the consequences arising from the structural integrity of any existing foundation, anchorage or other structures upon which the Equipment may be used or installed.

28

Catalog #031716

TERMS AND CONDITIONS OF SALE

THE WARRANTIES AND REMEDIES STATED HEREIN ARE TRINITY’S EXCLUSIVE WARRANTIES IN CONNECTION WITH THE PRODUCTS AND BUYER’S SOLE

REMEDIES IN CONNECTION WITH ANY BREACH THEREOF. THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS AND IMPLIED,

INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED.

TRINITY shall not be liable for any costs, losses, expenses or damages beyond the cost of repair or replacement. All costs associated with the removal and reinstallation of the Product shall be borne by Buyer. The foregoing exclusions and limitations on remedies shall apply notwithstanding any failure of essential purpose.

8) Patent Indemnity

TRINITY will defend any suit or proceeding brought against Buyer to the extent that such suit or proceeding is based on a claim that any Product purchased by Buyer or any part thereof constitutes an infringement of any United States patent issued as of the date of TRINITY’s quotation or proposal. TRINITY shall have no obligation of defense or indemnity to the extent that any alleged infringement is attributable to any design or other special requirement specified by Buyer. In the event that a Product or part thereof is held to infringe a patent and the use thereof is enjoined, TRINITY shall, at its expense and option, either (a) obtain for Buyer the right to continue using such Product or part, (b) replace the Product or part with a Product or part that is non-infringing,

(c) modify the Product or part so that it becomes non-infringing, or (d) accept the return of the Product and refund the purchase price, less applicable depreciation. The foregoing states the entire liability of TRINITY for patent infringement by the Products.

9) Modifications; Cancellation

Any changes in the Specifications or delivery of an order or any cancellation of an order must be requested by a party with reasonable advance written notice to the other party and instituted only on such terms as are mutually agreed in writing by Buyer and TRINITY.

10) Limitation of Liability

IN NO EVENT SHALL TRINITY BE LIABLE TO BUYER AND BUYER WAIVES ALL CLAIMS FOR ANY CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR SPECIAL

DAMAGES, WHETHER BASED UPON NEGLIGENCE, BREACH OF WARRANTY, STRICT LIABILITY IN TORT OR ANY OTHER THEORY OF RECOVERY. TRINITY’S

LIABILITY IN CONNECTION WITH ANY ORDER SHALL NOT EXCEED THE INVOICED AMOUNT OF THE ORDER.

11) Back charges and Setoffs

Unless such charges are authorized by TRINITY in writing in advance, no allowances will be made to Buyer and Buyer shall not withhold any back charges, setoffs, deductions or credits against amounts otherwise due TRINITY.

12) Use of Intellectual Property

The ownership of all copyrights and other intellectual property rights in all designs, drawings, technical reports and technical calculations developed or provided by TRINITY will remain with TRINITY. TRINITY grants to Buyer a perpetual, royalty-free, world-wide non-exclusive license to use and reproduce any designs, drawings, technical reports and technical calculations developed by TRINITY in connection with the Products. This license is limited to the right to use and reproduce such designs, drawings, reports and calculations for Buyer’s own use in the erection, installation and maintenance of the specific

Product for which the applicable design, drawing, report or calculation was developed.

13) Insurance

TRINITY agrees to maintain the following insurance:

(i) Commercial General Liability in the amount of $2 million each occurrence and annual aggregate.

(ii) Workers’ Compensation in accordance with statutory requirements of the state where Trinity’s manufacturing facility is located and Employers’ Liability in the amount of $1 million.

(iii) Automobile Liability Insurance in the amount of $ 2 million covering owned, non-owned and hired vehicles.

A certificate of insurance evidencing the above coverage will be furnished upon request.

14) Confidentiality

Buyer shall not disclose to any third party these terms and conditions, the Product price, or any data, information, or designs provided by TRINITY in manufacturing and delivering the Products, which obligation shall survive Delivery of any Products. The obligations of this provision shall not apply to any information, data, or design(s) which Buyer can show it possessed prior to disclosure thereof by TRINITY, was or has become generally publicly known through no breach hereof by Buyer or its suppliers or contractors, or is subsequently provided to Buyer by another party having the right to possess and disclose the information, data, or designs.

15) Miscellaneous

The validity, construction and interpretation of all orders and releases; the sale of the goods or materials by TRINITY to Buyer; the rights and duties of the parties with respect to such sale; and any disputes arising out of the foregoing shall be governed by and construed under the laws of the State of