VCR® Metal Gasket Face Seal Fittings, (MS-01

advertisement

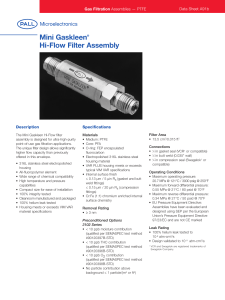

www.swagelok.com VCR ® Metal G asket Face Se al Fit tings ■ 1/16 to 1 in. and 6 to 18 mm sizes ■ High-purity stainless steels ■ The original design, the authentic VCR brand 2 VCR Metal Gasket Face Seal Fittings Contents Typical VCR Assemblies . . . . . . . . . . . 2 Features . . . . . . . . . . . . . . . . . . . . . . . . 3 Materials of Construction . . . . . . . . . . 3 Pressure Ratings . . . . . . . . . . . . . . . . . 3 Temperature Ratings . . . . . . . . . . . . . . 3 Testing . . . . . . . . . . . . . . . . . . . . . . . . . 3 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 4 Ultrahigh-Purity Processing . . . . . . . . 4 Ordering Information, Pressure Ratings, and Dimensions . . . 4 Welded Assemblies Male NPT Connector . . . . . . . . . . . . . . 13 Female NPT Connector . . . . . . . . . . . . 13 Swagelok Tube Fitting Connector . . . . 13 Rotating Female Union . . . . . . . . . . . . 13 Nuts, Caps, and Plugs . . . . . . . . . . . 14 High-Flow Connections—“H” Type VCR Glands . . . . . . . . . . . . . . . . . . . . . . . . . 15 Glands Bodies . . . . . . . . . . . . . . . . . . . . . . . . . 15 Tube Butt Weld . . . . . . . . . . . . . . . . . . 4 Socket Weld . . . . . . . . . . . . . . . . . . . . 6 Male Weld . . . . . . . . . . . . . . . . . . . . . . 7 Tube Adapter . . . . . . . . . . . . . . . . . . . . 7 Blind . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Gaskets . . . . . . . . . . . . . . . . . . . . . . . . 17 Options and Accessories Flow Restrictors . . . . . . . . . . . . . . . . . 18 Bodies Lock and Tag Devices . . . . . . . . . . . . . 18 Male Connectors . . . . . . . . . . . . . . . . . 8 Female Connector . . . . . . . . . . . . . . . . 9 Swagelok Tube Fitting Connector . . . . 9 Side-Load Installation Tool and Tray . . . . . . . . . . . . . . . . . . . . 18 Installation Instructions . . . . . . . . . . 19 Male Unions . . . . . . . . . . . . . . . . . . . . . 10 Tube Butt Weld Bulkhead Connector . . . . . . . . . . . . . . 10 Coupling . . . . . . . . . . . . . . . . . . . . . . . 11 Reducers . . . . . . . . . . . . . . . . . . . . . . . 11 Elbows, Tee, Cross . . . . . . . . . . . . . . . 11 Typical VCR Assemblies Female nut Gland Side-load retainer gasket Gland OR Female nut Gland Gasket Body Male nut VCR Metal Gasket Face Seal Fittings 3 Features Swagelok® VCR fittings offer the high purity of a metalto-metal seal, providing leak-tight service from vacuum to positive pressure. Minimal clearance required for removal The seal on a VCR assembly is made when the gasket is compressed by two beads during the engagement of a male nut or body hex and a female nut. Side-load retainer gasket for easy installation and minimal clearance for removal Test port at two locations for easy leak testing Markings identify manufacturer, material, and when applicable, the appropriate process designator, in accordance with Swagelok Ultrahigh-Purity Process Specification (SC‑01), MS-06-61 Standard surface finish on glands and bodies is a roughness average of 10 µin. (0.25 µm) Ra No “virtual leak” zones Precision manufactured gasket for maximum performance Female threads are silver plated to prevent galling, ensure easy, consistent assembly Materials of Construction Material Pressure Ratings Designator Specification Glands, Bodies, and Nuts Bar stock: ASME SA479 ASTM A276 316 stainless steel SS Forged shapes: ASME SA182 ASTM A314 316L stainless steel 316L VAR stainless steel 316L Bar stock: ASME SA479 ASTM A276 Forged shapes: ASME A182 6LV Material heat code is stamped on glands and all shapes to ensure raw material traceability SEMI F20‑0305 High-Purity➀ ■ All ratings comply with calculations in accordance with ASME Code for Pressure Piping B31.3, Process Piping, and ASME B31.1, Power Piping. ■ Working pressure ratings determined at room temperature with gasket materials shown. Temperature Ratings Components Fittings NI ASTM F3 316L stainless steel SS ASTM A240 Copper CU ASTM B152 Temperature, °F (°C) 316L stainless steel 1000 (537) 316L stainless steel 1000 (537) Nickel 600 (315) Copper 400 (204) 316L VAR stainless steel Gaskets Nickel Material 316 stainless steel Gaskets ➀ 20 % minimum elongation allowed. Testing Plating The VCR fitting design has been helium leak tested to a maximum leak rate of 4 3 10 –9 std cm3/s with silver-plated and copper gaskets and to a maximum leak rate of 4 3 10 –11 std cm3/s with unplated gaskets. VCR female nuts are silver plated. Avoid chemical processes used for cleaning, electropolishing, and passivation that will remove plating. If the plating is damaged or removed, thread galling may occur, damaging fitting components and preventing a proper seal. 4 VCR Metal Gasket Face Seal Fittings Cleaning Ultrahigh-Purity Processing Components are cleaned to remove oil, grease, and loose particles. For more information, see Swagelok Standard Cleaning and Packaging (SC-10), MS-06-62. A variety of VCR face seal glands and bodies is available with controlled surface finishes, electropolished, and specially cleaned to meet ultrahigh-purity system requirements. For more information, see Swagelok UltrahighPurity Process Specification (SC-01), MS-06-61. Ordering Information, Pressure Ratings, and Dimensions ■ Dimensions are for reference only and are subject to change. ■ The E dimension refers to the smallest nominal inside diameter of the part. ■ To order fittings manufactured in accordance with Swagelok Ultrahigh-Purity Process Specification (SC-01), MS-06-61, add P to the ordering number. Example: 6LV-4-VCR-3-4TB7P Glands Short Tube Butt Weld E C Tube Size Nominal Wall Thickness VCR Size in. Ordering Number Dimensions A C Working Pressure E Dimensions, in. (mm) A 1/8 1/8 6LV-2-VCR-3S-2TB7➀ 0.028 1/4 6LV-4-VCR-3S-2TB7 6LV-4-VCR-3S-4TB2 1/4 1/4 6LV-4-VCR-3S-4TB3 0.035 6LV-4-VCR-3S-4TB7 1/2 6LV-8-VCR-3S-4TB7 6LV-8-VCR-3S-6TB2 3/8 0.035 1/2 6LV-8-VCR-3S-6TB7 6LV-8-VCR-3S-8TB2 1/2 0.049 1/2 6LV-8-VCR-3S-8TB3 6LV-8-VCR-3S-8TB7 Ni 1.0 1/4 6LV-4-VCR-3S-6MTB7 8 1.0 1/4 6LV-4-VCR-3S-8MTB7 10 1.0 1/2 6LV-8-VCR-3S-10MTB7 12 1.0 1/2 6LV-8-VCR-3S-12MTB7 18 1.5 3/4 6LV-12-VCR-3S-18MTB7 ➀ Not designed for gasket retainer assembly. Cu 1.08 (27.4) 0.75 0.06 (585) (585) (468) 1.10 (19.1) (1.5) 5100 5100 5100 (351) (351) (351) 5100 5100 5100 (351) (351) (351) (27.9) 0.60 0.25 (15.2) (6.4) 0.72 0.38 (18.3) (9.6) 0.18 1.10 0.75 (4.6) (27.9) (19.1) 1.12 0.75 3500 4300 2800 (28.4) (19.1) (241) (296) (192) 0.62 0.25 (15.7) (6.4) 0.31 3300 3300 2600 1.12 0.75 (7.9) (227) (227) (179) (28.4) (19.1) 0.62 0.25 (15.7) (6.4) 0.74 0.38 0.40 3500 3500 2800 (18.8) (9.6) (10.2) (241) (241) (192) 1.12 0.75 (28.4) (19.1) 29.5 4.0 468 (1.16) (0.16) (6800) (6800) 29.5 6.0 337 337 337 (1.16) (0.24) (4900) (4900) (4900) Dimensions, mm (in.) 6 SS psig (bar) 8500 8500 6800 bar (psig) 468 372 (5400) 29.5 19.1 8.0 241 241 192 (1.16) (0.75) (0.31) (3500) (3500) (2800) 29.5 10.0 213 213 165 (1.16) (0.39) (3100) (3100) (2400) 31.0 15.0 206 206 165 (1.22) (0.59) (3000) (3000) (2400) VCR Metal Gasket Face Seal Fittings Glands 5 Long Tube Butt Weld E C Tube Size Nominal Wall Thickness VCR Size in. Dimensions Ordering Number A C Working Pressure E Dimensions, in. (mm) A 1/8 0.028 1/8 6LV-2-VCR-3-2TB7➀ 6LV-4-VCR-3-4TB2 6LV-4-VCR-3-02205 1/4 1/4 0.035 6LV-4-VCR-3-4TB3 6LV-4-VCR-3-4TB7 1/2 6LV-8-VCR-3-4TB7 6LV-8-VCR-3-6TB2 3/8 0.035 1/2 6LV-8-VCR-3-6TB7 6LV-8-VCR-3-8TB2 1/2 0.049 1/2 6LV-8-VCR-3-8TB3 6LV-8-VCR-3-8TB7 3/4 1 0.049 0.065 3/4 1 6LV-12-VCR-3-12TB7 6LV-16-VCR-3-16TB7 1.42 0.75 (36.1) (19.1) 1.20 0.25 (30.5) (6.4) 1.31 0.36 0.06 (1.5)➁ (33.3) (9.1) 1.32 0.38 0.18 (33.5) (9.6) (4.6) 1.70 0.75 (43.2) (19.1) 1.0 1/4 6LV-4-VCR-3-6MTB7 8 1.0 1/4 6LV-4-VCR-3-8MTB7 10 1.0 1/2 6LV-8-VCR-3-10MTB7 12 1.0 1/2 6LV-8-VCR-3-12MTB7 18 1.5 3/4 6LV-12-VCR-3-18MTB7 SS Cu psig (bar) 8500 8500 6800 (585) (585) (468) 5100 5100 5100 (351) (351) (351) 1.80 0.75 3500 4300 2800 (45.7) (19.1) (241) (296) (192) 1.29 0.25 (32.8) (6.4) 0.31 3300 3300 2600 1.79 0.75 (7.9) (227) (227) (179) (45.5) (19.1) 1.29 0.25 (32.8) (6.4) 1.41 0.38 0.40 3500 3500 2800 (35.8) (9.6) (10.2) (241) (241) (192) 1.79 0.75 (45.5) (19.1) 1900 2.03 0.75 0.65 2400 2400 (51.6) (19.1) (16.5) (165) (165) (130) 2.32 0.75 0.87 2400 2400 1900 (58.9) (19.1) (22.1) (165) (165) (130) Dimensions, mm (in.) 6 Ni bar (psig) 468 468 372 43.2 4.0 (1.70) (0.16) (6800) (6800) 43.2 6.0 337 337 337 (1.70) (0.24) (4900) (4900) (4900) (5400) 45.5 19.1 8.0 241 241 192 (1.79) (0.75) (0.31) (3500) (3500) (2800) 45.5 10.0 213 213 165 (1.79) (0.39) (3100) (3100) (2400) 51.6 15.0 206 206 165 (2.03) (0.59) (3000) (3000) (2400) ➀ Not designed for gasket retainer assembly. ➁ May contain internal diameter transitions. Short Automatic Tube Butt Weld Tx D E C Tube Size Nominal Wall Thickness VCR Size in. Ordering Number Dimensions A C Working Pressure D E Tx 0.02 0.18 0.29 Dimensions, in. (mm) A 1/4 3/8 1/2 0.035 0.035 0.049 1/4 1/2 1/2 316L-4-VCR-3AS 316L-8-VCR-3AS6 316L-8-VCR-3AS 1.12 (28.4) 1.15 0.75 (29.2) (19.1) 1/4 316L-4-VCR-3-6MAS 1/4 316L-4-VCR-3-8MAS 10 1/2 316L-8-VCR-3-10MAS 12 1/2 316L-8-VCR-3-12MAS 8 1.0 SS Cu psig (bar) 5100 5100 5100 (0.5) (4.6) (7.4) (351) 0.03 0.31 0.41 3300 3300 2600 (351) (0.8) (7.9) (10.4) (227) 0.04 0.40 0.55 3500 3500 2800 (29.5) (1.0) (10.2) (14.0) (241) 30.0 0.5 4.0 (1.18) (0.02) (0.16) 30.2 (1.19) 19.1 31.0 (0.75) (1.22) 0.8 6.0 (0.03) (0.24) 0.8 8.0 (0.03) (0.31) 6.8 (227) (351) 1.16 Dimensions, mm (in.) 6 Ni (241) (179) (192) bar (psig) 468 468 372 (0.27) (6800) (6800) (5400) 8.9 337 337 337 (0.35) (4900) (4900) (4900) 10.9 241 241 192 (0.43) (3500) (3500) (2800) 30.5 1.0 10.0 13.2 (1.20) (0.04) (0.39) (0.52) (3100) (3100) (2400) 213 213 165 6 VCR Metal Gasket Face Seal Fittings Glands Long Automatic Tube Butt Weld E Tx D C Tube Size Nominal Wall Thickness VCR Size in. Dimensions Ordering Number A C D Working Pressure E Tx Ni Dimensions, in. (mm) A 1/4 1/4 1/2 3/8 1/2 3/4 1 1.72 316L-4-VCR-3A 0.035 0.035 0.049 0.049 0.065 1/2 1/2 3/4 1 316L-8-VCR-3A4 316L-8-VCR-3A 316L-12-VCR-3A 316L-16-VCR-3A 0.75 0.02 0.18 0.29 (351) 1.82 (19.1) (0.5) (4.6) (7.4) 3500 3500 2800 1.82 0.75 0.03 0.31 0.41 3300 3300 2600 (46.2) (19.1) (0.8) (7.9) (10.4) (227) 1.83 0.75 0.04 0.40 0.55 3500 3500 2800 (46.5) (19.1) (1.0) (10.2) (14.0) (241) 2.07 0.75 0.04 0.65 0.80 2400 2400 2400 (52.6) (19.1) (1.0) (16.5) (20.3) (165) 2.57 0.96 0.04 0.87 1.06 2400 2400 1900 (65.3) (24.4) (1.0) (22.1) (26.9) (165) (241) Dimensions, mm (in.) 6 1.0 1/4 316L-4-VCR-3-6MA 12 1.0 1/2 316L-8-VCR-3-12MA 18 1.5 3/4 316L-12-VCR-3-18MA 43.7 0.5 4.0 (1.72) (0.02) (0.16) E D Tube Socket Size VCR Size 1/16 1/8 1/4 3/8 1/2 5/8 3/4 1 A D 1/8 1/8 SS-2-VCR-3➁ 1/4 SS-4-VCR-3 1/2 SS-6-VCR-3➂ 1/2 5/8 3/4 1 SS-8-VCR-3 SS-10-VCR-3 SS-12-VCR-3 SS-16-VCR-3 6.8 D Tube Socket Size VCR Size 1.0 10.0 13.2 (0.39) (0.52) (3100) (3100) (2400) 213 206 1.0 15.0 19.3 (0.04) (0.59) (0.76) (3000) (3000) (2400) Working Pressure Tx Ni SS Cu psig (bar) 9000 9000 7200 0.13 (3.3) (620) (620) (496) 0.70 0.10 0.09 0.20 7100 7100 7100 (17.8) (2.5) (2.3) (5.1) (489) (489) (489) 1.31 0.28 0.18 0.35 5500 5500 5500 (33.3) (7.1) (4.6) (8.9) (378) (378) (378) 1.50 0.31 0.28 0.60 3500 4300 2800 (38.1) (7.9) (7.1) (15.2) (241) (296) (192) 1.50 0.38 0.40 0.60 3000 3000 2400 (38.1) (9.6) (10.2) (15.2) (206) (206) (165) 1.56 0.41 0.50 0.72 2800 2800 2200 (39.6) (10.4) (12.7) (18.3) (192) (192) (151) 2.00 0.44 0.62 0.88 2800 2800 2200 (50.8) (11.2) (15.7) (22.4) (192) (192) (151) 2.22 0.62 0.87 1.19 2400 3000 1900 (56.4) (15.7) (22.1) (30.2) (165) (206) (130) Dimensions A 1/4 1/4 SS-4-VCR-3-.75LG E Working Pressure Tx Ni SS Cu psig (bar) (12.7) 0.28 0.18 0.35 5500 5500 5500 0.75 (7.1) (4.6) (8.9) (378) (378) (378) (19.1) 206 165 52.6 (1.3) Dimensions, in. (mm) 0.50 SS-4-VCR-3-.50LG 213 (2.07) 0.05 D (130) (0.04) (2.5) A (165) (165) 19.1 (17.8) Ordering Number (165) (192) (0.75) Short Socket Weld E (241) (179) (0.27) (6800) (6800) (5400) ➀ Uses 1/8 in. gasket and nut. ➁ Not designed for gasket retainer assembly. ➂ Uses 1/2 in. gasket and nut. Tx (227) (192) 46.5 E Dimensions, in. (mm) 0.70 0.10 SS-1-VCR-3➀➁ A (241) (351) (1.83) Dimensions Ordering Number (351) bar (psig) 468 468 372 Socket Weld Tx Cu (43.7) (46.2) 316L-8-VCR-3A6 SS psig (bar) 5100 5100 5100 165 VCR Metal Gasket Face Seal Fittings Glands Reducing Socket Weld E Tube Socket Size Tx D VCR Size A 1/8 1/4 1/4 1/2 Dimensions Ordering Number A D Working Pressure E Tx Ni SS Cu Dimensions, in. (mm) 1.31 SS-4-VCR-3-2TSW 0.10 0.09 (2.5) (2.3)➀ 0.35 (33.3) (8.9) (551) (551) (551) 1.50 0.28 0.18 0.60 3500 3500 3500 (38.1) (7.1) (4.6) (15.2) (241) (241) (241) SS-8-VCR-3-4TSW psig (bar) 8000 8000 8000 ➀ May contain internal diameter transitions. Male Weld Tube Size E C VCR Size Dimensions Ordering Number A C Working Pressure E Ni Dimensions, in. (mm) A 1/8 0.70 SS-2-VCR-3-2MTW➀ 1/8 1/4 1/4 SS-4-VCR-3-2MTW SS-4-VCR-3-4MTW 1/4 1/2 3/8 1/2 3/4 1 1/2 1/2 3/4 1 SS-8-VCR-3-4MTW (17.8) 0.28 1.31 (7.1) 0.06 (1.5)➁ SS-8-VCR-3-8MTW SS-12-VCR-3-12MTW SS-16-VCR-3-16MTW (620) (771) (496) 8000 10 000 6400 (551) (689) (440) 1.31 8000 10 000 6400 (33.3) 0.41 0.12 (551) (689) (440) 1.50 (10.4) (3.0) 3500 4300 2800 (241) (296) (192) 1.50 0.41 0.28 3500 4300 2800 (38.1) (10.4) (7.1) (241) (296) (192) 1.50 0.50 0.40 3500 3500 3500 (38.1) (12.7) (10.2) (241) (241) (241) 2.00 0.62 0.53 3000 3700 2400 (50.8) (15.7) (13.5) (206) (254) (165) 2.22 0.81 0.75 2400 3000 1900 (56.4) (20.6) (19.1) (165) (206) (130) ➀ Not designed for gasket retainer assembly. ➁ May contain internal diameter transitions. Tube Adapter E C Tube Size VCR Size A 1/4 3/8 1/2 1/4 1/2 1/2 Dimensions Ordering Number A Dimensions, in. (mm) 1.62 SS-4-VCR-3-4TA SS-8-VCR-3-6TA SS-8-VCR-3-8TA A Ordering Number 0.64 Working Pressure E 0.17 Ni SS Cu psig (bar) 8000 10 000 6400 (16.2) (4.3) (551) (689) (440) 1.81 0.70 0.27 4300 2800 (46.0) (17.8) (6.8)➀ 3500 (241) (296) (192) 1.94 0.96 0.37 3500 4300 2800 (49.3) (24.4) (9.4) (241) (296) (192) Blind (Undrilled) Gland VCR Size C (41.0) ➀ May contain internal diameter transitions. A Dimensions, in. (mm) 1/8 SS-2-VCR-3-BL➀ 0.70 (17.8) 1/4 SS-4-VCR-3-BL 1.31 (33.3) 1/2 SS-8-VCR-3-BL 1.50 (38.1) 3/4 SS-12-VCR-3-BL 2.00 (50.8) 1 SS-16-VCR-3-BL 2.22 (56.4) ➀ Not designed for gasket retainer assembly. Cu (33.3) (38.1) SS-8-VCR-3-6MTW SS psig (bar) 9000 11 200 7200 7 8 VCR Metal Gasket Face Seal Fittings Bodies Male NPT Connector ➀ F flat NPT Size VCR Size E 1/16 C A Dimensions Ordering Number A 1/8 1/8 SS-2-VCR-1-2➁ (27.2) 1/4 1/4 SS-4-VCR-1-2 SS-4-VCR-1-4 1/4 1/2 1/2 3/4 1/2 1/2 3/4 1 1 E SS-8-VCR-1-4 0.09 (9.6) (2.3)➂ (27.2) 0.38 (2.3)➂ 1.31 (9.6) 0.18 (33.3) (4.6) 1.49 0.18 (37.8) 0.56 (4.6) 1.65 (14.2) 0.28 SS-8-VCR-1-8 SS-12-VCR-1-12 SS-16-VCR-1-16 0.56 0.38 (41.9) (14.2) (9.6) 1.84 0.75 0.40 (46.7) (19.1) (10.2) 2.19 0.75 0.62 (55.6) (19.1) (15.7) 2.47 0.94 0.87 (62.7) (23.9) (22.1) SS Cu psig (bar) 7200 9000 9000 7/16 5/8 5/8 15/16 (7.1)➂ 1.65 Ni 3/8 0.09 (41.9) SS-8-VCR-1-6 F 0.38 1.07 1/8 3/8 C Dimensions, in. (mm) 1.07 SS-2-VCR-1-1➁ Working Pressure 15/16 15/16 1 5/16 1 5/8 (620) (620) (496) 9000 9000 7200 (620) (620) (496) 8000 10 000 6400 (551) (689) (440) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) Select male connectors are available with ISO/BSP tapered thread (RT) ends. Contact your authorized Swagelok representative. ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. ➂ May contain internal diameter transitions. F flat Male NPT Bulkhead Connector ➀ F1 flat E1 E C L A D Dimensions NPT Size VCR Size Ordering Number 1/4 A SS-4-VCR-A1-4M 1/4 1/2 SS-8-VCR-A1-4M C D E E1 F 2.34 Dimensions, in. (mm) 0.62 0.18 (15.7) (4.6) 0.56 0.28 (7.1) 0.75 (14.2) 0.40 (59.4) (19.1) 2.21 (56.1) (10.2) Working Pressure F1 Panel Hole Dia L Max Panel Thickness Ni SS Cu psig (bar) 8000 8000 6400 13/16 13/16 15/16 1.24 21/32 0.38 (551) (551) (440) (31.5) (16.8) (9.7) 3500 4370 2800 (241) (301) (192) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. F flat Straight Thread O-Ring Seal Male Connector ➀ E1 E A Straight Thread Size 9/16-18 7/8-14 9/16-18 VCR Size 1/4 1/2 1/2 C D Uniform O-Ring➁ Size Ordering Number Dimensions A C D E Working Pressure E1 906 Dimensions, in. (mm) 1.33 SS-4-VCR-1-00032 0.39 0.25 0.18 0.28 (33.8) (9.9) (6.4) (4.6) (7.1) 910 1.66 0.50 0.40 0.28 0.59 (42.2) (12.7) (10.2) (7.1) (15.0) 1.48 0.39 0.28 0.28 (37.6) (9.9) (7.1) (7.1) 906 SS-8-VCR-1-00176 SS-8-VCR-1-01081 — F 3/4 1 15/16 Ni SS Cu psig (bar) 4500 4500 4500 (310) (310) (310) 3500 3500 2800 (241) (241) (192) 3500 3500 2800 (241) (241) (192) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Fluorocarbon FKM is standard, other materials are available. O-rings are assembled with a silicone vacuum grease. VCR Metal Gasket Face Seal Fittings Bodies Female NPT Connector ➀ F flat NPT Size VCR Size Ordering Number E 1/16 A 0.09 (27.9) (2.3) 1/8 SS-2-VCR-7-2➁ 1.19 0.09 (30.2) (2.3) 1.41 0.18 (35.8) (4.6) 1.54 0.18 (39.1) (4.6) 1.76 0.40 (44.7) (10.2) 1.99 0.40 (50.5) (10.2) 2.36 0.62 (59.9) (15.7) 2.51 0.87 (63.8) (22.1) SS-4-VCR-7-2 1/4 SS-4-VCR-7-4 1/2 1/2 SS-8-VCR-7-6 1/2 3/4 SS-8-VCR-7-8 3/4 1 SS-12-VCR-7-12 1 SS-16-VCR-7-16 Working Pressure E 1/8 1/4 3/8 A Dimensions, in. (mm) 1.10 SS-2-VCR-7-1➁ 1/8 1/4 Dimensions F Ni 7/16 9/16 5/8 3/4 15/16 1 1/16 1 5/16 1 5/8 SS Cu psig (bar) 6700 6700 6700 (461) (461) (461) 6500 6500 6500 (447) (447) (447) 8000 8000 6400 (551) (551) (440) 6600 6600 5200 (454) (454) (358) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Swagelok Tube Fitting Connector ➀ F flat G flat Tube Size E D C A VCR Size Ordering Number Dimensions A C D 1/8 1/4 Dimensions, in. (mm) 0.60 0.50 1.53 SS-4-VCR-6-200 1/4 1/4 SS-4-VCR-6-400 3/8 1/2 SS-8-VCR-6-600 1/2 1/2 SS-8-VCR-6-810 E 0.09 (38.9) (15.2) (12.7) (2.3)➁ 1.62 0.70 0.60 0.18 (41.1) (17.8) (15.2) (4.6) 1.84 0.76 0.66 0.28 (46.7) (19.3) (16.8) 1.95 0.86 0.90 (49.5) (21.8) (22.9) Working Pressure F 5/8 7/16 5/8 9/16 15/16 (7.1)➁ 0.40 15/16 (10.2) G 11/16 7/8 Ni SS Cu psig (bar) 8000 10 000 6400 (551) (689) (440) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) Dimensions A, C, and D are typical finger-tight. Swagelok nuts and ferrules are provided assembled, as shown. For tubing maximum pressure ratings for use with Swagelok tube fittings, see Swagelok Tubing Data, MS-01-107. ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ May contain internal diameter transitions. F flat F1 flat G flat Swagelok Tube Fitting Bulkhead Connector ➀ E A C D Dimensions Tube Size VCR Size Ordering Number SS-4-VCR-A1-400 1/4 1/4 SS-4-VCR-A1S-400 3/8 1/2 1/2 1/2 SS-8-VCR-A1-600 SS-8-VCR-A1-810 A C D E F 1.88 Dimensions, in. (mm) 1.32 (33.5) 0.60 0.18 5/8 (4.6) 1.05 (15.2) (47.8) (26.7) 2.54 1.45 0.66 0.28 (64.5) (36.8) (16.8) (7.1) 2.74 1.65 0.90 0.40 (69.6) (41.9) (22.9) (10.2) 2.25 (57.2) 15/16 F1 Working Pressure G Panel Hole Size Max Panel Thickness 0.40 5/8 3/4 15/16 15/16 9/16 11/16 7/8 Ni SS Cu psig (bar) 8000 10 000 6400 15/32 (10.2) (551) (11.9) 0.13 8000 10 000 6400 (689) (440) (3.3) (551) (689) (440) 19/32 (15.0) 25/32 0.44 3500 4300 2800 (11.2) (241) (296) (192) 0.50 3500 4300 2800 (19.8) (12.7) (241) (296) (192) Dimensions A, C, and D are typical finger-tight. Swagelok nuts and ferrules are provided assembled, as shown. For tubing maximum pressure ratings for use with Swagelok tube fittings, see Swagelok Tubing Data, MS-01-107. ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. 9 10 VCR Metal Gasket Face Seal Fittings Bodies Male Union ➀ F flat VCR Size E 1/8 A 1/4 1/2 3/4 1 Dimensions Ordering Number A E Dimensions, in. (mm) 1.13 SS-2-VCR-6-DM➁ SS-4-VCR-6-DM SS-8-VCR-6-DM SS-12-VCR-6-DM SS-16-VCR-6-DM Working Pressure F 0.09 (28.7) (2.3) 1.55 0.18 (39.4) (4.6) 1.84 0.40 (46.7) (10.2) 2.44 0.62 (62.0) (15.7) 2.59 0.87 (65.8) (22.1) Ni 3/8 5/8 15/16 1 5/16 1 5/8 SS Cu psig (bar) 9000 11 200 7200 (620) (771) (496) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Male Reducing Union ➀ F flat E1 VCR Size E 1/4 A 1/2 VCR Size 1/8 1/4 Dimensions Ordering Number A E Dimensions, in. (mm) 1.37 SS-4-VCR-6-DM-2➁ SS-8-VCR-6-DM-4 Working Pressure F E1 0.09 0.18 (34.8) (2.3) (4.6) 1.71 0.18 0.40 (43.4) (4.6) (10.2) 5/8 15/16 Ni SS Cu psig (bar) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Male Bulkhead Union ➀ F1 flat F flat Dimensions VCR Size E A C Ordering Number SS-4-VCR-61 1/4 SS-4-VCR-61S SS-8-VCR-61 1/2 SS-8-VCR-61S A C E F Working Pressure Panel Hole Dia F1 Dimensions, in. (mm) 2.23 1.30 (56.6) (33.0) 0.18 3/4 3/4 1.82 0.99 (4.6) 2.57 2.14 Ni SS Cu psig (bar) 0.44 19/32 (11.2) 8000 10 000 6400 (15.0) 0.13 (551) (689) (440) (46.2) (25.1) (3.3) 1.48 (65.3) (37.6) Max Panel Thickness 0.50 0.40 1.11 (10.2) 1 1/16 1 1/16 29/32 (12.7) 3500 4300 2800 (23.1) 0.13 (241) (296) (192) (54.4) (28.2) (3.3) ➀ VCR components with fixed threads must remain stationary during installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. F flat Tube Butt Weld Bulkhead Connector ➀ F flat E1 E B A C Dimensions Tube Size VCR Size Ordering Number 6LV-4-VCR-61-4TB7 1/4 1/4 6LV-4-VCR-61S-4TB7 A B C E Dimensions, in. (mm) 1.30 2.36 (59.9) (33.0) 0.75 0.18 (19.1) (4.6) 0.99 1.95 (49.5) (25.1) E1 Working Pressure F Panel Hole Dia Max Panel Thickness Ni SS Cu psig (bar) 0.44 0.22 (5.6) 3/4 19/32 (11.2) 5100 5100 5100 (15.0) 0.13 (351) (351) (351) (3.3) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. VCR Metal Gasket Face Seal Fittings Bodies Coupling Leak test port F flat VCR Size Dimensions Ordering Number A F Dimensions, in. (mm) A 1/8 SS-2-VCR-CG 0.66 (16.8) 1/4 SS-4-VCR-CG 1.19 (30.2) 7/16 3/4 1/2 SS-8-VCR-CG 1.31 (33.3) 1 1/16 3/4 SS-12-VCR-CG 1.68 (42.7) 1 1/2 1 SS-16-VCR-CG 2.04 (51.8) 1 3/4 Female Reducing Union ➀ Leak test ports F flat VCR Size 1/4 Y A E 1/2 VCR Size 1/8 1/4 Dimensions Ordering Number A E Dimensions, in. (mm) 1.16 SS-4-VCR-6-DF-2 SS-8-VCR-6-DF-4 Working Pressure F 0.13 (29.5) (3.3) 1.41 0.25 (35.8) (6.4) Y Ni 0.36 3/4 1 1/16 SS Cu psig (bar) 8000 10 000 6400 (9.1) (551) (689) (440) 0.35 3500 4300 2800 (8.9) (241) (296) (192) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. Reducing Adapter ➀ Leak test port F flat E VCR Size 1/8 A Y 1/4 VCR Size 1/4 1/2 Dimensions Ordering Number A E F Dimensions, in. (mm) 1.19 SS-2-VCR-7-4VCRF➁ 0.09 (30.2) (2.3) 1.41 0.18 (35.8) (4.6) SS-4-VCR-7-8VCRF Working Pressure Y 3/4 1 1/16 Ni SS Cu psig (bar) 8000 10 000 6400 0.69 (17.5) (551) (689) (440) 0.85 3500 4300 2800 (21.6) (241) (296) (192) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Reducing Bushing ➀ Leak test port E Y F flat VCR Size VCR Size Dimensions Ordering Number A E 1/4 1/8 Dimensions, in. (mm) 1.06 SS-4-VCR-7-2VCRF 1/2 1/4 SS-8-VCR-7-4VCRF A Working Pressure F 0.13 (26.9) (3.3) 1.41 0.25 (35.8) (6.4) Y Ni 0.76 5/8 15/16 SS Cu psig (bar) 8000 10 000 6400 (19.3) (551) (689) (440) 0.91 3500 4300 2800 (23.1) (241) (296) (192) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. Male NPT Elbow ➀ B F flat E C NPT Size 1/8 VCR Size 1/4 Ordering Number 3/8 1/2 1/4 E Dimensions, in. (mm) 0.87 1.07 SS-4-VCR-2-2 0.38 0.18 (27.2) (22.1) (9.6) (4.6) 1.07 1.05 0.56 0.18 (27.2) (26.7) (14.2) (4.6) 1.45 1.26 0.56 0.40 1/2 (36.8) (32.0) (14.2) (10.2) 1.45 1.45 0.75 0.40 1/2 (36.8) (36.8) (19.1) (10.2) SS-4-VCR-2-4 SS-8-VCR-2-6 SS-8-VCR-2-8 C Working Pressure D D 1/4 Dimensions B F 1/2 1/2 13/16 13/16 Ni 8000 SS Cu psig (bar) 10 000 6400 (551) (689) (440) 8000 8000 8000 (551) (551) (551) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. 11 12 VCR Metal Gasket Face Seal Fittings Bodies Union Elbow ➀ F flat VCR Size E 1/8 1/4 B 1/2 3/4 1 Ordering Number Dimensions B E F Dimensions, in. (mm) 0.09 0.89 SS-2-VCR-9➁ SS-4-VCR-9 SS-8-VCR-9 SS-12-VCR-9 SS-16-VCR-9 Working Pressure (22.6) (2.3) 1.07 0.18 (27.2) (4.6) 1.45 0.40 (36.8) (10.2) 1.92 0.62 (48.8) (15.7) 2.00 0.87 (50.8) (22.1) 7/16 1/2 13/16 1 1/4 1 11/16 Ni SS Cu psig (bar) 9000 11 200 7200 (620) (771) (496) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Union Tee ➀ F flat VCR Size E B B A Ordering Number Dimensions A B E 1/8 Dimensions, in. (mm) 0.89 1.78 SS-2-VCR-T➁ 1/4 SS-4-VCR-T 1/2 SS-8-VCR-T 3/4 SS-12-VCR-T 1 SS-16-VCR-T Working Pressure F 0.09 (45.2) (22.6) (2.3) 2.14 1.07 0.18 (54.4) (27.2) (4.6) 2.90 1.45 0.40 (73.7) (36.8) (10.2) 3.84 1.92 0.62 (97.5) (48.8) (15.7) 4.00 2.00 0.87 (102) (50.8) (22.1) Ni 7/16 1/2 13/16 1 1/4 1 11/16 SS Cu psig (bar) 9000 11 200 7200 (620) (771) (496) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. Union Cross ➀ VCR Size F flat E 1/8 B 1/4 1/2 B A 3/4 1 Ordering Number Dimensions A B E Dimensions, in. (mm) 0.89 1.78 SS-2-VCR-CS➁ 0.09 (45.2) (22.6) (2.3) 2.14 1.07 0.18 (54.4) (27.2) (4.6) 2.90 1.45 0.40 (73.7) (36.8) (10.2) 3.84 1.92 0.62 (97.5) (48.8) (15.7) 4.00 2.00 0.87 (102) (50.8) (22.1) SS-4-VCR-CS SS-8-VCR-CS SS-12-VCR-CS SS-16-VCR-CS Working Pressure F 7/16 1/2 13/16 1 1/4 1 11/16 Ni SS Cu psig (bar) 9000 11 200 7200 (620) (771) (496) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) 3000 3700 2400 (206) (254) (165) 2400 3000 1900 (165) (206) (130) ➀ VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating male or female threaded nuts. ➁ Not designed for gasket retainer assembly. VCR Metal Gasket Face Seal Fittings Welded Assemblies Male NPT Connector NPT Size Leak test port F flat E G flat C 13 1/4 B A 1/8 3/8 1/2 VCR Size Dimensions Ordering Number A B C E Dimensions, in. (mm) 0.38 0.95 1.58 SS-4-WVCR-1-2 1/4 1/4 SS-4-WVCR-1-4 1/2 SS-8-WVCR-1-6 1/2 SS-8-WVCR-1-8 Working Pressure F 0.18 (40.1) (9.6) (24.1) (4.6) 1.79 0.56 0.92 0.18 (45.5) (14.2) (23.4) (4.6) 1.89 0.56 1.00 0.40 (48.0) (14.2) (25.4) (10.2) 2.09 0.75 1.01 0.40 (53.1) (19.1) (25.6) (10.2) G 7/16 Ni 3/4 9/16 3/4 11/16 1 1/16 7/8 SS Cu psig (bar) 8000 8000 6400 1 1/16 (551) (551) (440) 8000 8000 6400 (551) (551) (440) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) Female NPT Connector Leak test port NPT Size F flat E 1/4 G flat C 3/8 A 1/2 VCR Size 1/4 1/2 Dimensions Ordering Number A 0.18 (45.0) (23.4) (4.6) 1.95 1.06 0.40 (49.5) (26.9) (10.2) 2.18 1.04 0.40 (55.4) (26.4) (10.2) SS-8-WVCR-7-8 Working Pressure E Dimensions, in. (mm) 0.92 1.77 SS-4-WVCR-7-4 SS-8-WVCR-7-6 1/2 C F G 3/4 Ni 6600 3/4 7/8 1 1/16 1 1/16 1 1/16 SS Cu psig (bar) 6600 5200 (454) (454) (358) 3500 4300 2800 (241) (296) (192) 3500 4300 2800 (241) (296) (192) Swagelok Tube Fitting Connector Leak test port F flat E G1 flat Tube Size 1/4 G flat A D C 3/8 1/2 VCR Size 1/4 1/4 1/2 Dimensions Ordering Number A C D E Dimensions, in. (mm) 1.94 0.70 0.60 SS-4-WVCR-6-400 SS-4-WVCR-6-600 SS-8-WVCR-6-810 Working Pressure F 0.18 (49.3) (17.8) (15.2) (4.6) 1.97 0.76 0.66 0.18 (50.0) (19.3) (16.8) (4.6) 2.23 0.86 0.90 0.40 (56.6) (21.8) (22.9) (10.2) 1/2 5/8 G 3/4 3/4 13/16 1 1/16 G1 9/16 11/16 7/8 Ni SS Cu psig (bar) 8000 10 000 6400 (551) (689) (440) 6500 6500 5200 (447) (447) (358) 3500 4300 2800 (241) (296) (192) Dimensions A, C, and D are typical finger-tight. Swagelok nuts and ferrules are provided assembled, as shown. For tubing maximum pressure ratings for use with Swagelok tube fittings, see Swagelok Tubing Data, MS-01-107. Rotating Female Union Leak test ports VCR Size E G flat A 1/4 Elbows, crosses, Micro-Fit® fittings, and tees are available with welded male and female ends. For more information, contact your authorized Swagelok sales and service representative. A E Dimensions, in. (mm) 1.71 SS-4-WVCR-6-DF G flat 1/2 Dimensions Ordering Number SS-8-WVCR-6-DF 0.18 (43.4) (4.6) 1.84 0.40 (46.7) (10.2) Working Pressure G 3/4 1 1/16 Female Elbow Leak test port Ni SS Cu psig (bar) 8000 10 000 6400 (551) (689) (440) 3500 4300 2800 (241) (296) (192) Female Tee 1.00 (25.4) Ordering number: 6LV-4-WVCR-9-DF 1.00 (25.4) Ordering number: 6LV-4-WVCR-T-FFF Leak test port 14 VCR Metal Gasket Face Seal Fittings Nuts, Caps, and Plugs Leak test port Female Nut F flat VCR Size 1/8 Tx 1/4 A Ordering Number SS-4-VCR-1 SS-8-VCR-1 5/8 SS-10-VCR-1 1 Dimensions A F Tx Dimensions, in. (mm) 0.53 SS-2-VCR-1 7/16 1/2 3/4 Cap with Lanyard SS-12-VCR-1 SS-16-VCR-1 (5.3) 0.81 0.36 (20.6) 0.88 1 1/16 (22.4) 0.88 1 3/16 (22.4) 1.12 1 1/2 (28.4) 1.34 1 3/4 (34.0) Lanyard material is 302 SS. Lanyard length is 6 in. (15.2 cm). 0.21 (13.5) 3/4 (9.1) VCR Size 0.74 (18.8) 0.89 Tx A Ordering Number 1/2 SS-8-VCR-CP-BP (23.9) F 1.20 1/8 0.21 (12.7) (5.3) 1/4 0.71 SS-4-VCR-4➀ 0.36 1/2 5/8 SS-8-VCR-4 SS-10-VCR-4 3/4 SS-12-VCR-4 1 SS-16-VCR-4 0.81 15/16 (20.6) 0.81 1 1/16 (20.6) 1.00 1 5/16 (25.4) 1.19 1 5/8 (30.2) A (9.1) 0.61 (18.8) A F (13.7) SS-4-VCR-4-.65NC SS-8-VCR-P 3/4 SS-12-VCR-P 1 SS-16-VCR-P 5/8 1.08 15/16 (27.4) 1.43 1 5/16 (36.3) 1.52 1 5/8 (38.6) Plug with Lanyard 0.65 5/8 0.36 Dimensions 1/8 Dimensions, in. (mm) 0.63 0.30 SS-2-VCR-CP 1/4 SS-4-VCR-CP 1/2 SS-8-VCR-CP 3/4 SS-12-VCR-CP 1 SS-16-VCR-CP (16.0) (7.6) 0.94 0.44 (23.9) (11.2) 1.01 0.45 (25.6) (11.4) 1.29 0.54 (32.8) (13.7) 1.54 0.63 (39.1) (16.0) A 1/4 Dimensions, in. (mm) 0.92 SS-4-VCR-BP 1/2 SS-8-VCR-BP Protective Cap C Dimensions Ordering Number (23.4) 1.08 (27.4) F 5/8 15/16 (9.1) (16.5) A VCR Size Tx Cap A 1/2 0.92 (23.4) Ordering number: SS-4-VCR-RP 1.20 Dimensions 1/4 C SS-4-VCR-P➁ ➁ Also available as a rotatable plug. F flat Ordering Number Ordering Number 1/4 3/8 (17.3) Lanyard material is 302 SS. Lanyard length is 6 in. (15.2 cm). Dimensions, in. (mm) 0.54 SS-4-VCR-4-.54NC VCR Size 1/8 F (30.5) For use with short gland. F flat A assembly. (22.6) F flat Leak test port Dimensions Ordering Number ➀ Not designed for gasket retainer 0.89 Short Male Nut A 1 1/16 Dimensions, in. (mm) 0.68 SS-2-VCR-P➀ 0.74 around 90° tube bends. Tx 0.45 (11.4) VCR Size (15.5) ➀ A taper at the hex end allows the nut to move VCR Size 1.01 Plug (30.5) Dimensions, in. (mm) 0.50 SS-2-VCR-4 3/8 (18.0) 3/4 (22.6) Tx 5/8 F (11.2) (25.6) Dimensions A C 1/4 F flat VCR Size A Dimensions, in. (mm) 0.94 0.44 SS-4-VCR-CP-BP 0.61 (15.5) Dimensions Ordering Number Male Nut F flat F flat F 7/16 3/4 1 1/16 1 1/2 1 3/4 Made of 304 stainless steel and supplied as bead protection during shipping for a variety of VCR face seal fittings processed to Swagelok Ultrahigh-Purity Process Specification (SC-01), MS-06-61. VCR Size in. Ordering Number 1/4 304-4-VCR-SC 1/2 304-8-VCR-SC 3/4 304-12-VCR-SC 1 304-16-VCR-SC VCR Metal Gasket Face Seal Fittings Nuts, Caps, and Plugs Split-Nut Assemblies Female Male A B B E Split Nut Type VCR Size A D 15 1/4 A B C Dimensions, in. (mm) 0.36 Female SS-4-VCR-1-SN 3/4 (9.1) 1/4 C Dimensions Ordering Number Male 5/8 SS-4-VCR-4-SN D E 0.81 0.63 0.68 (20.6) (16.0) (17.4) — — 0.36 0.60 (9.1) (15.2) C High-Flow Connections—“H” Type VCR “H” Type VCR connections are compatible with 1/4 in. VCR connections and are designed for use with Swagelok high-flow diaphragm valves and gas regulators. For uniform flow, use 1/4 in. side-load retainer style gasket. See page 17. Tube Butt Weld Glands Tube Size B Nominal Wall Thickness VCR Size A B Working Pressure E E1 Ni SS Dimensions, in. (mm) E E1 Dimensions Ordering Number 6LV-4-HVCR-3-.60SR A 3/8 0.035 1/4 6LV-4-HVCR-3-1.19SR 6LV-4-HVCR-3-1.31SR Cu psig (bar) 0.60 0.41 (15.2) (10.4) 1.19 1.00 0.25 0.31 3300 3300 3300 (30.2) (25.4) (6.4) (7.9) (227) (227) (227) 1.31 1.12 (33.3) (28.4) F Tube Butt Weld Bodies F flat B Tube Size E1 VCR Size E 3/8 C A 1/4 Dimensions Ordering Number A B Dimensions, in. (mm) 1.68 0.75 6LV-4-HVCR-1-6TB7 (42.7) (19.1) Working Pressure C E E1 0.62 0.25 0.31 (15.7) (6.4) (7.9) Ni SS 3300 5/8 Cu psig (bar) 3300 3300 (227) (227) (227) Automatic Tube Weld D F flat B VCR Size Ordering Number 3/8 1/4 316L-4-HVCR-1A6 E Tx E1 A C Dimensions Tube Size A B C D E Working Pressure E1 Dimensions, in. (mm) 1.71 0.75 0.62 0.03 0.25 0.31 (43.4) (19.1) (15.7) (0.8) (6.4) (7.9) F 5/8 Tx Ni SS Cu psig (bar) 0.41 3300 3300 3300 (10.4) (227) (227) (227) 16 VCR Metal Gasket Face Seal Fittings High-Flow Connections—“H” Type VCR Bodies Bulkhead Connector F flat F1 flat E1 E B A C Dimensions Tube Size 3/8 VCR Size 1/4 Ordering Number A 316L-4-HVCR-61-6TB7 B C E E1 F Dimensions, in. (mm) 2.36 0.75 1.30 0.31 0.25 (59.9) (19.1) (33.0) (7.9) F1 3/4 (6.4) Working Pressure Panel Hole Dia 19/32 3/4 Max Panel Thickness 0.44 (11.2) (15.0) Ni (227) Union Elbow F flat E VCR Size 1/4 Ordering Number Dimensions B E Dimensions, in. (mm) 0.25 1.07 SS-4-HVCR-9 (27.2) Working Pressure F Ni Cu psig (bar) 8000 10 000 6400 1/2 (6.4) SS (551) (689) (440) B Union Tee F flat VCR Size E B 1/4 B Ordering Number Dimensions A B E Dimensions, in. (mm) 1.07 2.14 SS-4-HVCR-T (54.4) (27.2) 0.25 (6.4) A Nuts Female Leak test port F flat VCR Size Ordering Number Dimensions A F Tx Dimensions, in. (mm) Tx SS-4-HVCR-1SR 1/4 A SS-4-HVCR-1 0.39 0.81 (20.6) (9.9) 3/4 0.46 (11.7) Male F flat VCR Size Tx A 1/4 Ordering Number Dimensions A F Dimensions, in. (mm) 0.71 SS-4-HVCR-4SR 5/8 (18.0) Tx 0.39 (9.9) Working Pressure F 1/2 Ni SS Cu psig (bar) 8000 10 000 6400 (551) (689) SS Cu psig (bar) 3300 3300 3300 (440) (227) (227) VCR Metal Gasket Face Seal Fittings 17 Gaskets Ordering Information Options Specify gasket material by adding a material designator to the basic ordering number. Blind Gaskets Material Designator Example Blind (undrilled) gaskets are available in nonretained and retainer assembly styles. Blind gaskets have a maximum differential pressure rating (p) of 100 psi (6.8 bar). Nickel NI NI-4-VCR-2-VS 316L stainless steel SS SS-4-VCR-2-VS To order, add -BL to a basic ordering number. CU➀ CU-4-VCR-2 Example: SS-4-VCR-2-VS-BL Copper Nickel and copper gasket retainer assemblies use a 316 stainless steel retainer. ➀ Copper gaskets are unplated. However, to order, add CU to a basic ordering number for silver-plated gaskets. Example: CU-4-VCR-2. Side-load retainer style gaskets are not available in copper. Snubber Gaskets Silver Plated Unplated (VS) Nonretained Cannot be used in a gasket retainer assembly. 0.028 (0.7) VCR Size 1/8 1/4 E Tx Gasket Retainer Assembly Retainer and gasket must be used as an assembly. 0.028 (0.7) E Tx Basic Ordering Number E Nonretained Tx 0.028 Dimensions, in. (mm) 0.26 0.09 -2-VCR-2 -4-VCR-2 1/2 -8-VCR-2 5/8 -10-VCR-2 3/4 -12-VCR-2 1 -16-VCR-2 VCR Size Dimensions Snubber gaskets in 0.5 to 60 µm sizes for 1/4 through 1 in. VCR fittings are available. Contact your authorized Swagelok representative for more information. (2.3) (6.6) 0.22 0.47 (5.6) (11.9) 0.44 0.78 (11.2) (19.8) 0.58 0.91 (14.7) (23.1) 0.66 1.14 (16.8) (29.0) 0.89 1.40 (22.6) (35.6) Basic Ordering Number Dimensions E 1/4 Dimensions, in. (mm) 0.24 -4-VCR-2-GR 1/2 -8-VCR-2-GR 3/4 -12-VCR-2-GR 1 -16-VCR-2-GR (6.1) VCR Size (0.7) 1/8 E Tx 1/4 Gasket Retainer Assembly Tx 0.028 0.50 0.44 0.79 (11.2) (20.1) 0.66 1.14 (16.8) (29.0) 0.89 1.40 (22.6) (35.6) E Tx Side-Load Retainer 0.028 (0.7) E Tx E Tx 0.26 (2.3) (6.6) 0.22 0.47 (5.6) (11.9) -4-VCR-2-VS -8-VCR-2-VS 5/8 -10-VCR-2-VS 3/4 -12-VCR-2-VS 1 -16-VCR-2-VS VCR Size Dimensions Dimensions, in. (mm) 0.09 -2-VCR-2-VS 1/2 0.44 0.78 (11.2) (19.8) 0.58 0.91 (14.7) (23.1) 0.66 1.14 (16.8) (29.0) 0.89 1.40 (22.6) (35.6) Basic Ordering Number Dimensions E 1/4 Dimensions, in. (mm) 0.24 -4-VCR-2-GR-VS 1/2 -8-VCR-2-GR-VS 3/4 -12-VCR-2-GR-VS 1 -16-VCR-2-GR-VS VCR Size Basic Ordering Number (0.7) (12.7) Basic Ordering Number (6.1) Tx 0.50 (12.7) 0.44 0.79 (11.2) (20.1) 0.66 1.14 (16.8) (29.0) 0.89 1.40 (22.6) (35.6) Dimensions E 1/4 Dimensions, in. (mm) 0.24 -4-VCR-2-ZC-VS 1/2 -8-VCR-2-ZC-VS (6.1) Tx 0.45 (11.4) 0.43 0.75 (11.0) (19.1) 18 VCR Metal Gasket Face Seal Fittings Flow Restrictors This product can be used in liquid or gas delivery systems where repeatable flow reduction or limiting is required. Ordering Information and Dimensions 0.18 5/8 in. flat Ex (4.6) VCR components with fixed threads must remain stationary during normal installation. These fitting connections should be assembled only to glands with rotating female nuts. 1.55 ■ One piece, (39.4) compact design saves space ■ Standard orifice sizes drilled through a 1/4 in. male VCR union ■ No dead volume for clean operation ■ Identification of orifice and heat code marked clearly on the body ■ Electropolished, cleaned, and packaged in accordance with Swagelok Ultrahigh-Purity Process Specification (SC-01), MS‑06‑61 ■ Working pressure 10 000 psig (689 bar) Ex, in. (mm) 0.010 (0.254) 0.012 (0.305) 0.015 (0.381) 0.017 (0.432) 0.020 (0.508) 0.023 (0.584) 0.025 (0.635) 0.026 (0.660) 0.027 (0.686) Ordering Number 6LV-4-VCR-6-DM-010P 6LV-4-VCR-6-DM-012P 6LV-4-VCR-6-DM-015P 6LV-4-VCR-6-DM-017P 6LV-4-VCR-6-DM-020P 6LV-4-VCR-6-DM-023P 6LV-4-VCR-6-DM-025P 6LV-4-VCR-6-DM-026P 6LV-4-VCR-6-DM-027P Ex, in. (mm) 0.050 (1.270) 0.055 (1.397) 0.060 (1.529) 0.065 (1.651) 0.070 (1.778) 0.075 (1.905) 0.080 (2.032) 0.085 (2.159) 0.090 (2.286) Ordering Number 6LV-4-VCR-6-DM-050P 6LV-4-VCR-6-DM-055P 6LV-4-VCR-6-DM-060P 6LV-4-VCR-6-DM-065P 6LV-4-VCR-6-DM-070P 6LV-4-VCR-6-DM-075P 6LV-4-VCR-6-DM-080P 6LV-4-VCR-6-DM-085P 6LV-4-VCR-6-DM-090P 0.030 (0.762) 6LV-4-VCR-6-DM-030P 0.093 (2.362) 6LV-4-VCR-6-DM-093P 0.035 (0.889) 0.040 (1.016) 0.045 (1.143) 6LV-4-VCR-6-DM-035P 6LV-4-VCR-6-DM-040P 6LV-4-VCR-6-DM-045P 0.095 (2.413) 0.100 (2.540) 6LV-4-VCR-6-DM-095P 6LV-4-VCR-6-DM-100P Lock and Tag Devices These devices help prevent unintentional disassembly of VCR connections. Additionally, both devices include a wire hole to allow for a tag to support identification and quality verification programs. Fitting Lock Device Fitting Lock Device for Valves This device is intended for use on Swagelok VCR metal gasket face seal assemblies with standard male and female nuts. This device is intended for use on Swagelok valves with integrally machined male VCR metal gasket face seal end connections. Size Ordering Number Size Ordering Number 1/4 in. SS-4-VCR-FLC 1/4 in. SS-4-VCR-VLC 1/2 in. SS-8-VCR-FLC 1/2 in. SS-8-VCR-VLC Side-Load Installation Tool and Tray Tool Tray (includes 30 gaskets) ■ Makes gasket handling easy, ■ Keeps gaskets secure preserves cleanliness ■ Enables gasket installation where space is limited ■ Is used to easily remove gasket from storage tray Material: Polyethersulfone (PES) Description Installation tool Tray (nickel gaskets) Tray (SS gaskets) Ordering Number MS-4-VCR-ZC-TL NI-4-VCR-2-ZCT-VS SS-4-VCR-2-ZCT-VS ■ Keeps gaskets aligned for easy removal with side-load gasket tool ■ Cleaned and packaged in accordance with Swagelok Ultrahigh-Purity Process Specification (SC-01), MS-06-61 Material: Tray—polypropylene Lid—clean polycarbonate VCR Metal Gasket Face Seal Fittings VCR Fitting Installation Instructions 6 1 GTAW 2 3 7 Finger-tight GTAW 4 8 1/4 Cu turn 5 5a 5b 1/8 SS, turn Ni 5c 19 VCR Split-Nut Installation Instructions Male Female 1 1 2 2 3 Swagelok Orbital Welding System For information on the Swagelok welding system, see the Swagelok Orbital Welding System Quick Reference Guide, MS-02-143. Safe Product Selection When selecting a product, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user. Caution: Do not mix or interchange parts with those of other manufacturers. Warranty Information Swagelok products are backed by The Swagelok Limited Lifetime Warranty. For a copy, visit swagelok.com or contact your authorized Swagelok representative. Swagelok, VCR, Micro-Fit—TM Swagelok Company © 2007–2010 Swagelok Company Printed in U.S.A., AGS February 2010, R10 MS-01-24