SPRING-LOADED CONNECTORS

advertisement

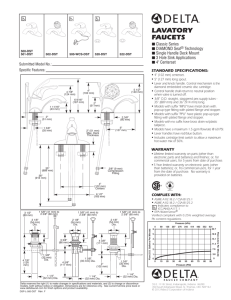

M PR E CI NE D ON S I CHI A PINS SPRING-LOADED CONNECTORS Mill-Max Spring-Loaded Connectors are ideal for a wide range of applications, from portable data acquisition units and mobile communication to medical and military equipment applications. Their unique design can be the perfect answer for many situations, establishing electrical continuity on virtually any surface including problematic vibratory environments. Unlike the fixed mating height created by pins and receptacles, spring-loaded connectors are able to compensate for floating heights and uneven mating surfaces, thus maintaining a reliable electrical connection. When strategically placed within an assembly and utilized correctly (shielded from over compression and direct side load forces,) miniature spring-loaded connectors can provide a reliable connection up to a million cycles. Some typical applications include: • • • The internal battery connection in portable instruments, or as the external battery connection for charging these instruments (docking stations.) As a method for stacking printed circuit boards in an assembly. Utilizing spring pin connectors is a convenient approach to creating mezzanine-tiered board modules that can be assembled and disassembled quickly. Blind-mating applications. The spring pin piston need only make contact with its mating surface. This is typically a land or pad that is larger than the plunger diameter. Compare this to a pin and socket connection where alignment must be more precise for the pin to enter the socket. Mill-Max Spring-Loaded Connectors can mate to the following surfaces: • • • • A conductive input/output pad found on the instrument pack itself. A gold-plated land on a circuit board. A hard gold over nickel plated surface is recommended for the mating surface. This is the same as would be used for the printed circuit fingers associated with card edge connectors. Individual Mill-Max gold-plated nail head pins which can be soldered to the mating circuit board to serve as targets. Mill-Max Target Connectors which provide a large 1,78mm flat, gold-plated circuit path to the board. w w w. m i l l - m a x . c o m 5 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount, Low Profile Single and Double Row Strips Series 811, 813 • Modular contacts for use on 2,54 grid, available in five heights from 3,48 to 5,99, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a long stroke relative to the low profile of the assembly. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • Both 811 & 813 series, contact styles 1 thru 4, are available on 32mm wide carrier tape for pick and place assembly per EIA-481. See page 9 for strip lengths available and ordering information. SINGLE ROW Series 811 Number of Pins X 2,54 2,54 Stroke Stroke 2,54 1,07 DIA. B B A A 2,79 1,8 Style 0 only 0,41 1,83 DIA. DOUBLE ROW Series 813 Number of Pins X 2,54 / 2 5,08 2,54 Ordering Information Single Row Series 811 811-22-0XX-30-00X-101 Specify contact style 0-4 Specify # of contacts 01-64 Double Row Series 813 813-22-0XX-30-00X-101 Specify contact style 0-4 Specify # of contacts 04-72 For 811 & 813 Tape & Reel packaging See page 9 CONTACT STYLE 0 1 2 3 4 INITIAL HEIGHT A 3,48 4,50 5,0 5,51 5,99 MAX. STROKE B 0,99 1,14 1,39 1,39 1,39 Stroke 2,54 Technical Specifications Style 0 only B A Stroke 1,8 2,54 1,07 DIA. B A 2,79 0,41 w w w. m i l l - m a x . c o m 1,83 DIA. Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic, rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Coplanarity: 0,13 (Single Row up to 10 pins; Double Row up to 20 pins) For higher pin counts contact Tech Support. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. RoHS 2002/95/EC Dielectric strength: 700Vrms min. Capacitance: 1pF max. 6 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount, High Profile Single and Double Row Strips Series 812, 814 • Modular contacts for use on 2,54 grid, available in ten heights from 6,48 to 10,9, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a long stroke relative to the low profile of the assembly. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • Both 812 & 814 series are available on 32mm or 44mm wide carrier tape for automated pick and place assembly per EIA-481. See page 9 for strip lengths available and ordering information. SINGLE ROW Series 812 Ordering Information Single Row Series 812 812-22-0XX-30-00X-101 Specify contact style 0-9 Specify # of contacts 02-64 Double Row Series 814 814-22-0XX-30-00X-101 Specify contact style 0-9 Specify # of contacts 04-72 Number of Pins X 2,54 2,54 Stroke 2,54 1,07 DIA. 1,4 1,5 DIA. For 812 & 814 Tape & Reel packaging See page 9 A CONTACT STYLE 0 1 2 3 4 5,03 2,79 1,83 DIA. 0,41 DOUBLE ROW Series 814 INITIAL HEIGHT A 6,48 6,99 7,49 8,0 8,51 CONTACT STYLE 5 6 7 8 9 INITIAL HEIGHT A 8,89 9,4 9,91 10,4 10,9 Number of Pins X 2,54 / 2 5,08 2,54 2,54 Stroke 2,54 1,07 DIA. 1,4 1,5 DIA. A 5,03 2,79 1,83 DIA. 0,41 w w w. m i l l - m a x . c o m Technical Specifications Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (0,7mm): 60 grams Durability: 1,000,000 cycles min. Coplanarity: 0,13 (Single Row up to 10 pins; Double Row up to 20 pins) For higher pin counts contact Tech Support. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. RoHS Dielectric strength: 700Vrms min. 2002/95/EC Capacitance: 1pF max. 7 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount, High Profile Single and Double Row Strips Series 819, 820 • Modular contacts for use on 2,54 grid, available in a height of 7,32, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 1,14 mid. stroke and a 2,29 max. stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 819 & 820 series contact strips are designed for placement onto a Ø 2,08mm solder pad prior to reflow soldering. SINGLE ROW Series 819 Ordering Information Number of Pins X 2,54 Single Row Series 819 2,54 2,54 Max. Stroke 1,07 DIA. 819-22-0XX-30-001101 Fig. 1 Specify # of contacts 01-64 2,29 Double Row Series 820 1,5 DIA. 7,32 5,03 820-22-0XX-30-001101 Fig. 2 2,79 1,83 DIA. Specify # of contacts 0,41 DOUBLE ROW Series 820 Technical Specifications Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 0,25µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Number of Pins X 2,54 / 2 5,08 2,54 2,54 Mechanical: Spring force @ initial height : 25 grams Spring force @ mid stroke : 60 grams Durability: 1,000,000 cycles min. Max. Stroke 2,54 1,07 DIA. 04-72 2,29 1,5 DIA. 7,32 5,03 2,79 1,83 DIA. 0,41 w w w. m i l l - m a x . c o m Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. Capacitance: 1pF max. 7.1 RoHS 2002/95/EC 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount, Horizontal Mount Single Row Strips Series 810...001101 • Modular contacts for use on 2,54 grid, supplied in single row contact strips. Piston action is parallel to the board surface. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 1,14 mid. stroke & 2,29 max. stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 810 series contact strips are designed for manual placement onto solder pads. Single Row Series 810 Ordering Information Number of Pins x 2,54 2,54 1,27 (TYP) (TYP) 2,54 1,88 Series 810 Single Row Surface Mount 810-22-0_ _-40-001101 TOP VIEW A (TYP) 1,88 Specify # of pins 01-10 2,79 FRONT VIEW Number of Pins x 2,54 2,54 1,27 For Electrical, Mechanical & Enviromental Data, See pg. 4.1 For RoHS compliance select plating code. 2,54 (TYP) Technical Specifications (Max. Stroke) 2,29 2,54 1,07 2,24 2,03 7,54 DETAIL ‘A’ Suggested P.C.B. FOOTPRINT 2,13 2,54 2,54 Coplanarity 0,13. For Pin Counts >10 positions consult Technical Support. w w w. m i l l - m a x . c o m Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel. Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height: 25 grams Spring force @ mid stroke: 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. RoHS 2002/95/EC Capacitance: 1pF max. 7.2 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount with Alignment pins Single and Double Row Strips Series 812...01X101 814...01X101 • Modular contacts for use on 2,54 grid, available in ten heights from 6,48 to 10,92, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 0,69 mid stroke & 1,4 max stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 812 & 814 series contact strips are designed for manual placement into Ø 0,58±0,08 plated-thruholes in the circuit board prior to intrusive reflow soldering. Ordering Information Single Row Series 812...01X101 Number of Pins X 2,54 Single Row Series 812...01X101 2,54 812-22-0XX-30-01X-101 Specify contact style 0-9 Specify # of contacts 03-64 Stroke 2,54 MM #0907-X Spring Loaded Connector 1,07 DIA. Double Row Series 814...01X101 1,4 1,5 DIA. 0,41 2,79 5,03 A 814-22-0XX-30-01X-101 Specify contact style 0-9 Specify # of contacts 06-72 1,83 DIA. 0,43 DIA. 1,75 2,54 (TYP) MM #0908-X Alignment pins (2x) Double Row Series 814...01X101 CONTACT STYLE 0 1 2 3 4 INITIAL HEIGHT A 6,48 6,99 7,49 8,0 8,51 Number of Pins X 2,54 / 2 Stroke 2,54 MM #0907-X Spring Loaded Connector 1,07 DIA. 1,4 1,5 DIA. 0,41 2,79 5,03 A 1,83 DIA. 0,43 DIA. 1,75 2,54 (TYP) MM #0908-X Alignment pins (4x) w w w. m i l l - m a x . c o m INITIAL HEIGHT A 8,89 9,4 9,91 10,41 10,92 Technical Specifications 5,08 2,54 CONTACT STYLE 5 6 7 8 9 Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. RoHS 2002/95/EC Capacitance: 1pF max. 8 516-922-6000 SPRING-LOADED CONNECTORS Surface Mount Carrier Tape & Packaging Series 811, 812 813, 814 Ordering Information for Series 811/812/813/814 in Carrier Tape Single Row Series 811 811-22-0XX-30-00X-191 Double Row Series 813 813-22-0XX-30-00X-191 Specify contact style 0-4 Specify contact style 0-4 Specify # of contacts 02 - 08 Specify # of contacts 04 - 16 ( 32mm wide tape, 400 parts per 330mm reel ) ( 32mm wide tape, 400 parts per 330mm reel ) Single Row Series 811 811-22-0XX-30-00X-191 Double Row Series 813 813-22-0XX-30-00X-191 Specify contact style 1-4 Specify contact style 1-4 Specify # of contacts 09 - 12 Specify # of contacts 18 - 24 ( 44mm wide tape, 200 parts per 330mm reel ) ( 44mm wide tape, 200 parts per 330mm reel ) Single Row Series 812 812-22-0XX-30-00X-191 Double Row Series 814 814-22-0XX-30-00X-191 Specify contact style 0-2 Specify contact style 0-2 Specify # of contacts 02 - 08 Specify # of contacts 04 - 16 ( 32mm wide tape, 400 parts per 330mm reel ) ( 32mm wide tape, 400 parts per 330mm reel ) Single Row Series 812 812-22-0XX-30-00X-191 Double Row Series 814 814-22-0XX-30-00X-191 Specify contact style 0-2 Specify contact style 0-2 Specify # of contacts 09 - 12 Specify # of contacts 18 - 24 ( 44mm wide tape, 200 parts per 330mm reel ) ( 44mm wide tape, 200 parts per 330mm reel ) Single Row Series 812 812-22-0XX-30-00X-191 Double Row Series 814 814-22-0XX-30-00X-191 Specify contact style 3-9 Specify contact style 3-9 Specify # of contacts 02 - 12 Specify # of contacts 04 - 24 ( 44mm wide tape, 200 parts per 330mm reel ) ( 44mm wide tape, 200 parts per 330mm reel ) 32mm wide, 9mm deep or 44mm wide, 13mm deep 32mm wide, 9mm deep or 44mm wide, 13mm deep 16mm 16mm 4,47 4,47 9,75 7,14 VACUUM PICK-UP CLIP REMOVED AFTER SOLDERING w w w. m i l l - m a x . c o m VACUUM PICK-UP CLIP REMOVED AFTER SOLDERING 9 516-922-6000 SPRING-LOADED CONNECTORS Through Hole Mount Single and Double Row Strips Series 821, 823 • Modular contacts for use on 2,54 grid, available in five heights from 3,48 to 5,99, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a long stroke relative to the low profile of the assembly. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 821 & 823 series contact strips are designed for manual placement into Ø0,56±0,08 plated-thruholes in the circuit board prior to hand, wave or reflow soldering. SINGLE ROW Series 821 Ordering Information Number of Pins X 2,54 Single Row Series 821 2,54 Stroke Stroke 2,54 1,07 DIA. B 821-22-0XX-10-00X-101 Specify contact style 0-4 Specify # of contacts 02-64 Double Row Series 823 B A A 2,79 1,8 1,75 0,41 0,43 DIA. Style 0 only 1,83 DIA. DOUBLE ROW Series 823 Number of Pins X 2,54 / 2 5,08 2,54 Stroke 2,54 CONTACT STYLE 0 1 2 3 4 INITIAL HEIGHT A 3,48 4,5 5,0 5,51 5,99 MAX. STROKE B 0,99 1,14 1,39 1,39 1,39 Technical Specifications B A 1,80 Style 0 only Stroke 823-22-0XX-10-00X-101 Specify contact style 0-4 Specify # of contacts 04-72 2,54 1,07 DIA. B A 2,79 1,75 0,41 0,43 DIA. 1,83 DIA. w w w. m i l l - m a x . c o m Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. RoHS 2002/95/EC Capacitance: 1pF max. 10 516-922-6000 SPRING-LOADED CONNECTORS Through Hole Mount Single and Double Row Strips Series 825, 827 • Modular contacts for use on 2,54 grid, available in a height of 7,67, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 1,14 mid stroke & 2,29 max stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 825 & 827 series contact strips are designed for manual placement into Ø 0,76±0.07 plated-thruholes in the circuit board prior to hand, wave or reflow soldering. SINGLE ROW Series 825 Ordering Information Number of Pins X 2,54 Single Row Series 825 2,54 Stroke 2,54 825-22-0XX-10-001101 Fig. 1 1,07 DIA. Specify # of contacts 2,29 02-64 7,67 0,41 Double Row Series 827 2,79 1,12 2,92 0,64 DIA. Specify # of contacts 1,83 DIA. DOUBLE ROW Series 827 Number of Pins X 2,54 / 2 5,08 2,54 Stroke 2,54 2,54 2,29 7,67 0,41 2,79 1,12 2,92 0,64 DIA. 1,83 DIA. 04-72 Technical Specifications Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 0,25µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. 1,07 DIA. w w w. m i l l - m a x . c o m 827-22-0XX-10-001101 Fig. 2 Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. Capacitance: 1pF max. 11 RoHS 2002/95/EC 516-922-6000 SPRING-LOADED CONNECTORS Through Hole Mount Single and Double Row Strips Series 816...00X101 818...00X101 • Modular contacts for use on 2,54 grid, available in ten heights from 6,48 to 10,92, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 0,69 mid stroke & 1,4 max stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 816 & 818 series contact strips are designed for manual placement into Ø 0,58±0,7 plated-thruholes in the circuit board prior to intrusive reflow soldering. Ordering Information Single Row Series 816...00X101 Single Row Series 816...00X101 Number of Pins X 2,54 816-22-0XX-10-00X-101 2,54 2,54 Specify # of contacts Double Row Series 818...00X101 Stroke 1,07 DIA. 818-22-0XX-10-00X-101 1,4 1,5 DIA. 0,41 2,79 5,03 A 1,83 DIA. 0,43 DIA. 1,75 2,54 (TYP) Double Row Series 818...00X101 5,08 Stroke 2,54 1,07 DIA. 1,4 1,5 DIA. 0,41 2,79 5,03 A 1,83 DIA. 0,43 DIA. 1,75 2,54 (TYP) w w w. m i l l - m a x . c o m Specify # of contacts CONTACT STYLE 0 1 2 3 4 INITIAL HEIGHT A 6,48 6,99 7,49 8,0 8,51 Specify contact style 0-9 04-72 CONTACT STYLE 5 6 7 8 9 INITIAL HEIGHT A 8,89 9,4 9,91 10,41 10,92 Technical Specifications Number of Pins X 2,54 / 2 2,54 Specify contact style 0-9 02-64 Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. Dielectric strength: 700Vrms min. RoHS 2002/95/EC Capacitance: 1pF max. 12 516-922-6000 SPRING-LOADED CONNECTORS 1,27 Grid Through Hole Mount Single and Double Row Strips Series 854...10-001101 855...10-001101 • Modular contacts for use on 1,27 grid, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 0,69 mid stroke & 1,4 max stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 854 & 855 series contact strips are designed for manual placement into Ø 0,58±0,08 plated-thruholes in the circuit board. Single Row Series 854 Ordering Information (Number of Pins 1,10 X 1,27) + 2,92 Series 854 Single Row Through Hole Mount 2,21 (TYP) 2,1 854-22-0_ _-10-001101 Specify # of pins Stroke (TYP) 1,27 0,48 DIA. 1,4 0,51 1,04 DIA. Series 855 1,55 3,78 4,72 Double Row Through Hole Mount 855-22-0_ _-10-001101 8,89 Specify # of pins 1,14 0,41 DIA. 02-20 04-40 2,62 1,27 (TYP) For Electrical, Mechanical & Enviromental Data, See pg. 4.1 For RoHS compliance select plating code. Double Row Series 855 (Number of Pins 1,27 Technical Specifications X 1,27/2) + 2,92 3,0 (TYP) 2,1 Stroke (TYP) 1,27 0,48 DIA. 1,4 0,51 1,04 DIA. 1,55 3,78 4,72 1,14 0,41 DIA. 2,62 1,27 (TYP) w w w. m i l l - m a x . c o m 8,89 Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. RoHS Dielectric strength: 700Vrms min. 2002/95/EC Capacitance: 1pF max. 12.1 516-922-6000 SPRING-LOADED CONNECTORS 1,27 Grid Surface Mount, High Density Single and Double Row Strips Series 854...30-001101 855...30-001101 • Modular contacts for use on 1,27 grid, supplied in single and double row contact strips. • Precision-machined piston / base and gold plated components assure a 1,000,000 min. cycle life. • Pistons have a 0,69 mid stroke & 1,4 max stroke. • Low resistance, high current contacts are rated at 2 amps continuous, 3 amps peak. • High temperature thermoplastic insulators are suitable for surface mount processes. • 854 & 855 series contact strips are designed for manual placement onto 1,02 Ø solder pads. Single Row Series 854 Ordering Information (Number of Pins 1,10 X 1,27) + 0,38 Series 854 Single Row Surface Mount 2,21 (TYP) 0,83 854-22-0_ _-30-001101 Specify # of pins Stroke (TYP) 1,27 0,48 DIA. Series 855 1,4 4,09 0,61 0,76 DIA. 1,27 02-20 Double Row Surface Mount 855-22-0_ _-30-001101 6,4 4,7 Specify # of pins 04-40 (TYP) For Electrical, Mechanical & Enviromental Data, See pg. 4.1 For RoHS compliance select plating code. Double Row Series 855 (Number of Pins 1,27 Technical Specifications X 1,27/2) + 0,38 3,05 (TYP) 0,83 Stroke (TYP) 1,27 0,48 DIA. 1,4 3,78 0,91 0,76 DIA. 1,27 w w w. m i l l - m a x . c o m (TYP) 6,4 4,7 Materials: Contact piston & Base: Machined copper alloy plated 0,51µm gold over 2,54µm nickel Spring: Beryllium copper plated 0,25µm gold Insulator: High temp. thermoplastic rated UL94 V-0 Mechanical: Spring force @ initial height (A): 25 grams Spring force @ mid stroke (B/2): 60 grams Durability: 1,000,000 cycles min. Electrical: Voltage rating: 100Vrms/150Vdc Current rating: 2A (continous), 3A (peak) per contact Contact resistance: 20mΩ max. Insulation resistance: 10,000MΩ min. RoHS Dielectric strength: 700Vrms min. 2002/95/EC Capacitance: 1pF max. 12.2 516-922-6000 Series 319, 330, 399 SPRING-LOADED CONNECTORS 2,54 Grid Target Connectors for Spring-Loaded Assemblies Single Row Number of Pins X 2,54 2,54 2,54 2,54 1,78 DIA. 2,79 1,35 DIA. 4,19 4,29 7,37 0,51 DIA. • Series 319, 330 and 399 single row strips may be cut to any length. • Spring Target connectors present a large flat surface for making tangent connections to our standard 1,07 dia spring pin plungers. The target connectors provide an excellent gold plated conductive path back to the board mounted spring pin connector. • Target connectors use MM #1938, #1940, #1941, #1942 and #3024 pins. See page 185 for details. Fig. 1 1,78 DIA. • Insulators are high temp. thermoplastic. 2,79 4,19 1,35 DIA. Ordering Information 7,37 0,51 DIA. 3,18 Fig. 2 Fig. 1 1,83 DIA. 2,79 1,35 DIA. Specify # of pins Fig. 2 5,51 Series 319...001 Standard Solder Tails 319-10-1_ _-00-001000 Specify # of pins Fig. 3 1,83 DIA. 2,79 Fig. 3 4,19 1,35 DIA. 14,4 0,86 DIA. Fig. 4 3,20 1,83 DIA. 2,79 7,37 1,35 DIA. 1,52 Fig. 5 01-64 Series 319...005 Elevated Solder Tails 319-10-1_ _-00-005000 Specify # of pins Fig. 4 01-64 Series 319...002 Long Solder Tails 319-10-1_ _-00-002000 Specify # of pins 11,2 0,51 DIA. 01-64 4,19 9,70 0,46 DIA. Series 319...041 SMT w/ Alignment Pins 319-10-1_ _-30-041000 01-64 Series 330...240 Solder Cups 330-10-1_ _-00-240000 Specify # of pins 01-64 2,29 0,97 DIA. HOLE Fig. 6 Fig. 5 Series 399...008 Right Angle Solder Tails 399-10-1_ _-10-008000 Specify # of pins 4,19 01-64 2,79 2,54 0,46 DIA. 4,47 5,59 Fig. 6 w w w. m i l l - m a x . c o m 5,74 For Electrical, Mechanical & Enviromental Data, See pg. 4 PLATING CODE = RoHS 2002/95/EC 10 0,25μm Au Pin Plating 13 516-922-6000 Series 419, 430, 499 SPRING-LOADED CONNECTORS 2,54 Grid Target Connectors for Spring-Loaded Assemblies Double Row Number of Pins X 2,54 / 2 5,08 2,54 • Spring Target connectors present a large flat surface for making tangent connections to our standard 1,07 dia spring pin plungers. The target connectors provide an excellent gold plated conductive path back to the board mounted spring pin connector. 2,54 2,54 1,78 DIA. 2,79 1,35 DIA. • Series 419, 430 and 499 double row strips may be cut to any length. 4,29 Coplanarity 0,13. For Pin Counts >20 positions consult Technical Support. Fig. 1 2,54 • Target connectors use MM #1938, #1940, #1941, #1942 and #3024 pins. See page 185 for details. • Insulators are high temp. thermoplastic. 1,78 DIA. 2,79 4,19 1,35 DIA. Ordering Information 7,37 0,51 DIA. 3,18 Fig. 2 Fig. 1 2,54 Series 419...041 Surface Mount 419-10-2_ _-30-041000 Specify # of pins 1,83 DIA. 2,79 1,35 DIA. 4,19 9,70 0,46 DIA. 5,51 Fig. 2 2,54 Fig. 3 1,83 DIA. 2,79 04-64 Series 419...002 Long Solder Tails 419-10-2_ _-00-002000 Specify # of pins 4,19 1,35 DIA. Series 419...001 Standard Solder Tails 419-10-2_ _-00-001000 Specify # of pins Fig. 3 04-64 04-64 11,2 14,4 0,86 DIA. 0,51 DIA. 3,20 Fig. 4 Series 419...005 Elevated Solder Tails 419-10-2_ _-00-005000 Specify # of pins Fig. 4 2,54 1,83 DIA. Fig. 5 2,79 1,52 2,29 0,97 DIA. HOLE Fig. 6 Fig. 5 Series 430...240 Solder Cups 430-10-2_ _-00-240000 Specify # of pins 7,37 1,35 DIA. 04-64 Series 499...008 Right Angle Solder Tails 499-10-2_ _-10-008000 Specify # of pins 4,19 04-64 04-64 2,79 5,08 2,54 5,74 RoHS 2002/95/EC 4,47 0,46 DIA. 5,59 For Electrical, Mechanical & Enviromental Data, See pg. 4 2,54 Fig. 6 w w w. m i l l - m a x . c o m 10 PLATING CODE = 0,25μm Au Pin Plating 14 516-922-6000 SPRING-LOADED CONNECTORS Series 856, 857 1,27 Grid Target Connectors for Spring-Loaded Assemblies Single and Double Row • Series 856, 857 single and double row strips may be cut to any length. (Number of Pins X 1,27) + 0,38 1,10 2,21 (TYP) 1,27 Number of Pins X 1,27 + 0,38 2,21 1,07 DIA. 0,25 2,21 • Target connectors use MM #1933 and #1935 pins. See page 180 for details. 5,0 0,41 DIA. • Spring Target connectors present a large flat surface for making tangent connections to our standard 0,48 dia spring pin plungers. The target connectors provide an excellent gold plated conductive path back to the board mounted spring pin connector. 2,54 • Insulators are high temp. thermoplastic. 1,27 Ordering Information Fig. 1 Series 856...051 Number of Pins X 1,27 + 0,38 2,21 Standard Solder Tails 1,07 DIA. 0,25 Fig. 1 2,21 2,46 0,66 DIA. 856-10-0_ _-10-051000 Specify # of pins 1,27 Coplanarity 0,13. For Pin Counts >20 positions consult Technical Support. Series 856...051 01-20 Surface Mount Fig. 2 Fig. 2 856-10-0_ _-30-051000 (Number of Pins / 2 X 1,27) + 0,38 1,27 Specify # of pins 02-20 3,05 Series 857...051 (TYP) Standard Solder Tails 1,27 3,05 Number of Pins / 2 X 1,27 + 0,38 0,25 Fig. 3 1,07 DIA. Specify # of pins 1,91 2,41 0,41 DIA. Series 857...051 2,59 1,27 Fig. 4 Fig. 3 3,05 0,25 857-10-0_ _-10-051000 04-40 Surface Mount 857-10-0_ _-30-051000 Specify # of pins 04-40 Number of Pins / 2 X 1,27 + 0,38 1,07 DIA. 1,91 2,46 0,66 DIA. 1,27 Coplanarity 0,13. For Pin Counts >40 positions consult Technical Support. Fig. 4 w w w. m i l l - m a x . c o m For Electrical, Mechanical & Enviromental Data, See pg. 4 RoHS 2002/95/EC 10 PLATING CODE = 0,25μm Au Pin Plating 14.1 516-922-6000 SPRING-LOADED CONNECTORS Discrete Spring-Loaded Contacts M PR E CI ⇒4 0900-1⇒ 0900-0 0,7 1,4 1,4 Basic Part Number Length A 0900-1 0900-2 0900-3 0900-4 4,5 5,0 5,51 5,99 1,07 DIA. 1,5 DIA. A 1,63 DIA. 2,69 0,71 1,5 DIA. 0,7 1,5 DIA. 5,0 1,63 DIA. 0,71 0,71 1,83 DIA. 1,4 1,07 DIA. 2,69 1,63 DIA. 1,83 DIA. PINS 0934 0,7 1,07 DIA. NE D ON S I CHI A 1,83 DIA. 3,2 0,81 0,41 0,41 0900-0-00-00-00-00-11-0 0900-X-00-00-00-00-11-0 0934-0-15-20-74-14-26-0 Short Stroke, Surface mount Lowest profile Standard Stroke, Surface mount Low profile Standard Stroke Surface mount 0936 ⇒9 0907-0⇒ 0928 1,0 0,7 0,64 1,4 1,07 DIA. 1,07 DIA. 2,0 1,07 DIA. 1,27 1,5 DIA. 5,5 4,2 7,5 1,5 DIA. 5,03 5,0 1,63 DIA. 0,41 1,63 DIA. 0,71 1,83 DIA. A 1,5 DIA. 0,41 1,63 DIA. 0,71 1,83 DIA. 0,71 1,83 DIA. 0,41 Basic Part Number Length A 0907-0 0907-1 0907-2 0907-3 0907-4 0907-5 0907-6 0907-7 0907-8 0907-9 6,48 6,99 7,49 8,0 8,51 8,89 9,4 9,91 10,41 10,92 0936-0-15-20-75-14-11-0 0928-0-15-20-77-14-11-0 0907-X-15-20-75-14-11-0 Standard Stroke Surface mount Long Stroke Surface mount Standard Stroke, Surface mount High profile 0,7 0,7 1,07 DIA. 1,14 0,76 DIA. 2,29 7,32 8,5 1,5 DIA. 1,83 DIA. 0,41 0,71 0,71 1,83 DIA. 1,4 1,5 DIA. 1,5 DIA. 16,21 9,7 17,6 7,9 0,41 1,63 DIA. 0,7 1,4 6,4 5,03 1,63 DIA. 1,07 DIA. 1,07 DIA. 1,4 1,07 DIA. 1,5 DIA. 0905 0927 0925 0913 0,41 1,63 DIA. 1,83 DIA. 0,41 1,63 DIA. 1,83 DIA. 0,71 0,71 0913-0-15-20-77-14-11-0 0925-0-15-20-73-14-26-0 0927-0-15-20-75-14-11-0 0905-0-00-00-00-00-11-0 Long Stroke Surface mount Standard Stroke Surface mount Standard Stroke Surface mount Standard Stroke, Surface mount Highest Profile MECHANICAL & ELECTRICAL SPECIFICATIONS: ORDER CODE: 09XX - X - 15 - 20 - 7X - 14 - XX - 0 DURABILITY: 1,000,000 cycles Spring Number CURRENT RATING: 2A continuous, 3A peak MATERIAL SPECIFICATIONS: SLEEVE & PLUNGER MATERIAL: Copper Alloy SPRING MATERIAL: Beryllium Copper SLEEVE & PLUNGER FINISH: 0,51 μm Gold over Nickel SPRING FINISH: 0,25 μm Gold over Nickel DIMENSION IN INCHES: TOLERANCES ON: LENGTHS: ±0,15 DIAMETERS: ±0,05 ANGLES: ± 2° w w w. m i l l - m a x . c o m CONTACT RESISTANCE: 20 mΩ max. RoHS 2002/95/EC SPRING NUMBER Mid. STROKE Max. STROKE 73 74 75 77 0,7 0,7 0,7 1,14 1,4 1,4 1,4 2,29 FORCE @ Mid. Stroke 60 50 60 60 Initial Force (Pre-load) g g g g 25 15 25 25 g g g g 73, 74, 75, 77 Springs are not Interchangeable 15 516-922-6000 SPRING-LOADED CONNECTORS Discrete Spring-Loaded Contacts M PR E CI ⇒4 0906-1⇒ 0906-0 1,07 DIA. 1,4 1,07 DIA. 1,5 DIA. Basic Part Number Length A 0906-1 0906-2 0906-3 0906-4 4,5 5,0 5,51 5,99 A 1,63 DIA. 2,49 0,71 1,83 DIA. 1,5 DIA. 1,63 DIA. 2,69 1,75 0,41 0,7 1,4 1,07 DIA. 1,5 DIA. 0,71 1,83 DIA. 0,43 DIA. PINS 0930 0,7 0,99 0,5 NE D ON S I CHI A 5,1 0,41 1,63 DIA. 0,38 1,83 DIA. 0,43 DIA. 1,75 0,41 2,7 0,64 0,43 DIA. 0906-0-15-20-76-14-11-0 0906-X-15-20-75-14-11-0 0930-0-15-20-75-14-11-0 Short Stroke Solder mount in 0,46 min. mounting hole Standard Stroke Solder mount in 0,46 min. mounting hole Standard Stroke Solder Mount in 0,46 min. mounting hole ⇒9 0908-0⇒ 0932 0914 0,7 2,29 1,14 1,07 DIA. MID STROKE 2,3 1,07 DIA. MAX STROKE 1,4 1,5 DIA. 1,5 DIA. 5,38 0,41 1,63 DIA. 1,83 DIA. 1,07 DIA. 1,1 4,7 0,71 1,83 DIA. 0,64 DIA. 5,03 0,71 0914-0-15-20-77-14-11-0 0,71 1,83 DIA. 0,64 DIA. 4,3 0,43 DIA. 1,75 0932-0-15-20-77-14-11-0 Length A 0908-0 0908-1 0908-2 0908-3 0908-4 0908-5 0908-6 0908-7 0908-8 0908-9 6,48 6,99 7,49 8,0 8,51 8,89 9,4 9,91 10,41 10,92 0908-X-15-20-75-14-11-0 Long Stroke Long Stroke Solder mount in 0,69 min. mounting hole Solder Mount in 0,69 min. mounting hole 0929 0901 0,41 1,63 DIA. 0,41 2,92 A 12 0,71 1,4 DIA. 0,71 1,4 DIA. 1,5 DIA. 4,7 1,63 DIA. Basic Part Number Standard Stroke Solder mount in 0,46 min. mounting hole 0980 0922 0,7 0,7 1,07 DIA. 1,4 5,74 1,63 DIA. 5,8 8,13 1,63 DIA. 7,75 1,83 DIA. 1,2 14,6 1,1 1,4 DIA. 1,5 DIA. 1,17 1,52 DIA. 5,0 1,96 0,64 DIA. 0,64 DIA. 6,0 5,08 7,6 0,41 1,63 DIA. 0,71 1,83 DIA. 0,71 0,41 1,3 0,71 0,71 1,78 DIA. 0,64 DIA. 0,71 1,83 DIA. 1,5 DIA. 1,07 DIA. 1,5 DIA. 1,63 DIA. 6,12 1,4 1,4 1,5 DIA. 1,5 DIA. 0,7 0,7 1,07 DIA. 1,07 DIA. 0,7 DIA. 1,3 1,32 0,7 0901-0-00-00-00-00-11-0 0922-0-15-20-75-14-11-0 0980-0-15-20-75-14-11-0 Standard Stroke Solder mount in 0,69 min. mounting hole Double action, *1,4 Combined Stroke Mount between parallel circuit boards 0929-0-15-20-75-14-11-0 Standard Stroke Standard Stroke Solder mount in 0,69 min. mounting hole Solder Mount in 0,69 min. mounting Hole MECHANICAL & ELECTRICAL SPECIFICATIONS: ORDER CODE: 09XX - X - 15 - 20 - 7X - 14 - 11 - 0 DURABILITY: 1,000,000 cycles Spring Number CURRENT RATING: 2A continuous, 3A peak MATERIAL SPECIFICATIONS: SLEEVE & PLUNGER MATERIAL: Copper Alloy SPRING MATERIAL: Beryllium Copper SLEEVE & PLUNGER FINISH: 0,51 μm Gold over Nickel SPRING FINISH: 0,25 μm Gold over Nickel DIMENSION IN INCHES: TOLERANCES ON: LENGTHS: ±0,15 DIAMETERS: ±0,05 ANGLES: ± 2° w w w. m i l l - m a x . c o m CONTACT RESISTANCE: 20 mΩ max. RoHS 2002/95/EC SPRING NUMBER Mid. STROKE Max. STROKE FORCE @ Mid. Stroke Initial Force (Pre-load) 75 76 77 0,7 0,5 1,14 1,4 0,99 2,29 60 g 60 g 60 g 25 g 25 g 25 g 75, 76, 77 Springs are not Interchangeable 16 516-922-6000 SPRING-LOADED CONNECTORS Discrete Spring-Loaded Contacts M PR E CI NE D ON S I CHI A PINS ⇒4 0910-1⇒ 0910-0 MID STROKE 0,7 0,5 1,07 DIA. 1,0 1,4 MID STROKE MAX STROKE 1,07 DIA. MAX STROKE 1,98 DIA. 1,83 1,78 DIA. A 1,98 DIA. 3,48 2,49 2,03 1,78 DIA. 1,83 DIA. 2,69 1,83 DIA. 0,41 0910-X-57-20-75-14-11-0 Short Stroke, Surface mount Packaged on 16mm wide carrier tape: 1,500 parts per 330 reel. Standard Stroke, Surface mount Packaged on carrier tape. See chart for tape width and qty. per reel 0967 Length A 0910-1 0910-2 0910-3 0910-4 4,5 5,0 5,51 5,99 Basic Part Number Tape Width Quantity per Reel 0910-1 0910-2 0910-3 0910-4 16mm 24mm 24mm 24mm 1,500 1,100 1,100 1,100 0,41 0910-0-57-20-76-14-11-0 Basic Part Number 0990-0 1,07 DIA. 3,94 DIA. 2,54 0,5 MID STROKE 1,07 DIA. 3,0 DIA. 2,29 1,5 DIA. MID STROKE 1,63 DIA. 0,7 0,76 1,0 MAX STROKE 2,49 MAX STROKE 0,81 1,4 P.C.B. Layout 5,23 3,96 DIA. 8,41 3,56 0967-0-15-20-75-14-11-0 Standard Stroke, Horizontal Surface mount Also available on 16mm wide carrier tape: 2,200 parts per 330 reel. Order as: 0967-0-58-20-75-14-11-0 2,67 0990-0-50-20-76-14-11-0 1,02 Short Stroke, Surface mount Large Base 4,98 ⇒4 0990-1⇒ ⇒9 0997-0⇒ 0,7 0,7 1,4 1,07 DIA. 1,07 DIA. A 1,5 DIA. 2,69 1,63 DIA. 1,4 Basic Part Number Length A 0990-1 0990-2 0990-3 0990-4 4,5 5,0 5,51 5,99 A 1,5 DIA. 5,03 1,63 DIA. 0,81 0,81 3,96 DIA. 3,96 DIA. Basic Part Number Length A 0997-0 0997-1 0997-2 0997-3 0997-4 0997-5 0997-6 0997-7 0997-8 0997-9 6,48 6,99 7,49 8,0 8,51 8,89 9,4 9,91 10,41 10,92 0990-X-50-20-75-14-11-0 0997-X-50-20-75-14-11-0 Standard Stroke, Surface mount Large Base Standard Stroke, Surface mount Large Base ORDER CODE: 09XX - X - XX - 20 - 7X - 14 - 11 - 0 MECHANICAL & ELECTRICAL SPECIFICATIONS: DURABILITY: 1,000,000 cycles Spring Number CURRENT RATING: 2A continuous, 3A peak MATERIAL SPECIFICATIONS: SLEEVE & PLUNGER MATERIAL: Copper Alloy SPRING MATERIAL: Beryllium Copper SLEEVE & PLUNGER FINISH: 0,51 μm Gold over Nickel SPRING FINISH: 0,25 μm Gold over Nickel DIMENSION IN INCHES: TOLERANCES ON: LENGTHS: ±0,15 DIAMETERS: ±0,05 ANGLES: ± 2° w w w. m i l l - m a x . c o m CONTACT RESISTANCE: 20 mΩ max. RoHS SPRING NUMBER Mid. STROKE Max. STROKE FORCE @ Mid. Stroke Initial Force (Pre-load) 75 76 0,7 0,5 1,4 0,99 60 g 60 g 25 g 25 g 2002/95/EC 75 & 76 Springs are not Interchangeable 17 516-922-6000 SPRING-LOADED CONNECTORS Discrete Spring-Loaded Contacts M PR E CI NE D 0950 ON S I CHI A PINS 0951 0,7 MID STROKE 0,48 DIA. 0,7 1,4 MID STROKE 0,48 DIA. MAX STROKE 1,4 MAX STROKE 0,94 DIA. 0,94 DIA. 4,7 6,4 8,92 1,07 DIA. 4,72 0,71 1,09 DIA. 0,64 1,07 DIA. 0,71 0,41 DIA. 2,62 1,09 DIA. 0,76 DIA. 0,64 0,25 0950-0-15-20-71-14-11-0 0951-0-15-20-71-14-11-0 Standard Stroke Solder Mount in 0,46 min. mounting hole Standard Stroke, Surface mount High profile ORDER CODE: 09XX - X - 15 - 20 - 71 - 14 - 11 - 0 MECHANICAL & ELECTRICAL SPECIFICATIONS: DURABILITY: 1,000,000 cycles Spring Number CURRENT RATING: 2A continuous, 3A peak MATERIAL SPECIFICATIONS: SLEEVE & PLUNGER MATERIAL: Copper Alloy SPRING MATERIAL: Beryllium Copper SLEEVE & PLUNGER FINISH: 0,51 μm Gold over Nickel SPRING FINISH: 0,25 μm Gold over Nickel DIMENSION IN INCHES: TOLERANCES ON: LENGTHS: ±0,15 DIAMETERS: ±0,05 ANGLES: ± 2° w w w. m i l l - m a x . c o m CONTACT RESISTANCE: 20 mΩ max. SPRING NUMBER Mid. STROKE Max. STROKE FORCE @ Mid. Stroke Initial Force (Pre-load) 71 0,7 1,4 50 g 15 g RoHS 2002/95/EC Springs are not Interchangeable 17.1 516-922-6000 SPRING-LOADED CONNECTORS Discrete Spring-Loaded Contacts M PR E CI NE D ON S I CHI A PINS 0850 MID STROKE Specifications for #0850-0: 1,14 Material: 1,27 DIA. 2,29 - Sleeve & Plunger Material: Copper Alloy - Spring Material: Stainless Steel 302. MAX STROKE 2,41 DIA. 3,89 DIA. 10,03 0,76 7,72 2,21 DIA. 5,18 Mechanical Characteristics: - Force @ mid-stroke (1,14) = 120 grams - Maximum stroke length = 2,29 - Mechanical life: 1,000,000 cycles Electrical Characteristics: 0850-0-15-20-83-14-11-0 Power Spring Pin Solder Mount in 2,29 min. mounting hole - Rated Current (Free air): Continuous 9 amps @ 10° C temperature rise. 0851 MID STROKE Specifications for #0851-0: 1,14 1,27 DIA. Material: 2,29 - Sleeve & Plunger Material: Copper Alloy - Spring Material: Stainless Steel 302. MAX STROKE 2,41 DIA. 9,6 6,73 3,89 DIA. 2,21 DIA. 0,76 2,34 Mechanical Characteristics: - Force @ mid-stroke (1,14) = 120 grams - Maximum stroke length = 2,29 - Mechanical life: 1,000,000 cycles Electrical Characteristics: 0851-0-15-20-82-14-11-0 Power Spring Pin Solder Mount in 2,29 min. mounting hole - Rated Current (Free air): Continuous 9 amps @ 10° C temperature rise. MECHANICAL & ELECTRICAL SPECIFICATIONS: ORDER CODE: 085X - X - 15 - 20 - 8X - 14 - 11 - 0 DURABILITY: 1,000,000 cycles Spring Number Rated Current (Free air): Continuous 9 amps @ 10° C temperature rise MATERIAL SPECIFICATIONS: SLEEVE & PLUNGER MATERIAL: Copper Alloy SPRING MATERIAL: Stainless Steel 302 SLEEVE & PLUNGER FINISH: 0,51 μm Gold over Nickel SPRING FINISH: 0,25 μm Gold over Nickel DIMENSION IN INCHES: TOLERANCES ON: LENGTHS: ±0,15 DIAMETERS: ±0,05 ANGLES: ± 2° w w w. m i l l - m a x . c o m CONTACT RESISTANCE: 20 mΩ max. SPRING NUMBER Mid. STROKE Max. STROKE FORCE @ Mid. Stroke Initial Force (Pre-load) 82 83 1,14 1,14 2,29 2,29 120 g 120 g 25 g 25 g RoHS 2002/95/EC 82 & 83 Springs are not Interchangeable 17.2 516-922-6000