ABET

Self-Study Report

for the

BACHELOR OF AEROSPACE ENGINEERING

PROGRAM

at

AUBURN UNIVERSITY

AUBURN, ALABAMA

July 1, 2010

CONFIDENTIAL

The information supplied in this Self-Study Report is for the confidential use of ABET and its authorized agents,

and will not be disclosed without authorization of the institution concerned, except for summary data not

identifiable to a specific institution.

1

Table of Contents

BACKGROUND INFORMATION……………………………………….…..3

CRITERION 1. STUDENTS………………………………………..….………7

CRITERION 2. PROGRAM EDUCATIONAL OBJECTIVES..…….…....15

CRITERION 3. PROGRAM OUTCOMES……………………..…………..22

CRITERION 4. CONTINUOUS IMPROVEMENT……..…………………29

CRITERION 5. CURRICULUM…………………..…………………………34

CRITERION 6.

FACULTY……………………………..…………………….400

CRITERION 7 FACILITIES…………………………………………………49

CRITERION 8. SUPPORT………………………………...………………….56

CRITERION 9. PROGRAM CRITERIA ……………..…………….……..62

APPENDIX A – COURSE SYLLABI……………………….……………….63

APPENDIX B – FACULTY RESUMES…………………..………………....88

APPENDIX C – LABORATORY EQUIPMENT…………..……………...110

APPENDIX D – INSTITUTIONAL SUMMARY….……….………….......112

2

Self­Study Report Aerospace Engineering

Bachelor of Aerospace Engineering

Auburn University

BACKGROUND INFORMATION

A. Contact Information

The primary pre-visit contact person, is

Dr. John E. Cochran, Jr.

Professor and Head

Department of Aerospace Engineering

211 Aerospace Engineering Building

Auburn University

Auburn, Alabama 36849-5338

(334) 844-6815

cochrjo@auburn.edu

However, for many Program details, the Program Evaluator may wish to contact

Dr. Robert S. (“Steve”) Gross

Undergraduate Program Coordinator

Department of Aerospace Engineering

211 Aerospace Engineering Building

Auburn University

Auburn, Alabama 36849-5338

(334) 844-6846

rgross@eng.auburn.edu

B. Program History

The origins of the undergraduate program in aerospace engineering at Auburn University

are found in the courses in aeronautical engineering at the Alabama Polytechnic Institute

in the late 1920’s. Over more than seven decades, the program has evolved to meet the

changing educational requirements of engineers who specialize in “things that fly.” A

paper on the history of aerospace education at Auburn University may be found on our

website, www.eng.auburn.edu/department/ae/.

The 2009-2010 Auburn University Undergraduate and Graduate Bulletin

www.auburn.edu/student_info/bulletin/engineering.pdf includes the following

descriptive information of the current curriculum:

“Aerospace engineers are concerned with the application of scientific

principles and engineering concepts and practices to design, build, test,

and operate aerospace systems. The curriculum is intended to provide

students with a broad understanding of fundamental scientific and

technological principles, and to develop the ability to use these principles

in developing solutions to engineering problems. … Required courses

cover aeronautical and astronautical subjects. Technical electives allow

concentration in such areas as aerodynamics, astronautics, flight dynamics

and control, propulsion, structures and structural dynamics. The design of

aerospace components and systems is considered to be an integral part of

the education of aerospace engineers. Hence, design is included

throughout the curriculum, beginning with a sophomore course in

aerospace fundamentals and culminating in the senior design course

sequence. Students are required to apply their theoretical knowledge of

aerodynamics, dynamics, structures and propulsion to solve open-ended

problems and to produce portions of preliminary designs.”

A program in Aeronautical Engineering was implemented at Alabama Polytechnic

Institute in 1942 and the Department of Aeronautical Engineering was established in

1945. In 1960, Alabama Polytechnic Institute was renamed Auburn University and the

designation “Aeronautical” in the program and department names was changed to

“Aerospace” to reflect changes in curriculum in response to the start of the “Space Age.”

The Aerospace Engineering Program (“the Program”) has continuously produced

graduates since 1960.

Major Program changes occurred in 2000 when Auburn University changed to the

semester system. The most significant change was the developing new courses in the

semester format from our quarter format courses while keeping the total content the

same. This was rather difficult due to the constraints of 128 total semester hours with 36

of those in “core” curriculum. We restructured our labs and combined some courses. For

example, the two, three-quarter-hour courses, Static Stability and Control and Dynamic

Stability and Control, were combined as Flight Dynamics, a four-semester-hour course.

Since there are fewer courses in the semester system curriculum than the quarter system,

options are more limited and we are still looking for ways to get more variety.

Additional aspects of these changes were discussed during the 2004 ABET visit. Since

2004, a number of changes “fine-tuning” have been made as a part of the ABET

continuous quality improvement process. These are discussed in section 4-B of this SelfStudy.

C. Options

There are no options or tracks in the Program. The Program is more heavily weighted

toward aeronautical engineering with a required course in orbital mechanics, some rocket

4

propulsion in AERO 4510 Aerospace Propulsion, and electives in orbital mechanics,

rocket propulsion, space propulsion, and other astronautical subjects.

D. Organizational Structure

The Aerospace program is the responsibility of the Aerospace department chair, Dr. John

Cochran, with the assistance of the Aerospace Curriculum Committee, chaired by the

Undergraduate Program Coordinator, Dr. Steve Gross. On academic matters, Dr.

Cochran reports to the Dean of Engineering, Dr. Larry Benefield, via the Associate Dean

for Academics, Dr. Joe Morgan, and the Associate Dean for Assessment, Dr. Nels

Madsen. The Dean of Engineering reports to Provost and Vice-President for Academic

Affairs, Dr. Mary Ellen Mazey. Under the provost is the Associate Provost for

Undergraduate Studies, who chairs the University Curriculum Committee, which reviews

and approves all curriculum changes. The provost reports to the University President, Dr.

Jay Gogue, who in turn reports to the Board of Trustees. Further details on the

Organizational Structure are available in the College Self-Study.

E. Program Delivery Modes

All undergraduate engineering programs are on-campus in nature. Courses include a

variety of experiences including lectures, recitations, and laboratories. Many courses and

instructors make extensive use of the Blackboard Learning System (campus learning

management system). A substantial portion of the classrooms used are technologyenabled. Within the College of Engineering most lecture courses are taught by faculty.

Graduate teaching assistants provide support and often conduct laboratory sessions.

Cooperative education opportunities are available and are exploited by many students,

but do not replace any program requirements. Many extra-curricular professional

activities are explored by students, but again those do not replace any program

requirements.

F. Deficiencies, Weaknesses or Concerns from Previous Evaluation(s) and the

Actions Taken to Address Them

The Final Statement for the Program in the 2004 ABET Report included program

strengths, observations, and concerns, but no weaknesses or deficiencies. Only two

Concerns were mentioned.

The first Concern was that the number of faculty members (ten full-time and one parttime) was not large enough to meet the requirements of the Program and achieve the

goals and objectives of the college in research and graduate education. Although funds

have not been available to add additional faculty members, we have done well in finding

new faculty members to fill positions left vacant by retirements. Dr. Rhonald M. Jenkins

retired in August 2004 and we hired Dr. Brian S. Thurow, an Ohio State graduate, in

December 2005. Dr. Thurow, who specializes in non-obtrusive measurement of fluid

flows, has done exceptionally well in both instruction and research. He achieve tenure

and promotion in 2009. When Dr. John E. Burkhalter retired in December 2004, we

started a search for a faculty member with expertise in the area of dynamics and control.

5

We were fortunate to find and hire Dr. Andrew J. Sinclair, a Texas A&M Ph.D., who has

also done very well, achieving tenure and promotion this year (2010). Another change

occurred in 2005 when Dr. Ron Barrett went back to his alma mater, the University of

Kansas. We conducted another search and found Dr. Gilbert L. Crouse (Ph.D.,

University of Maryland). As explained later in this report, Dr. Crouse was an excellent

replacement for aircraft design. Still another change occurred in 2005. Col. James Voss,

a former astronaut, who was an associate dean in the College of Engineering, but also

taught our Space Mission Design course, left the university to take a position in the

aerospace industry. Finally, another personnel change occurred in 2007 when Dr.

Christopher J. Roy, went to Virginia Tech. We were fortunate to rather quickly find

another CFD expert, Dr. Andrew B. Shelton, who has made the transition for industry to

academia without any problems.

The result of all the foregoing changes is that we have gotten some very good new faculty

members, who will contribute in both instruction and research, but the number full-time

Program faculty members has not increased. Our overall numbers have however

increased because we were provided funds by the College for an additional staff member,

Ms. Lisa Avrit, to serve as a Student Advisor. Ms. Avrit has done an excellent job,

thereby relieving the Program Coordinator, Dr. Gross, of a substantial portion of the load

he had been carrying. We are hopeful that our increased success in obtaining extramural

research and a strong economic recovery will allow us to add some more faculty

members, perhaps on non-tenure track appointments, who will also help with instruction.

We also plan to seek some help from some of our alumni who have retired from NASA

to add some more space related content to our Program.

The second Concern was that the documentation of the assessment process needed to be

improved. We have made a concerted effort to address this Concern and those efforts are

detailed in the body of this Self-Study.

6

CRITERION 1. STUDENTS

A. Student Admissions

All entering students, both freshmen and transfers, apply for admission through the

Admissions Office of Auburn University. Freshmen are required to submit copies of

high school transcripts ACT or SAT records, answers to essay questions, information

provided in the activities and interest from, and an application form with required fees.

Transfer student admission and processes is described below in Section D.

The Office of Admissions is responsible for evaluating all applicants to Auburn

University. That office is authorized to admit students to the pre-engineering program.

Transfer students who are admitted to pre-engineering are reviewed by personnel within

the College of Engineering and may be admitted to the upper division, if qualified.

Admission requirements for freshmen entering the pre-engineering program are based

upon the evaluation of a number of criteria and meeting the needs and capacity

requirements of the university. While no minimum test scores and grade point average

are specified, generally students are expected to present a minimum 3.0 cumulative grade

point average, ACT score of 23 or SAT score of 1090, and successful completion of 4

years of English, 3 years of mathematics, 2 years of science, and 3 years of social studies.

Exceptions to these “general” requirements may be made for applicants that fall within

the range of acceptance based on university policy. Tables 1.1 Tables 1.1a, 1.1b and 1.1c:

Students section provides historical information on admitted students over the past few years.

B. Evaluating Student Performance

Engineering Student Services advises, supports, and monitors the performance of

engineering students. Freshmen admitted to pre engineering are expected to complete the

requirements for admission to the upper division within four academic semesters and

maintain a minimum cumulative grade point average of 2.2. Course requirements include

the completion of two semesters of calculus, two semesters of lab science, one class in

computing, one introductory class in engineering problem solving, and an engineering

seminar. In addition, students must complete other freshman level courses in the

university core curriculum and achieve sophomore standing. If a student does not satisfy

the requirements within four semesters, prior to achieving junior status (61 hours), they

are dismissed from the College of Engineering.

Transfers admitted to pre engineering are evaluated by academic advisors within the

College of Engineering to determine eligibility for advancement to the upper division.

When a student has satisfied the pre-engineering requirements, they are advanced to the

upper division and permitted to take course work within their chosen major. In the case of

students who are not prepared to advance to the upper division, they are advised to take

course work that will ensure the completion of all requirements. The time required for a

transfer student to advance to the upper division is predicated on the number of

transferable credit hours.

7

After admission to an engineering program, Engineering Student Services continues to

provide student support and record keeping, however a larger share of the guidance

progress moves to the academic program.

C. Advising Students

Academic advising is paramount for entering freshmen. At Auburn University this begins

with Camp War Eagle. This two-day summer session is attended by nearly all entering

freshman (over 98% in 2009). Students admitted to Pre-Engineering meet with faculty

and staff from the College of Engineering and begin planning their academic career. Fall

schedules are planned and finalized during Camp War Eagle. Academic advisors rely on

high school grades, standardized test scores, math placement exams, and individual

counseling when advising students. Advising policies are guided by the results of an

extended research program conducted for the College of Engineering by two former

Auburn University faculty members and researchers: Drs. Gerald Halpin and Glennelle

Halpin. After Camp War Eagle, Engineering Student Services (ESS) continues to serve

as a primary resource to students. Prior to every semester, every pre-engineering student

works with ESS or specified departmental advisors to develop an approved schedule.

After admission to an engineering program, schedule approval is a joint responsibility of

ESS and the academic program.

Academic advising is an extremely important part of the Aerospace Engineering

program. Pre-aerospace engineering students are advised by personnel in Engineering

Student Services. Once a student is in major (meaning they have completed all of the

pre-aerospace requirements), our Academic Advisor, advises him/her. All official

student records are maintained by Engineering Student Services; however, the Academic

Advisor and Undergraduate Program Coordinator have access to all student records

through BANNER. The Academic Advisor also keeps a folder on each student in the

program and updates the progress of each student at least once per semester.

Prior to the summer of 2009, all advising was done by the Undergraduate Program

Coordinator, Dr. R. Steven Gross. Based on one of the Concerns noted by ABET in the

2004 review, the Dean of the College of Engineering authorized the creation of a fulltime, staff, Academic Advisor position. In June of 2009, the department hired Mrs. Lisa

Avrit into this position as Departmental Academic Advisor. She has a B.S. in Chemical

Engineering and three years of industrial experience.

Currently, the Academic Advisor advises all aerospace engineering students on a one-onone basis. Face-to-face meetings are the primary means of advisement, but

communication via e-mail is also used. All aerospace students are required to meet with

the academic advisor at least once per semester prior to registering for next semester’s

classes. This is accomplished by blocking registration for students until they have met

with the academic advisor. The Undergraduate Program Coordinator and Academic

Advisor encourage and motivate students who appear to be having academic difficulties

to contact them for further help.

8

Based on senior exit interviews and informal discussions with students, the students

appear to be pleased with the advising process. The total enrollment of sophomores,

juniors and seniors in the aerospace engineering program in the fall of 2010 was 117.

D. Transfer Students and Transfer Courses

Transfer students with 30 semester hours or more of credit are required to submit copies

of transcripts from all colleges/universities attended and an application with required

fees. If a transfer applicant presents fewer than 30 semester hours, in addition to the

aforementioned information, high school transcripts and ACT or SAT records must be

provided.

Auburn University requires a 2.5 GPA on a 4.0 scale on all college work attempted by

transfer students applying for enrollment to the university. Students must also be eligible

to re-enter the institution last attended. Transfer applicants who were not eligible for

admission to Auburn when they graduated from high school must present a minimum of

32 semester hours of college credit. At least one course in each of the following areas

must be completed: English (college-level composition or literature), History,

Mathematics (approved core mathematics for articulation and general studies), and

Natural Science with a laboratory. Exceptions to these requirements are cleared through

the Engineering Student Services Office.

All students admitted to the College of Engineering by the Office of Enrollment

Management are accepted to the pre-engineering program. Engineering advisors

determine when a transfer student is eligible to advance into a departmental major based

on the completion of courses required in their respective curricula.

Alabama public institutions have an articulation agreement that outlines equivalent

courses among member schools. The agreement is adhered to in accepting credit from

Alabama institutions. More information on the articulation agreement can be found in

the College Self-Study. Credit for engineering content course work from any program

(within or outside of the state of Alabama) that is not specifically accredited by the EAC,

is granted only after the fact, based upon careful review of the course content, and is

limited to lower-level fundamental engineering science courses such as statics, for

example.

The articulation agreement led to the establishment of an Internet world wide web site

(http://stars.troyst.edu/agsc_stars_home.htm) for the use of prospective transfer students

and others who may have interests in learning more about the system and ascertaining

which courses are likely to be readily transferred to specific Auburn University

engineering programs.

Transfer work from private institutions and out of state institutions is judged on the basis

of catalog descriptions of general courses and a syllabus from specific courses. Core

courses in question are referred to the equivalent department on campus to make a

judgment. Engineering courses that are offered in other state institutions are evaluated

9

and accepted upon approval of the department of the incoming transfer student.

University policy provides that credit for courses taken at another institution may be

awarded, but the earned grade is not transferable and is not calculated in the student’s

Auburn grade point average. Courses in which a student earned a grade of “D’ at another

institution may be accepted for credit, however, the student is expected to present the

required grade point average of 2.5 for admission. Transfer students are treated in the

same manner as native students. If a “D” grade is considered passing for an Auburn

student, the same treatment is provided for the transfer student. The state of Alabama

requires a grade of “C” in English Composition I and II. Therefore, any grade below this

level for a transfer student is not acceptable. Those cases in which an engineering

department specifies that a grade of “C” or better is required for a course that serves as a

prerequisite to the next course in the curriculum, transfer credit below the required “C” is

not acceptable.

Table 1.2 at the end of Criterion 1: Students section provides historical information on

transfer students.

E. Graduation Requirements

Auburn University requires an overall 2.0 cumulative grade point average, and a 2.0

grade point average within the student’s major. Any additional program specific

guidelines or requirements are described in the program self-study. Students preparing to

graduate with an undergraduate engineering degree are required to “clear for graduation”

through an academic advisor in Engineering Student Services. Prior to entering the

scheduled term of graduation, students are required to enroll for UNIV 4AA0, a nongraded course entitled “Undergraduate Graduation”. Enrollment in this course alerts the

Registrar’s Office and the academic advisor to the student’s status.

Academic folders are maintained on each student with current information that indicates

the satisfactory completion of all course requirements. During the student’s meeting with

the advisor to clear for graduation, course completion is reviewed, grade point averages

are calculated, and students are cleared to graduate if all requirements are fulfilled. If the

student fails to meet any course requirements they are advised on the course(s) to take

prior to graduation. In such cases where there is a deficit in the required grade point

average, students are advised on the grades that must be earned for graduation. Sample

student transcripts will be provided to the visiting team. Copies of the student folder and

the corresponding checklist appropriate to the student program will accompany the

transcripts. A written analysis of the student record by the Aerospace Engineering

Academic Advisor will be prepared and included.

For students completing their final semester, at the conclusion of final examinations and

prior to graduation, the academic advisor reviews all information. If a student fails to

meet the graduation requirements, in either the required curriculum or grade point

average, the Registrar’s Office is notified and the student is not permitted to graduate.

10

F. Enrollment and Graduation Trends

The strategic plans of Auburn University and the College of Engineering identify optimal

enrollment levels as roughly 25,000 and 4,000 students respectively. Current enrollments

at both the University and College levels are consistent with the plan, however both the

University and the College would like to increase the percentage of enrolled students

seeking graduate degrees. Auburn University targets a new freshman enrollment of

roughly 4,000 each fall. The University seeks a talented, diverse student body. Table 11a indicates a steady climb in the average ACT and SAT scores of entering freshman.

Entering freshman pre-engineering students are described in table 1-1b and their ACT

and SAT score trends tend to reflect but typically exceed those of the general student

body. The enrollment in the College of Engineering has been increasing, both at the

undergraduate and graduate levels. Graduation numbers have remained relatively stable

reflecting enrollment trends up to 2005. Table 1.3a and 1.3b at the end of the Criterion 1:

Students section provides historical information on enrollment and graduation numbers

for both the College of Engineering and Auburn University as a whole.

11

Table 1-1a. History of Admissions Standards for Freshmen Admissions for Past

Five Years

Aerospace Engineering

Academic Year

2009-10

2008-09

2007-08

2006-07

2005-06

Composite ACT

MIN.

AVG.

17

28

21

28

16

27

16

26

20

27

Composite SAT

MIN.

AVG.

1090

1321

1020

1256

800

1194

1030

1207

1020

1204

Percentile Rank in High

School

MIN.

AVG.

25

82

37

77

33

74

33

76

40

84

Number of New

Students

Enrolled

94

119

89

73

71

Table 1-1b. History of Admissions Standards for Freshmen Admissions for Past

Five Years

Auburn University

Academic Year

2009-10

2008-09

2007-08

2006-07

2005-06

Composite ACT

MIN.

AVG.

15

26.2

16

25.9

16

24.9

14

24.3

14

24.1

Composite SAT

MIN.

AVG.

710

1183

690

1175

570

1138

770

1128

610

1127

Percentile Rank in High

School

MIN.

AVG.

10

78

14

78

3

76

4

75

5

74

Number of New

Students

Enrolled

3,918

3,984

4,191

4,092

4,197

Table 1-1c. History of Admissions Standards for Freshmen Admissions for Past

Five Years

Auburn University – Pre-Engineering

Academic Year

2009-10

2008-09

2007-08

2006-07

2005-06

Composite ACT

MIN.

AVG.

17

27.8

18

26.9

16

26.3

16

25.4

16

25.5

Composite SAT

MIN.

AVG.

940

1266

790

1236

800

1198

790

1199

900

1194

Percentile Rank in High

School

MIN.

AVG.

22

81

20

79

7

79

10

78

12

77

Table 1-2. Transfer Students for Past Five Academic Years

College of Engineering

Number of Transfer Students

Enrolled

214

209

200

181

166

Academic Year

2009-10

2008-09

2007-08

2006-07

2005-06

12

Number of New

Students

Enrolled

890

841

770

712

692

Table 1-3a. Engineering Enrollment Trends for Past Five Academic Years

(College of Engineering)

Year

2005-06

2,491

Full-time Students

280

Part-time Students

1

2,578

Student FTE

651

Graduates

1

FTE = Full-Time Equivalent

Year

2006-07

2,514

Year

2007-08

2,701

Year

2008-09

2,977

Year

2009-10

3,235

302

2,600

653

312

2,795

671

357

3,086

720

316

3,347

754

Table 1-3b. Enrollment Trends for Past Five Academic Years

(Auburn University)

Year

2005-06

17,778

Full-time Students

1,476

Part-time Students

18,455

Student FTE1

4,079

Graduates

1

FTE = Full-Time Equivalent

Year

2006-07

17,810

Year

2007-08

18,148

Year

2008-09

18,377

Year

2009-10

18,387

1,557

18,493

4,180

1,664

18,901

4,325

1,660

19,134

4,493

1,539

19,099

4,676

Table 1-3c. Enrollment Trends for Past Five Academic Years

(Aerospace Engineering)

Year

2005-06

221

Full-time Students

19

Part-time Students

1

?

Student FTE

48

Graduates

1

FTE = Full-Time Equivalent

Year

2006-07

241

Year

2007-08

237

Year

2008-09

281

Year

2009-10

317

6

?

48

18

?

55

19

?

45

12

?

43

13

Table 1-4. Program Graduates

Prior

Degree(s) if

Master

Student

Certification/Licensure

(If Applicable)

Initial or Current

Employment/Job

Title/Other

Placement

Graduate

Student/Purdue

Numerical

Identifier

Year

Matriculated

Year

Graduated

1

2005

2009

2

2005

2009

3

2005

2009

4

2005

2009

5

2005

2009

6

2003

2009

7

2004

2009

8

2004

2009

9

2005

2009

Decisive Analytics

10

2004

2009

11

2001

2009

Northrup Grumman

Mando/Quality

Engineer

12

2005

2009

13

2004

2009

14

2003

2009

15

2006

2009

16

2005

2009

17

2003

2009

18

2004

2009

19

2005

2009

20

2005

2009

21

2005

2009

22

2003

2009

23

2005

2009

24

2004

2009

25

2006

2009

Graduate

Student/Auburn

Decisive Analytics

Graduate

Student/Florida State

Graduate

Student/Auburn

US Navy

Department of

Defense

Graduate

Student/Auburn

Graduate

Student/Purdue

Graduate

Student/Purdue

Graduate

Student/Auburn

14

CRITERION 2. PROGRAM EDUCATIONAL OBJECTIVES

A. Mission Statement

The Mission Statement of Auburn University, published on page 5 of the Auburn

University Bulletin, www.auburn.edu/student_info/bulletin/university.pdf is reproduced

here:

“Mission. Auburn University’s mission is defined by its land-grant traditions of

service and access. The university will serve the citizens of the State through its

instructional, research and outreach programs and prepare Alabamians to respond

successfully to the challenges of a global economy. The university will provide

traditional and non-traditional students broad access to the institution’s educational

resources. In the delivery of educational programs on campus and beyond, the

university will draw heavily upon the new instructional and outreach technologies

available in the emerging information age.

As a comprehensive university, Auburn University is committed to offering highquality undergraduate, graduate, and professional education to its students. The

university will give highest priority for resource allocation for the future development

of those areas that represent the traditional strengths, quality, reputation, and

uniqueness of the institution and that continue to effectively respond to the needs of

students and other constituents. Consistent with this commitment, the university will

emphasize a broad and superior undergraduate education that imparts the knowledge,

skills, and values so essential to educated and responsible citizens. At the same time,

the university will provide high-quality graduate and professional programs in areas

of need and importance to the state and beyond. To accomplish these educational

goals, Auburn University will continue to compete nationally to attract a faculty

distinguished by its commitment to teaching and by its achievements in research, both

pure and applied. The university will strive to attract a faculty that will bring

distinction and stature to the undergraduate, graduate, and professional programs

offered by the university. Because research is essential to the mission of a land-grant

university, Auburn University will continue development of its research programs.

The primary focus of this research will be directed to the solution of problems and the

development of knowledge and technology important to the state and nation and to

the quality of life of Alabama citizens.”

B. Program Educational Objectives

The Educational Objectives of the Program are:

1. to provide our new graduates with the necessary analytical and communication

skills either to pursue graduate study or to enter the aerospace workforce directly;

15

2. to provide our alumni with an appreciation of the necessity to adapt, through lifelong learning, to both the constantly changing needs and demands of society and

to their evolving personal career goals.

These objectives are published on our web site

http://www.eng.auburn.edu/programs/aero/programs/accreditation.html .

C. Consistency of the Program Educational Objectives with the Mission of the

Institution

A portion of the Mission of Auburn University Mission statement reads, “… The

university will serve the citizens of the State through its instructional, research and

outreach programs and prepare Alabamians to respond successfully to the challenges of a

global economy...” and also provides “…Consistent with this commitment, the university

will emphasize a broad and superior undergraduate education that imparts the

knowledge, skills, and values so essential to educated and responsible citizens.”

(emphasis added) Thus, the mission of Auburn University is consistent with Objective 1.

There is implied consistency with Objective 2 because one of the values of “educated and

responsible citizens” should be an appreciation of life-long learning.

D. Program Constituencies

The Program Constituencies are

1. Students

2. Alumni

3. Aerospace Employers

4. Government Employers

We consider our students, who are later alumni, and (in some cases) citizens of the State

of Alabama, to be our primary constituency. Other “constituencies,” who are more like

third party beneficiaries, are the aerospace industry and government employers of our

graduates. All of these are represented on various committees and boards that provide

advice and feedback to the Department, either directly, or indirectly. In fact, most of the

above identified constituencies are represented by members of our Aerospace

Engineering Advisory Council (AEAC), since it consists primarily of residents of the

State of Alabama, who are, or were, affiliated with industry and/or government

employers of our graduates, and were students in this department.

E. Process for Establishing Program Educational Objectives

Educational Objective 1 is intended to be broad enough to cover all graduates, if they do

as well as we intend. Of course some graduates of our program enter a part of the

workforce that is not categorized as “aerospace.” This is sometimes dictated by the

graduate and sometimes by circumstances beyond their control, such as the economy.

However, our program is intended to provide analytical and communication skills that

will allow them all to enter the aerospace workforce and/or to pursue graduate study in

aerospace engineering, or a closely related field, immediately upon graduation. For those

16

who choose other types of jobs or graduate education, the analytical and communication

skills they acquire will enable them to be initially successful also.

After the initial step of obtaining a job or entering graduate school, Objective 2 comes

into play. Regarding the need for life long learning, faculty members frequently remind

students in classroom lectures that, since aerospace engineering is a changing field,

subsequent to their graduation they must continue to learn in order to remain competitive

as an aerospace engineer.

Before the 2004 visit, our educational objectives were developed and adopted in a

collaborative effort. Faculty members formulated objectives similar to the ones adopted.

Then, the Aerospace Engineering Advisory Council (AEAC) reviewed and discussed the

proposed objectives and recommended changes, which were reviewed by the faculty and

incorporated. We then established a process for periodically evaluating and, if necessary,

modifying these Educational Objectives. The process includes the faculty, students,

alumni, and AEAC members. Annually, the faculty, students, and the AEAC review our

educational objectives, and the assessment results, and recommend actions to be taken.

Our Aerospace Engineering Advisory Council played a major role adopting our

Educational Objectives. In the Spring of 2010, the more active members of the AEAC

were:

• Lawrence Burger '80 (ChE), Director, U.S. Army Space and Missile Defense

Command's (SMDC’s) Space and Missile Battle Lab, Huntsville, AL.

• Louis Connor '66, Retired Principal Engineer, Lockheed Martin Space & Missile

Defense Technologies.

• Frederick A. Davis ‘72, Technical Director, Assessment and Demonstrations

Division, Air Force Research Laboratory Munitions Directorate, Eglin AFB, FL.

• U. S. Air Force Research Lab, Eglin AFB

• Charles E. "Gene" Fuller ’63, '65*, CEO, REMTECH, Inc., Birmingham, AL

• Ronald Harris '59, Senior Executive, NASA and Boeing (retired)

• Ralph Hoodless '59, Senior Executive, NASA, MSFC (retired)

• Robert M. Jones '66, ’68, Retired, Business Development Manager, Missile

Defense Programs, Northrop-Grumman

• Richard Kretzschmar ’89, Deputy Director, Systems Simulation and Modeling

Development Directorate, AMRDEC, AMCOM, Huntsville, AL.

• Mark Miller, '84, '85, Manager, Missile Systems Department, Dynetics, Inc.,

Huntsville, AL.

• Morris Penny '59, Retired, Senior Engineer Lockheed Martin

• Rex Powell '49, Retired, Director Applied Sensors, Guidance, and

Electronics Directorate, AMRDEC, AMCOM, Huntsville, AL.

• Norman O. Speakman ‘72, ‘74, Principal Research Engineer, Georgia Tech

Research

Institute, Inc, Huntsville, AL.

• James Voss ‘72, Retired NASA Astronaut, Col. (Ret.) U.S. Army, Currently,

Scholar in Residence Aerospace Engineering Sciences and Roubos Chair, University

of Colorado, Boulder, CO.

• Thomas J. Williams ‘87 (ME), Manager, Propulsion Systems Department

17

NASA/MSFC, Huntsville, AL.

• John E. Cochran, Jr. ‘66, ‘67, Professor and Head, Department of Aerospace

Engineering, Auburn University.

All members of the AEAC except Mr. Burger and Mr. Williams are graduates of the

Program. Two members, Mr. Burger and Mr. Williams, accepted membership on the

Council because of the relationships of their positions to aerospace.

Since its formation in the early 1990’s, the AEAC has been actively involved in

providing assistance to the department in achieving its goals and objectives regarding

instruction and research. The AEAC meets twice a year and also at the request of the

department head when circumstances warrant.

In the mid to late 1990’s, AEAC members reviewed the aerospace engineering

curriculum and the new semester curriculum prior to its implementation in 2000. The

chairman and other members, frequently provide advice to the department head on the

state of the aerospace industry and the suitability of the curriculum for preparing

engineering graduates to contribute. Moreover, members serve as advocates to the

university administration in efforts to obtain additional resources and faculty members.

Although it pertains more to outcomes than educational objectives, we note here that

three members of the AEAC, Mr. Morris Penny, Mr. Gene Fuller, and Mr. Louis Connor,

have interviewed graduating seniors on essentially an annual basis since 2002. Initially,

these interviews were face-to-face meetings between a sample of the graduating senior

class and the members of the AEAC team. The current system is an on-line survey that is

completed by all graduating seniors in the Spring semester with the survey results being

directly sent to the AEAC team. The team members analyze the survey results and then

write a summary report for the Department Head, Dr. Cochran. Prior to the students

completing the on-line survey, the AEAC team comes to campus for a discussion with

the students concerning the survey and their experiences with situations concerning

professional ethics.

The results obtained from the AEAC senior surveys are discussed in the section dealing

with Outcomes. The on-line survey questionnaire and AEAC summary reports will be

provided to the Visitor at the time of the visit.

F. Achievement of Program Educational Objectives

Although it is impossible to ensure 100% achievement of our educational objectives

(because they are based on what our graduates achieve after graduation), we do expect

that a large percentage of our graduates will either be employed in the aerospace field or

enter graduate school. We are confident that our graduates who achieve a cumulative

grade point average of 3.0 or better are qualified to pursue post-graduate engineering

education. We are confident that all our graduates are prepared for entry-level positions

in aerospace engineering.

18

In order to assess how well the Department is meeting these two Educational Objectives,

a survey questionnaire was sent to a total of one-hundred and thirteen (113) of our alumni

who graduated within the last five years. Twenty-nine (29) responses were received, for

a response rate of 25.7%. The questions and a breakdown of responses follow. All

questions were not answered by all respondents, nor were explanations and/or

elaborations given in all cases. In some cases, multiple answers were given.

Regarding Objective 1, the responses indicate that:

• 45% entered the aerospace workforce directly;

• 45% either pursued and obtained (38%), or are still working towards (7%) an

advanced degree;

• 10% entered the workforce in a non-aerospace related area (this includes military

service).

These results are consistent with exit interviews of students conducted over the last six

years by the Department Head. Results of those interviews will be provided at the time

of the visit.

Of those graduates who indicated that they entered the aerospace workforce directly,

• 14% obtained a job related to aerodynamics;

• 17% obtained a job related to aerospace structures;

• 3% obtained a job related to aerospace guidance, navigation, stability, and

control;

• 7% obtained a job related to propulsion;

• 34% obtained a job related to aerospace design, modeling, and/or simulation;

• 21% obtained a job in “other” aerospace applications.

We think that this demonstrates that the Aerospace Engineering Department provides a

well-balanced program which allows our graduates to successfully enter the aerospace

workforce in a wide variety of program areas.

Results concerning preparation for employment and/or graduate education are contained

in Table 1:

Table 2-1. Assessment results for Educational Objective 1

Inadequate

Adequate, with

Deficiencies*

Adequate, with no

Deficiencies

Analytical Preparation

4%

50%

46%

Oral Communications

Preparation

7%

29%

64%

Written Communications

Preparation

7%

32%

61%

*Notes: (1) The word deficiencies was used in the questionnaire to indicate that

something that the graduate would have liked to be included in the Program was, in

19

his/her opinion not present to the degree desired. (2) In this section it means that

Percentages have been rounded to nearest percent.

Regarding analytical preparation, one individual (4%) replied that analytical preparation

was inadequate, but provided no additional feedback. The primary curriculum criticisms

noted were: no business related curriculum content; no formal CAD instruction, and a

need for a stronger connection between classroom theory and the “real world.” If we are

to cover adequately the engineering component of our program, then there is currently no

room in our curriculum for business-related content. However, students may now choose

a Business-Engineering-Technology minor (16 hours of business).

Regarding CAD instruction, the constraint of a maximum 128 semester hours limits the

number of hours that can be devoted to CAD, machine shop practices and other

technology-related activities. Courses introducing the students to CAD software

packages such as Solid Edge and AutoCAD are offered by the Mechanical and Industrial

Engineering departments at Auburn. Aerospace students are encouraged by the

Academic Advisor and Program Coordinator to consider taking these courses as part of

their Aero/Astro elective hours. Some students take the available courses. Others learn

on their own when they perceive the need. Still others make drawings by hand, are work

in teams with members who can provide assistance with CAD software.

Regarding oral and written communications skills: 2 individuals (7%) replied that

preparation was inadequate, but provided no additional feedback. A large portion of

those responding cited the need for more oral classroom presentation experiences and

additional technical writing experiences. In AERO 3130: Aerodynamics Laboratory, the

students produce multiple, extensive individual written reports. In the two-semester,

capstone design sequence (AERO 4710 and 4720), the students must submit an

individual written report and make an oral presentation during the Fall semester. In the

Spring semester, each student team completes both a final written report and oral

presentation.

Regarding Objective 2, the responses to the alumni survey indicate that:

• 41% believe that their personal career goals have not changed since graduation

• 59% believe that their career goals have changed “somewhat” or “greatly”

Concerning the importance of life-long learning and intellectual growth, all respondents

(100%) indicated that such activity was very important.

The final survey question encompasses both Objective 1 and Objective 2 and relates to an

overall assessment of our program with regard to its effectiveness:

• 4% said “overall, it could have been better”

• 14% said “mostly adequate, but with some deficiencies”

• 39% said “my preparation was adequate”

• 43% said “my preparation was excellent”

Thus, the survey indicated that 82% of the respondents considered the Program to have

been adequate to excellent.

20

The most common comments about the overall curriculum were (in no particular order):

• Too little relation between textbook equations and “real world” applications

• A lack of “hands on experiences”

Making the connection between classroom theory and the “real world” is something that

we are working on continuously. The ENGR 1100: Engineering Orientation course

exposes the students to “real” engineers and the AIAA Student Chapter host speakers

several times each year. Coursework involving “hands-on” experiences include the

AERO 3130: Aerodynamics Laboratory and the AERO 3610: Aerospace Structures I

courses. Students may also elect to participate on the AIAA, Design, Build and Fly team,

the NASA Reduced Gravity Experiment team and several other College of Engineering

student team projects.

21

Criterion 3. PROGRAM OUTCOMES

A. Process for Establishing and Revising Program Outcomes

The entire departmental faculty developed the original set of program outcomes in 2002.

These original (and current) outcomes consist of the ABET program outcomes a-k and an

additional outcome specific to aerospace engineering. The entire faculty meets on a sixyear cycle to consider program outcomes. The last meeting that specifically addressed

the program outcomes was held during the Fall of 2008.

B. Program Outcomes

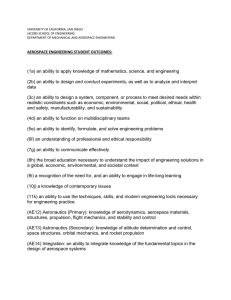

Our program outcomes are listed below

Table 3-1. Program Outcomes

Outcome

a

b

c

d

e

f

g

h

i

j

k

l

Definition

An ability to apply knowledge of mathematics, science, and engineering appropriate to

aerospace engineering

An ability to design and conduct experiments, as well as to analyze and interpret data

An ability to design a system, component, or process to meet desired needs

An ability to function on multi-disciplinary teams

An ability to identify, formulate, and solve engineering problems

An understanding of professional and ethical responsibility

An ability to communicate effectively

the broad education necessary to understand the impact of engineering in a societal

context

a recognition of the need for, and an ability to, engage in life-long learning

a knowledge of contemporary issues

An ability to use the techniques, skills, and modern engineering tools necessary for

engineering practice

a basic knowledge of the following aerospace fields: aerodynamics, flight dynamics,

orbital mechanics, propulsion and structures/materials

The program outcomes listed above encompass the ABET Outcomes and satisfy the

Aerospace Program criteria. These program outcomes our documented on the Aerospace

Engineering Department website.

C. Relationship of Program Outcomes to Program Educational Objectives

The relationship between the Program Outcomes and Educational Objectives is depicted

in the following table.

22

Table 3-2. Relationship of Educational Objectives to Program Outcomes

Outcomes

Educational Objectives

a) an ability to apply knowledge of mathematics, science, and engineering.

b) an ability to design and conduct experiments, as well as to analyze and

interpret data.

c) an ability to design a system, component, or process to meet desired goals.

d) an ability to function on multi-disciplinary teams.

e) an ability to identify, formulate, and solve engineering problems.

f) an understanding of professional and ethical responsibility

g) an ability to communicate effectively.

h) the broad education necessary to understand the impact of engineering

solutions in a global context.

li) atirecognition

i

l bofl thedneedi for,

t l andt antability to engage in life-long learning

j) a knowledge of contemporary issues.

k) an ability to use the techniques, skills, and modern engineering tools

necessary for engineering practice.

l) a basic knowledge of the following aerospace fields: aerodynamics,

flight dynamics, orbital mechanics, propulsion and structures/materials

1

♠

♠

2

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

♠

D. Relationship of Courses in the Curriculum to the Program Outcomes

The relationships between the departmental courses and the program outcomes are

depicted in following table.

Table 3-3. Course-Outcome Matrix

Outcome

/Course

2200

3110

3120

3130

3220

3230

3310

3610

4140

4510

4620

4630

4710

4720

4AA0

a

X

X

X

X

X

X

X

X

X

X

X

X

X

X

b

c

d

X

X

X

X

X

X

e

X

X

X

X

X

X

X

X

X

f

g

X

X

X

X

X

X

X

h

X

X

X

X

X

j

X

X

X

X

X

X

X

i

X

X

X

k

l

X

X

X

X

X

X

X

X

X

X

X

X

X

X

23

Since the last ABET review in 2004, the departmental faculty has seen an approximately

50% turnover, due to retirements and departures. Consequently, it became clear that the

“newer” and “older” faculty needed to meet and discuss each course in detail to maintain

continuity in the course material and coverage.

The above table was created by the departmental faculty through a Course Review

process that started in September of 2008 and extended to the end of January 2009.

Small review committees (2-5 faculty members) were created to review each of the

courses listed in the above table. The committee members consisted of faculty that were

either responsible for teaching the particular course or those who taught “follow-on”

courses.

Each committee discussed and agreed upon the course topic coverage, the course

textbook, and the program outcomes that are encompassed by the course material. A

Course Review document was prepared for each course by the program coordinator, Dr.

Steve Gross, for use in the discussion at each committee meeting. Also, a final set of

minutes were produced for each of the Course Review meetings. These documents will

be available for the ABET Visitor to review at the time of his/her visit.

E. Documentation

The documentation of the attempts by the Department to verify that our graduates meet

all of the Program Outcomes is primarily associated with the coursework produced by

our students as they progress toward their undergraduate degree. Samples of student

coursework will be available for review by the ABET Visitor. We have set aside a small

conference room (Davis 207) in which we will provide the information on the conference

table and bookcases using labeled notebooks and files.

Another important method employed to verify the achievement of these Program

Outcomes is the self-assessment completed by our graduating senior students. Two selfassessments are done by the seniors. The first is a one-on-one interview with the

Department Head, Dr. Cochran, during the semester of their graduation (Senior Exit

Interview-SEI). The second self-assessment is on on-line instrument that was created by

one of our AE Advisory Council members, Mr. Morris Penny (Advisory Council

Instrument- ACI). The students fill out the on-line instrument and the results are sent via

email to Mr. Penny. Mr. Penny and two other AE Advisory Council members, Mr. Gene

Fuller and Mr. Louis Connor review the student assessments and then write a report to

Dr. Cochran summarizing their findings. The on-line assessment offers the students an

opportunity to evaluate the achievement of the Program Outcomes in an anonymous

environment. The documentation associated with both of these self-assessments will be

available for review during the ABET visit.

Finally, our graduating seniors complete a series of assessment instruments collectively

called the Comprehensive Program Assessment Instrument (CPAI) in the areas of

aerodynamics, flight dynamics, orbital mechanics, propulsion and structures/materials

24

which are associated with Program Outcome l. The original intent of the CPAI was to try

to measure the basic retained knowledge of the five subject areas associated with

Outcome l. The five component instruments of the CPAI and results will be available for

review during the ABET visit.

F. Achievement of Program Outcomes

It is the goal of the Aerospace Engineering department to make continual improvements

in the undergraduate academic program. If the “product” of our undergraduate program

is to be considered our students, then we can use the Program Outcomes as a set of goals

for our Improvement Process (IP). The basic steps of the ideal IP are listed below

Step #1: Assess the “product” with respect to the Program Outcomes

Step #2: Note any “weaknesses” with the “product”

Step #3: Inform the “controllers” of these “weaknesses”

Step #4: Have the “controllers” make adjustment to the “process” to strengthen the

“weaknesses”

The definitions of the terms used above are

“products” - undergraduate student

“weaknesses” – weak attainment of a Program Outcome

“controllers” - academic faculty

To produce a complete IP, all factors that can affect the “product” have to be under the

control of the “controllers.” In reality, within the Auburn University system, a significant

set of factors, which influence the “product” that are outside the control of the

“controllers.”

First, the size of the undergraduate curriculum is fixed in terms of the allowable credit

hours. University requirements limit the Aerospace Engineering undergraduate program

in such a way that the Department has control over a maximum of 61 semester credit

hours (out of 128 hours). The current curriculum is in a “zero-sum” situation. The

introduction of any “new” course material must entail the removal of an equivalent

amount of “old” material. Second, the undergraduate enrollment in the Aerospace

Engineering program is controlled by the admissions policy of the University and by the

College of Engineering. The undergraduate enrollment in the College of Engineering

was 2578 (FTE) in 2005 and has risen to 3347 (FTE) in 2009 with a goal of 4000 in the

near future. The Aerospace Engineering Department has no control over how many of

these students enter the Aerospace Engineering program. Consequently, the “controllers”

(faculty) must operate an IP that conforms to these outside constraints.

Two factors that are somewhat within the control of the department faculty and which

influence the “product” are course frequency and course instructor assignments. The

Aerospace Engineering department is comprised of ten faculty members. To maintain

viable bachelor, master and doctoral programs with such a small faculty, the required

undergraduate courses are only offered once each academic year (Fall or Spring

25

semester). Along with offering the undergraduate courses on a yearly cycle, most

required undergraduate courses are taught by the same faculty member from year to year.

The faculty feels that this system is beneficial to the IP, since the faculty member has a

“vested” interest in improving the course from year to year. The department is fortunate

to have a faculty composed of individuals that are very interested in devoting the time

and effort to continually improving the undergraduate curriculum. The faculty consider

the IP to be a important task that is an expected activity associated with their professional

duties.

The Aerospace Engineering IP places the faculty as the sole “controller” for the process.

Faculty members assess students through their coursework, discuss student “weaknesses”

through faculty meetings and the Course Review process, obtain industrial-oriented input

from the AE Advisory Council and review the data from the two student self-assessment

instruments. The inputs from these various sources guide the faculty in altering the

course content and curriculum to strengthen the “weaknesses” identified through the

Program Outcomes.

In an attempt to quantify the level of achievement of the Program Outcomes, numerical

scores are collected from three sources: faculty course instructors, the senior interview

with Dr. Cochran (SEI) and the online instrument created by the AE Advisory Council

(ACI). The 2009-2010 scores from this effort are listed in the table below.

Table 3-4. Outcome Achievement Composite Data

(Score out of 10 points)

Outcome

Instructor

SEI

Score

Score

(2010)

(2005,6,8)

a

8

8

b

8

8

c

9

7

d

9

9

e

8

8

f

*

9

g

9

9

h

9

8

i

*

9

j

9

7

k

8

8

*Not assessed by course instructors

ACI

Score

(2010)

8

8

7

8

8

8

8

7

8

6

8

Average

Score

Acceptable

Score

Goal

8

8

8

9

8

8

9

8

8

7

8

5

5

5

5

5

5

5

5

5

5

5

10

10

10

10

10

10

10

10

10

10

10

The “Instructor Score” listed in the above table are mean values computed from the

scores supplied by the various instructors whose courses had that particular Outcome

“covered” through the course material (Table 3-3). The student course material

associated with the “Instructor Score” will be available for the ABET Visitor to review

on-site. The documentation associated with the “SEI Score” and “ACI Score” will also

be available for the ABET Visitor to review.

26

Both of the self-assessment instruments, SEI and ACI provided the students with the

ability to identify “weaknesses” with the academic program by expressing verbal or

written comments. These identified “weaknesses” are listed and discussed in the

following section of this report.

As mentioned previously, the faculty members responsible for each course review student

performance after completion of the course (Spring or Fall semester) and make

improvements to the course content and instructional process. This faculty-driven

component of the IP is considered part of the faculty member’s professional

responsibility to constantly improve our undergraduate program. Faculty members

discuss these “weaknesses” through formal means such as department faculty meetings

and the Course Review process. Faculty discussion of “weaknesses” also occurs

informally through unscheduled meetings such as lunches and office meetings. With

such a small faculty, information passes very easily and quickly through the department.

Outcome l is assessed through the Comprehensive Program Assessment Instrument

(CPAI). The details of the CPAI are

1. A required, zero credit, pass/fail, course entitled AERO 4AA0: Program

Assessment, has been created as a vehicle for administering the CPAI.

2. The AERO 4AA0 course is included in the program curriculum in the

spring semester of the senior year (see Table I-1) and it meets once every

week for a 50 minute period.

3. The CPAI consists of five separate components with one each in

aerodynamics, structures/materials, orbital mechanics, flight dynamics and

propulsion.

4. Each component of the CPAI is presented in the form of short-answer

questions. These questions are designed to cover material from the

required courses in each of the five areas mentioned in Outcome l.

5. The faculty did not want the students to prepare (study) in any way for the

CPAI, since the premise of the instrument is that it should be a measure of

retained knowledge. The satisfactory/unsatisfactory grading scheme was

constructed in such a way as to discourage the student from preparing. A

“satisfactory” grade in the course is earned, not by achieving any

particular numerical grade on each component of the CPAI, but by simply

completing each component.

The results of the CPAI are listed in the table below

Table 3-5. CPAI Average Results for Outcome l

Year

Topic

Aerodynamics

Flight Dynamics

Orbital Mechanics

Propulsion

Structures

2005

46

76

62

57

53

(Score out of 100 points)

2006 2007 2008 2009

39

71

63

55

49

35

76

60

58

49

27

33

72

65

56

37

50

69

68

66

50

2010

Acceptable

42

77

65

63

49

40

40

40

40

40

Although the CPAI scores have been acceptable since 2005, there is a feeling among the

faculty that the philosophy behind the CPAI needs to be re-evaluated. Some criticisms of

the CPAI that have been voiced are listed below.

1. The students have no real incentive to devote significant effort on the various

elements of the CPAI given that they receive no academic credit for this effort.

(zero-credit course)

2. Since this is an “exit exam” and the questions are supposed to assess a basic

understanding of the subject areas, it is difficult to use it as a feedback to the

“controller” of the IP system to improve the subject courses.

3. Some of the material covered in the CPAI is from course work that the students

may have taken almost 2 years prior to completing the CPAI. Is the CPAI just

assessing an individual student’s memory capacity? Does a student typically

remember material that he/she enjoyed and forget material that they found

boring?

4. Can Outcome l be more efficiently assessed by using a passing grade in

coursework associated with aerodynamics, flight dynamics, orbital mechanics,

propulsion and structures?

One suggestion that has been made to alter the CPAI involves the construction of a

problem or set of problems that will provide a measure of a student’s critical thinking

skills associated with the areas of aerodynamics, flight dynamics, orbital mechanics,

propulsion and structures. The faculty will be discussing the future of the CPAI after the

upcoming ABET visit.

28

Criterion 4. CONTINUOUS IMPROVEMENT

A. Information Used for Program Improvement

Information used for the Improvement Process (IP) of the Aerospace Engineering

Program is obtained from multiple sources listed in the table below.

Table 4-1. Improvement Process Source Characteristics

Source

Student discussion with Faculty

Senior Exit Interviews with Dr. Cochran (SEI)

AE Advisory Council Senior Interviews (ACI)

CPAI Assessments

Faculty member assessment of student performance in

individual courses

Faculty member involvement in the Course Review Process

Faculty member involvement in Faculty Meetings

Alumni Survey

Procurement

Cycle

Continuous

Yearly

Yearly

Yearly

Yearly

Documentation

Available?

No

Yes

Yes

Yes

Yes

3 Year

Continuous

5 Year

Yes

Yes

Yes

The data from the sources listed above will be available for review by the ABET Visitor.

B. Actions to Improve the Program

Information obtained through the IP described in Table 4-1 pointed to several

“weaknesses” with regard to the Program Outcomes. Such “weaknesses” that were noted

by several sources and that were consistently mentioned during the 2005 to 2010 time

period have been addressed by the Department.

Student Identified Weakness #1: Outcome f: An understanding of professional and

ethical responsibilities.

Student comments from the self-assessment instruments SEI and ACI during the 20052006 period indicated that they felt the area of professional engineering ethics was not

adequately covered in any of the Aerospace Engineering course material. The students

did not feel that the required Philosophy 1020: Introduction to Ethics course covered

what they felt constituted “professional ethics.”

In response to this “weakness,” a lecture on Professional Ethics was introduced in Spring

2007 into the AERO 4AA0: Program Assessment course that all graduating seniors must

complete. Dr. Cochran, a licensed attorney, prepares and delivers this lecture.

Comments made as part of the Spring 2007 AEI indicated that the students felt that this

lecture by Dr. Cochran did improve their knowledge and appreciation of professional

engineering ethics.

In a further attempt to strengthen this perceived “weakness”, starting this Spring 2010

semester, an additional lecture was added to the AERO 4AA0 course that was presented

29

by three of our AE Advisory Board members: Mr. Morris Penny, Mr. Gene Fuller and

Mr. Louis Connor. They discussed various professional ethics situations that they have

encountered during their industrial careers. Material related to these two ethics lectures

will be available for review by the ABET Visitor.

Student Identified Weakness #2: Outcome h: the broad education necessary to

understand the impact of engineering solutions in a global context. and Outcome j: a

knowledge of contemporary issues.

Student comments from the self-assessment instruments SEI and ACI during the 20052006 period indicated that the program was “weak” with respect to these outcomes. This

issue was discussed in several faculty meetings and during the 2008 Course Review. The

faculty indicated that they did discuss this topic in their courses, but that they would

increase their emphasis on this topic in the future. The three members of the AE

Advisory Council responsible for the ACI have made some suggestions regarding this

“weakness” during this last assessment cycle which the faculty will consider for this

upcoming academic year.

Student Identified Weakness #3: Senior Capstone Design Course

At the time of the last ABET visit in 2004, the senior students could choose from two,

year-long, senior design course sequences. The first, Aircraft Design, was taught by Dr.

Ron Barrett. Dr. Barrett started with the Department in 1993 and his teaching specialty

was aircraft design. He was a very experienced and excellent design instructor. The

second design sequence, Space Mission Design, was taught by Col. Jim Voss. Col. Voss

retired from the NASA astronaut program in 2003 after flying several Space Shuttle

missions and came to Auburn as a Adjunct Professor. He had extensive experience in

Space Mission definition and design and was an excellent instructor.

Unfortunately, Dr. Barrett left Auburn in the Summer of 2005 and Col. Voss also left

Auburn in the Summer of 2006. The Department lost two very experienced and excellent

design instructors over a one year period. The Department was able to replace Dr.

Barrett by hiring Dr. Gil Crouse, but Col. Voss could not be replaced since he occupied

an Adjunct position. The Department returned to a single year-long (two semester)

design course sequence in Aerospace Design with Dr. Crouse as the instructor. A

significant number of students were very disappointed that the Space Mission Design

course sequence had to be terminated and this is reflected in the comments in the ACI

and SEI.

Dr. Crouse has a significant amount of experience in aircraft design, but prior to his

arrival at Auburn, he had never taught such a course in a university setting. It took a

while for him to fully develop his teaching style and the structure for the Aerospace

Design course. During the 2007 and 2008 academic years, the student comments from

the ACI reflected a “weakness” associated with this design course. Dr. Crouse has

worked very hard to create a strong Aircraft Design course and this has been reflected in

the 2010 ACI comments. As soon as he arrived in Auburn, Dr. Crouse formed a AIAA

30

Design, Build and Fly team for the students and they have sent a team and plane to the

national competition each year since 2006. Prior to Dr. Crouse’s arrival, the Department

had never competed in these competitions.

Dr. Crouse and the Department are dedicated to continually improving this sequence and

the negative comments regarding the capstone design sequence found in the AEI and SEI

have decreased.

Student Identified Weakness #4: Limited computer programming experience

Starting in 2005, the faculty has added more programming assignments to many of the

required courses to strengthen the achievement of Program Outcome k. The curriculum

in place in 2005 and the current curriculum contains only one official programming

course COMP 1200: Introduction to Computing that students must completed during the

Pre-Engineering program. The COMP 1200 course has two versions, a C++ and a

MATLAB variant. The Aerospace students are expected to take the MATLAB version of

this course. Many of the students do take this course during their freshmen year as

shown in the curriculum model.

The first Aerospace courses that require students to develop MATLAB programs are

typically in the Spring of the junior year. These courses are AERO 3220: Aerospace

Systems and AERO 3230: Flight Dynamics. Student feedback to the faculty and in the

SEI during the Spring of 2006 indicated that they felt unprepared to complete the

MATLAB programs due to the fact that either they did not do any extensive

programming in the COMP 1200 course or that it had been “too long” since they had

taken COMP 1200 (freshmen year).

In response to this feedback, the Department created two, one-credit, elective courses

under the heading of AERO 3970: Special Topics. The first AERO 3970 course is

designed for the juniors to take in the Fall semester. This course instructs the students in

developing MATLAB programs to solve problems commonly found in the AERO 3220

and AERO 3230 courses that they will take the following Spring semester. The second

AERO 3970 course is designed for the juniors to take in the Spring semester. This course

instructs students in developing FORTRAN programs to solve problems typically found

in AERO 4510: Aerospace Propulsion and AERO 4620: Aerospace Structures II which

are senior level courses they will be taking the following Fall semester.

Although the faculty would rather that these two courses be required of all students, this

could only be accomplished by reducing the size of some currently required course by

two credits to offset the two credits associated with these elective programming courses.

The faculty does not feel that the programming material present in these two courses is

more valuable for our students, then any of the current material in the curriculum. The

curriculum has six credit hours of Aero/Astro electives which are necessary to satisfy the

University requirement to accommodate six credit hours of optional ROTC instruction.

The two credits awarded for completing both of the AERO 3970 programming courses

31

can be used by the student to partially satisfy the six credit hours of Aero/Astro elective

credit.

On the average, 60% of our students take the optional MATLAB and FORTRAN

courses. Since the introduction of these two elective programming courses, the number

of student complaints regarding their preparedness for completing class assignments

using MATLAB and FORTRAN has dropped significantly.

Faculty Identified Weakness #1: Aerospace Structures Sequence was inefficient

Up until the 2007-2008 academic year, the students were required to take a four course

sequence in Aerospace Structures.

AERO 3610: Aerospace Structures I (2 credit-Laboratory course)

AERO 4620: Aerospace Structures II (3 credit-Lecture course)