Platform shoe 2420, 2425, 2426 USER INSTRUCTIONS

advertisement

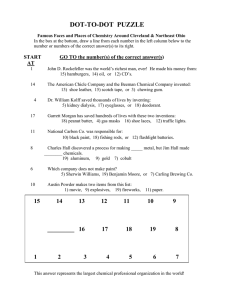

2420_001 Platform shoe 2420, 2425, 2426 USER INSTRUCTIONS Contents Platform shoe 2420, 2425, 2426 Contents GENERAL .................................................................................................... 3 SAFETY INSTRUCTIONS ............................................................................. 4 Always check products and equipment before use................................. 4 Do not combine products ...................................................................... 4 Always use personal fall arrest equipment.............................................. 4 Inspection after a fall.............................................................................. 4 Remember ............................................................................................. 5 TECHNICAL DATA...................................................................................... 6 Dimensions and weights ........................................................................ 6 Accessories, platform shoe..................................................................... 7 Cast-in sleeve 2430 .......................................................................... 8 Platform shoe angle 2435................................................................. 9 DESIGN AND FUNCTION ........................................................................ 11 Installation configuration options: ........................................................ 11 Option 1 ........................................................................................ 11 Option 2 ........................................................................................ 12 Option 3 ........................................................................................ 12 Option 4 ........................................................................................ 13 Option 5 ........................................................................................ 13 INSTALLATION......................................................................................... 14 Delivery............................................................................................... 14 Preparations......................................................................................... 14 Installation ........................................................................................... 14 DISMANTLING ......................................................................................... 19 MAINTENANCE ........................................................................................ 19 Safety checks ....................................................................................... 19 Inspection of the installed platform shoe .............................................. 19 Scrapping............................................................................................. 21 Identification........................................................................................ 20 Scrapping............................................................................................. 21 Storage................................................................................................. 21 © Combisafe international AB – UI 2420-2425-2426-EN-1034 Subject to changes 2 Platform shoe 2420, 2425, 2426 General General The platform shoe is used as a support for a working platform made up of timber joists and scaffold boards. Primary joists are supported in the shoes and a platform of scaffold boards or other timber decking is placed across them. The working platform is quick and easy to assemble, and provides useful access for painting and concrete finishing in confined areas such as lift shafts. It is also useful for decking over service voids or other large floor openings. The platform reduces the risk of falling whilst working within the lift shaft. Positioning the pin support high on the bracket minimises the risk of rotation under load. The platform shoe is available in three sizes, to suit different joist dimensions. The selection of the joist depends on the span, the loading, and other conditions relevant to the application. 3 Safety instructions Platform shoe 2420, 2425, 2426 Safety instructions Always check products and equipment before use Check the platform shoe before it is installed. Never use damaged or rusty material that could impact on safety. Do not combine products It is not recommended to install, combine or interconnect platform shoes using products other than those supplied by COMBISAFE. Combisafe product liability only applies to combinations with correctly fitted COMBISAFE products. Always use personal fall arrest equipment 1974_600 Personal fall arrest equipment must always be worn during assembly and dismantling when a risk of falling exists. This also applies to work carried out from a MEWP (mobile elevating working platform). Figure 1. Personal fall arrest equipment. Inspection after a fall If a guard rail is subject to an accident or exposed to a heavy load, the rail must be checked by a competent person. Contact Combisafe in the event of uncertainty. 4 Platform shoe 2420, 2425, 2426 Safety instructions Remember • Plan the fall guard at an early stage; this will benefit everyone. • Only use inspected safety products. • Ensure sound and safe access to the installation site/work site. • Cordon off below and around the assembly area in connection with the installation so that unauthorized personnel are not injured if, for example, you should drop tools or material. • Use tools designed for the type of work to be carried out. • Tighten screws properly and check that split pins lock correctly. • Keep threads clean and lubricated. • Keep the installation area in order. • A safe workplace is an agreeable workplace. • Many fall accidents occur from a low height. 5 Technical data Platform shoe 2420, 2425, 2426 Technical data Dimensions and weights 130 155 Ø19 80 235 X 127 Figure 2. Platform shoe dimensions. Prod. No. 2420 2425 2426 X [mm] 62 82 105 Surface treatment: Hot-dip galvanized. 6 Weight [kg] 1.8 1.9 2.0 2420_002 Ø20 Platform shoe 2420, 2425, 2426 Technical data Accessories, platform shoe 1 2 2420_003 3 Figure 3. Accessories, platform shoe. Item 1 2 3 Quantity 1 1 1 Part no. 2430 2435 2436 Description Cast-in sleeve Platform shoe angle Platform shoe angle Weight 0.03 kg 2.10 kg 2.20 kg 7 Technical data Platform shoe 2420, 2425, 2426 Cast-in sleeve 2430 Ø 24,4 2 90 70 Figure 4. Cast-in sleeve. The cast-in sleeve is made of polypropylene plastic (PP) and is used to create an anchoring point for the platform shoe. Note the four nail holes use to secure the sleeve during the casting-in process. 8 Platform shoe 2420, 2425, 2426 Technical data Platform shoe angle 2435 50 200 12 158 70 Ø17 247 2420_005 197 267 50 M16x20 Figure 5. Platform shoe angle 2435 in the upper and lower installation positions. 9 Technical data Platform shoe 2420, 2425, 2426 Platform shoe angle 2436 200 50 12 158 55 Ø17 2420_006 257 182 277 75 M16x20 Figure 6. Platform shoe angle 2436 in the upper and lower installation positions. The platform shoe angles are used to cover openings in slabs. The angle is fitted on the platform shoe and then the entire unit is fitted to the edge of the slab. The platform shoe angles are hot-dip galvanized. 10 Platform shoe 2420, 2425, 2426 Design and function Design and function The platform shoe is designed for the following maximum loads: Material Lightweight concrete Concrete Maximum permitted load 200 kg/shoe 850 kg/shoe Comments An increased load can be permitted if a support plate is fitted to the lightweight concrete under the shoe pin. Contact Combisafe for confirmation. Maximum load must not be imposed until the concrete has achieved design strength. Installation configuration options: 2420_007 Option 1 Figure 7. Securing with cast-in sleeve 2430. 11 Design and function Platform shoe 2420, 2425, 2426 2420_008 Option 2 Figure 8. Securing with the shoe pin in a drilled hole. 2420_009 Option 3 Figure 9. Securing with an expanding anchor. 12 Platform shoe 2420, 2425, 2426 Design and function 2420_010 Option 4 Figure 10. Securing with platform shoe angle and expanding anchor. 2420_011 Option 5 Figure 11. Creation of a working platform using scaffold tube and boards. 13 Installation Platform shoe 2420, 2425, 2426 Installation Delivery The platform shoe is delivered without accessories, casting sleeves, or anchors, which must be ordered separately. Preparations • Read through the installation instructions before beginning installation. • Refer to any instructions from the lift installer. • Pay attention to any details such as cables, guides, etc. • Check the timber quality before installation. • Make sure that there are good access routes to the work area. Installation It is important that securing holes are level so that the work platform is flat and steady. NOTE The distance between the centre of the cast-in sleeve/securing hole and working surface depends on the size of the primary joist and the thickness of the boards. 2420_012 The spacing c/c distance between the platform shoes is dependant on the load and the board thickness. Figure 12. Shoes level. 14 Platform shoe 2420, 2425, 2426 Installation 1. Install the platform shoes using one of the five methods below. 1: Casting in (Fig. 7) Nail cast-in sleeves 2430 securely to the formwork. Secure the sleeve to the reinforcement if necessary. After casting is complete and the formwork has been removed, the platform shoe is installed by inserting the shoe pin into the cast-in sleeve hole. 2: Securing with the shoe pin in a drilled hole (Fig. 8) Drill a 20 mm dia, straight and level hole at least 85 mm deep. Remember to blow out the hole after drilling so the shoe can be securely placed against the wall. Install the platform shoe by inserting the shoe pin in the drilled hole. 3: Securing with an expanding anchor (Fig. 9) Drill a hole for the anchor in accordance with the manufacturer's instructions. Check that the platform shoe fits closely to the wall after installation. 4: Securing with platform shoe angles (Fig. 10) Fit the platform shoe to the platform shoe angle 2435/2436 to form a single unit using the M16x20 set screw supplied with the platform shoe angle. To ensure that the floor surface is level, decide whether you are going to install the platform shoe in the upper or lower hole of the platform shoe angle, depending on the dimensions of the primary joist. (See fig. 5 or fig. 6). Drill the hole for the surface anchor in accordance with the manufacturer's instructions. Fix the unit securely in place. 5: Creation of floor surface with tubing, couplings and scaffolding planks (Fig. 11) Install the platform shoe as described in option 2. It may be helpful to fit the coupler on the platform shoe before installing the decking or boards. 15 Installation Platform shoe 2420, 2425, 2426 2420_013 2. Once the platform shoes have been installed and it has been ascertained that they fit against the wall, measure the internal distance between two shoes. Figure 13. Dimensions for cutting primary joists. 3. Cut the primary joist to length. Note that the joist must have a minimum bearing in the platform shoe (see diagram). 2420_014 MAX 10mm Figure 14. Minimum length of primary plank. 16 Platform shoe 2420, 2425, 2426 Installation 2420_015 4. Position primary joists in the shoes. It is important that the platform shoe is mounted tight to the wall. Therefore, place a wedge between the primary joist and the platform shoe to eliminate all free play. For higher joists above 145mm it can sometimes can be difficult to reach down to the platform shoe with the wedge. Then chamfer (not shorten) the edge of the primary joist according to lower pictures in figure 15. Finally, tighten the primary joist o the platform shoe with screws to ensure a tight fit sideways as well. Figure 15. Secure primary joist, using screws and wedges. 17 Installation Platform shoe 2420, 2425, 2426 5. Install scaffolding planks to form a floor. The side openings to the wall edge must be as small as possible, and must not exceed 200 mm, according to the recommendations of the Swedish Work Environment Authority. Minimise the cantilever of the boards beyond the joist to prevent tipping. They should not cantilever more than 250 mm Nail the boards to the joists, and ensure that they are flat and do not pose a trip hazard. 2420_016 Max 200 mm Figure 16. Maximum permissible gap along wall. 2420_017 MAX 250mm Figure 17. Maximum recommended side protrusion for boards. 18 Platform shoe 2420, 2425, 2426 Dismantling Dismantling The installation procedure should be performed in the reverse order when dismantling. Maintenance Clean the platform shoes after use to ensure they are fit for use next time. Safety checks Safety checks are to be performed before use and after dismantling and before parts are placed in the store. Safety checks are to be carried out by competent personnel. Combisafe recommends that only competent personnel trained by us carry out the safety checks. Check the condition of the platform shoe with regard to corrosion, welded joints, cracks and deformations. Inspection of the installed platform shoe Check that: • the shoe fits against the wall • primary joists are properly secured to the shoe with nails • boards and decking are properly secured to primary joists with nails • the concrete has cured sufficiently to have achieved full strength • all bolts are properly tightened • there are no gaps bigger than 200 mm • cantilever of the boards does not exceed 250 mm • CC distance between the platform shoes and joist dimensions are correct for the required loading • boards have no cracks or knots. 19 Maintenance Platform shoe 2420, 2425, 2426 Identification The platform shoe is marked in two places (see figure 18) with a five character identification number. This number can be of use during correspondence with Combisafe. Figure 18. Identification numbering. 20 Platform shoe 2420, 2425, 2426 Maintenance Scrapping Platform shoes and platform shoe angles that no longer meet the requirements for flawless products should be scrapped as steel. Cast-in sleeves should be scrapped as Polypropylene (PP). Storage Store Combisafe products in a dry and ventilated area protected from the effects of the weather and from corrosive substances. 21 Maintenance 22 Platform shoe 2420, 2425, 2426 Platform shoe 2420, 2425, 2426 Maintenance 23 Combisafe International AB www.combisafe.com