Future Prospects of Selected Supporting Industries in Thailand

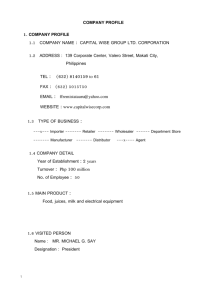

advertisement