Three phase permanent magnet brushless DC motor Controller

advertisement

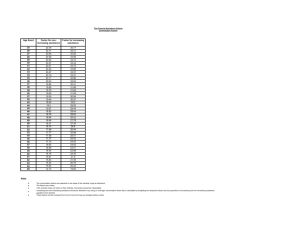

Faculty of Electrical Engineering Three phase permanent magnet brushless DC motor Controller Student: Mohd Syafiq Bin Mohd Supervisor: Dr. Abdul Rashid Husain reference speed. The actual speeds that will be used as feedback for this system can be obtained by manipulate the hall sensor signal. The internal timer in PIC and external interrupt can be used for measuring the speed of a PMBLDC motor. The pole pair numbers is one of the parameter that will determine the actual speed of BLDC motor. This actual speed can be display by using LCD display and the speed data is transferred serially to the PC by using RS232. For interfacing purpose which is to receive the speed data from PIC, a special GUI has been developed based on Visual Basic. INTRODUCTION Permanent magnet brushless DC (PMBLDC) motors have been used in many applications due to their high efficiency, silent operation, compact size, high reliability and low maintenance requirements [1]. The operation of PMBLDC is based on electronic commutation where it requires a drive unit, which consists of inverter and driver, positioning sensor for sensored type drive and a microcontroller controlling the step of commutation. Precise commutation steps is crucial in order to achieve reliable speed and radial displacement control which make the control of PMBLDC remain crucial in many applications. RESULT AND ACHIEVEMENT Figure 1a shows the circuitry of the control system where it contains the six FB180SA10 HEXFET power mosfet that serves as the switched and hall effect sensor for obtaining the feedback signal, while figure 1b shows the PMBLDC motor with the mounting. It has been shown in this work that both the open- and closed-loop control of PMBLDC is achieved with good speed control. PROJECT OBJECTIVES The aim of this project is to develop a prototype of three phase PMBLDC motor controller based on electronic commutation system open- and closed-loop control tecniques. Hall effect sensor will be used to obtain the commutation signals where it will be used as the feedback signal in performing the closed-loop control on the system. The measurement of the sensor will also be displayed online for verification of the value used in the controller. METHODOLOGIES The basic principle of controlling the PMBLDC is to produce the correct commutation pulse such that the rotor of the motor can be rotated at desired angle based on stator axis as the reference. The sequence analysis can be used in order to get the commutation sequence by analyzing hall sensor and phase current signals. The speed of BLDC can be controlled by varying the average voltage or current that passes through the motor. This average voltage can be controlled by adjusting the duty cycle of the PWM. For open loop speed control, the desired speed can be utilized by using potentiometer that is connected to analog to digital. The output from the ADC will be feed to the duty cycle register. For closed loop speed control, the ADC value from potentiometer will be used to get the (a) (a) (b) Figure 1: Control system of PMBLDC REFERENCE [1] T. Kenjo & S. Nagamori, Pemanent Magnet and Brushless DC motor, Clarendon Press, Oxford, 2005.