Getting Off the Rectangular

advertisement

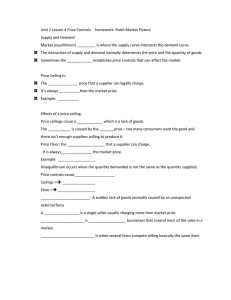

Getting Off the Rectangular Grid Tessellated ceiling and wall panels can be both beautiful and practical by Nancy Mercolino, Les Eisner, and Michael Chusid, RA, FCSI Photo courtesy Ceilings Plus When it comes to Wall and ceiling finishes, patterns based on triangles, pentagons, hexagons, trapezoids, and other polygons have become economically feasible. these new shapes provide alternatives to the square and rectangular grids that dominated so much of 20th century design. The use of tessellated surfaces appears to be a growing trend in contemporary architectural design. ‘Tessellation’ is the geometric term for dividing a surface into polygons (i.e. multi-sided shapes). The term comes from the Latin ‘tessellare,’ meaning ‘to pave with tiles.’ While tessellated tile designs can be seen in recently constructed façades, floor finishes, and skylights, this article focuses on their use for ceiling and interior wall panel systems. A project currently under construction demonstrates the architectural potential of tessellations. The main concourse of the New Doha International Airport (NDIA) in Qatar, designed by HOK, has a wide-span, undulating ceiling vault. Its ceiling is assembled with triangular panels with edges as long as 1.3 m (4 ft). To better match the large scale of the concourse, the triangles are overlain with a rhombic pattern created by using wider joint spacing around clusters of eight triangular panels. A third visual element introduces rhythm by placing trapezoidal openings beneath skylights that allow filtered light to cast dappled shadows onto the floor below. All these geometric elements are projected onto curved surfaces sweeping beyond the glass walls in order to create overhanging 84 the construction specifier | May 2010 Exciting new designs are now possible. The Great Hall of the British Museum has a tessellated skylight formed by triangles projected onto a curved surface. Photo © Lindsay Watt soffits that must resist fluctuations in air pressure due to strong winds blowing off the Persian Gulf. In addition to meeting aesthetic considerations, the aluminum panels had to: • be lightweight to minimize loads on the structure’s long spans; • provide a high noise reduction coefficient (NRC) to compensate for the hard floor surfaces and glazing; • integrate with lighting, ventilation, and other building services; • offer access to above-ceiling HVAC equipment for commissioning and servicing; and • address rigorous sustainable construction goals. Form follows technology Tessellations have been used as decorative architectural motifs since antiquity, featured in various flooring designs and ornaments. In every epoch, architectural motifs have related to the design and fabrication technologies in use. In eras of manual craftsmanship, for example, elegant tessellations could be laid out using simple tools such as a straightedge and compass. In the Industrial Age, the production line shaped modern architecture. Ribbons of material—whether glass, ceramic, metal, wood, or mineral fiber—moved down the line to cut-off mechanisms that produced rectangular sheets or panels. These right-angled building components were compatible with the drafting tools epitomizing the era—the sliding parallel rule and right-angled triangle. While non-orthogonal examples can be cited—such as Frank Lloyd Wright’s experiments with hexagonal modules in his Usonian houses and Buckminster Fuller’s geodesic and Dymaxion projects —rectangles have been the dominant planning module of the architectural era drawing to a close. This is nowhere more apparent than in the nearly ubiquitous use of the 610 x 1120-mm (24 x 48-in.) lay-in grid ceiling. May 2010 | the construction specifier 85 Sealeze_V3.indd 1 3/23/10 4:13:10 PM A close-up showing differently sized reveals and precise location of perforations. Panels are made to tolerances measured in thousandths of an inch. Photo courtesy Ceilings Plus Various tessellated designs can be used for floors, walls, and skylights. Photo © Lindsay Wat The view of the New Doha International Airport ceiling shows how triangular panels are grouped to form large rhombic pattern more in scale with the large, vaulted terminal. Parallelograms indicate locations of skylights. The ceiling is being made with lightweight, perforated aluminum panels with a light-reflective finish. Image courtesy Ceilings Plus 86 the construction specifier | May 2010 In the architectural era now dawning, new technologies are redefining what is practical to build. Computer-aided design (CAD) and building information modeling (BIM) require only a modicum of additional computing power to define curved and tessellated shapes instead of orthogonal shapes. Innovative designers can now write algorithms based on building-program requirements—such as access to sunlight or audience sightlines—and then use computational analysis to suggest ‘generative designs’ not constrained by historical building forms. Increasingly, there is little or no rise in cost to fabricate the digitally created shapes. Acoustical panels, for example, can now be mass-customized using computer numerically-controlled (CNC) machinery that requires less than a minute to convert aluminum or wood-veneered metal into ready-to-use ceiling or wall panels. Each panel is individually trimmed to the required configuration, perforated for acoustical control, notched to accept installation hardware and lighting fixtures, and then folded to create stiffened edges.1 The machinery does not ‘care’ what shapes are required. It is capable of producing components to a precision measured in thousandths of an inch, which allows even the most complex Tessellations have been used as decorative architectural motifs since antiquity, featured in flooring designs and ornaments. Most tessellations can be altered by elongation or skewing. Regular hexagons can be deformed by changing the parallel edge lengths, while a pattern of squares can be skewed to create a field of rhombi. Images courtesy Ceilings Plus patterns to be prefabricated to fit precisely in the field. Even construction layout has gone digital with lasers and jobsite robots. Moreover, new technologies allow the use of an array of metal, painted, and wood finishes. system; these springs hold the panels securely in place while still allowing individual ones to be easily removed and reinstalled for above-ceiling access. For exterior panels, cam locks can be added to resist wind loads. Tessellar geometry The building blocks of tessellations are multi-sided shapes called polygons. In ‘regular’ polygons (e.g. equilateral triangles, squares, pentagons, hexagons, and octagons), all the edges are the same length, and all the angles between adjacent edges are equal. There are three ‘regular’ tessellations that can fill a surface with just a single type of regular polygon—equilateral triangles, squares, and regular hexagons. There are also eight ‘semi-regular’ tessellations in which two or more types of regular polygons can be arranged so the configuration of polygons meeting at each vertex is the same. Further, there are 20 ‘demi-regular’ tessellations that are more complex, but still formable with regular polygons. Many of these tessellations can be altered by elongation or skewing. For example, a tessellation of regular hexagons can be deformed by changing the parallel edge lengths, while a pattern of squares can be skewed to create a field of rhombi. Beyond these, are the tessellations composed of ‘irregular’ polygons including non-equilateral triangles, quadrilaterals (e.g. rhombi and trapezoids), and polygons with non-uniform edge lengths. While the number of tessellation patterns is practically unlimited, architectural applications are typically constrained by construction practicalities. For example, the most common installation method for tessellated ceiling panels employ torsion springs that clip the panels to a concealed suspension May 2010 | the construction specifier 87 CR_Laurence_V4.indd 1 4/7/10 5:01:57 PM Wall panels are typically set into slotted hat channels or onto Z-clips. It is the most economical to select a tessellation that can be superimposed onto parallel or other regularly spaced suspension members; more complex suspension systems will slow construction by requiring rigorous layout and assembly. Layouts needing suspension systems with radial or other symmetries are also possible. Ceiling suspension systems should comply with standards applicable to a project, such as: • ASTM C 635, Standard Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings; • ASTM C 636, Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels; and • ASTM E 580, Standard Specification Practice for Installation of Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels in Areas Subject to Earthquake Ground Motions. Facetted geometry in this ceiling, rising above the Tompkins Community College (Dryden, New York) repeats polygonal forms created by the structural cross bracing. Photo courtesy Ceilings Plus Advanced design options Once a basic tessellation pattern has been determined, it can be embellished in a number of ways. For example, the edges of adjacent panels may be of different heights so panel faces lay in different planes. To create even more pronounced facets, the panel faces themselves can also contain folds. Tesselations at While this wall in the Museum of Modern Art (Loda, Poland) shows a great variety of shadows and highlights, it consists of just a single k-dron-shaped panel type. Alternating rows are offset and panels are individually rotated to create visual interest. The facets also help break up standing sound waves for improved acoustics in performance spaces. Photo © Janusz Kapusta 88 the construction specifier | May 2010 Co-authors Nancy Mercolino and Michael Chusid, RA, FCSI, will delve deeper into the subject of ceilings at CONSTRUCT2010 in Philadelphia. In a session on May 11 entitled, “Taking Ceilings Off the Grid,” they will explore how modern metal and wood assemblies can simultaneously meet goals for sustainable and aesthetic design. Topics include building information modeling (BIM), product shapes and dimensions, and green aspects like recycled content materials and simplified building commissioning. For more information on the event, cs see page 32. The primary function of perforations is to enable panels to absorb sound, allowing noise reduction coefficients as substantial as NRC = 0.95. However, their locations are individually controlled to allow them to function as pixels in a graphic design. Many playful visual devices can be employed as a result. For example, a circular motif can be superimposed over the intersection of six triangular panels, which allows soft curves to play counterpoint to acute angles. Where perforations are not a desirable visual element, using micro-perforations all but invisible when viewed from the normal ceiling heights can still provide noise reduction. Specifying panels with different colors or finishes creates additional effects. The interplay between exposed metal panels and wood veneered ones can be especially dramatic, creating visual tension between smoothness and grain, and cool and warm—in some cases, this can create the illusion of three-dimensionality. Rotation of polygons creates another set of design opportunities. For example, the wall shown in is composed of a single polyhedral form—the k-dron, a geometric shape discovered by architect Janusz Kapusta.2 Each k-dron panel has a square, fourfold rotary symmetry. Rotating adjacent panels allows a single module to be assembled into combinations that capture light and shadow in endless ways and can be used to diffuse sound reflections. Curved surfaces can also be tessellated. In a manner similar to that used in finite element analysis, they can be approximated by using flat polygons to create facetted surfaces. Alternatively, panels themselves can be given curvature, and then assembled into spherical or other curved surfaces. sprinklers, and other fixtures integrated into a complete ceiling or wall system. One approach is to locate fixtures in gaps between panels or in voids created by omitting panels at regular intervals. However, precision manufacturing can also create cutouts where fixtures can penetrate a panel. Special attention must be paid to the intersection of tessellated surfaces with adjoining construction—for example, a ceiling adjoining a flat wall. One approach is to hold the ceiling away from the wall to allow the full ceiling panels to form a ‘floating’ edge. Alternatively, many tessellated patterns can be trimmed to neatly fit into a right-angled corner of a room. Another option is Practically speaking Tessellated panels must still be compatible with lighting fixtures, air diffusers, fire May 2010 | the construction specifier 89 SSMA.indd 1 6/1/09 2:45:44 PM Tessellated panels must still be compatible with lighting fixtures, air diffusers, fire sprinklers, and other fixtures integrated into a complete ceiling or wall system. to blur the distinction between walls and ceilings and allow a tessellation to wrap around corners and transitions. With off-the-shelf acoustical ceiling panels, off-the-shelf details can be used. However, tessellated systems are produced through mass-customization, and collaboration with a fabricator throughout the design process can help ensure project success. Having a fully coordinated set of shop and installation drawings is critical, either as part of a BIM or as 2-D drawings, since each unique component in an installation has to be marked and individually located for installation. Specification of a mockup is also recommended to verify design intent and to resolve coordination issues before the rest of the panels are fabricated. Tessellated panels around a polygonal window are mocked-up for the façade of Ravensbourne College in London, England. Photo courtesy FOA » Shape of ceilings to come While tessellation is an ancient art, new possibilities are still being discovered. For example, Penrose tessellations that form quasi-crystalline patterns were not defined Additional Information Author Nancy Mercolino is president of Ceilings Plus, a producer of specialty ceiling and wall systems. She can be contacted via www.ceilingsplus.com. Les Eisner is a structural engineer. As senior engineer at Ceilings Plus, he provides customer service to help designers translate their vision into practical solutions. He can be reached at leseisner@ceilingsplus.com. Michael Chusid, RA, FCSI, is president of Chusid Associates, a technical and marketing consultant to building product manufacturers. He can be contacted online by visiting www.buildingproductmarketing.com. Abstract The use of non-orthogonal angles is a major trend in contemporary design, made possible by advances in CAD and the latest in building information modeling (BIM)-driven equipment. This article examines tessellations (i.e. tiling of a plane with polygons), discussing which patterns are most 90 the construction specifier | May 2010 practical from an architectural standpoint, and explains how ceilings and wall façades can be designed and manufactured off the ‘square’ grid. MasterFormat No. 01 71 23.13–Construction Layout 05 58 00–Formed Metal Fabrications 06 42 99–Wood Paneling 09 50 00–Acoustical Ceilings 09 53 00–Acoustical Ceiling Suspension Assemblies 09 54 00–Specialty Ceilings UniFormat No. C3010–Wall Finishes C3030–Ceiling Finishes Key Words Divisions 05, 06, 09 Acoustics Ceilings Tessellations Wall façades until the 1970s. That same decade also brought the ‘Café Wall Illusion,’ which causes parallel lines to appear to converge and diverge . Rectangular fluorescent light troffers impose pernicious constraints on the creative possibilities of reflected ceiling plans. As light-emitting diodes (LEDs) approach an affordability tipping point, many industry prognosticators expect new illumination paradigms to emerge. An amazing variety of ceiling and wall systems have been built during the reign of the straightedge and compass. With the speed of digital design and fabrication, we can expect to be amazed by the new forms still yet to be created in the next cs few years. Notes 1 For more background, see the author’s previous article, “Metal and Wood Ceiling Systems,” in the April 2008 issue of The Construction Specifier. Visit www.constructionspecifier.com and select ‘Archives.’ 2 Patented in 1987, the k-dron is an 11-sided spatial form with unique optical, acoustical, and structural properties. For more information, visit www.k-dron.com. A sphere or other curved surface can also be tessellated. Panels laid out along longitude and meridian lines are shown in this view of the underside of the New Hayden Planetarium at the Rose Center for Earth and Space, Museum of Natural History, New York City. The planetarium is inside a 27-m (87-ft) diameter sphere clad. It is clad with metal panels with over 5 million perforations to help control noise. Photo courtesy Ceilings Plus May 2010 | the construction specifier 91 CSI_FallCDT_H2.indd 1 4/12/10 9:02:00 AM