IMO MARITIME SAFETY COMMITTEE 75th session Agenda item 19

advertisement

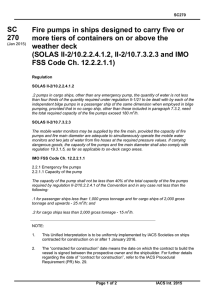

INTERNATIONAL MARITIME ORGANIZATION E IMO MARITIME SAFETY COMMITTEE 75th session Agenda item 19 MSC 75/19/2 31 October 2001 Original: ENGLISH RELATIONS WITH OTHER ORGANIZATIONS IACS Unified Interpretations Submitted by IACS SUMMARY Executive summary: This paper advises on a number of IACS Unified Interpretations implemented by IACS Members from 1 January and 1 July 2001, respectively. Action to be taken: Paragraph 4 Related documents: MSC 74/24, paragraphs 19.4 and 19.5 1 Attached as annexes 1 to 15 are IACS Interim Unified Interpretations, which are being applied by IACS Members in accordance with their respective implementation date (see the note at the bottom of each interpretation), as follows: Annex 1 SC 3 – Emergency source of electrical power SC 152 – Use of emergency generator in port (SOLAS regulations II-1/42.1.4 and 43.1.4) Annex 2 SC 10 - Precautions against shock, fire and other hazards of electrical origin (SOLAS regulation II-1/45.5.2) Annex 3 SC 25 – Fixed gas fire-extinguishing systems (SOLAS regulation II-2/5.1.6) Annex 4 SC 30 – Fire-extinguishing arrangements in machinery (SOLAS regulations II-2/7.1 and 7.2) Annex 5 SC 70 – Area classification and selection of electrical equipment (SOLAS regulations II-2/59.1.7 and 59.1.9 [1981]; IBC Code, paragraph 8.3.3.2; IGC Code, paragraph 8.2.10) Annex 6 SC 73 – Fire protection arrangements in cargo spaces including special category spaces (SOLAS regulations II-2/37.1.5.3 and 53.2.2.3 [1981]) For reasons of economy, this document is printed in a limited number. Delegates are kindly asked to bring their copies to meetings and not to request additional copies. I:\MSC\75\19-2.doc MSC 75/19/2 -2- Annex 7 SC 126 – Fire protection materials for cargo ships (SOLAS regulations II-2/49.2, 50.2, 50.3.1, 50.3.2 and 50.3.3) Annex 8 SC 155 – Lightweight check in lieu of inclining test (SOLAS regulation II-1/22) Annex 9 SC 157 – Main source of electrical power (SOLAS regulation II-1/41.5) Annex 10 SC 158 – Horizontal fire zone concept (SOLAS regulation II-2/37.1.1.1) Annex 11 SC 159 – Equivalent protection (SOLAS regulations II-2/53.1.2 and 54.2.1 and MSC/Circ.671) Annex 12 SC 160 – Method IIIC construction (SOLAS regulation II-2/52.3) Annex 13 SC 161 – Timber deck cargo in the context of damage stability requirements (SOLAS regulation II-1/25-8.1) Annex 14 LL 65 – Ships with assigned reduced freeboards intended to carry deck cargo (LL regulation 27; SOLAS regulation II-1/25-1, footnote 6) Annex 15 PASSUB 1 – Viewports in passenger submersible craft (IMO Guidelines for the design, construction and operation of passenger submersible craft (MSC/Circ.981), paragraph 2.2.3) 2 Since these interpretations are considered relevant to port State control inspections, they are brought to the attention of the Committee. 3 The attached interpretations will be applied by IACS members when acting individually as recognized organizations, authorized by flag State Administrations to act on their behalf, until the relevant results of IMO deliberations have been promulgated, thereby superseding these Interim Unified Interpretations. Action requested of the Committee 4 The Committee is invited to note the foregoing and take action as appropriate. *** I:\MSC\75\19-2.DOC ANNEX 1 SC3 (1985) (Rev.1 May 1999) SC3 Emergency source of electrical power (Chapter II-1, Regulation 42.1.4 & 43.1.4) SOLAS Regulation II-1/42.1.4 and 43.1.4 read: Provided that suitable measures are taken for safeguarding independent emergency operation under all circumstances, the emergency generator may be used exceptionally, and for short periods, to supply non-emergency circuits. Interpretations Exceptionally, whilst the vessel is at sea, is understood to mean conditions such as 1. 2. 3. 4. blackout situation dead-ship situation routine use for testing short-term parallel operation with the main source of electrical power for the purpose of load transfer Unless instructed otherwise by the Administration, the emergency generator may be used during lay time in port for the supply of the ship mains, provided the requirements of UI SC 152 are complied with. Note: Rev.1 of UI SC 3 is to be uniformly implemented by IACS Members and Associates from 1 January 2000 IACS Int. 1985/Rev.1 1999 SC152 SC152 Use of emergency generator in port (May 1999) 1999) (Chapter II-1, Regulations 42.1.4 and 43.1.4) SOLAS Regulations II-1/42.1.4 and 43.1.4 read: Provided that suitable measures are taken for safeguarding independent emergency operation under all circumstances, the emergency generator may be used exceptionally, and for short periods, to supply non-emergency circuits. Interpretations 1. General Unless instructed otherwise by the Administration the emergency generator may be used during lay time in port for the supply of the ship mains, provided the requirements as per items 2 and 3 below are complied with. 2. Requirements 2.1 To prevent the generator or its prime mover from becoming overloaded when used in port, arrangements are to be provided to shed sufficient non-emergency loads to ensure its continued safe operation. 2.2 The prime mover is to be arranged with fuel oil filters and lubrication oil filters, monitoring equipment and protection devices as required for the prime mover for main power generation and for unattended operation. 2.3 The fuel oil supply tank to the prime mover is to be provided with a low level alarm, arranged at a level ensuring sufficient fuel oil capacity for the emergency services for the period of time as required by SOLAS. 2.4 The prime mover is to be designed and built for continuous operation and should be subjected to a planned maintenance scheme ensuring that it is always available and capable of fulfilling its role in the event of an emergency at sea. 2.5 Fire detectors are to be installed in the location where the emergency generator set and emergency switchboard are installed. 2.6 Means are to be provided to readily change over to emergency operation. 2.7 Control, monitoring and supply circuits, for the purpose of the use of the emergency generator in port are to be so arranged and protected that any electrical fault will not influence the operation of the main and emergency services. When necessary for safe operation, the emergency switchboard is to be fitted with switches to isolate the circuits. 3. Operation Instructions* are to be provided on board to ensure that when the vessel is under way all control devices (e.g. valves, switches) are in a correct position for the independent emergency operation of the emergency generator set and emergency switchboard. * These instructions are also to contain information on required fuel oil tank level, position of harbour/sea mode switch if fitted, ventilation openings etc. Note: This UI SC 152 is to be uniformly implemented by IACS Members and Associates from 1 January 2000. *** IACS Int. 1999 ANNEX 2 SC10 Precautions against shock, fire and other SC10 (Rev 1 1997) hazards of electrical origin (Rev.2 (Chapter II-1, Regulation 45.5.2) Text: "shall be at least of a flame-retardant type . Interpretation: This may be achieved by cables which have been tested in accordance with IEC Publication 60332-1 or a test procedure equivalent thereto. Text: shall be so installed as not to impair their original flame-retarding properties . Interpretation: This may be achieved by: Method 1 Cables which have been tested in accordance with IEC Publication 60332-3 Category A/F or a test procedure for cables installed in bunches equivalent thereto. Method 2 2.1 1 2 3 4 (See Figures 1-4) Fire stops having at least B-0 penetrations fitted as follows: cable entries at the main and emergency switchboard, where cables enter engine control rooms, cable entries at centralized control panels for propulsion machinery and essential auxiliaries, at each end of totally enclosed cable trunks; and 2.2 In enclosed and semi-enclosed spaces, cable runs are to comply with the following: 1 2 to have fire protection coating applied: to at least 1 metre in every 14 metres to entire length of vertical runs, or fitted with fire stops having at least B-0 penetrations every second deck or approximately 6 metres for vertical runs and at every 14 metres for horizontal runs. The cable penetrations are to be installed in steel plates of at least 3 mm thickness extending all around to twice the largest dimension of the cable run for vertical runs and once for horizontal runs, but need not extend through ceilings, decks, bulkheads or solid sides of trunk. In cargo area, fire stops need only be fitted at the boundaries of the spaces. Note: Changes introduced in Rev.2 are to be implemented by IACS Members and Associates from 1 July 2001. ▼ May 2001) IACS Int. 1985/Rev 2 2001 SC10 SC10 FIRE STOPS (STEEL PLATE AT LEAST 3mm THICKNESS) NON TOTALLY ENCLOSED TRUNKS FIRE STOPS (STEEL PLATE AT LEAST 3mm THICKNESS) TOTALLY ENCLOSED TRUNKS HORIZONTAL STEEL PLATE 14m B-0 PENETRATION B-0 PENETRATION ; ; B-0 PENETRATION a B-0 PENETRATION a STEEL PLATE 1a REMARK: THE LENGTH (a) OF THE FIRE STOPS FOR HORIZONTAL CABLE RUNS SHOULD BE AT LEAST ONCE OF THE LARGEST DIMENSION OF THE CABLE BUNCH OR UP TO THE DECK Fig. 3 FIRE STOPS (STEEL PLATE AT LEAST 3mm THICKNESS) OPEN CABLE RUNS VERTICAL OR Fig. 1 a 2a COATING ENTIRE LENGTH FIRE STOP 2a 2a FIRE STOPS (STEEL PLATE AT LEAST 3mm THICKNESS) NON TOTALLY ENCLOSED TRUNKS 6m VERTICAL FIRE STOP a A B-0 PENETRATION STEEL PLATE 2a 6m HORIZONTAL FIRE STOP WITH STEEL PLATE AND B-0 PENETRATION 1a a 1a 14m STEEL PLATE FIRE STOP B-0 PENETRATION B 2a a 1a 14m 1a 2a 1m 1m COATING Fig. 2 OR COATING Fig. 4 ▼ ▼ IACS Int. 1985/Rev.2 2001 *** ANNEX 3 SC25 SC25 Fixed gas fire-extinguishing systems (1985) (Rev.1 June 2000) (Chapter II-2, Regulation 5.1.6) Text: "The alarm shall operate for a suitable period before the medium is released". Interpretation: 1) Certain spaces for which the automatic warning of release of the extinguishing medium is required: Ordinary cargo holds need not comply with Reg. II-2/5.1.6. However, ro/ro cargo spaces, holds in container ships equipped for integrated reefer containers and other spaces where personnel can be expected to enter and where the access is therefore facilitated by doors or manway hatches shall comply with the above regulation. Small spaces, such as small compressor rooms, paint lockers, lamp stores etc. need not comply with Reg. II-2/5.1.6. 2) Advance period of time of alarm sounding: The alarm shall sound for the period of time necessary to evacuate the space but not less than 20 s. Note: Changes introduced in Rev.1 are to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 1985/Rev.1 2000 ANNEX 4 SC30 SC30 Fire-extinguishing arrangements in machinery (May 1998) (Rev. 1 spaces June 2000) (Interpretation of Chapter II-2, Regulation 7.1 and 7.2) Number of systems, appliances and extinguishers required by Reg. II-2/7.1 & 7.2 Systems, appliances & extinguishers Category A machinery spaces SOLAS paragraph Oil-fired boilers Oil-fired boilers and oil fuel units Oil fuel units only Internal combustion machinery Internal combustion machinery and oil fuel units Fixed fireextinguishing system 7.1.1, 7.2.1 1 1 1 Portable foam applica -tor *1 Add’l portable foam extinguishers Portable foam extinguishers 135 l foam extinguisher 45 l foam extinguishers *2 7.1.3 7.2.3 7.1.4 1 *4 - N NA 1 *4 - N Engine room containing: 2 NA - - - 7.1.2, 7.1.3 7.2.3 7.2.2 Boiler room containing: 1 2N NA 1 2N + 2 Sand boxes 1 1 x - y - 1 1 x - y - *3 Combined engine/boiler room containing: Internal (2N + 2) or x combustion 1 1 y*5 N 1 *4 machinery, oil whichever is fired boilers and greater oil fuel units N = number of firing spaces. “2N” means that two extinguishers are to be located in each firing space. x = sufficient number, minimum two in each space, so located that there are at least one portable fire extinguisher within 10 m walking distance from any point. y = sufficient number to enable foam to be directed onto any part of the fuel and lubricating oil pressure systems, gearing and other fire hazards. Notes: *1. May be located at outside of the entrance to the room. *2. May be arranged outside of the space concerned for smaller spaces of cargo ships. *3. The amount of sand is to be at least 0.1 m3. A shovel is to be provided. Sand boxes may be substituted by approved portable fire extinguishers. *4. Not required for such spaces in cargo ships wherein all boilers contained therein are for domestic services and are less than 175 kW. *5. In case of machinery spaces containing both boilers and internal combustion engines (case not explicitly considered in Reg. 7) reg. 7.1 and 7.2 apply, with the exception that one of the foam fire-extinguishers of at least 45 l capacity or equivalent (required by Reg. 7.2.3) may be omitted on the condition that the 135 l extinguisher (required by Reg. 7.1.3) can protect efficiently and readily the area covered by the 45 l extinguisher. *6. Oil fired machinery other than boilers such as fired inert gas generators, incinerators and waste disposal units are to be considered the same as boilers insofar as the required number and type of fire fighting appliances are concerned IACS Int. 1998/Rev. 1 2000 *** ▼ ▼ Note: Changes introduced in Rev.1 are to be implemented by IACS Members and Associates from 1 January 2001. ANNEX 5 SC70 SC70 Area Classification and selection of electrical (1985) equipment (Rev.1 May 2001) (Chapter II-2, Regulation 59.1.7 [1981]) Text: Be arranged at the furthest distance practicable but not less than 5m from the nearest air intakes and openings to enclosed spaces containing a source of ignition and from deck machinery and equipment which may constitute an ignition hazard. Interpretation: 1. Areas on open deck, or semi-enclosed spaces on open deck, within 3m of cargo tank ventilation outlets which permit the flow of small volumes of vapour, air or inert gas mixtures caused by thermal variation are defined as Zone 1. - Permitted electrical equipment: Certified safe type equipment for Zone 1. 2. Areas within 2m beyond the zone specified in 1 above are defined as Zone 2. - Permitted electrical equipment: Certified safe type equipment for Zone 1, Equipment of a type, which ensures the absence of sparks, arcs and of “hot spots” during its normal operation, Equipment having an enclosure filled with a liquid dielectric, when required by the application, or encapsulated, Pressurised equipment, Equipment specifically designed for Zone 2 (for example type “n” protection in accordance with IEC 60079-15). (Chapter II-2, Regulation 59.1.9 [1981]) Text: Not less than 10m measured horizontally from the nearest air intakes and openings to enclosed spaces containing a source of ignition and from deck machinery and equipment which may constitute an ignition hazard. Note: Changes introduced in Rev.1 are to be implemented by IACS Members and Associates from 1 July 2001. ▼ IACS Int. 1985/Rev. 1 2001 SC 70 SC 70 (Cont d) (IBC Code, Para. 8.3.3.2) Text: The position of vent outlets of a controlled tank venting system should be arranged at a distance of at least 10m measured horizontally from the nearest air intake or openings to accommodation, service and machinery spaces and ignition sources. (IGC Code, Para 8.2.10) Text: All other vent exits connected to the cargo containment system should be arranged at a distance of at least 10m from the nearest air intake or opening to accommodation spaces, service spaces and control stations, or other gas-safe spaces. Interpretation: 1. Areas on open deck, or semi-enclosed spaces on open deck, within a vertical cylinder of unlimited height and 6m radius centred upon the center of the outlet, and within a hemisphere of 6m radius below the outlet which permit the flow of large volumes of vapour, air or inert gas mixtures during loading/discharging/ ballasting are defined as Zone 1. Permitted electrical equipment: Certified safe type equipment for Zone 1. 2. - Areas within 4m beyond the zone specified in 1 above are defined as Zone 2. Permitted electrical equipment: Certified safe type equipment for Zone 1, Equipment of a type, which ensures the absence of sparks, arcs and of “hot spots” during its normal operation, Equipment having an enclosure filled with a liquid dielectric, when required by the application, or encapsulated, Pressurised equipment, Equipment specifically designed for Zone 2 (for example type “n” protection in accordance with IEC 60079-15). ▼ ▼ IACS Int. 1985/Rev.1 2001 *** ANNEX 6 SC 73 SC73 Fire protection arrangements in cargo spaces (1985) (Rev.1 including special category spaces May, 2001) (Chapter II-2, Regulation 37.1.5.3, 53.2.2.3 [1981]) Portable extinguishers suitable for fighting oil fires shall be provided at each car deck level in each hold of compartment where vehicles are carried, spaced not more than 20m apart, on both sides of the ship. One of these extinguishers shall be positioned at each entrance to the car spaces. Notes: 1. This need not apply to weather decks used as ro-ro cargo spaces. ▼ ▼ 2. Changes introduced in Rev.1 are to be implemented by IACS Members and Associates from 1 July 2001. *** IACS Int. 1985/Rev. 1 2001 ANNEX 7 SC126 SC126 Fire Protection Materials for Cargo Ships (May, 1998) 14 (3) Only in corridors and stairway enclosures (3) Reg.II-2/49.2 Reg.II-2/50.1 Reg.II-2/50.3.1 Reg.II-2/49.1 Reg.II-2/50.3.3 Reg.II-2/50.3.2 Reg.II-2/49.3 (Rev.1 June 2000) ▼ Note: Changes introduced in Rev.1 are to be implemented by IACS Members and Associates from 1 January 2001. 126-1 IACS Int. 1998/Rev.1 2000 ▼ ▼ IACS Int. 1998/Rev.1 2000 (4) Reg.II- (6) Reg.II- Reg.II- Reg.II- Reg.II- Reg.II- SC126 cont’d 126-2 *** (6)Only incorridorsand stairway enclosures 14 Reg.II- SC126 ANNEX 8 SC 155 SC155 Lightweight check in lieu of inclining test (June 2000) (Regulation II-1/22) SOLAS regulation Il-1/22.1 requires every new passenger ship regardless of size and every new cargo ship of 24 m or greater in length to be inclined. Regulation 22.4 permits an inclining test to be waived for an individual vessel provided basic stability data is available from the inclining test of a sister vessel and that it can be satisfactorily shown that such data is valid for the exempted vessel. 1. A sister vessel is a vessel built by the same yard from the same plans. 2. A lightweight check is considered the acceptable means of being satisfied that the data from a lead sister vessel's inclining test can be used for a subsequent vessel. Members may request regular repeats of inclining tests and /or require each individual passenger ship to be inclined, if deemed necessary. 3. For any new built sister vessel with known differences from the lead sister vessel or for a vessel in service which undergoes alterations with calculable differences in light ship properties, a detailed weights and centres calculation, to adjust the lead vessel lightship properties or original lightship properties, shall be carried out. The validity of the calculated lightship properties shall be assessed by carrying out a lightweight check unless the implications regarding the stability of the vessel indicate that an inclining test should be performed. 4. For acceptance of the lightweight check results, the deviation of lightship displacement determined by a light weight check is not to exceed 2% of the expected value, if applicable determined by detailed weights and centres calculation as in paragraph 3 above. In addition, the deviation of lightship longitudinal centre of gravity is not to exceed 1% of LBP of the vessel. Where the deviation exceeds either of these limits, an inclining test should be carried out. 5. This interpretation is applicable to all vessels for which intact stability is a matter of class per UR L2. Note: This UI SC 155 is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 2000 ANNEX 9 SC157 SC157 Main Source of Electrical Power (June 2000) (Regulation II-1/41.5) Interpretation of the clause “...will be maintained or immediately restored” as detailed in Reg. II-1/41.5.1.1 amending SOLAS Reg. II-1/41 - Main Source of electrical power and lighting systems. 1. Reg. II-1/41.5.1.1 - Where the main source of electrical power is necessary for propulsion and steering of the ship, the system shall be so arranged that the electrical supply to equipment necessary for propulsion and steering and to ensure safety of the ship will be maintained or immediately restored in case of loss of any one of the generators in service. 2. To fulfil the above the following measures are required: 2.1 Where the electrical power is normally supplied by more than one generator set simultaneously in parallel operation, provision of protection, including automatic disconnection of sufficient non-essential services and if necessary secondary essential services and those provided for habitability, should be made to ensure that, in case of loss of any of these generating sets, the remaining ones are kept in operation to permit propulsion and steering and to ensure safety. 2.2 Where the electrical power is normally supplied by one generator provision shall be made, upon loss of power, for automatic starting and connecting to the main switchboard of stand-by generator(s) of sufficient capacity with automatic restarting of the essential auxiliaries, in sequential operation if required. Starting and connection to the main switchboard of one generator should be as rapid as possible, preferably within 30 seconds after loss of power. Where prime movers with longer starting time are used, this starting and connection time may be exceeded upon approval from the society. 2.3 Load shedding or other equivalent arrangements should be provided to protect the generators required by this regulation against sustained overload. 2.3.1 The load shedding should be automatic. 2.3.2 The non-essential services, service for habitable conditions may be shed and where necessary, additionally the secondary essential services, sufficient to ensure the connected generator set(s) is/are not overloaded. Note: This UI SC 155 is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 2000 ANNEX 10 SC 158 SC158 Horizontal fire zone concept (June 2000) (Reg. II-2/37.1.1.1) The "Total overall clear height" is the sum of distances between deck and web frames of the decks forming one horizontal zone. Note: This UI SC 158 is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 2000 ANNEX 11 SC 159 SC159 Equivalent Protection (June 2000) (Corr.1 May 2001) (Reg. II-2/53.1.2) Water supplies defined in Reg. II-2/54.2.1.2 are considered as an acceptable protection for cargoes listed in Table 2 of MSC/Circ. 671. Note: This UI SC 159 is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 2001 ANNEX 12 SC 160 SC160 Method IIIC Construction (June 2000) (Reg. II-2/52.3) In the case of ships built in accordance with Method IIIC, the detection system is only relevant to the accommodation block. Service spaces built away from the accommodation block need not be fitted with a fixed fire detection system. Note: This UI SC 160 is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ *** IACS Int. 2000 ANNEX 13 SC161 Timber deck cargo in the context of damage stability requirements (May 2000) (Chapter II-1, Regulation 25-8.1) SOLAS Regulation II-1/25-8.1 reads: Stability information 1 The master of the ship shall be supplied with such reliable information as is necessary to enable him by rapid and simple means to obtain accurate guidance as to the stability of the ship under varying conditions of service. The information shall include: .1 a curve of minimum operational metacentric height (GM) versus draught which assures compliance with the relevant intact stability requirements and the requirements of regulations 25-1 to 25-6, alternatively a corresponding curve of the maximum allowable vertical centre of gravity (KG) versus draught, or with the equivalents of either of these curves; .2 instructions concerning the operation of cross-flooding arrangements; and .3 all other data and aids which might be necessary to maintain stability after damage. Scope The provisions given hereunder apply to ships that are subject to SOLAS, Chapter II-1, Part B-1 subdivision and damage stability calculations and engaged in carrying timber deck cargoes. The buoyancy of the timber deck cargo can optionally be taken into account in the damage stability calculations, subject to the provisions that have been set forth in this document. They shall comply with the requirements of the CODE OF SAFE PRACTICE FOR SHIPS CARRYING TIMBER DECK CARGOES, 1991, and Ships that are provided with and make use of their timber load line shall also comply with the requirements of regulations 41 to 45 of the LOAD LINE CONVENTION, 1966. Definitions The following definitions apply for the purposes of this interpretation: timber means sawn wood or lumber, cants, logs, poles, pulpwood and all other types of timber in loose or packaged forms. The term does not include wood pulp or similar cargo; timber deck cargo means a cargo of timber carried on an uncovered part of a freeboard or superstructure deck. The term does not include wood pulp or similar cargo; timber load line means a special load line assigned to ships complying with certain conditions related to their construction set out in the LOAD LINE CONVENTION 1966 and used when the cargo complies with the stowage and securing conditions of the CODE OF SAFE PRACTICE FOR SHIPS CARRYING TIMBER DECK CARGOES, 1991 (Resolution A.715(17)); IACS Int. 2000 Page 2 SC161 cont’d deepest timber subdivision load line is the subdivision load line which corresponds to the timber summer draught to be assigned to the ship; respective partial load line is the light ship draught plus 60% of the difference between the light ship draught and the deepest timber subdivision load line. Interpretation 1. The stowage of timber deck cargoes shall comply with the provisions of Chapter 3 of the CODE OF SAFE PRACTICE FOR SHIPS CARRYING TIMBER DECK CARGOES, 1991 (resolution A.715(17)). 2. The ship shall be supplied with comprehensive stability information which takes into account timber deck cargo. Such information shall enable the master, rapidly and s i m p l y, to obtain accurate guidance as to the stability of the ship under varying conditions of service, and as required in SOLAS Regulation II-1,25-8 it shall include, among other damage stability related issues, a curve of minimum operating metacentric height (GM) versus draught which covers the requirements of SOLAS Regulation II-1/25-8.1.1. 3. The height and extent of the timber deck cargo shall be in accordance with Chapter 3.2 of the CODE OF SAFE PRACTICE FOR SHIPS CARRYING TIMBER DECK CARGOES, 1991, and shall be at least stowed to the standard height of one superstructure, if considered buoyant in the context of the subdivision and damage stability calculations. 4. Account may be taken of the buoyancy of the timber deck cargo, assuming that such cargo has a permeability of 25% of the volume occupied by the cargo, however, the buoyancy of only one standard superstructure height of timber deck cargo may be considered. 5. Unless instructed otherwise by the Administration, the stability information for ships with timber deck cargoes may be supplemented by a second curve of limiting GM (or KG) covering the then permissible draught range as specified below. Thus when accepting two stability limiting curves one curve shall be applicable when carrying timber deck cargo and a second curve for any other loading condition. 6. The above described provision of two curves are to be developed as described in SOLAS Regulation II-1/25-8.3, if they have been determined from considerations related to the subdivision index, based on the following: 6.1. for any loading condition other than timber deck cargo the limiting GM with the draughts as described in SOLAS Regulation II-1/25-8.3, and 6.2. for timber deck cargo the limiting GM shall be varied linearly between that the deepest timber subdivision load line and the respective timber partial load line. Where timber freeboards are not assigned the deepest and partial draughts shall relate to the summer load line. 7. For the purpose of the subdivision and damage stability calculations, the permeabilities of each space or part of space shall be as described in SOLAS Regulation II-1/25-7, however supplemented by the following for the undamaged timber deck cargo: Spaces Permeability Timber cargo on deck 0.25 for both draughts. IACS Int. 2000 Page 3 SC161 cont’d 8. When considering the vertical extent of damage, the upper deck may be regarded as a horizontal subdivision (in accordance with SOLAS Regulation II-1/25-6.3). Thus when calculating damage cases limited vertically to the upper deck with the corresponding v-factor, the timber deck cargo may be considered to remain buoyant with an assumed permeability of 0.25. For damage extending above the upper deck the timber deck cargo buoyancy in way of the damage zone is to be ignored. Footnote: Implementation date 1 January 2001 *** IACS Int. 2000 ANNEX 14 LL65 (June 2000) LL65 Ships with assigned reduced freeboards intended to carry deck cargo (LLC 66, Regulation 27 and SOLAS, Chapter II-1, Reg. 25-1 footnote 6) General: This UI pertains to ships assigned reduced freeboards in accordance with Regulation 27 of the International Convention on Load Lines, 1966 (ILLC 1966) and intended to carry deck cargo. In .6 of the footnote to SOLAS Chapter II-1, Regulation 25-1, ships shown to comply with ICLL Regulation 27 as applied in compliance with IMO Res. A.320 and A.514, may be excluded from the application of Part B-1. The footnote accepts the deterministic damage stability analysis according to the load line regulations in lieu of the probabilistic method of Part B-1. This was considered an acceptable substitution because of the very conservative assumptions of the initial load case made in the deterministic calculation under Regulation 27(7) of the 1966 ICLL. This can only be presumed for bulk carriers where the cargo is carried solely within the cargo holds, but may not always be true for bulk carriers which may occasionally also carry deck cargo, or other cargo ships intended for carriage of deck cargo which have been designed to take advantage of a reduced freeboard assignment. Therefore for such ships damage stability calculations shall be carried out: a) Due to the assigned reduced freeboards, in compliance with damage stability requirements of Regulation 27 ICLL and the 1988 Protocol to the ICLL. b) Due to the intended deck cargo capacity, the limiting GM or KG curve required by Regulation 25-8 shall be provided to the master for guidance, based on compliance with the probabilistic damage stability analysis of Part B-1. The KG used for demonstrating compliance with the deterministic damage stability requirements of ICLL Regulation 27 should be the same as that used for the probabilistic damage stability calculations required by SOLAS Chapter II-1, Part B-1, at the deepest subdivision load line. Note: This UI LL 65 is to be uniformly implemented by IACS Members and Associates from 1 July 2001. ▼ ▼ *** IACS INT. 2000 ANNEX 15 PASSUB 1 PASSUB Viewports in Passenger Submersible Craft 1 (May 1999) (Rev. 1 Aug. 2000) (para. 2.2.3, IMO Guidelines for Design, Construction and Operation of Passenger Submersible Craft, 2000) Paragraph 2.2.3.1 reads: Viewports should be of acrylic material and in accordance with the requirements of a recognised organisation to the satisfaction of the Administration. Viewports may be of other material, as appropriate, provided viewports of such material are at least as effective and in accordance with the requirements of a recognised organisation to the satisfaction of the Administration. Interpretation Acrylic viewports are to be designed, fabricated and maintained in accordance with the requirements of the latest edition of the American Society of Mechanical Engineers Safety Standard for Pressure Vessels for Human Occupancy (ASME PVHO) Section 2 Viewports and Section 3 Window Fabricators . Other standards and materials may be accepted by the Society provided they achieve an equivalent level of safety with respect to design, fabrication and maintenance. Note: Rev.1 of this UI is to be uniformly implemented by IACS Members and Associates from 1 January 2001. ▼ ▼ PAS-1 IACS Int. 1999/Rev. 1 2000 __________