NEC Conductors Course

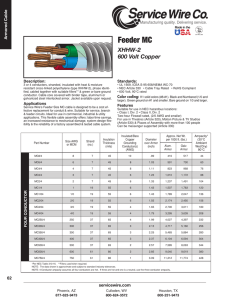

advertisement

NEC CONDUCTOR CALCULATIONS PDH Enterprises, LLC PO Box 942 Morrisville, NC 27560 (919)208-5296 NEC Conductor Calculations Course #201 This course provides a review of the basic calculations associated with Article 310 of the National Electrical Code. Students successfully completing this course will be able to correctly size circuit conductors and apply necessary temperature correction and derating factors. Students will also be shown the difference between continuous and non-continuous loads and the considerations that must be adhered to when working with them. You may need to reference the National Electrical Code book for tables that will be used in this course. To receive credit for this course, each student must pass an online multiple choice exam of ten (10) questions. A passing score is 70% or better. Completion of this course and successfully passing the exam will qualify the student for one (1) hour of continuing education credit. All information necessary to complete the examination will be presented within this course document and within the 2008 version of the National Electrical Code or NEC. Course Author: Chris Barrow, PE Copyright © 2010 PDH Enterprises Page 1 of 10 NEC CONDUCTOR CALCULATIONS General In this chapter we will be learning how to size general branch circuit conductors and overcurrent protection devices. The following definitions and NEC Articles should be understood or looked up for you to get a basic understanding of the subject matter covered in this chapter. Code definitions are presented in Article 100 of the NEC. Ampacity. The current, in amperes, that a conductor can carry continuously under the conditions of use without exceeding its temperature rating. Ampacity is the amount of current a conductor can carry as listed in the NEC Tables or after the conditions of use have been applied such as (1) ambient temperature derating factor; (2) the number of current carrying conductors in a raceway derating factors. Ambient Temperature is the temperature of the area surrounding a conductor and/or the raceway. The ambient temperature selected for ampacity correction factors will be based upon the highest temperature a conductor is subjected to from and including its source to the load being served. Branch Circuit Rating - Article 210.3 states that the rating of the overcurrent device determines the circuit rating. Article 210.3 also states that the overcurrent protection device (OCPD) determines the maximum rating of a branch circuit even if the ampacity of the conductor is higher. Example: We have a 20 amp fuse connected to a 30 amp wire. This would be a 20 amp circuit according to Article 210.23 Permissible Loads. The total loads shall not exceed the rating of the branch circuit. For selecting the over-current protection device for a circuit, Article 240.4(B) states that where the ampacity of the conductor does not correspond with the standard ampere rating of a fuse or circuit breaker, the next higher rated device may be used if the following conditions are met (1) The conductors being protected do not supply cord and plug connected loads (2) The ampacity does not correspond to a standard rating (3) The next higher standard rating is less than 800 amps. The standard size ratings of Fuses and Fixed-trip circuit breakers are listed in Article 240.6. They are as follows: 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 110, 125, 150, 175, 200, 225, 250, 300, 350, 400, 450, 500, 600, 700, 800, 100, 1200, 1600, 2000, 2500, 3000, 4000, 5000, and 6000 amperes. Conductor Lettering. When looking at wiring properties, you will notice that the wires Copyright © 2010 PDH Enterprises Page 2 of 10 NEC CONDUCTOR CALCULATIONS contain some type of letter identifier such as THHN or THW. These letters serve to identify specific properties of the conductor and/or its insulation. Listed below are some of the letters commonly used (See 310.13, Table 310.13, and Table 402.3) T - Thermoplastic F - Fixture Wires W - Wet or Damp R - Rubber H - Heat FF - Fixture wire, flexible stranding The combination of letters will tell you most of what you need to know about the conductor. The first letter indicates what the insulation is made of. One H indicates a conductor insulation rating of 75° C. HH would indicate a conductor insulation rating of 90° C. Zero H’s usually indicate an insulation rating of 60° C. Examples: TW - Thermoplastic (T) insulation, (W) suitable for wet and dry locations (When suitable for wet generally means it can be used for dry also), and is rated 60° C (no H in group). RHW - Rubber (R) insulation, (H) rated 75° C and (W) suitable for wet and dry locations. NOTE: This is a general rule and there are exceptions such as THW (see Table 310.13). The one H indicates 75° C rating but it can be used at a 90° C conductor with ballasts in dry locations. TF - Thermoplastic (T) insulation, (F) fixture wire RFH – Rubber (R) insulation, (F) fixture wire, (H) rated 75° C Using Wire Tables Tables 310.16 through 310.19 are the ampacities of one to three conductors rated 0-2000 volts. These tables all work basically the same and you will probably find several of them useful. Table 310.16 is the most commonly used table for the type of conductors and installations generally used and it is based on temperatures and conditions most likely to be found in normal field conditions. For each Table 310.16 through 310.19 the conditions under which the ampacities given in the table are based on is always stated at the top of the table. Table 310.16 is based on an ambient temperature of 30°C (86° F), and not more than three conductors in a raceway. This means the conductors listed have been tested and found suitable for use under these conditions. Table 310.16 is basically two tables, the left half is temperature rating of the conductor, size and insulation type for copper and the right side is for aluminum. Copyright © 2010 PDH Enterprises Page 3 of 10 NEC CONDUCTOR CALCULATIONS The main body of this table gives us the ampacity of a conductor. Example: a #4 copper THW has an ampacity of 85 amps. The lower part of the Table 310.16 gives us the correction factors for temperatures other than 30° C or 86° F. These correction factors when used will establish a new ampacity for any conductor. The absence of a multiplying factor in a column indicates that this conductor with this insulation shall not be used in these ambient temperatures. The asterisk (*) next to wire sizes 10, 12, and 14 AWG refers to article 240.4(D) and is letting you know that conductor sizes #14, #12, and #10 copper and aluminum are limited to certain size overcurrent protection devices (OCPD) even if the ampacity of the #14, #12, and #10 conductor is higher. The limitations are: • #14 copper limited to 15 amp OCPD #12 copper limited to 20 amp OCPD #10 copper limited to 30 amp OCPD • #14 aluminum not allowed #12 aluminum limited to 15 amp OCPD #10 aluminum limited to 25 amp OCPD Table 310.15(B)(2)(a): Adjustment Factors Due to the closeness of conductors in the same raceways or trench when more than three current carrying conductors are together, the ampacity of the conductors must be lowered because the heat generated cannot be displaced as quickly due to the bunching of conductors. This is called derating. When there are more than three current carrying conductors in a raceway, we must use 310.15(B)(2)(a) to reduce conductor ampacities. The following are not considered current carrying conductors: (1) Control wiring conductors, T310.15(B)(2)(a), Exception No. 1 (2) Conductors in cable trays, 310.15(B)(2)(a), Exception No. 2 (3) Conductors in nipples (24” or less), Exception No. 3 (4) Neutral conductors of balanced circuits of three or more conductors, 310.15(B)(4)(a) (5) A grounding or bonding conductor, 310.15(B)(5) The following are current carrying conductors: (1) All phase conductors or Ungrounded conductors (hot wires) (2) Neutral conductors in a circuit consisting of two phase conductors and the neutral conductor of a 4-wire 3-phase wye-connected system. 310.15(B)(4)(b) (3) Neutral conductor of a 3-phase, 4-wire, wye circuit where the major portion of the load consist of nonlinear loads, 310.15(B)(4)(c) Example: Fluorescent lighting, computer equipment. Copyright © 2010 PDH Enterprises Page 4 of 10 NEC CONDUCTOR CALCULATIONS (4) Any 2-wire circuit (series circuit) Practice Problems I. Wire sizing. Using Table 310.16, find the conductor ampacity and overcurrent protection. Wire Size/Type #12 THW #12 THHN #4 TW 3/0 XHHW-2 al 500 kcmil THHN Ampacity OCPD Required II. Ambient Temperature Correction Factors. Using Table 310.16, what is the correction factor for the conductor and ambient temperatures? Ambient Temperature 55° C 72° C 35° C Conductor Correction Factor THHN THWN TW III. To find new ampacity of a conductor using the correction factors you multiply the ampacity of the conductor by the correction factor. New Ampacity = (conductor ampacity * correction factor) Find the new ampacity for the following conductor operating in the ambient temperature listed. Conductors #6 TW cu. 250 kcmil THHN #1 RH al. #3 TW #12 THW Ambient Temperature 47° C 78° C 89° F 44° C 50° C Copyright © 2010 PDH Enterprises New Ampacity OCPD Page 5 of 10 NEC CONDUCTOR CALCULATIONS IV. Table 310.15(B)(2)(a) - Derating - No Load Diversity Derated Ampacity = Conductor ampacity * factors in Table 310.15(B)(2)(a) Find the correction factor and new ampacity for the following conductors in a conduit. NOTE: To work the problems below first find the ampacity of the conductor in Table 310.16. Conductor in a Conduit 8 - no. 3 THW wires 6 - no. 1/0 ZW wires 40 - no. 10 THHN wires 12 - no. 2/0 XHHW dry Correction Factor New Ampacity V. New ampacity of conductors when you have more that 3 conductors in a raceway and a temperature correction factor is determined as follows. New ampacity = (conductor ampacity * temperature correction factor * adjustment factor in Table 310.15(B)(2)(a)) Find the maximum load for the following: Conductors 6 - no. 6 TW 25 - no. 3/0 THW al. 43 - no. 12 SIS 20 - no. 10 RHH al. 5 - no. 3/0 RHH Ambient Temperature 105° F 40° C 112° F 47° C 150° F New Ampacity Continuous vs. Non-continuous loads The ampacities listed on the Tables in Article 310 are tested and approved for continuous use. The table ampacities can be used as continuous or non-continuous loads after all temperature and derating factors have been applied. A continuous load is a load where the maximum current is expected to continue for 3 hours or more. It is for this reason that the conductors and their overcurrent protection devices face special rules to account for the increased heat that it will encounter during operation. Typical continuous loads are those such as lighting in an office, bank, etc. Outdoor signs are also assumed to be continuous when sizing conductors and over current protection. Copyright © 2010 PDH Enterprises Page 6 of 10 NEC CONDUCTOR CALCULATIONS Non-continuous: Overcurrent protection devices (fuses and circuit breakers) are rated 100% for non-continuous loads. In other words, no special consideration or increased loading factors are given to non-continuous loads outside of what we looked at in the previous section. Conductor Calculations – Non-continuous Loading We have learned how to find new ampacity of conductors using temperature correction factors and derating factors for more than three conductors in a raceway. Most noncontinuous loads are sized by going to the tables and selecting a conductor then using 240.6 and 240.4(B) to select the overcurrent device. Example: What size circuit breaker and THW conductor would you need for noncontinuous load of 73 amps? Protective device 80 amps, Article 240.4(B), 240.6 Conductor size - #4THW copper, Table 310.16 If ambient temperature and/or more than three conductors are involved, the conductor ampacity needed must be calculated to find the conductor size. The overcurrent protection device is still selected out of the NEC by using 240.4(B) and 240.6 Formula: Wire ampacity needed from table = Load at 100% (Non - Continuous) Temp Correction Factors x T310.15(B)(2)(a) Protection device = 100% of non-continuous Example: There is a 34 amp load and the raceway is installed over a roof where the ambient temperature is 110° F, 2 wire circuit. Assume a non-continuous load. (A) What size protection device is required? (B) What size RHW conductor is required? (A) Protection device = 100% of non continuous load Protection device = 35 amps, 240.4(B), 240.6 (B) Wire ampacity needed from table = Load at 100% (Non - Continuous) Temp Correction Factors x T310.15(B)(2)(a) Copyright © 2010 PDH Enterprises Page 7 of 10 NEC CONDUCTOR CALCULATIONS ampacity = 34 amps Ambient Temperature 110°F = 82 TCF for RHW T310.15(B)(2)(a) does not apply because there are only 2 wires Wire ampacity needed from table = 34 amps = 41.46 amps .82 Wire Ampacity needed = 41.5 amps Using Table 310.16, we find the wire size needed to be #8 RHW Example: There are ten current carrying conductors installed in an ambient temperature of 57°C. A 48 amp load 2-wire circuit must be added. (A) What size protection device is required for the 48 amp load? (B) What size THHN copper conductor is required for the 48 amp load? (A) Protection device = 100% of non-continuous load. 240.4(B), 240.6, Protection device = 50 amps (B) Wire ampacity needed from table = Load at 100% (Non - Continuous) Temp Correction Factors x T310.15(B)(2)(a) Temperature correction factor for the THHN is .71 (from Table 310.16) 10 existing current carrying conductors plus 2 new current carrying conductors = 12 current carrying conductors. Using T310-15(B)(2)(a) gives us a derating factor of 50% or .5 Wire ampacity needed = 48ampsat100% = 135.3 amps .71CF * .5 DF Wire ampacity needed = 135.3 amps Using table 310.16 gives us a wire size of #1 THHN copper Sizing overcurrent protection for non-continuous loads In order to select OCP for a non-continuous load, you would select the same size as the conductor amperage rating, or next size up. Example: We have four current carrying conductors in a raceway and two are #6TW. The ambient temperature is 40° C. Copyright © 2010 PDH Enterprises Page 8 of 10 NEC CONDUCTOR CALCULATIONS (A) What is the new ampacity? (B) What size is the protection device? (C) What is the maximum non-continuous load? A. New Ampacity = Conductor Ampacity * TCF * T310.15(B)(2)(a) Derate Factor Table 310.16 #6 TW = 55 amps Table 310.16 400°C = .82 TCF Note from table 310.15(B)(2)(a), 4 current carrying conductors = 80% New Ampacity = 55 amps x .82 TCF * .8 derating factor New Ampacity = 36.1 amps B. Size OCP device: using Article 240.4(B) and 240.6 we get: 36.1 amps = 40 amp device C. The maximum non-continuous load on the 40 amp OCP device is 40 amps but the ampacity of the conductor is 36.1 amps. Article 310.10 states that a conductor cannot be used in such a manner that its operating temperature rating is exceeded. To determine the maximum non-continuous load, compare the OCP at 100% against the ampacity of the conductor. 40 amp OCP device = 40 amps, non-continuous #6 TW new ampacity = 36.1 amps Conductor Calculations – Continuous Loading The first step in continuous load problems is to always find the overcurrent protection device. Article 210.20(A) Continuous Loads. The total load on any overcurrent device located in a panel board shall not exceed 80% of its rating where in normal operation the load will continue for three hours or more. You could also look at it and say that the over-current protection of a continuous load shall be sized at 125% of the full load current. According to Article 210.19(A)(1), continuous loads shall be protected at 125% of the branch circuit rating. Copyright © 2010 PDH Enterprises Page 9 of 10 NEC CONDUCTOR CALCULATIONS Example: What is the maximum continuous load placed on a 20 amp fuse or breaker? 20 x .8 = 16 amps is the maximum continuous load that can be applied to a 20 amp breaker Sizing Overcurrent Protection - Continuous loads (1) To find the maximum continuous load of a protection device, use the following formula. Maximum continuous load = OPD x .8 (or 80%) Example: What is the maximum continuous load of a 100 amp over current protection device? Maximum continuous load = 100 x .8 Maximum continuous load = 80 amps (2) To find the overcurrent protection device for continuous load, use the following formula. OPD (continuous) = continuous load x 125% Example: What is the overcurrent protection device for an 80 amp continuous load? Using Articles 240.4(B), 240.6 and the formula for a continuous load: OPD (continuous) = 80 amps x 1.25 OPD (continuous) = 100 amps Copyright © 2010 PDH Enterprises Page 10 of 10