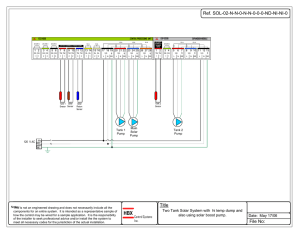

SRCC OG-300 Certified Solar Water Heating System Installation

advertisement