Fire DNF, Fire HSF

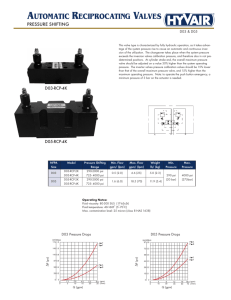

advertisement