Seepage meter errors - Association for the Sciences of Limnology

advertisement

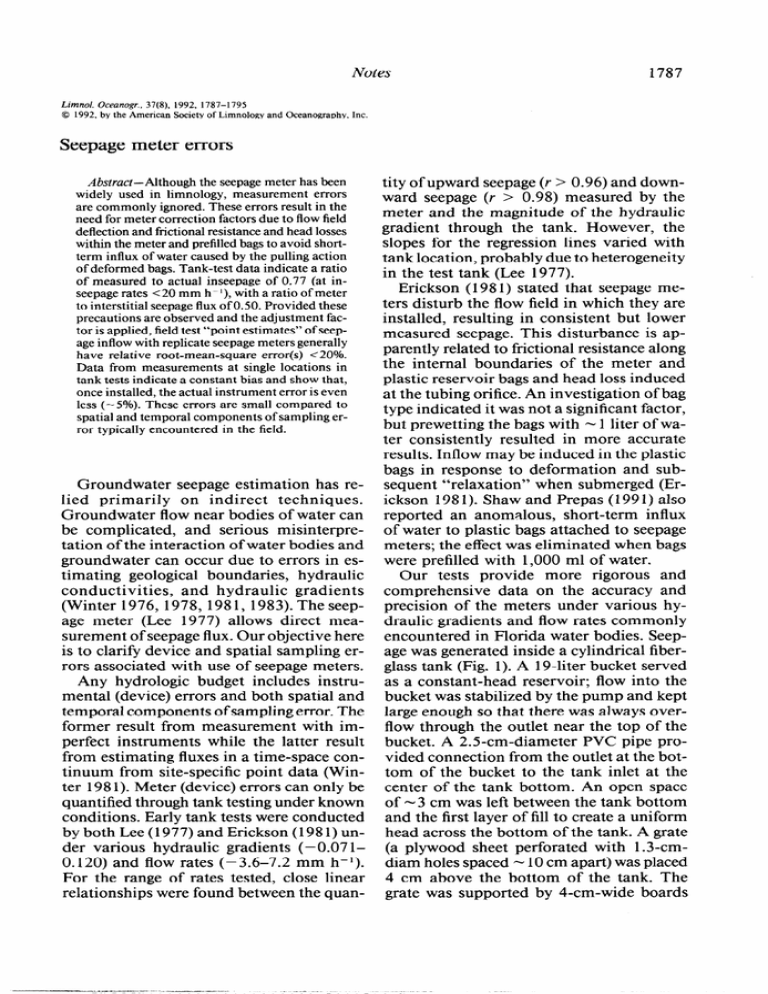

Notes 1787 Limnol. Oceanogr., 37(8), 1992, 1787-1795 0 1992, by the American Society of Limnology and Oceanography, Inc. Seepage meter errors Abstract-Although the seepagemeter has been widely used in limnology, measurement errors are commonly ignored. These errors result in the need for meter correction factors due to flow field deflection and frictional resistance and head losses within the meter and prefilled bags to avoid shortterm influx of water caused by the pulling action of deformed bags. Tank-test data indicate a ratio of measured to actual inseepage of 0.77 (at inseepagerates < 20 mm h- I), with a ratio of meter to interstitial seepageflux of 0.50. Provided these precautions are observed and the adjustment factor is applied, field test “point estimates” of seepage inflow with replicate seepagemeters generally have relative root-mean-square error(s) ~20%. Data from measurements at single locations in tank tests indicate a constant bias and show that, once installed, the actual instrument error is even less (w 5%). These errors are small compared to spatial and temporal components of sampling error typically encountered in the field. Groundwater seepage estimation has relied primarily on indirect techniques. Groundwater flow near bodies of water can be complicated, and serious misinterpretation of the interaction of water bodies and groundwater can occur due to errors in estimating geological boundaries, hydraulic conductivities, and hydraulic gradients (Winter 1976, 1978, 198 1, 1983). The seepage meter (Lee 1977) allows direct measurement of seepage flux. Our objective here is to clarify device and spatial sampling errors associated with use of seepage meters. Any hydrologic budget includes instrumental (device) errors and both spatial and temporal components of sampling error. The former result from measurement with imperfect instruments while the latter result from estimating fluxes in a time-space continuum from site-specific point data (Winter 198 1). Meter (device) errors can only be quantified through tank testing under known conditions. Early tank tests were conducted by both Lee (1977) and Erickson (198 1) under various hydraulic gradients (- 0.07 l0.120) and flow rates (-3.6-7.2 mm h-l). For the range of rates tested, close linear relationships were found between the quan- tity of upward seepage (r > 0.96) and downward seepage (r > 0.98) measured by the meter and the magnitude of the hydraulic gradient through the tank. However, the slopes for the regression lines varied with tank location, probably due to heterogeneity in the test tank (Lee 1977). Erickson (198 1) stated that seepage meters disturb the flow field in which they are installed, resulting in consistent but lower measured seepage. This disturbance is apparently related to frictional resistance along the internal boundaries of the meter and plastic reservoir bags and head loss induced at the tubing orifice. An investigation of bag type indicated it was not a significant factor, but prewetting the bags with - 1 liter of water consistently resulted in more accurate results. Inflow may be induced in the plastic bags in response to deformation and subsequent “relaxation” when submerged (Erickson 198 1). Shaw and Prepas (1991) also reported an anomalous, short-term influx of water to plastic bags attached to seepage meters; the effect was eliminated when bags were prefilled with 1,000 ml of water. Our tests provide more rigorous and comprehensive data on the accuracy and precision of the meters under various hydraulic gradients and flow rates commonly encountered in Florida water bodies. Seepage was generated inside a cylindrical fiberglass tank (Fig. 1). A 19-liter bucket served as a constant-head reservoir; flow into the bucket was stabilized by the pump and kept large enough so that there was always overflow through the outlet near the top of the bucket. A 2.5-cm-diameter PVC pipe provided connection from the outlet at the bottom of the bucket to the tank inlet at the center of the tank bottom. An open space of - 3 cm was left between the tank bottom and the first layer of fill to create a uniform head across the bottom of the tank. A grate (a plywood sheet perforated with 1.3-cmdiam holes spaced - 10 cm apart) was placed 4 cm above the bottom of the tank. The grate was supported by 4-cm-wide boards Notes 1788 1g-liter U-Tube Manometer Test tank L I - t I 183cm i Ah 20 cm water T 122cm I fi. .-.&I-... b c Concrete Pad L Grate 2.5-cm-diam PVC Pipe / L 3.2-cm-diam Flexible Pipe Electric Water Pump F‘rom Well Fig. 1. Tank test setup. laid out in radial pattern to allow flow to move outward from the center. On top of the grate, a 15-cm layer of coarse, drainfield gravel was distributed, followed by another 1%cm layer of finer gravel. Finally, a 60-cm layer of sand (Table 1) was placed on top of the gravel. The outlet from the tank was located on its side, near the top, allowing -20 cm of water to stand above the top of the sand layer when the tank was full. The overflow from the tank was allowed to free fall into a catchment where it entered the drainage system. The overflow could also be collected in a volumetric container to calculate the flow rate leaving the tank. Average rate of seepage through the test tank was calculated by measuring flow rate through the tank Table 1. Particle-size distribution ment. of tank sedi- Mean grain diam (mm) Fraction Classification 0.03 l-0.062 0.062-o. 125 0.125AI.250 0.250-0.500 0.500-l .ooo 0.01 0.11 0.70 0.14 0.03 Coarse silt Very fine sand Fine sand Medium sand Coarse sand outlet and dividing by the cross-sectional area of the tank (2.63 m2). The flow rate through the tank could be controlled by adjusting the head difference between the inlet reservoir and the free surface in the tank (Ah in Fig. 1). The head in the surface water was essentially constant because the position of the tank outlet was fixed, but the head at the bottom of the tank could be adjusted by increasing or lowering the elevation of the inlet reservoir (Fig. 1). After experiment 1 (see below), the tank was covered to shield it from the wind because wind stress caused errors in the measure of outflow (actual seepage). The tank was allowed to run undisturbed for at least 3 h before outflow measurements were taken. The outflow from the tank was measured repeatedly to ensure that a constant flow rate had been reached. Seepage meters used in our tests were constructed according to Lee (1977) with slight modifications. The body of a meter was made by cutting off the end of a 2.1 -m3 steel drum (0.257 m2). A hole, drilled into the top of the meter, accommodated a cored rubber stopper fitted with a hard polyethylene tube (5.6-mm i.d., 8.3-mm o.d.) through its center. This tube served as the Notes connection point for the collection bag, which acted as a seepage reservoir. The open end of a 4-liter plastic bag was connected to a piece of hard polyethylene tubing by a rubber band. The tube from the collection bag was connected to the meter outlet tube with a piece of flexible Tygon tubing (6.7mm i-d., 10.2-mm o-d.). When the meter was ready (>3 h), 1,000 ml of water was funneled into an empty reservoir bag. The timing for the test began when the bag tube was connected to the meter outlet tube. After a suitable period, the bag was removed from the meter and the water in the bag was measured in a graduated cylinder. The seepage inflow or outflow is expressed in liters m-2 h-l (eq uivalently mm h-l). Three separate sets of tests (experiments) were performed with the test tank. Experiment 1 was designed to assess the uniformity of flow in the tank and to pinpoint any problems with the seepage meters. In this experiment the same meter was used to measure seepage at 13 different locations covering most of the tank (Fig. 2a). As a measure of pure device error, two measurements were taken at each location, the second immediately after completion of the first. In experiment 2, three different meters were installed at the locations corresponding to 3a, center, and 7a in Fig. 2a, and left there for the entire series of tests. To further test the precision of the measurement procedure after installation, we measured the seepage rate through each meter separately at different times and then simultaneously at all three locations. Each measurement was made twice, as in the first experiment. The tests were performed twice with average seepage rates (calculated from the tank total) of 9.5 and 18.5 mm h-l, respectively. Flow variation in the test tank was assessed further in experiment 3. Seven meters (Fig. 3) permitted seepage across the area of the tank to be measured completely in one simultaneous measurement test. Four different tank-mean flow rates were tested, ranging from 4.6 to 28.8 mm h-l. Two measurements were taken from each meter for each flow rate. One measurement was taken from each meter individually while the other meters were left undisturbed, followed by 1789 another measurement taken from all seven meters simultaneously. Although care was taken in designing and building the test tank, sediment heterogeneity or inflow short-circuiting caused considerable variation in the flow rates measured at different locations in the tank (Fig. 2b). Flow variations due to the test setup thus had to be separated from measurement variations due to the meter itself. This separation was achieved by comparing variation in seepage rates measured among locations and comparing the average of seepage measurements across the tank to the measured seepage. In experiment 1, the measured seepage rates ranged from 2.1 to 15.7 mm h-l, with a mean value of 6.0. The variation in replicate measurements taken at the same location, however, was consistently small (Fig. 2b), indicating the variation was due to conditions in the tank and not the measurement device. For the 13 pairs of duplicate measurements (Exp. l), the relative difference between pairs of measurements averaged 6.2%. Seepage values measured in experiments 2 and 3 for the same location and driving head also exhibited small variation (Fig. 4) with average relative differences of 1.5 and 4.1% between pairs of measurements, respectively. The seepage rates measured at each meter location were regressed against the total head difference used in each test (Figs. 5, 6). Although the rates of seepage varied from one location to the next, as evidenced by the differing slopes of the regression lines, the correlation between head difference and seepage for each location was very high (r > 0.99). This finding verifies the previous conclusion that the distribution of seepage flow in the tank was not uniform. Accuracy of the meters was estimated in tank experiment 3 by comparing the average seepage rate measured by the meters to the actual average seepage rate determined by measuring the outflow from the tank (Fig. 6). At the highest flow rate, the flow rate measured through the tank appears to have deviated from its linear relationship with head difference. However, when only the first three data points are considered, the regression analysis indicates an almost per- 1790 Notes (a) 8a *. jb *.*. .* ‘.‘. ::. 5a .. ... . . . Outlet [ ..... ... . la ... . jb..($&..5b r..5b . .... 5a (W 16 , I . 30 8 6 la 2a 3a 4a 5a 6a 7a 8a lb 3b 5b 7b c Meter Location Fig. 2. Seepage meter test locations used in experiment 1 (a) and comparison of duplicate seepage rates at each location at a head difference of 3.94 (b). feet linear relationship (r = 1.00; n = 56) between head difference and flow rate, with a slope of 3.08 mm h-l cm-l and an intercept of 0.26 mm h-r. When the last point is included in the linear regression, the slope increases to 3.67 mm h-l cm-l, the intercept is lowered significantly to - 1.46 mm h-l, and the correlation coefficient is low- ered slightly (Y = 0.99). The offset of the last point could be due to measurement error or to nonlinear effects in the tank such as channelization of flow. The relationship between the average meter seepage rates and head difference was linear, as regression analysis of these data yielded a correlation coefficient of r = 0.998 Notes Fig. 3. Meter measurement locations used during tank experiment 3 (seven meters cover 68% of the tank area). (n = 56) and a slope of 2.3 1 mm h-l cm-l. The average seepage rates in the tank in this experiment were 4.6, 12.7, 18.3, and 28.8 mm h- l, for which the average seepage meter values were 77, 76, 78, and 64% of the respective average rates in the tank. The decreased ratio at the highest flow rate may 1791 be due to increased deflection of the flow field around the seven meters because of increased resistance to flow by the tubing and meter. Further analysis was completed to determine if the ratios of measured to actual seepage in experiment 3 were biased due to the large fraction (68%) of tank area covered by the seven meters. In experiment 1, at a head difference of 3.94 cm and a seepage rate of 12.0 mm h- l, the mean seepage rate determined from one meter positioned at 13 different locations was 57% of the calculated interstitial seepage rate (seepage rate of the uncovered sediment). This ratio is less affected by site-specific location effects in the tank than is the meter:tank ratio. In experiment 3, with seven seepage meters in place, the measured mean seepage rate at head potentials of 1.40, 4.06, and 5.84 cm represented 5 1, 50, and 47% of the calculated interstitial seepage (seepage rate between meters). These percentages were calculated from experimental data where actual seepage rates varied from 4.6 to 18.3 mm h- l. At a higher head potential (7.87 cm) and seepage rate (28.8 mm h-l), however, 40 I 0 Individual, tank seepage = 9.5 mm h-’ m Simultaneous, tank seepage = 9.5 mm h-’ I Individual, tank seepage = 18.5 mm h-’ 3a Center Meter Location 7a Fig. 4. Comparison of seepagerates measured in experiment 2 at sites 3a, center, and 7a. Results are presented for measurements made sequentially (one meter at a time) and simultaneously at actual tank seepage rates of 9.5 and 18.5 mm h-l. 1792 Notes Table 2. Comparison of experiment 1 and experiment 3 mean seepage rates (mm h-l) at similar tank locations and the same head difference (3.94 cm). Tank locations in parentheses (cf. Figs. 2a, 3). c.v.96 Exp. 1 15.8 (3a) 8.3 (7a) 8.2 (2a, 8a) 5.3 (4a, 6a) 2.9 (c) 0 0 1 2 3 4 5 6 7 6 Exp. 3 21.1 (2) 7.4 (5) ll.O(l + 6) 5.3 (3 + 4) 4.6 (c) Head Difference (cm) C.V.% (among locations) 59.9 68.3 (between experiments) 20.3 8.1 20.6 0.0 32.0 R = 16.3 R = 64.1 40 'i r E L 30 iti f KJ 20 10 0 0 1 2 3 4 5 6 7 6 7 8 Head Difference (cm) 0 1 2 3 4 5 a Head Difference (cm) Fig. 5. Measured seepage vs. tank-head difference in experiment 3. the ratio of measured to interstitial seepage dropped significantly (to 36%). These data indicate that, except at the higher seepage rate (28.8 mm h-l), the measured seepage was a similar percentage of the interstitial or unmeasured seepage in both experiment 1 and 3 (47-57%). This variation was even less (0.50-0.57%) at similar head potentials (3.94 cm, 4.06 cm). The relatively stable measured : interstitial ratio indicates that coverage effects from the seven meters in experiment 3 did not significantly bias the results at normal seepage rates. At the highest seepage rate, effects discussed above increased greatly, increasing the seepage between meters and changing the correction factor. Although further testing should be done to determine the source of this decrease in accuracy, it appears that the meter: tank and meter: interstitial seepage rate ratios of 0.77 and 0.55, respectively, are accurate for normal seepage rates encountered in the field (O-20 mm h-l). The 0.77 meter : tank flux ratio is similar to the average ratio (0.76) found in tank tests by Erickson (198 1) at various flow rates (6.3-61.9 mm h-l) with the same seepage meter design used in our study. The importance of prefilled bags was discussed earlier. In all experiments, the meters and sediment were allowed to equilibrate and settle for several days prior to measurement to minimize insertion effects. Seepage data from experiment 1, where only one meter was used at a time, and experiment 3, where seven meters were used simultaneously, were compared under similar head values (Table 2) to determine if the true variance at a point arose primarily from changes in the hydraulic conductivity of the substrate accompanying meter insertion (installation error). Meter sites 2, 5, 1 and 6, 3 and 4, and center in experiment 3 (Fig. 3) correspond closely to locations 3a, 7a, 2a and 8a, 4a and 6a, and center, respectively in experiment 1 (Fig. 2a). Experiment 1 measurements were run at a slightly lower head potential (3.94 cm) Notes 0 Average Tank Seepage Rate 0 Average of Seven Meter Seepage Rates 1793 Possible Outlier Head Difference (cm) Fig. 6. Average meter seepage and average tank seepage vs. tank-head difference in experiment 3. Dotted line represents correlation of average tank seepage and head difference when all data points are included; one solid line (0) represents the correlation of average tank seepage and head difference when the possible outlier is omitted; the other solid line (0) represents correlation of meter seepage and head difference. than experiment 3 (4.06 cm). After adjusting for this 3% head difference, data from the two experiments were compared. The cross-experiment coefficients of variation (C-V.) at these five locations ranged from 0 to 32%. The average C.V. (between experiments) was 16%. Slight differences in meter locations in the two experiments may have contributed to this variation. The cross-site C.V.s from the same two experiments were 60 and 68% (Table 2), illustrating that even within the small tank, location effects are much more important than meter insertion effects. In general, data from tank tests indicate relative root-mean-square (rms) errors for measurements are <5% at a particular location once a meter is installed. The meter insertion error is larger but still < 20%. These device errors are small compared to spatial and temporal components of sampling error typically encountered in the field. Data from 120 measurements at duplicate meters located at five locations along a 3-km transect in the Indian River lagoon also indicate ex- cellent field precision, particularly considering that field problems such as clogging of tubing, incomplete sealing in the sediment, etc. may have caused wide variations in some duplicate meter data. At these sites, the rms relative difference between adjacent meters (12%) was small compared to mean square variability over time (108%). Although the variable nature of the seepage rates in the tank tests were not expected, the highly nonuniform moisture and solute transport in sandy soils has long been noted. Research by Glass et al. (1989a,b) shows how wetting front instability occurs when water infiltrates into an unsaturated porous medium. When a wetting front becomes unform and move down stable, “fingers” through the vadose zone bypassing much of the unsaturated medium. Heterogeneities cause the merger of fingers and the formation of faster, wider fingers, a process not accounted for directly in the linear theory (Glass et al. 1989a,b). Although Glass et al. discuss how a wetting front moves through unsaturated soil, it is known that these pre- 18 19 20 21 22 2324a24b25 26 2728a28b2930 31 Distance (m) Fig. 7. Location, depth, and mean seepage rate for each meter in a transect across Indian River lagoon near Jensen Beach, Florida. ferred paths of flow persist after the medium is fully saturated and this phenomenon may have contributed to the tank test variability. Although the tank test variability discussed above cannot be easily generalized to actual field situations, it illustrates the location-specific variability problem in using seepage meters. Localized variations in seepage rates over short distances have been documented in field studies (e.g. Belanger and Walker 1990; Brock et al. 1982; Isiorho and Matisoff 1990; Shaw et al. 1990). For example, data from 33 seepage meters positioned along a 3-km transect across the Indian River lagoon showed site seepage rates varying from -0.0 13 to 5 5.2 liters mm2 h-l (Fig. 7) (Belanger and Walker 1990). In Mountain Lake, Florida, a 43-ha lake in which 47 seepage meters were placed, maximum site-to-site variation of - 5.1 to + 1.2 liters m-2 h- l was measured (Belanger unpubl.). The large variations in seepage in the two bodies of water were not expected based on adjacent well and hydrogeologic data, but they are reasonable considering the variety of factors influencing groundwater flow near water bodies and the well-known occurrence of natural springs. In particular, the distribution of groundwater seepage across the sediment surface is greatly influenced by “leakance” (hydraulic conductivity/thickness) of the benthic sediments and water-table configuration (Winter 1976, 1983; Winter et al. 1988; McBride and Pfannkuch 1975). Although tank test results discussed here have established seepage meters as precise measurement devices with relatively constant bias, there is considerable uncertainty and misunderstanding about the design of seepage meter studies and the interpretation of data to obtain useful water budget information. Generally, temporal variability is much less than site-to-site variability (Brock et al. 1982; Belanger and Walker 1990), and this should be reflected in the sampling design. Due to the complexity of groundwater-surface water interactions and variations in the direction and magnitude of seepage rates recorded in a single water body, special concern must be placed on extrapolation of seepage data for entire systems based on a limited number of seepage meters. It is imperative that whole-lake seepage estimates be made from a large data set obtained from sites throughout the water body. Notes T. V. Belanger M. T. Montgomery Department of Oceanography, Ocean Engineering and Environmental Science Florida Institute of Technology Melbourne 32901-6988 References BELANGER, T. V., AND R. B. WALKER. 1990. Ground water seepagein the Indian River lagoon, Florida, p. 367-375. In Tropical hydrology and Caribbean water resources. Proc. Int. Symp. Am. Water Resour. Assoc. BROCK,T. D., D. R. LEE, D. JANES,AND D. WINEK. 1982. Ground water seepage as a nutrient source to a drainage lake; Lake Mendota, Wisconsin. Water Res. 16: 1255-1263. ERICKSON,D. R. 198 1. The hydrogeology of Williams Lake, Minnesota with special emphasis on quantification of littoral ground water contributions using seepage meters and wells. M.S. thesis, Univ. Minnesota. 153 p. GE, AND T. S. STEENHUIS. GLASS,R. J., J.-Y. PARL.AN 1989a. Wetting front instability. 1. Theoretical discussion and dimension analysis. Water Resour. Res. 25: 1187-l 194. -, T. S. STEENHUIS, AND J.-Y. PARLANGE. 1989b. Wetting front instability. 2. Experimental determination of relationships between system parameters and two-dimensional unstable flow field behavior in initially dry porous media. Water Resour. Res. 25: 1195-1207. ISIORHO,S. A., AND G. MATISOFF. 1990. Ground wa- -.-^ 1795 ter recharge from Lake Chad. Limnol. Oceanogr. 35: 93 l-938. LEE, D. R. 1977. A device for measuring seepage flux in lakes and estuaries. Limnol. Oceanogr. 22: 140147. MCBRIDE, M. S., AND H. 0. PFANNKUCH. 1975. The distribution of seepagewithin lake beds. U.S. Geol. SUIT. J. Res. 3: 505-5 12. SHAW,R. D., AND E. E. PREPAS. 1991. Anomalous, short-term influx of water into seepage meters. Limnol. Oceanogr. 34: 1343-l 35 1. -, J. F. H. SHAW,H. FRICKER,AND E. E. PREPAS. 1990. An integrated approach to quantify ground water transport of phosphorus to Narrow Lake, Alberta. Limnol. Oceanogr. 35: 870-886. WINTER, T. C. 1976. Numerical simulation analysis of the interaction of lakes and ground water. U.S. Geol. Surv. Prof. Pap. 100 1. 45 p. -. 1978. Numerical simulation of steady state three-dimensional ground water flow near lakes. Water Resour. Res. 14: 245-254. 1981. Uncertainties in estimating the water balance of lakes. Water Resour. Bull. 17: 82-l 15. . 1983. The interaction of lakes with variably saturated porous media. Water Resour. Res. 19: 1203-1218. -, J. W. LABAUGH, AND D. 0. ROSENBERRY. 1988. The design and use of a hydraulic potentiomanometer for direct measurement of differences in hydraulic head between groundwater and surface water. Limnol. Oceanogr. 33: 1209-1214. Submitted: 12 December 1990 Accepted: 29 January 1992 Revised: 16 July 1992