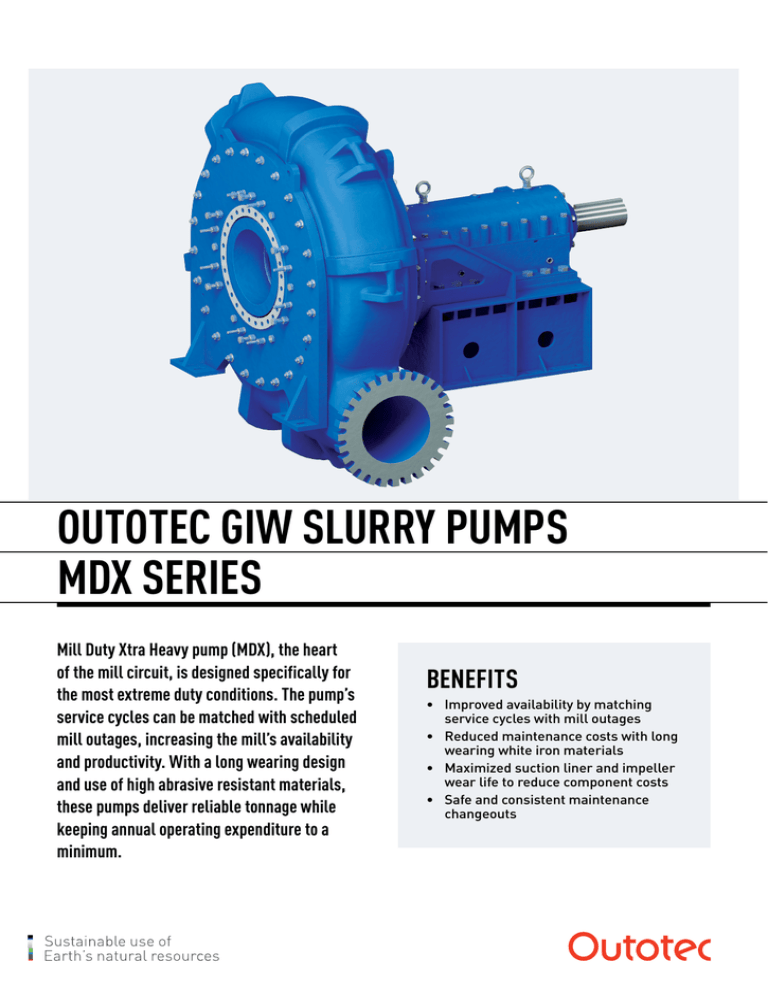

OUTOTEC GIW SLURRY PUMPS

MDX SERIES

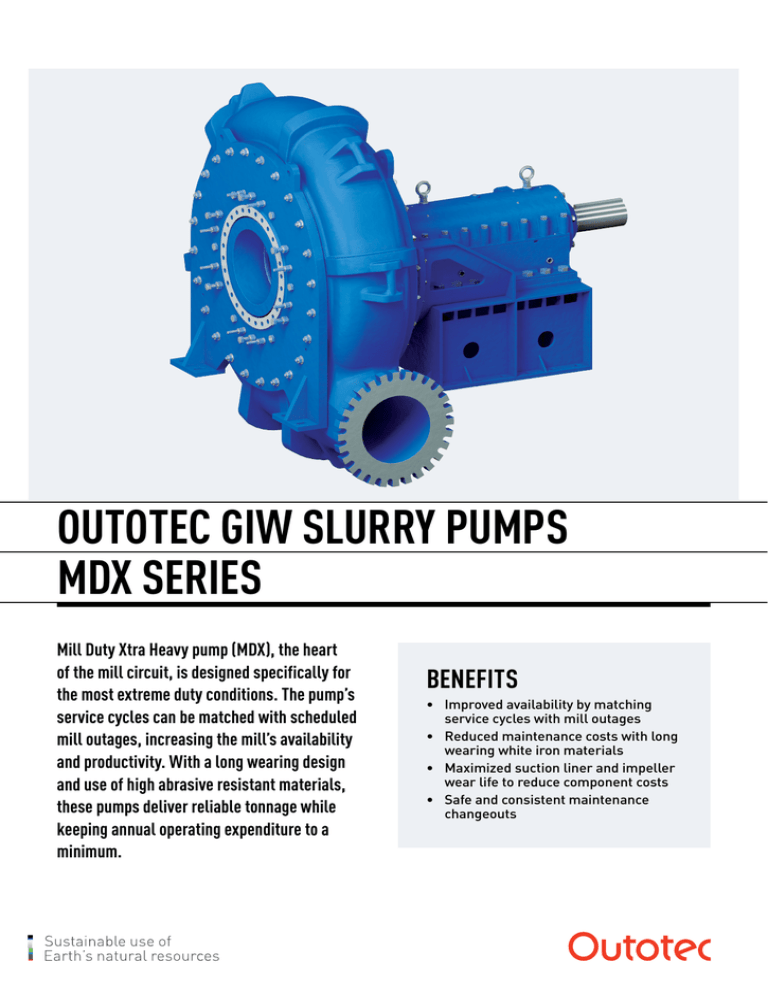

Mill Duty Xtra Heavy pump (MDX), the heart

of the mill circuit, is designed specifically for

the most extreme duty conditions. The pump’s

service cycles can be matched with scheduled

mill outages, increasing the mill’s availability

and productivity. With a long wearing design

and use of high abrasive resistant materials,

these pumps deliver reliable tonnage while

keeping annual operating expenditure to a

minimum.

BENEFITS

• Improved availability by matching

service cycles with mill outages

• Reduced maintenance costs with long

wearing white iron materials

• Maximized suction liner and impeller

wear life to reduce component costs

• Safe and consistent maintenance

changeouts

2

OPTIMIZED PRODUCTIVITY FOR GRINDING CIRCUITS

The MDX series of Outotec GIWTM slurry pumps* is optimized for heavy-duty use in the grinding mill circuit of a

concentrator plant. With Outotec’s extensive expertise in comminution processes and global service and support network,

we support you throughout the pump’s life cycle, improving the productivity of your process and operations.

The MDX pumps offer many unique features that improve reliability, performance and productivity of the grinding circuit.

Lower specific speed design

A large diameter impeller results in slower pump

rotational speed than competing designs, leading to

extended wear life. The lower specific speed design

also allows the pump to better meet the variable flow

conditions encountered in mill circuits.

Longer wearing materials

MDX slurry pumps offer a wide range of white iron

materials designed specifically to resist the abrasive

nature of aggressive slurries. This, combined with thicker

cross sections, translates into long and reliable pump

service life.

Deep base circle

Minimizes aggressive particle impingement and

encourages sliding wear. Typical abrasive wear drops

dramatically.

Slurry diverter

The latest technology dramatically increases suction

liner life by reducing particle recirculation between the

impeller and liner.

Oversize shrouds

Larger shrouds and extended vanes work in conjunction

with the slurry diverter to provide additional clearing

action, further reducing recirculation and grinding wear

between the impeller and suction liner.

Adjustable suction liner

Allows nose gap adjustment on the fly, which in turn

reduces downtime and extends the wear life.

Patented inlet 5 vane impeller

Designed to efficiently transport aggressive slurries

while maximizing pump performance and wear life, and

minimize vibration.

Reduce downtime by matching life cycles

Select the MDX pump for your next mill circuit application

to help ensure cost-effective and continuous operations.

The MDX pump maximizes productivity and minimizes

cost by matching operating cycle times with scheduled

mill outages.

Comprehensive service offering

Our extensive service portfolio and customized

solutions cover all phases of your plant’s life cycle,

and our service scope is always tailored to meet your

unique business challenges.

• Advisory Services, including technical and

process audits, equipment inspections

• Maintenance Services, including installation and

commissioning, component repair and rebuild

services

• Spare and Wear Parts

• Training Services

Options are available to customize the MDX to suit a wide range of

applications.

* GIW is a trademark of GIW Industries, Inc.

3

THE MDX SERIES OFFERS A WIDE RANGE OF OPTIONS

Whatever needs you may have for mill duty pumping, the MDX pump offers a suitable solution. From the MDX 150 all the

way to the MDX 750, the pumps offer flow rates up to 14,000 m3/h. The pumps are a perfect fit for SAG, ball and rod mill

discharge as well as cyclone and screen feed applications.

Flowrate (m3/hr)

500

200

1,000

5,000

10,000

20,000

60

36

100

30

80

24

60

18

40

12

20

6

0

1,000

2,000

5,000

10,000

20,000

50,000

100,000

Head (m)

750

42

MDX

MDX

500

MDX

550

MDX

600

MDX

650

MDX

MDX

120

300

MDX

350

MDX

400

MDX

450

48

MDX

250

160

200

54

MDX

150

180

140

Head (ft)

2,000

0

Flowrate (gpm)

Custom options

•

•

•

•

1.

2.

1.

TECHNICAL DATA

Discharge

Flow rates

Total head

Pressure rating

150 to 750 mm

Up to 14,000 m3/h or 61,650 gpm

Up to 51 m or 170 ft

Up to 9.6 bar or 140 psi

Reduced eye suction liners

Adjustable liner assemblies

Quick release wet end

Full vanes to fit oversized shrouds

1. Suction liners and hub liners are available in a wide

variety of white irons

2. Open back shell offered on larger sizes for right or left

hand pumping applications

Finland, May, 2016

Outotec provides leading technologies and services for the sustainable use of Earth’s natural resources. As the global leader in minerals

and metals processing technology, we have developed many breakthrough technologies over the decades for our customers in metals

and mining industry. We also provide innovative solutions for industrial water treatment, the utilization of alternative energy sources and

the chemical industry. Outotec shares are listed on NASDAQ OMX Helsinki. www.outotec.com

Outotec® is a registered trademark. Copyright © 2016 Outotec Oyj. All rights reserved.