Screened Separable

Connectors

CA650023EN

Effective April 2015

Supersedes I550-12 May 1999

COOPER POWER

SERIES

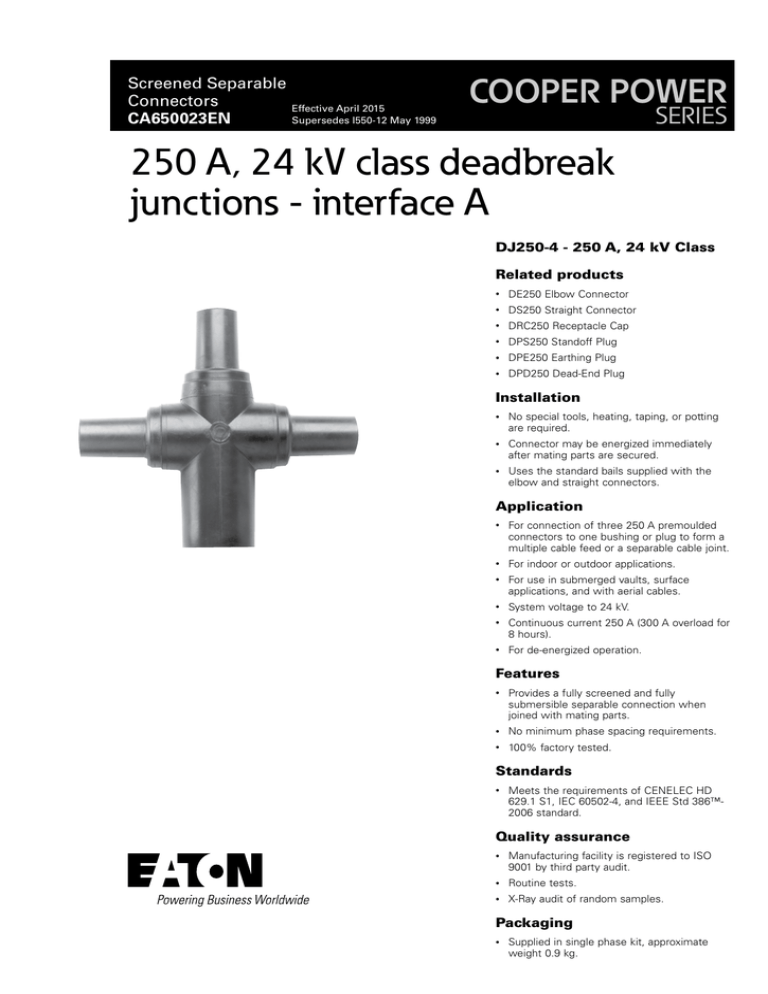

250 A, 24 kV class deadbreak

junctions - interface A

DJ250-4 - 250 A, 24 kV Class

Related products

•

DE250 Elbow Connector

•

DS250 Straight Connector

•

DRC250 Receptacle Cap

•

DPS250 Standoff Plug

•

DPE250 Earthing Plug

•

DPD250 Dead-End Plug

Installation

•

No special tools, heating, taping, or potting

are required.

•

Connector may be energized immediately

after mating parts are secured.

•

Uses the standard bails supplied with the

elbow and straight connectors.

Application

•

For connection of three 250 A premoulded

connectors to one bushing or plug to form a

multiple cable feed or a separable cable joint.

•

For indoor or outdoor applications.

•

For use in submerged vaults, surface

applications, and with aerial cables.

•

System voltage to 24 kV.

•

Continuous current 250 A (300 A overload for

8 hours).

•

For de-energized operation.

Features

•

Provides a fully screened and fully

submersible separable connection when

joined with mating parts.

•

No minimum phase spacing requirements.

•

100% factory tested.

Standards

•

Meets the requirements of CENELEC HD

629.1 S1, IEC 60502-4, and IEEE Std 386™2006 standard.

Quality assurance

•

Manufacturing facility is registered to ISO

9001 by third party audit.

•

Routine tests.

•

X-Ray audit of random samples.

Packaging

•

Supplied in single phase kit, approximate

weight 0.9 kg.

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

Features and detailed description

1. Socket Contacts

Finger-type socket contact of plated copper mates with the

pin contact of the premoulded connector.

5

1

2.Busbar

Internal copper current-carrying part.

3. Internal Screen

Moulded semi-conductive EPDM rubber controls electrical

stress.

2

4. External Screen

Moulded semi-conductive EPDM rubber mates with the

screen of the connector to maintain screen continuity.

5.Insulation

Moulded EPDM rubber provides the phase-to-earth insulation

and forms the interface with the mating connectors to

maintain dielectric ratings and a watertight seal.

3

4

Figure 1. 250 A, 24 kV Class DJ250 deadbreak junction.

Table 1. Electrical Ratings

Maximum System Voltage (Um)

24 kV

Partial Discharge Extinction (<3 pC)*

20 kV

AC Withstand*

54 kV

Impulse Withstand

125 kV

Continuous Current

250 A

Overload (8 hrs max.)

300 A

Short Circuit Withstand, 1 sec. (rms sym.)

12.5 kA

* Denotes routine tests on 100% of production.

Ordering information

To order, simply specify DJ250-4. Kit includes junction, silicone

lubricant, and paper towel. Mating parts and bails are ordered

separately.

2

www.eaton.com/cooperpowerseries

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

DJ250-T1, 250 A, 24 kV Class

Application

•

For connection of two 250 A premoulded connectors to one

bushing or plug to form a parallel cable feed or a separable

cable joint.

•

For indoor or outdoor applications.

•

For use in submerged vaults, surface applications, and with

aerial cables.

•

System voltage to 24 kV.

•

Continuous current 250 A (300 A overload for 8 hours).

•

For de-energized operation.

Features

•

Provides a fully screened and fully submersible separable

connection when joined with mating parts.

•

No minimum phase spacing requirements.

•

100% factory tested.

Standards

•

Meets the requirements of CENELEC HD 629.1 S1, IEC 605024, and IEEE Std 386™-2006 standard.

Quality assurance

Figure 2. DJ250-T1 deadbreak junction.

Related products

•

Manufacturing facility is registered to ISO 9001 by third party

audit.

•

Routine Tests.

•

X-Ray audit of random samples.

Packaging

•

Supplied in single phase kit, approximate weight 0.9 kg.

•

DE250 Elbow Connector

•

DS250 Straight Connector

•

DRC250 Receptacle Cap

Table 2. Electrical Ratings

•

DPS250 Standoff Plug

Maximum System Voltage (Um)

24 kV

•

DPE250 Earthing Plug

Partial Discharge Extinction (<3 pC)*

20 kV

DPD250 Dead-End Plug

AC Withstand*

54 kV

Impulse Withstand

125 kV

Continuous Current

250 A

•

Installation

•

No special tools, heating, taping, or potting are required.

Overload (8 hrs)

300 A

•

Can be energized immediately after the mating parts are

secured.

Short Circuit Withstand, 1 sec (rms sym)

12.5 kA

•

Uses the standard bail supplied with the elbow and straight

connectors.

* Denotes routine tests on 100% of production.

www.eaton.com/cooperpowerseries

3

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

Features and detailed description

1. Socket Contacts

Finger-type socket contact of plated copper mates with the

pin contact of the premoulded connector.

2.Busbar

1

Internal copper current-carrying part.

3. Internal Screen

Moulded semi-conductive EPDM rubber controls electrical

stress.

4. External Screen

2

5

3

4

Figure 3. 250 A, 24 kV Class DJ250-T1 deadbreak junction.

Ordering information

To order, simply specify DJ250-T1. Kit includes junction, silicone

lubricant, and paper towel.

Mating parts and bails are ordered separately.

Bail braket assembly: 2638617C01

4

www.eaton.com/cooperpowerseries

Moulded semi-conductive EPDM rubber mates with the

screen of the connector to maintain screen continuity.

5.Insulation

Moulded EPDM rubber provides the phase-to-earth insulation

and forms the interface with the mating connectors to

maintain dielectric ratings and a watertight seal.

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

DJ250-T2 - 250 A, 24 kV Class

Application

•

For connection of three 250 A premoulded connectors to form a

separable cable joint.

•

For indoor or outdoor applications.

•

For use in submerged vaults, surface applications, and with

aerial cables.

•

System voltage to 24 kV.

•

Continuous current 250 A (300 A overload for 8 hours).

•

For de-energized operation.

Features

•

Provides a fully screened and fully submersible separable

connection when joined with mating parts.

•

No minimum phase spacing requirements.

•

100% factory tested.

Standards

•

Figure 4. DJ250-T2 deadbreak junction.

Related products

Meets the requirements of CENELEC HD 629.1 S1, IEC 605024, and IEEE Std 386™-2006 standard.

Quality assurance

•

Manufacturing facility is registered to ISO 9001 by third party

audit.

•

Routine tests.

•

X-Ray audit of random samples.

•

DE250 Elbow Connector

Packaging

•

DS250 Straight Connector

•

•

DRC250 Receptacle Cap

Supplied in single phase kit, approximate weight 0.9 kg.

Installation

•

No special tools, heating, taping, or potting are required.

•

Can be energized immediately after the mating parts are

secured.

•

Uses the standard bails supplied with the elbow and straight

connectors.

Table 3. Electrical Ratings

Maximum System Voltage (Um)

24 kV

Partial Discharge Extinction (<3 pC)*

20 kV

AC Withstand*

54 kV

Impulse Withstand

125 kV

Continuous Current

250 A

Overload (8 hrs)

300 A

Short Circuit Withstand, 1 sec (rms sym)

12.5 kA

* Denotes routine tests on 100% of production.

www.eaton.com/cooperpowerseries

5

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

Features and detailed description

1. Socket Contacts

Finger-type socket contact of plated copper mates with the

pin contact of the pre-moulded connector.

2.Busbar

1

Internal copper current-carrying part.

4

3. External Screen

2

3

Moulded semi-conductive EPDM rubber mates with the

screen of the connector to maintain screen continuity.

4.Insulation

Moulded EPDM rubber provides the phase-to-earth insulation

and forms the interface with the mating connectors to

maintain dielectric ratings and a watertight seal.

Figure 5. 250 A, 24 kV Class DJ250-T2 deadbreak junction.

Ordering information

To order, simply specify DJ250-T2. Kit includes junction, silicone

lubricant, and paper towel. Bails and mating parts are ordered

separately.

Bail bracket assembly: 2638617C01

6

www.eaton.com/cooperpowerseries

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

DJ250-2 - 250 A, 24 kV Class

Application

•

For connection of two 250 A premoulded connectors to form a

separable cable joint.

•

For indoor or outdoor applications.

•

For use in submerged vaults, surface applications, and with

aerial cables.

•

System voltage to 24 kV.

•

Continuous current 250 A (300 A overload for 8 hours).

•

For de-energized operation.

Features

•

Provides a fully screened and fully submersible separable

connection when joined with mating parts.

•

No minimum phase spacing requirements.

•

100% factory tested.

Standards

•

Meets the requirements of CENELEC HD 629.1 S1, IEC 605024, and IEEE Std 386™-2006 standard.

Quality assurance

•

Manufacturing facility is registered to ISO 9001 by third party

audit.

•

Routine Tests.

•

X-Ray audit of random samples.

Packaging

•

Supplied in single phase kits, approximate weight 0.7 kg.

Figure 6. DJ250-2 deadbreak junction.

Related products

•

DE250 Elbow Connector

•

DS250 Straight Connector

•

DRC250 Receptacle Cap

Installation

•

No special tools, heating, taping, or potting are required.

•

Can be energized immediately after the mating parts are

secured.

•

Uses the standard bail supplied with the elbow or straight

connector.

Table 4. Electrical Ratings

Maximum System Voltage (Um)

24 kV

Partial Discharge Extinction (<3 pC)*

20 kV

AC Withstand*

54 kV

Impulse Withstand

125 kV

Continuous Current

250 A

Overload (8 hrs)

300 A

Short Circuit Withstand, 1 sec (rms sym)

12.5 kA

* Denotes routine tests on 100% of production.

www.eaton.com/cooperpowerseries

7

Catalog Data CA650023EN

250 A 24 kV class deadbreak junction - interface A

Effective April 2015

Features and detailed description

1. Socket Contacts

Finger-type socket contact of plated copper mates with the

pin contact of the pre-moulded connector.

1

2.Busbar

Internal copper current-carrying part.

3. External Screen

2

Moulded semi-conductive EPDM rubber mates with the

screen of the connector to maintain screen continuity.

4.Insulation

3

Moulded EPDM rubber provides the phase-to-earth insulation

and forms the interface with the mating connectors to

maintain dielectric ratings and a watertight seal.

4

Figure 7. 250 A, 24 kV Class DJ250-2 deadbreak junction.

Ordering information

To order, simply specify DJ250-2. Kit includes junction, silicone

lubricant, and paper towel. Bails and mating parts are ordered

separately.

Bail bracket: 2639524B01 (2 required)

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

Eaton’s Cooper Power Systems Division

2300 Badger Drive

Waukesha, WI 53188

Eaton.com/cooperpowerseries

© 2015 Eaton

All Rights Reserved

Printed in USA

Publication No. CA650023EN

Eaton and Cooper Power are valuable

trademarks of Eaton in the U.S. and other

countries. You are not permitted to use

these trademarks without the prior written

consent of Eaton.